Bruciatori caldaie murali e terra a gas gruppi termici in ghisa e in acciaio generatori di aria calda trattamento acqua condizionamento 11/00 cod. 97.50419.0 lamborghini calor s.P.A. Via statale, 342 44040 dosso (ferrara) italia tel. Italia 0532/359811 - export 0532/359913 fax italia 0532/359952 - e...

37 index page general instructions _______________________________________________ 39 description _________________________________________________________ 40 main components __________________________________________________ 41 dimensions _________________________________________________________ 42...

38 99 parabéns... ... Pela óptima escolha. Agradecemos a preferência dada aos nossos produtos. A lamborghini caloreclima encontra-se em actividade desde 1959 em itália e no mundo com uma vasta rede de agentes e concessionários, que garantem a presença constante dos seus produtos no mercado. Junta-se...

39 general instructions ● this booklet constitutes an integral and essential part of the product. Read carefully the instructions contained in this booklet as they provide important directions regarding the safety of installation, use and maintenance. Preserve this booklet with care for any further ...

40 description the thin boiler has been designed for outdoor installation in partially protected areas and can operate at winter temperatures as low as –15 °c. It is largely intended for installation on balconies and terraces. This unit is practically “invisible” as it is designed to be wall-mounted...

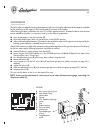

41 main components legend 1 ignition electrodes 2 manual air purge valve 3 fumes fan 4 total safety thermostat 5 fumes pressure switch 6 heating detector 7 3-way valve 8 hydrometer 9 filling cock 10 reset push-button with lock-out warning light 11 hot water pressure switch 12 lack of water pressure ...

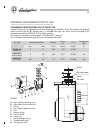

42 dimensions mm circulating pump features delivery/pressure available at the system technical features boiler version: mod. C type c12-c32-c42-b22 max. Water temperature 90 °c category: ii 2h3+ rated gas pressure: natural gas 20 mbars b 28/30 mbars - p 37 mbars model thermal capacity min. Thermal c...

43 the boilers leave the factory calibrated and predisposed to operate with natural gas and liquid gas. These calibrations are effected without the connection of the compensating joint (pos. A). For the calibrations to put into effect, see the table related below: burner pressure curves - output gas...

44 electrical connections - wiring diagrams the boiler must be connected to an earthed, single-phase 220-230v-50 hz mains supply by means of a three- wire cable, ensuring that connections to the line and neutral terminals are made correctly. A bipolar switch must be used with contacts opening to at ...

45 principle diagram bm modulating coil ca ignition control unit honeywell cir circulating pump ec control electrode es spark electrode l line max r max. Heating setting n neutral pf fumes pressure switch pma lack of water pressure switch pr reset push-button p.Risc. Heating potentiometer ps hot wat...

46 circuit diagram bm modulating coil ca ignition control unit honeywell cr remote control - room thermostat cir circulating pump ec control electrode es spark electrode ka anti-freeze thermostat (on request) l line max r max. Heating setting n neutral pf fumes pressure switch pma lack of water pres...

47 installation and start-up remove the control unit base-block by levering the two lower hooks (fig. 1). Fix the control unit to the wall via the holes in the base-block. This should be mounted 1.5 m above the floor in an area well away from entry/exit doors, windows or other factors that might inf...

48 once the connections have been made power up the boiler and, after the “con” signal, check that the legend “off” appears on the main display and that the time 00:00 on the lower display and the day indicator both appear . If the legend “con” persists this indicates improper connection of the cont...

49 ● “hot water/heating” mode ( and symbols displayed) this mode provides both hot water and heating, operated automatically according to requirements. ● “heating” function ( symbol displayed) this mode enables the boiler for activation of the heating circuit in “automatic” or “manual”. When this mo...

50 ● copying hourly programming to speed up programming, you can “paste” the settings for a specific day onto another day. Press v to select the day from which you wish to copy the settings. Press the copy key within 5 seconds to copy and then press the + and – keys to select the page onto which you...

51 setting the temperature the control unit allows the user to set 5 basic temperatures in order to provide maximum comfort and maximum system efficiency. ● hot water temperature this temperature may be set with either the hot water or hot water/heating function enabled. To set press the key and the...

52 to set press the key: the presently set temperature will appear on the display. Now hold the key down and press the – or + keys to modify the temperature setting as desired. Release the key to memorise the new setting. Viewing main boiler parameters press the key repeatedly to view the main boile...

53 re-establishing factory settings and control reset you may wish to re-establish the settings made at the factory: to do so press the key for 10 seconds and the message “fab” will appear on the display. Going through this procedure resets the following parameters: - standard temperature 20 °c - co...

54 installer settings the tasks in this section must only be carried out by qualified personnel. Carrying out these procedures wrongly may damage the control unit and boiler or cause them to malfunction. ● connecting up to the outdoor temperature sensor. The control unit can also be fitted with a se...

55 ● correcting room temperature measurement this allows the user to correct the room temperature detected by the control unit and adapt it to different user needs. The entire correction procedure must be done with the control unit powered and connected to the boiler. Room temperature correction: pr...

56 hydraulic connection fit the supporting hooks and attach the assembly template, moving it up to the wall; fit all the pipes, starting with the end pipe fittings already mounted on the template: system supply, system return, cold water, hot water, any gas pipes and electric mains leads with room t...

57 hydraulic circuit legend a gas b hot water outlet c cold water inlet d system supply e return 1 hot water circuit drain cock 2 hot water detector 3 gas valve 4 instantaneous water-heater 5 air purge manual valve 6 hot water pressure switch 7 3-way valve 8 lack of water pressure switch 9 burner 10...

58 starting up refilling installation open the inlet cock (1) slowly until the system pressure indicated on the hydrometer (2) reaches 1.5 bar, then close it. Check that the 3-way valve (3) is in the manual position and that the automatic air purge valve (4) on the circulator has its cap loosened an...

59 the boiler must be installed and function outdoors. For installation use only original lamborghini parts. Flue exhaust types double pipe outlet kit to install the double pipe kit insert the funnel 1 (supplied with the boiler) in the fan. Insert the diaphragm 3 between the adhesive seal 2 and the ...

60 flue exhaust connection to fan-forced draught version (b22) the boiler is envisaged being connected to a chimney and/or a flue pipe with the following specification: ● of being sealed airtight, as with the connection to the chimney itself; ● of being of suitable material; ● of being connected wit...

61 fumes evacuation/air intake 1 concentric flue pipe, from the terrace 2 fan-forced draught (b22), from a flue pipe 3 double pipe from separate flues 4 concentric, connected to concentric flues 5 fan-forced draught (b22), from the roof for positioning and for distances of draught terminals from win...

62 flue exhaust installation attention: use only air intake/ fumes evacuation kit produced by lamborghini caloreclima. Concentric flue pipe fit the concentric elbow pipe positioning it on the desired direction and insert on it the sealing gasket. Fit the air intake and flue pipes, observing the dist...

63 the boiler allows to adapt the heating thermal power (without involving the adjustment of the capacity available for the production of hot water) to the thermal need of the rooms to be heated. When leaving the factory all boilers are set to 70% of their maximum output. To adapt the boiler to the ...

64 switching off boiler switched off for a prolonged period and installed inside if the boiler should remain inactive at length close the gas cock and remove the electrical current from the appliance. Boiler switched off for a prolonged period and installed outside. Where there is risk of sub-zero t...

65 operation with different types of gas conversion from natural gas to liquid gas proceed with burner jets replacement. Insert the diaphragm (i) included in the kit. Also replace the spring (c) under the rod of the coil (e), checking that it is assembled the right way round. Switch the bridge on th...

66 anti-freeze kit (on request) the thin boiler is fitted as standard with an anti-freeze device that protects the hydraulic circuit. This device is tripped when the temperature falls to about 6 °c. The hot water circuit can be provided with even better protection by installing an anti-freeze kit wh...

67 fault-finding chart 1 no ignition 2 crackling ignition 3 smell of gas 4 smell of unburnt gas incombusti e and bad burner combustion 5 condensation in the boiler 6 cold radiators in winter 7 poor hot water supply fault cause rimedy a. Gas cock closed b. “off” button locked c. No flame detection d....

Bruciatori caldaie murali e terra a gas gruppi termici in ghisa e in acciaio generatori di aria calda trattamento acqua condizionamento 11/00 cod. 97.50419.0 lamborghini calor s.P.A. Via statale, 342 44040 dosso (ferrara) italia tel. Italia 0532/359811 - export 0532/359913 fax italia 0532/359952 - e...

Bruciatori caldaie murali e terra a gas gruppi termici in ghisa e in acciaio generatori di aria calda trattamento acqua condizionamento 11/00 cod. 97.50419.0 lamborghini calor s.P.A. Via statale, 342 44040 dosso (ferrara) italia tel. Italia 0532/359811 - export 0532/359913 fax italia 0532/359952 - e...

16 index page general instructions _______________________________________________ 17 instructions for the use ____________________________________________ 18 checks and maintenance___________________________________________ 19 setting the time/day of the week ___________________________________ 20 ...

17 general instructions ● this booklet constitutes an integral and essential part of the product and should be preserved for any further consultation. Read carefully the instructions contained in this booklet as they provide important directions regarding the operation of the appliance, allowing a g...

18 instructions for the use ● in case of breakdown and/or malfunctioning of the appliance, disconnect it avoiding any attempt of repair or direct intervention. Call exclusively professionally qualified personnel. Any repair must be carried out by an after-sale service centre “lamborghini service” au...

19 checks and maintenance ● before starting up the boiler ask qualified personnel “lamborghini service” to check: a) that the data on the information plate corresponds to that required by the gas, electrical and water supply networks; b) that the pipes which branch off from the boiler are lined with...

20 setting the time/day of the week you can set the clock time and the day of the week in any mode. To begin setting press the h/day key once. The minute figures will then start flashing. Press the + and – keys to set the minutes and then press h/day again to confirm. The hour figures on the display...

21 “automatic” temperature control mode the control unit has a daily/weekly timer that automatically adjusts room temperature to “comfort” or “low temperature” values over a 24 hour period, with independent settings for each of the seven days. To enable automatic operation press the key and the symb...

22 note: immediately after setting the date and the day (section 2) a factory-set default programme is activated. This programme is given in the table below. Standard programme from monday to friday saturday and sunday low temp. 23:00+06:00 23:00+08:00 comfort temp. 06:00+09:00 08:00+23:00 low temp....

23 release the key to memorise the new setting. Should the boiler be equipped with an outdoor sensor, the values being displayed and set are outdoor temperature and heating water temperature. ● standard room temperature sets the standard manual temperature in either the heating or hot water/heating ...

24 the appearance of the symbol on the display shows that the user has requested hot water or heating. Re-establishing factory settings and control reset you may wish to re-establish the settings made at the factory: to do so press the key for 10 seconds and the message “fab” will appear on the disp...

25 installer settings the tasks in this section must only be carried out by qualified personnel. Carrying out these procedures wrongly may damage the control unit and boiler or cause them to malfunction. ● connecting up to the outdoor temperature sensor. The control unit can also be fitted with a se...

26 ● correcting room temperature measurement this allows the user to correct the room temperature detected by the control unit and adapt it to different user needs. The entire correction procedure must be done with the control unit powered and connected to the boiler. Room temperature correction: pr...

27 fault-finding chart 1 no ignition 2 crackling ignition 3 smell of gas 4 smell of unburnt gas and bad burner combustion 5 condensation in the boiler 6 cold radiators in winter 7 poor hot water supply fault cause remedy a. Gas cock closed b. “off” button locked c. No flame detection d. No ignition ...

Bruciatori caldaie murali e terra a gas gruppi termici in ghisa e in acciaio generatori di aria calda trattamento acqua condizionamento 11/00 cod. 97.50419.0 lamborghini calor s.P.A. Via statale, 342 44040 dosso (ferrara) italia tel. Italia 0532/359811 - export 0532/359913 fax italia 0532/359952 - e...