- DL manuals

- Lanair

- Heater

- MX SERIES 250

- Installation And Operating Instructions Manual

Lanair MX SERIES 250 Installation And Operating Instructions Manual

Summary of MX SERIES 250

Page 1

Mx series 250 mx series 300 waste oil heater installation and operating instructions ® lanair products llc 4109 capital circle janesville, wisconsin 53546 1-888-370-6531 www.Lanair.Com.

Page 2: Important

® before you begin installation... Important read and understand this manual completely before beginning installation. S this heater is for commercial and industrial use only. This unit is not intended for residential use. S this heater must be installed and/or inspected by a licensed heating contra...

Page 3: Mx Series 250

Mx series 250 waste oil heater mx series 300 waste oil heater installation and operating instructions table of contents: rules for safe installation and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2 sec. 1 general specifications and hazards . . . . . . . . . ...

Page 4

Section 1 - general specifications & hazards questions?... Contact customer service at 1-888-370-6531 m-f 8:00 am- 4:15 pm cst 4 no. Description 1 mounting plate 2 ignitor transformer 3 fuel line inlet 4 fuel pressure gauge 5 combustion air baffle 6 view port 7 oil primary safety control 8 waste oil...

Page 5

Section 1 - general specifications & hazards visit our website at: www.Lanair.Com 5 1 3 2 2 2 2 4 8 5 6 7 9 no. Description 1 adjustable air flow louvers 2 mounting holes 3 fan limit switch 4 8" exhaust flue 5 flame view port 6 burner assembly 7 electrical connections cover 8 secondary air filter/re...

Page 6

Section 1 - general specifications & hazards questions?... Contact customer service at 1-888-370-6531 m-f 8:00 am- 4:15 pm cst 6 mx-250/300 front dimensions: mx-250 height: 36” width: 46” depth: 48” weight: 630 lbs mx-300 height: 36” width: 46” depth: 48” weight: 630 lbs firing capacities: mx-250 no...

Page 7

Section 1 - general specifications & hazards visit our website at: www.Lanair.Com 7 right side mx 250-300 left side mx 250-300 top view mx 250-300 36" 36" 16” 25” 24" 48” 46” 13.5" 59.5" 6" 9.5" 5.5” 8” dia. Flue.

Page 8

Section 1 - general specifications & hazards 8a pump assembly- pump assembly for use with by-pass regulator performance ratings voltage . . . . . . . . . . . . . . . . . . . . . . 115 vac cycles . . . . . . . . . . . . . . . . . . . . . . . . . . 60 hz weight . . . . . . . . . . . . . . . . . . . . ...

Page 9

8b pump assembly- performance ratings voltage . . . . . . . . . . . . . . . . . . . . . . 115 vac cycles . . . . . . . . . . . . . . . . . . . . . . . . . . 60 hz weight . . . . . . . . . . . . . . . . . . . . . . . . . 16 lbs pump motor . . . . . . . . . . . . . . . 0.59 amps questions?... Contact ...

Page 10: Warning!

Section 1 - general specifications & hazards visit our website at: www.Lanair.Com 9 dimensions: mx-250 height: 36” width: 46” depth: 48” weight: 630 lbs mx-300 height: 36” width: 46” depth: 48” weight: 630 lbs firing capacities: mx-250 nozzle @ 1.79 gallons/hour, no. 2 fuel oil/used crankcase oil mx...

Page 11

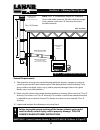

Section 2 - heater install w/ bypass regulator 10a class “a” chimney barometric damper 2-3 ft. Away from heater ceiling hung 8 ft. Min. 10 ft. Max. Secondary air regulator primary air regulator (not supplied) set to 30 lbs. Chimney connector 10 foot max. Length 1/4” rise per foot of length chimney c...

Page 12

Section 2 - heater install w/ metering pump 10b class “a” chimney barometric damper 2-3 ft. Away from heater ceiling hung 8 ft. Min. 10 ft. Max. Secondary air regulator primary air regulator (not supplied) set to 30 lbs. Chimney connector 10 foot max. Length 1/4” rise per foot of length chimney cap ...

Page 13

Section 2 - heater installation visit our website at: www.Lanair.Com 11 general requirements 1. Do not install the heater on a combustible surface of any kind. For minimum clearance to combustible material (see page 9) 2. Install the heater in a location to utilize total heat throw. 3. Install the h...

Page 14

Section 3 - chimney/vent system 12 class “a” chimney barometric damper 2-3 ft. Away from heater ceiling hung 8 ft. Min. 10 ft. Max. Chimney connector 10 foot max. Length 1/4” rise per foot of length chimney cap 3 ft. Taller than any object within 10 ft. 10 ft. Min. Figure 2 - typical chimney install...

Page 15

Section 3 - chimney/vent system visit our website at: www.Lanair.Com 13 general requirements (cont.) 4. Install a u.L. Listed barometric damper in the chim- ney. Do not reduce or enlarge the vent pipe. 5. Do not use more than one 90° elbow. Each 90° note: do not install chimney in front of the heate...

Page 16

Section 3 - chimney/vent system questions?... Contact customer service at 1-888-370-6531 m-f 8:00 am- 4:15 pm cst 14 17. If you are unable to attain the proper draft, check for exhaust fans in the building. To test if there is a problem, open an overhead door and see if you now have the proper draft...

Page 17: Section 4 - Draft

Section 4 - draft visit our website at: www.Lanair.Com 15a 9570 by-pass regulator (included) 8398 vacuum guage (included) 9807 primary strainer (included) 1/2” copper tube (to burner - not included) 8662 check valve (included) (included) 8748 strainer suction line pump assembly (included) pump assem...

Page 18: Section 4 - Draft

Section 4 - draft visit our website at: www.Lanair.Com 15b 8398 vacuum guage (included) 9807 primary strainer (included) 8662 check valve (included) (included) 8748 strainer suction line metering pump assembly (included) 3/8” copper tube (to burner - not included) 3/8” copper tube (to burner - not i...

Page 19

Section 5 - fuel supply tank installation 16 general requirements 1. The fuel supply tank and supply lines must be installed in accordance with the national fire protection association requirements, as well as state and local ordinances. 2. Regulations require oil storage tanks located inside not to...

Page 20

Section 6 - fuel supply pump/piping visit our website at: www.Lanair.Com 17 general requirements 1. Mount the fuel supply pump in a horizontal position (shaft horizontal) near the fuel sup- ply tank. 2. The oil pump has a maximum suction lift of 14 feet. Suction lift is the length of pipe run from t...

Page 21

Section 6 - fuel supply pump/piping 18 bottom view of the aluminum oil by-pass regulator figure 4 questions?... Contact customer service at 1-888-370-6531 m-f 8:00 am- 4:15 pm cst 14. 15. 16. 17. 18. 19. 20. When using a by-pass regulator install the fuel supply line from the fuel by-pass regulator ...

Page 22

Section 7 - air supply installation visit our website at: www.Lanair.Com 19 general requirements 1. Install an air pressure supply line connection to the air filter/regulator on the rear of the heater. 2. The air supply source must be capable of producing 2.0 cfm @ 60 psi. 3. Install a shut off valv...

Page 23

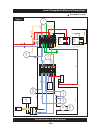

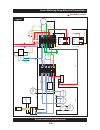

Section 8 - electrical connections 20 caution: hazard of electrical shock! ! Main electrical installation 1. All wiring must comply with the national electrical code. State and local ordinances, and be wired by a qualified electrician. 2. Electrical service must be connected to a separate 20 amp, 11...

Page 24

Visit our website at: www.Lanair.Com 21a e ti h w e ul b black e ti h w e ti h w e l p r u p e ti h w e g n a r o red e ti h w e ti h w blac k white white p a n s k si d r e m r o f s n a r t n oi t s u b m o c r e w ol b r e t a e h- e r p h c ti w s ri a di o n e l o s y r a mi r p li o 2 f 1 f 2 ...

Page 25

Visit our website at: www.Lanair.Com 21b e ti h w e ul b black e ti h w e ti h w e l p r u p e ti h w e g n a r o red e ti h w e ti h w blac k white white p a n s k si d r e m r o f s n a r t n oi t s u b m o c r e w ol b r e t a e h- e r p h c ti w s ri a di o n e l o s y r a mi r p li o 2 f 1 f 2 ...

Page 26

Section 8 - electrical connections 22 fuel supply pump electrical installation 1. All wiring must comply with the national electrical code, state and local ordinances, and be wired by a qualified electrician. 2. The electrical conductors to the fuel pump motor must be stranded 14 ga minimum. 3. The ...

Page 27: Section 9 - Controls

Section 9 - controls visit our website at: www.Lanair.Com 23 s room thermostat: the room thermostat automatically controls the on/off operation of the heater according to the setting of the desired room temperature. The thermostat works in conjunction with the oil primary safety control. S oil prima...

Page 28: Section 9 - Controls

Section 9 - controls 24 s electric air solenoid valve the electric air solenoid valve is controlled by the oil primary control. It acts as a shut-off valve, (it’s open during operation, and closed when the burner is off ). The electric air solenoid valve is located inside of the burner’s electrical ...

Page 29

Section 10 - priming the fuel pump visit our website at: www.Lanair.Com 25 figure 8 remove two yellow wires figure 9 install jumper wire priming the fuel pump 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. The fuel level in the supply tank must be above the check valve on the pick-up tube. Remove th...

Page 30

Section 10 - priming the fuel pump questions?... Contact customer service at 1-888-370-6531 m-f 8:00 am- 4:15 pm cst 26 12. Turn the room thermostat below room temperature or “off”. The fuel supply pump will now stop. 13. Reconnect the fuel supply line to the burner. 14. Remove the jumper wire from ...

Page 31

Section 11 - burner start-up procedure visit our website at: www.Lanair.Com 27 waste oil burner start-up 1. Make sure the main electrical service for the heater is turned off, and locked out. 2. Fill the oil supply tank with an approved fuel to a level that is above the pick-up tube check valve. 3. ...

Page 32

Section 11 - burner start-up procedure 28 15. When using the by-pass regulator adjust the fuel pressure gauge on the left side of the burner to read. Note: note: when using the metering pump the fuel flow is determined by the pump. Pressures may not be the same as shown above. Adjust the thumb screw...

Page 33

Section 12 - flame adjustment visit our website at: www.Lanair.Com 29 flame adjustment 1. Start the heater, let it run for at least 15 minutes to reach operating temperature before proceeding. 2. Check the chimney draft, set the barometric damper to -.06 wc when hot and running. 3. Check the atomizi...

Page 34

Section 12 - flame adjustment 30 lift the inspection port cover on the front of the combustion chamber to observe the flame. The flame tips should extend 3/4 of the way into the combustion chamber. When the unit is adjusted properly the ash inside the chamber will be white to off white. Flame tips t...

Page 35: Damage To Your Heater.

Section 12 - flame adjustment visit our website at: www.Lanair.Com 31 check flame daily (see page 30). Adjust accordingly ! Do not over fire your heater. Immediately adjust the burner to the proper flame length to prevent damage to your heater. ! Problem: too small a flame, similar to a blowtorch. 1...

Page 36

Section 13 - service / maintenance questions?... Contact customer service at 1-888-370-6531 m-f 8:00 am- 4:15 pm cst 32 daily s check fuel supply tank level (pre-strain all fuels). S check vacuum gauge reading on suction line. See section 19. S check atomizing air pressure at the air fil- ter/ regul...

Page 37

S ee pages 36-37 f or required annual oil block maintenance section 13 - service / maintenance visit our website at: www.Lanair.Com 33 1 2 3 4 5 6 7 9 3 1 4 1 5 1 8 1 9 1 0 2 2 1 7 1 6 1 1 1 0 1 8 2 2 3 2 this entire pre-heater assembly is available. Air pre-heater breakdown part# 9812 (for a tune-u...

Page 38

Section 13 - service / maintenance 34 maintenance - air pre-heater 1. Remove pre-heater assembly s disconnect the air line from the brass fitting on the air pre-heater and then from the air solenoid and remove. S disconnect wiring from the oil pre- heater cartridge, air pre-heater cartridge and snap...

Page 39

Section 13 - service / maintenance visit our website at: www.Lanair.Com 35 maintenance - air pre-heater (cont.) 6. Clean all parts using a parts washer s all passages must be thoroughly cleaned with a brush. 7. Replace nozzle assembly and quad ring s after cleaning air pre-heater assembly, blow dry....

Page 40

Section 13 - service / maintenance questions?... Contact customer service at 1-888-370-6531 m-f 8:00 am- 4:15 pm cst 36 6 8 12 7 9 5 2 3 1 4 6 7 12 10 12 13 14 11 oil pre-heater breakdown ref. Part no. No. Qty. Description 1 8992 1 cartridge heater 2 - 1 pre-heater face plate 3 - 6 hex cap screw 4 -...

Page 41

Section 13 - service / maintenance visit our website at: www.Lanair.Com 37 maintenance - oil pre-heater (cont.) 3. Clean oil pre-heater block s clean oil pre-heater block using a parts washer and brush. Note: make sure all passages are clean. S blow dry the oil pre-heater block. Inspect all passages...

Page 42

Section 13 - service / maintenance questions?... Contact customer service at 1-888-370-6531 m-f 8:00 am- 4:15 pm cst 38 bolt washer o-ring inlet 1” npt outlet 1” npt strainer strainer hex cap screws gasket gasket o-ring spring bowl water drain cleaning suction line strainer the suction line strainer...

Page 43

Section 13 - service / maintenance visit our website at: www.Lanair.Com 39 ignitor replacement / adjustment 1. Disconnect power to the heater. 2. Remove the pre-heater assembly from the burner housing. Disassemble and clean all parts as instructed on pages 33-37. 3. Using a 1/4" allen wrench, carefu...

Page 44

Section 13 - service / maintenance 40 air pre-heater diaphragm breakdown 1. Remove the four hex cap screws from the diaphragm assembly 2. Disassemble and inspect diaphragm, spring and o-ring . 3. Thoroughly clean remaining parts. 4. Re-assemble the diaphragm, o-ring, spring and hex cap screws. Air p...

Page 45

Section 13 - service / maintenance visit our website at: www.Lanair.Com 41 note: always wear eye, face and breathing protection and protective clothing when inspecting or cleaning chamber or heat exchanger. ! Warning: disconnect all electrical power to heater before servicing ! Fan limit switch ! Cl...

Page 46

6. Use an industrial type canister vacuum cleaner with a high efficiency filter, or suitable tool. Failure to clean heat exchanger tubes annually will impair draft. Reaching through the burner opening, vacuum or shovel the ash from the combustion chamber. Inspect the combustion chamber and target br...

Page 47

Section 13 - service / maintenance visit our website at: www.Lanair.Com 43 fuel by-pass regulator skip this section when using the optional metering pump note: diaphragm replacement 1. Disconnect power to the heater. 2. Remove the locking nut and adjusting screw from the by-pass regulator assembly. ...

Page 48

Section 14 - troubleshooting questions?... Contact customer service at 1-888-370-6531 m-f 8:00 am- 4:15 pm cst 44 remove two yellow wires warning: do not operate your heater if the oil primary safety circuit is not working! ! Initial diagnosis: when an operating problem occurs, a determination must ...

Page 49

Section 14 - troubleshooting visit our website at: www.Lanair.Com 45 s install a jumper wire between the two f-f terminals. Be careful not to touch the t-t terminals as it may damage the control. S push reset button for 2 seconds. S turn room thermostat up so that it calls for heat. S disable the ai...

Page 50

Section 14 - troubleshooting 46 burner fuel pressure gauge reading hints: fuel gauge fluctuates (jumps): s water/anti-freeze in fuel. S leak in suction line plumbing. S air in fuel, refer to troubleshooting chart item b. S quad ring seal for the nozzle may be damaged. S seal in adapter block may be ...

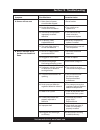

Page 51

Section 14 - troubleshooting visit our website at: www.Lanair.Com 47 n o i t c a e v i t c e r r o c e s u a c e l b i s s o p m o t p m y s a. Burner will not start 1. Main electrical power 1. Reset breaker circuit breaker tripped 2. Service disconnect 2. Turn switch on or switch off or fuse blown ...

Page 52

Section 14 - troubleshooting 48 n o i t c a e v i t c e r r o c e s u a c e l b i s s o p m o t p m y s c. Burner fires, and then 1. Contaminated fuel supply 1. Drain and clean fuel fails on oil primary safety (water/anti-freeze/gear lube) supply tank. Clean fuel or dirty fuel filter. Filter (see pa...

Page 53

Return guidelines and warranty questions?... Contact customer service at 1-888-370-6531 m-f 8:00 am- 4:15 pm cst 49 return guidelines warranty conditions 1. All returned merchandise must be unused and returned in the same new condition in which it was originally received, with all accompanying origi...

Page 54: Section 15 - Warranty

Section 15 - warranty lanair products llc, manufacturer, hereby warrants that any part of manufacturer’s product shall be free from defect in material and workmanship under normal use according to the provisions and limitations herein set forth for a period of one (1) year provided same is returned ...

Page 55

Section 16 - burner reference diagram visit our website at: www.Lanair.Com 51 oil pressure gauge manual reset & snap disk fuel supply pre-heater adjustment screw to combustion blower pre-heater switch air supply air supply air solenoid ignitor oil pre-heater block air pre-heater block to oil primary...

Page 56

® © 2009 lanair products llc lanair is a registered trademark of lanair products llc part # 5031 rev. 21a 11-16-10 lanair products llc 4109 capital circle janesville, wisconsin 53546 1-888-370-6531 www.Lanair.Com.