- DL manuals

- Lancer

- Beverage Dispenser

- 28-0586/07

- Operation Manual

Lancer 28-0586/07 Operation Manual

Lancer Corp.

6655 Lancer Blvd.

San Antonio, Texas 78219

800-729-1500

Technical Support/Warranty: 800-729-1550

custserv@lancercorp.com

lancercorp.com

Manual PN: 28-0586/07

FOR QUALIFIED INSTALLER ONLY

Minute Maid Juice Dispenser

Operation Manual

PN: 28-0586/07

“Lancer” is the registered trademark of Lancer © 2014 by Lancer, all rights reserved.

MMJ-2

MMJ-4

2 - Valve

85-3322 Two Valve, Push Button 115V/60 Hz

85-3332 Two Valve, Portion Control 115V/60 Hz

85-3324 Four Valve, Push Button 115V/60 Hz

85-3334 Four Valve, Portion Control 115V/60 Hz

4 - Valve

Summary of 28-0586/07

Page 1

Lancer corp. 6655 lancer blvd. San antonio, texas 78219 800-729-1500 technical support/warranty: 800-729-1550 custserv@lancercorp.Com lancercorp.Com manual pn: 28-0586/07 for qualified installer only minute maid juice dispenser operation manual pn: 28-0586/07 “lancer” is the registered trademark of ...

Page 2

About this manual this booklet is an integral and essential part of the product and should be handed over to the operator after the installation and preserved for any further consultation that may be necessary. Please read carefully the guidelines and warnings contained herein as they are intended t...

Page 3

3 6. Repair and replacement...................................................................................................22 6.1 lighted front display................................................................................................22 6.2 door removal/replacement......................

Page 4

2 - valve specifications dimensions width: 10 1/8 inches (257 mm) depth: 25 1/2 inches (648 mm) height: 33 inches (838 mm) refrigeration 1/4 horsepower (hp) compressor, using r134-a refrigerant 10.0 pounds (+/- 2.0 pounds) (4.54 kg) ice bank weight 4.5 gallon (17.0 liter) water bath capacity weight ...

Page 5

4 - valve specifications dimensions width: 18 1/16 inches (458 mm) depth: 26 1/4 inches (667 mm) height w/o legs: 29 5/8 inches (752 mm) height with legs: 33 inches (838 mm) refrigeration 1/3 horsepower (hp) compressor, using r134-a refrigerant 21.0 pounds (+/- 2.0 pounds) (9.55 kg) ice bank weight ...

Page 6

Pre-installation checklist before getting started each unit is tested under operating conditions and is thoroughly inspected before shipment. At the time of shipment, the carrier accepts responsibility for the unit. Upon receiving the unit, carefully inspect the carton for visible damage. If damage ...

Page 7

7 warning/advertencia/avertissement ! The dispenser is for indoor use only. This unit is not a toy. Children should not be supervised not to play with appliance. It should not be used by children or infirm persons without supervision. This appliance is not intended for use by persons (including chil...

Page 8

Dispenser installation highlights this unit has been factory sanitized per lancer specifications. Listed below are six critical elements which will aid in a successful installation. 1. Fill water bath until water overflows from tank overflow tube. 2. The carbonator pump motor must be disconnected fr...

Page 9

9 electrical warning/advertencia elÉctrica/ avertissement Électrique f check the dispenser serial number plate for correct electrical requirements of unit. Do not plug into a wall electrical outlet unless the current shown on the serial number plate agrees with local current available. Follow all lo...

Page 10

Water notice/agua aviso/ prÉavis de l’eau ! Provide an adequate potable water supply. Water pipe connections and fixtures directly connected to a potable water supply must be sized, installed, and maintained according to federal, state, and local laws. The water supply line must be at least a 3/8 in...

Page 11

1. Installation 1.1 selecting a location for the dispenser make sure the location meets these requirements: a. Select a location close to a properly grounded electrical outlet and water supply that meets the requirements on the specification page. B. Ensure the location provides a minimum of four in...

Page 12

1.4 alternate method: sight tube (4-valve only) a. Connect a short length of the appropriate-sized clear tubing over the hose barbed end of the drain fitting (see illustration 44 at end of manual). B. Rotate the fitting counterclockwise to open the drain. C. Open the doors, add water and hold the cl...

Page 13

1.7 grounding instructions f grounding warning this appliance must be properly grounded to avoid possible fatal electrical shock or serious injury to the operator. The power cord is provided with a three prong grounded plug. If a three hole grounded electrical outlet is not available, use an approve...

Page 14

F grounding warning improper connection of the equipment-grounding conductor can re- sult in a risk of electric shock. The conductor with insulation having an outer surface that is green, with or without yellow strips, is the equipment-grounding conductor. If repair or replacement of the cord or plu...

Page 15

2.3 changing menu lanuage the “change language” item allows the user to change the active language. The selected language will be used for all text displayed on the lcds. 2.4 sold out lock out options the sold out lockout item allows the user to change the sold out system features. Stop dispense: wh...

Page 16

3.2 priming the unit at install or with new minute pak a. Prime pump using the key. Dispense concentrate until product appears consistent. B. Turn key back to the to (on) position. 3.3 priming the unit after daily flush a. Prime pump using the key. Prime for one (1) second. B. Turn key back to the t...

Page 17

* * * 3.7 check/adjust ratios a. To check and/or adjust the ratio separately, measure the amount of water and finished product dispensed into a graduate cylinder. Adjust the finished product to equal the volume of water dispensed. To do this: • turn keyswitch to (flush). • press the and # buttons on...

Page 18

Portion control in this option, each valve can be individually programmed to dispense four different volumes. The valve will dispense the programmed volume amounts when the corresponding button on the touch sensor switch is activated. • place a vessel on the target located on the cup rest. • activat...

Page 19

4.2 cleaning and sanitizing solutions cleaning solution: mix a mild, non-abrasive detergent with clean, potable water at a temperature of 90 to 110°f (32 to 43°c). The mixture ratio is one ounce of cleaner to two gallons of water. Prepare a minimum of five gallons of cleaning solution. Do not use ab...

Page 20

4.3 daily - cleaning a. Turn the key to (flush) position. B. Flush each valve until only clear water is dispensed. C. Remove and wash drip tray and cup rest in cleaning solution. Rinse thoroughly with warm water and reinstall drip tray and cup rest to dispenser. D. Wipe down any areas where concentr...

Page 21

L. Remove check valve from sanitizing container, remove sanitizing container, and pour out any sanitizing solution that remains in the container. M. Repeat for each valve. N. Reinstall minute paks®, and connect check valves in containers. Replace nozzles. O. Using the button, run the pump until only...

Page 22

6. Repair and replacement 6.1 lighted front display a. Turn key to (flush). B. Open dispenser door (press # button on each door to open left and right doors). Lift the door. C. Turn the lens release handles on the lower part of the door liner 1/4 turn from the locked position to the open position. D...

Page 23

6.5 door latch solenoid removal/replacement a. Turn key to (flush). Press # key. B. Open door and remove the four screws that secure the solenoid mounting bracket to the interior surface of the door liner. C. Gently slide the bracket out of the door liner and unplug the connector. D. Connect harness...

Page 24

6.10 ice bank controller removal/replacement a. Unplug dispenser and remove the grill from the top cover. B. Remove the screw that secures the cover of the ice bank controller box and remove the cover. C. The ice bank controller is contained on the printed circuit board. To remove the board, grasp t...

Page 25

6.13 sold out sensor removal/replacement a. There is one sensor for each valve. B. Remove the concentrate packages. C. Turn key to (off). D. Remove nozzle from water fitting and concentrate delivery tube. E. Remove the platform base(s). F. Remove the screws that secure the pump assembly platform to ...

Page 26

6.15 water calibrations valve/flow washer removal/ replacement a. Remove the concentrate product. B. Turn key to (off). C. Remove nozzle from the water fitting and concentrate delivery tube. D. Remove the platform base(s). E. Remove the screws that secure the pump assembly platform base to the cabin...

Page 27

4-valve power supply removal/replacement a. Remove the drip tray by gently lifting the drip tray up and away from the dispenser. B. Remove the splash plate by pulling the bottom up slightly, then out from the dispenser. If there is a drop down drip tray, first remove the two screws holding the drip ...

Page 28

7. Troubleshooting 7.1 refrigeration system f warning the compressor deck is fed by line voltage. Disconnect power before attempting to repair any components on the deck. Advertencia la cubierta del compresor es alimentado por la tensiÓn de lÍnea. Desconecte la energÍa antes de intentar para reparar...

Page 29

Trouble cause remedy compressor does not turn off. Dispenser “frozen” up. Possible relay failure on ice bank control board. Check leds on pcb. If green light is on and red light is off, replace printed circuit board. Probe moved out of proper location. Faulty probe. Check leds on pcb. If both lights...

Page 30

9. Illustrations, parts listings, wiring and water flow diagrams 9.1 2-valve insulated tank assembly 4 5 6 12 3 7 8 9 11 10 2 1 16 15 14 13 2 item part no. Description 1 48-3158 water coil assy, 2v, fcoj 2 05-0017 washer seal, flr, nylon, 3/8 (5/8) 3 02-0155 o-ring 4 19-0422 valve assy, water, calib...

Page 31

9.2 4-valve insulated tank assembly item part no. Description 1 48-3208 tube, water coil 2 05-0017 washer seal, nylon, 3/8 (5/8) 3 19-0422 valve assy, water, calibration 4 02-0371 flow washer 5 02-0089 o-ring 6 48-1062 tube assy, interface, water out 7 17-0512 valve assy, ball, water inlet 8 02-0089...

Page 32

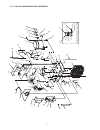

9.3 2-valve pump platforms/fan plate assembly 1 8 6 7 5 23 4 21 22 18 17 16 15 14 13 12 20 19 10 3 2 11 9 24 32.

Page 33

9.3 2-valve pump platforms/fan plate assembly (continued) item part no. Description 1 81-0650 fan assy, pump housing, fcoj 2 04-0741 screw, 6-32 x .375, php, pan hd 3 04-1290 screw, 10-14 x .375, ph, ph, pl, ss 4 30-9658 plate, product support, fcoj 5 01-2042 water connector, compass 6 02-0005 o-rin...

Page 34

9.4 4-valve pump platforms/fan plate assembly 1 2 3 4 5 6 8 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 7 9 34.

Page 35

9.4 4-valve pump platforms/fan plate assembly (continued) item part no. Description 1 81-0650 fan, pancake, 24vdc, 14.1 cfm 2 04-1290 screw, 10-14 x .375, ph, ph, pl, ss 3 01-2042 water connector, compass 4 02-0005 o-ring, 2-010 5 30-9637/01 platform, base, pump assy 6 91-0167 motor assy 7 04-0397 s...

Page 36

9.5 2-valve electrical component detail 1 2 4 3 5 6 7 8 item part no. Description 1 82-3706 deck assy, refrig., 115v/60hz 2 04-1638 screw, 1/4 - 20 x 1.000, hex hd with washer 3 08-0315 tube, drain, front 4 02-0047 o-ring 5 82-3717/02 control box assy, cpu, fcoj 6 52-1738 door harness assy 7 52-3087...

Page 37

9.6 4-valve electrical component detail item part no. Description 1 82-1542 deck assy, refrig., 115v/60hz - 82-1827 kit, deck assy, refrig., 115v/60hz 2 04-1638 screw, 1/4 - 20 x 1.000, hex hd with washer 3 08-0315 tube, drain, front 4 02-0047 o-ring 5 04-0470 screw, 6 -19 x 0.500, pan hd 6 05-0679 ...

Page 38

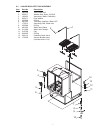

9.7 2-valve cabinet assembly 1 2 3 4 item part no. Description 1 04-0750 screw, 6 - 32 x 2.812, pan hd 2 82-3707 top cover assy 3 52-1668 key switch assy 4 82-3762 wrapper assy 38.

Page 39

9.8 4-valve cabinet assembly item part no. Description 1 04-0750 screw, 6 - 32 x 2.812, pan hd 2 82-1726 top cover assy 3 52-1668 key switch assy 4 82-1503 wrapper assy 5 81-0415 keyset 6 30-10019 mount, filter 7 23-1456 filter 1 2 3 4 5 6 7 39.

Page 40

9.9 2-valve peripheral components/final assembly 8 2 7 6 1 4 3 5 item part no. Description 1 82-3696 door assy, fcoj, 2v 2 54-0420 grill, drip tray 3 04-0591 screw, 6 - 19 x 0.563, flat hd, plastite 4 02-0409 seal, spout 5 81-0405 spring, gas, 30# 6 82-3789 drop-cup-rest assy 7 04-0477 screw, 8 - 32...

Page 41

9.10 4-valve peripheral components/final assembly item part no. Description 1 82-3677 door assy, left, retro, push, fcoj 2 82-3678 door assy, right, retro, push, fcoj 3 04-0591 screw, 6 - 19 x 0.563, flat hd, plastite 4 02-0409 seal, spout 5 81-0405 spring, gas, 30# 6 82-3751 drop-cup-rest assy 7 04...

Page 42

9.11 2-valve compressor deck assembly 1 2 14 3 4 35 7 10 37 38 36 5 11 17 25 19 8 33 9 34 20 15 16 30 29 28 27 23 6 22 21 26 31 24 13 18 32 12 39 42.

Page 43

9.11 2-valve compressor deck assembly (continued) item part no. Description 1 30-9580 plate, agitator, premia 2 50-0454 insulation, refrigeration deck 3 82-1832 evaporator coil assy 4 23-1052 condenser 5 30-10014 shroud, fan 6 04-0504 screw, 8 - 18 x 0.375 7 52-3175/01 motor, fan, 115v 8 23-1406 gri...

Page 44

9.12 4-valve compressor deck assembly ice bank control box wiring agit at or white power fa n to comp . Blk 7 53 16 42 20 22 21 26 25 24 23 43 2 35 40 36 11 19 4 19 45 31 30 29 33 12 15 13 5 19 37 14 10 18 17 50 18 19 51 49 1 18 39 49 52 46 32 34 38 3 28 27 47 8 9 19 53 7 6 48 43 19 54 44 44.

Page 45

9.12 4-valve compressor deck assembly (continued) item part no. Description 1 30-6000/01 plate assy, refrigeration deck 2 83-0040 compressor 3 82-1406 evaporator coil assy 4 23-1008 condenser 5 91-0094 motor, agitator, 115v 6 91-0093 motor, fan, 115v 7 52-1882 control housing assy, eibc iii 8 05-099...

Page 46

9.13 2-valve and 4-valve door assembly 46.

Page 47

9.13 2-valve and 4-valve door assembly (continued) item part no. Description 1 02-0417 seal, door, premia 2 04-0470 screw, 6 - 19 x 0.500, ph (x14) 3 04-0135 screw, 6 - 32 x 0.312, ph (x 14) 4 05-1021/01 hinge, door, premia (x 2) 5 24-0031/01 latch assy, door 6 05-0716/01 clevis, door, ita, premia 7...

Page 48

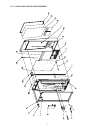

9.14 2-valve top cover assembly, detail 5 2 6 4 3 12 11 10 9 8 7 1 item part no. Description 1 54-0226 top cover, sub-assy 2 05-1019 cover, hinge, lh 3 05-1018 cover, hinge, rh 4 82-1523 hinge pin assy, left 5 82-1524 hinge pin assy, right 6 04-0135 screw, 6 - 32 x 0.312, pan head 7 30-6346 grid, co...

Page 49

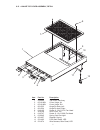

9.15 4-valve top cover assembly, detail item part no. Description 1 54-0205 top cover, sub-assy 2 05-1019/01 cover, hinge, lh 3 05-1018/01 cover, hinge, rh 4 82-1523 hinge pin assy, left 5 82-1524 hinge pin assy, right 6 04-0135 screw, 6 - 32 x 0.312, pan head 7 30-6158 grid, cover, top 8 04-0747 sc...

Page 50

9.16 2-valve water flow diagram valve 2 valve 1 base assembly foamed tank assembly foamed tank assembly ball valve water in water coil assembly umbrella check valve water out water out 1. " " denotes slip fit o-ring connection point. Note: t r e e m f l w o & s o e n l i o d t r e e m f l w o & s o ...

Page 51

9.17 4-valve water flow diagram valve 4 valve 3 valve 2 valve 1 water out base assembly foamed tank assembly foamed tank assembly ball valve water in water coil assembly umbrella check valve water out water out water out 1. " " denotes slip fit o-ring connection point. Note: t r e e m f l w o & s o ...

Page 52

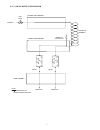

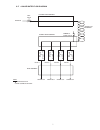

9.18 2-valve wiring diagram sol 2 fm 2 cal 2 cal 1 1 sol 1 fm p1 p2 rear s/o display 24 vdc f1 cpu key sw dr bd lt bd cab fan agitator deck pwr supply bd mtr 1 mtr 2 so so 1 2 ac in gr wht blk gr blk wht box fan cpu circuit breaker door solenoid 52.

Page 53

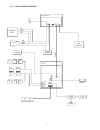

9.19 4-valve wiring diagram 53.

Page 54

Lancer corp. 800-729-1500 technical support/warranty: 800-729-1550 custserv@lancercorp.Com lancercorp.Com.