Page 1 installation, operating and service manual gold line ler electronic water softener with the lercv1 valve congratulations on purchasing your new lancaster water softener. This unit is designed to give you many years of trouble free service. When installed in accordance with the following instr...

Page 2 operating parameters minimum / maximum operating pressures 20 psi (138 kpa) - 125 psi (862 kpa) minimum / maximum operating temperatures 40°f (4°c) - 110°f (43°c) supply voltage/ frequency 120v ac/ 60 hz other options available power consumption 9.5 w output voltage 12v ac output current 500 ...

Page 3 the control valve uses no traditional fasteners (e.G. Screws); instead clips, threaded caps and nuts and snap type latches are used. Caps and nuts only need to be firmly hand tightened because radial seals are used. Tools required to service the valve include one small blade screw driver, one...

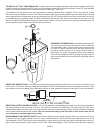

Page 4 assemble the brine tank: install a brine well cap (item a) on the bottom of the brine well (item b). Remove the brine valve assembly (item c) from the brine well by removing the nut (item d). Attach the brine well to the brine tank with the two-piece overflow (items e & f) using the lower hol...

Page 5 current time of day needs to be entered during initial installation, and adjusted when daylight saving time begins or ends. If an extended power outage occurs and depletes the on-board non-rechargeable coin cell battery, when power resumes the time of day should be reset and battery replaced....

Page 6 placing unit into service: make sure inlet and outlet valves are to their closed positions. If using optional bypass, place in bypass position. Turn on main water supply. Open a cold water faucet. This will clear the lines of any debris (solder, pipe dope, etc.) that may be in the line. Let w...

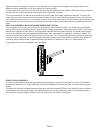

Page 7 optional maintenance wrench part number v3193 although no tools are necessary to assemble the valve, the optional maintenance wrench (shown in various positions on the valve) may be purchased to aid in assembly or disassembly. Loosens drain nut in polytube applications loosens injector and by...

Page 8 service instructions drive assembly: the drive assembly consists of the following parts: • drive bracket • printed circuit (pc) board • motor • drive gears • drive gear cover the drive bracket holds the pc board, the motor, the drive gears and the drive gear cover in place. The pc board recei...

Page 9 drive cap assembly, main piston and regenerant piston: the drive gears turn the main gear of the drive cap assembly, which moves the piston. The screw-driven, horizontally moving piston stops at specific positions to direct the flow of water to backwash, regenerate, rinse or refill. The pc bo...

Page 10 injector cap, screen, injector plug and injector: the screen, injector and/or injector plug(s) are installed under the injector cap in an easy to access location on top of the valve. The injector cap contains four slots so no water accumulates in the cap. The injector cap is designed to be h...

Page 11 ws1tc & ws1.25 tc manual page 13 6 2 4b 4a 5 1 3 7 8 ws1tc drive cap assembly, down ow piston, regenerant piston and spacer stack assembly drawing no. Order no. Description quantity 1 v3005 ws1 spacer stack assembly 1 2 v3004 drive cap asy 1 3 v3178 ws1 drive back plate 1 4 v3011 ws1 piston ...

Page 12 water meter and meter plug item no. Quantity part no. Description 1 1 v3151 nut 1” qc 2 1 v3003* meter assy 3 1 v3118-01 turbine assy 4 1 v3105 o-ring 215 5 1 v3003-01 meter plug assy *part no. V3003 includes items 2, 3 and 4 drain line - 3/4” item no. Quantity part no. Description 1 1 h4615...

Page 13 1 2 3 4 additional optional fittings part number description v3007-01 3/4” x 1” pvc solvent elbow assembly v3007-02 1” brass sweat assembly v3007-03 3/4” brass sweat assembly v3007-04 1” plastic male npt assembly v3007-05 1-1/4” plastic male npt assembly v3007-07 1-1/4” & 1-1/2” pvc solvent ...

Page 14 troubleshooting procedures problem possible cause solution 1. Timer does not display time of day. A. Transformer unplugged a. Connect power b. No electric power at outlet b. Repair outlet or use working outlet c. Defective transformer c. Replace transformer d. Defective pc board d. Replace p...