Page 1 in the event that you need assistance for servicing your water filter, please first contact the professional contractor who installed the system. Congratulations on purchasing your new lancaster water filter. This unit is designed to give you many years of trouble free service. For servicing ...

Page 2 minimum / maximum operating pressures 20 psi (138 kpa) - 125 psi (862 kpa) minimum / maximum operating temperatures 40°f (4°c) - 110°f (38°c) current draw & voltage 0.5 amperes - 110 volts other options available the control valve, fittings and/or bypass are designed to accommodate minor plum...

Page 3 the control valve is compatible with a variety of regenerants and resin cleaners. The control valve is capable of routing the flow of water in the necessary paths to regenerate or backwash water treatment systems. The injector regulates the flow of brine or other regenerants. The control valv...

Page 4 set time of day step 1: press and hold set hour for 3 seconds. Step 2: current time (hour): set the hour of the day using ▲ or ▼buttons. Am/ pm toggles after 12. Pres set hour to go to step 3. Step 3: adjust minutes with ▲ or ▼. Press set hour to exit set time of day. Power loss: only the cur...

Page 5 set regeneration time and days between backwashes step 1: from normal mode, press set hour + ▲ buttons simultaneously for 3 seconds and release. Step 2: backwash time hour: set the time for backwash to start using ▲ or ▼. Press set hour to go to the next step. Step 3:backwash time minutes: se...

Page 6 additional programming information available from lancaster water treatment upon request. Includes: 7-day option, regeneration cycles, times and 50 hz. Acid neutralizers, (7-letdan-): mineral used: calcite. Calcite will dissolve in proportion to the amount of acid in the raw water. The amount...

Page 7 remove the valve cover to access the drive assembly. Disconnect the power source plug (black wire) from the pc board prior to disconnecting the motor or water meter plugs from the pc board. The power source plug connects to the four-pin jack. The motor plug connects to the two-pin jack on the...

Page 8 injector cap, screen, injector plug and injector: the screen, injector and/or injector plug(s) are installed under the injector cap in an easy to access location on top of the valve. The injector cap contains four slots so no water accumulates in the cap. The injector cap is designed to be ha...

Page 9 refill flow control assembly or refill port plug: the refill flow control assembly consists of a refill flow elbow, refill flow control retainer assembly, refill flow control, polytube insert and nut assembly. The refill flow control retainer fits in the refill elbow. The refill flow control ...

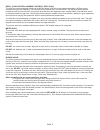

Page 10 optional maintenance wrench v3193 although no tools are necessary to assemble the valve, the optional maintenance wrench (shown in various positions on the valve) may be purchased to aid in assembly or disassembly. Loosens drain nut in polytube applications loosens injector and bypass caps l...

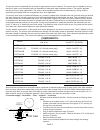

Page 11 3 2 1 4 item no. Quantity part no. Description 1 2 v3151 nut 1” quick connect 2 2 v3150 split ring 3 2 v3105 o-ring 215 4 2 v3188 fitting - 1” brass sweat item no. Quantity part no. Description 1 2 v3151 nut 1” quick connect 2 2 v3150 split ring 3 2 v3105 o-ring 215 4 2 v3188 fitting - 3/4” ...

Page 12 ws1tc & ws1.25 tc manual page 13 6 2 4b 4a 5 1 3 7 8 ws1tc drive cap assembly, down ow piston, regenerant piston and spacer stack assembly drawing no. Order no. Description quantity 1 v3005 ws1 spacer stack assembly 1 2 v3004 drive cap asy 1 3 v3178 ws1 drive back plate 1 4 v3011 ws1 piston ...

Page 13 meter plug item no. Quantity part no. Description 1 1 v3151 nut 1” qc 2 1 v3105 o-ring 215 3 1 v3003 meter plug assembly brine refill item no. Quantity part no. Description 1 1 h4615 elbow locking clip 2 1 h4614 polytube insert 3/8” ws1 & ws1.25 drawings & service manual page 15 drain line –...

Page 14 4/16 troubleshooting problem possible cause solution 1. Timer does not display time of day. A. Transformer unplugged a. Connect power b. No electric power at outlet b. Repair outlet or use working outlet c. Defective transformer c. Replace transformer d. Defective pc board d. Replace pc boar...