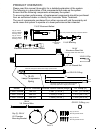

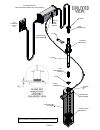

Lancaster 7-LWT-UV009 Installation, Operating And Service Manual

Manual is about: LANCASTER ULTRAVIOLET DISINFECTION SYSTEMS

of

13

PAGE 1

INSTALLATION, OPERATING AND SERVICE MANUAL

FOR

LANCASTER ULTRAVIOLET DISINFECTION SYSTEMS

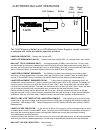

PLEASE CAREFULLY READ INSTRUCTIONS BEFORE INSTALLING SYSTEM

FOLLOW ALL STATE AND LOCAL CODES AND REGULATIONS FOR PLUMBING AND ELECTRICAL.

INSTALLATION BY A CERTIFIED PLUMBER IS RECOMMENDED.

In the event that you need assistance for servicing your UV system, please first contact the

professional contractor who installed the system.

Congratulations on purchasing your new

Lancaster Water UV Disinfection System

. This unit is

designed to give you many years of trouble free service. For servicing and future inspection purposes,

please file this booklet with your important documents.

7-LWT-UV009

7-LWT-UV016

7-LWT-UV030