Page 1 in the event that you need assistance for servicing your water filter, please first contact the professional contractor who installed the system. Congratulations on purchasing your new lancaster water filter. This unit is designed to give you many years of trouble free service. For servicing ...

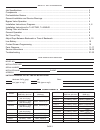

Page 2 model no. Job specifications model mineral tank- part no., dia.”x ht.” part id, mineral (bag qty.) 7-lxdan-1 fg1047dvt, 10x47 (with dome plug) a8021, calcite (2) 7-lxdan-1.5 fg1054dvt, 10x54 (with dome plug) a8021, calcite (3) 7-lxdan-2 fg1348dvt, 13x48 (with dome plug) a8021, calcite (4) 7-l...

Page 3 the control valve, fitting and/or bypass are designed to accommodate minor plumbing misalignments but are not designed to support the weight of a system or the plumbing. Do not use vaseline, oils, other hydrocarbon lubricants or spray silicone anywhere. A silicone lubricant may be used on bla...

Page 4 operation: 1. Normal operation position: the inlet and outlet handles point in the direction of flow indicated by the engraved arrows on the control valve. Water flows through the control valve during normal operation and this position also allows the control valve to isolate the media bed du...

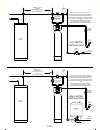

Page 5 (all electrical & plumbing should be done in accordance to all local codes) installation instructions brine line fitting connections drain line fitting connection using 5/8" poly tube click to buy now! Pd f-xchange w ww .Docu-track.C om click to buy now! Pd f-xchange w ww .Docu-track.C om 1. ...

Page 6 water filter pressure tank bypass plumbing recommended if optional bp2000 bypass valve is not used. From well pump minimum 10 feet between water filter outlet and water heater inlet water filter bypass plumbing recommended if optional bp2000 bypass valve is not used. To drain to outside tap w...

Page 7 7-lxctair, 7-lximair installation instructions add mineral per instructions in this filter manual. Water can be manually added at this time to begin the mineral soaking process. An in-line check valve is required, installed vertically prior to the aeration system, but after any untreated line...

Page 8 do not plug the transformer into the receptacle yet. Make sure inlet and outlet valves are to their closed positions. If using optional bypass, place in bypass position. Turn on main water supply. Open a cold water faucet. This will clear the line of any debris (solder, pipe dope, etc.) that ...

Page 9 current time of day needs to be entered during initial installation, and adjusted when daylight saving time begins or ends. If an extended power outage occurs and depletes the on-board non-rechargeable coin cell battery, when power resumes the time of day should be reset and battery replaced....

Page 10 step 5 step 5 – next regeneration time (minutes): set the minutes of day for backwash using or buttons. Press next to return to normal operation. Press regen to return to previous step. Return to normal mode contact screen programming step 1 - press next and simultaneously for 3 seconds to a...

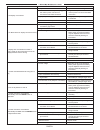

Page 11 drawing no. Order no. Description quantity 1 v3692-02lw lp front cover assembly 1 2 v3107-01 motor 1 3 v3106-01 drive bracket & spring clip 1 4 v3757lp-board pc board 1 5 v3110 drive gear 12x36 3 6 v3109 drive gear cover 1 ac adapter order no. (not shown) v3186 supply voltage 120v ac supply ...

Page 12 drawing no. Order no. Description qty 1 v3176 injector cap 1 2 v3152 o-ring 135 1 3 v3177-01 injector screen cage 1 4 v3010-1z injector assy z plug 1 5 † v3010-1c injector assy c violet 1 v3010-1f injector assy f blue v3010-1h injector assy h green not shown v3170 o-ring 011 * not shown v317...

Page 13 drawing no. Order no. Description qty 1 h3195 refill port plug assy 1 2 h4615 elbow locking clip 1 for 7-lxctair and 7-lximair models, refer to page 7 for diagram. This water meter should not be used as the primary monitoring device for critical or health effect applications. The nut and cap...

Page 14 drain line - 3/4” dwg no. Order no. Description qty 1 h4615 elbow locking clip 1 2 v3194 polytube insert 5/8 option 3 v3192 nut ¾ drain elbow option 4* v3158 drain elbow ¾ male 1 5 v3163 o-ring 019 1 6* v3159 dlfc retainer assy 1 7 v3162-007 dlfc 0.7 gpm for ¾ one dlfc must be used if ¾ fitt...

Page 15 drawing no. Order no. Description qty 1 v3151 nut 1” quick connect 2 2 v3150 split ring 2 3 v3105 o-ring 215 2 4 v3145 bypass 1” rotor 2 5 v3146 bypass cap 2 6 v3147 bypass handle 2 7 v3148 bypass rotor seal retainer 2 8 v3152 o-ring 135 2 9 v3155 o-ring 112 2 10 v3156 o-ring 214 2 bypass va...

Page 16 (order no. V3193) although no tools are necessary to assemble or disassemble the valve, the wrench (shown in various positions on the valve) may be purchased to aid in assembly or disassembly. Loosens injector and bypass caps loosens drive cap service spanner wrench.

Page 17 order no: v3007-01 description: fitting ¾” & 1” pvc solvent 90° assembly drawing no. Order no. Description quantity 1 v3151 nut 1” quick connect 2 2 v3150 split ring 2 3 v3105 o-ring 215 2 4 v3189 fitting ¾&1 pvc solvent 90 2 order no: v3007-02 description: fitting 1” brass sweat assembly dr...

Page 18 acid neutralizers, (7-lxdan-): mineral used: calcite. Calcite will dissolve in proportion to the amount of acid in the raw water. The amount of calcite in the tank should be monitored and replaced periodically. A tank with a dome plug is provided so that calcite may be added without removing...

Page 19 replace broken or damaged drive gears. Do not lubricate any of the gears. Avoid getting any foreign matter on the reflective coating because dirt or oils may interfere with pulse counting. The drive gear cover only fits on one way, with the large clip orientated towards the bottom. If all th...

Page 20 refill flow control assembly (refer to page 7 for diagrams): to clean or replace the refill flow control, pull out the elbow-locking clip and then pull straight up on the elbow. Replace the elbow locking clip in the slot so that it is not misplaced. Twist to remove the white flow control ret...

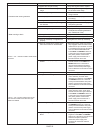

Page 21 troubleshooting problem possible cause solution 1. No display on pc board a. No power at electric outlet a. Repair outlet or use working outlet b. Control valve power adapter not plugged into outlet or power cord end not connected to pc board connection b. Plug power adapter into outlet or c...

Page 22 problem possible cause solution 8. Untreated water is being delivered a. Bypass valve is open or faulty a. Fully close bypass valve or replace b. Media is exhausted due to high water usage b. Check program settings or diagnostics for abnormal water usage c. Meter not registering c. Remove me...

Page 23 problem possible cause solution 12. Error – 103 = control valve motor ran too long and was unable to find the next cycle position a. Motor failure during a backwash a. Check motor connections then press next and regen buttons for 3 seconds to resynchronize software with piston position or di...

Page 24 a division of c-b tool co. 1340 manheim pike ● lancaster pa 17601-3196 ● tel:717-397-3521 ● fax: 717-392-0266 www.Lancasterwatertreatment.Com ● e-mail: info@lancasterpump.Com 8/12.