- DL manuals

- Lancaster

- Water System

- LRO-35

- Installation, Operation And Service Manual

Lancaster LRO-35 Installation, Operation And Service Manual

Summary of LRO-35

Page 1

Guardian r.O. Drinking water system with water quality monitor model lro-35 installation, operation and service manual tested and certified by nsf international against nsf/ansi standard 58 for the reduction of the claims specified on the performance data sheet..

Page 2

Table of contents page section i. Introduction ...................................................................................3 section ii. Specifications ................................................................................4 section iii. Preparation......................................

Page 3

3 section i. Introduction your new reverse osmosis (r.O.) drinking water system uses a combination of filtration technologies to reduce unwanted contaminants in a water supply. The following steps combine to give you the best in clear sparkling drinking water: mechanical filtration/activated carbon–...

Page 4

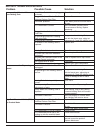

4 section ii. Specifications table a – qualified system performance because the performance of an r.O. Membrane is highly dependent upon pressure, temperature and tds, the following should be used for comparison purposes only. U.S. Metric membrane production 1 41-53 gpd 155–201 lpd membrane tds redu...

Page 5

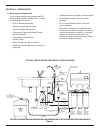

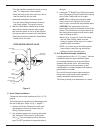

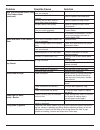

5 section iii. Preparation a. Major system components the following components comprise the r.O. Drinking water system. (refer to fig. 1, below for general system layout.) • an r.O. Manifold assembly. • housings and housing o–rings. • a drinking water holding tank. • a dispensing faucet with water q...

Page 6

6 optional lro-35 basement installation diagram holding tank shutoff valve (open position) drinking water holding tank dispensing faucet reverse osmosis membrane housing activated carbon post filter housing sediment/ carbon pre filter housing in-line activated carbon post filter product (3/8" blue) ...

Page 7

7 b. Tools recommended for installation the following tools will cover most of the installation sites encountered: 1. 3 / 8 " variable speed electric drill. 2. Extension work light with outlet. 3. Safety glasses. 4. 1¼" porcelain hole cutter kit. 5. 1¼" greenlee hole punch and 1 / 8 "and ½" metal dr...

Page 8

8 the manifold assembly as possible. Use a potable cold water supply only. Softened water is preferred as it will extend the life of the r.O. Membrane. 5. Drain connection–the waste water must go to drain through an anti–siphon air gap. The air gap is provided for in the base of thefaucet. If discha...

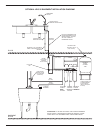

Page 9

9 mounting surface, 1¼" drill hole slotted washer cl 3/8" polytube quick connect fitting 3/8" blue polytube water quality monitor cable water quality monitor connector water quality monitor cable plastic spacer 7/16" washer 7/16" hex nut 7/16" stud note: assemble slotted washer, 3/8" polytube quick ...

Page 10

10 •locate the 3 / 8 " black drain tubing which is shipped loose in the box. Firmly press one end of the tubing over the 3 / 8 " drain outlet hose barb on the dispensing faucet. Allow tubing to relax, then press firmly again to insure proper seating. No connectors are required when attaching tubing ...

Page 11

11 •turn the handle to expose the lance no more than 3 / 16 " beyond the rubber gasket. •place the body of the valve over the hole so that the lance fits into the hole. •assemble and tighten the brass screw. •turn the valve handle clockwise (inward) until firmly seated. The valve is closed. 3. With ...

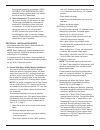

Page 12

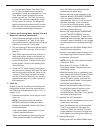

12 3/8" drain clamp assembly drain clamp front plate drain pipe 1/4" nut 1/4" screw drain clamp back plate black drain tubing compactor may require special fabrication of a mounting plate. 1. The mounting bracket will accept either #10 or #12 (5mm) mounting screws spaced on 6" (15 cm) centers. Allow...

Page 13

13 in–line activated carbon post filter. Slice the 3 / 8 " blue polytube where it would be convenient to install and change the in–line filter. Make a clean straight cut to insure proper connections. The “out” port on the in–line filter should be towards the faucet. Firmly press in the tubing. The f...

Page 14

14 fully counter clockwise. •the holding tank valve should be open. •check the air gap window on the dispensing faucet to be sure that the drain water is flowing. (refer to figure 2a, page 9.) the r.O. System is now making water. •do not open the faucet for at least 8 hours. •do not use the first th...

Page 15

15 •use a good quality unscented 5¼% liquid chlorine household bleach. •add one capful of bleach (this is 2 tsp. Or 10 ml) to the sediment/carbon prefilter housing and temporarily install the housing without the sediment/carbon prefilter. Check the housing o–ring for proper position in its groove, e...

Page 16

16 section vi. Trouble shooting guide problem possible cause solution open valve or unclog. Replace filters. Feed water pressure must be above 40 psig. See feed water operating limits. Correct cause of fouling, replace membrane. Replace post filter. Empty water from holding tank, and with the faucet...

Page 17

17 correct plumbing. Clear or replace drain restrictor. Clear or replace air gap faucet.. Repair or replace the aso valve components. Flush with several full tanks of product water. An increase in feed water tds will give a corresponding increase in product water tds. Replace filters. Clean, flush a...

Page 18

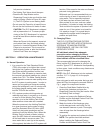

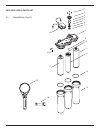

18 made in usa exploded view & parts list 19 15 1 2 3 4 5 6 7 8 9 10 11 12 13 14 18 16 17 21......... Nitrate/nitrite test kit.

Page 19

19 drawing no. Part no. Description 1 .................... S2009 ................................... Self tapping screw 2 .................... S2005 ................................... Aso cap 3 .................... S2013 ................................... Aso cap o–ring 4 .................... S201...

Page 20

A division of c-b tool co. 1340 manheim pike, lancaster, pa 17601-3196 phone (717) 397-3521 fax (717) 392-0266 www.Lancasterwatertreatment.Com form no. S1474-lp updated 12/19/07 r.O. Drinking water system five/one year limited warranty lancaster ® warrants its r.O. Drinking water system to be free f...