- DL manuals

- Lancer

- Beverage Dispenser

- CED Series 1500

- Operation Manual

Lancer CED Series 1500 Operation Manual

Summary of CED Series 1500

Page 1

1 ced series 1500 “lancer” is the registered trademark of lancer © 2016 by lancer, all rights reserved. 1500 lancer corporation 6655 lancer blvd. San antonio, texas 78219 800-729-1500 technical support/warranty 800-729-1550 custserv@lancercorp.Com lancercorp.Com pn: 28-0450/02 operation manual.

Page 2: Table of Contents

2 table of contents before getting started each unit is tested under operating conditions and is thoroughly inspected before shipment. At the time of shipment, the carrier accepts responsibility for the unit. Upon receiving the unit, carefully inspect the carton for visible damage. If damage exists,...

Page 3: ! Intended Use

3 • the dispenser is for indoor use only • this appliance is intended to be used in commercial applications such as restaurants or similar. • this appliance should not be used by children or infirm persons without supervision. • this appliance is not intended for use by persons (including children) ...

Page 4: ! Automatic Agitation

4 • units are equipped with an automatic agitation system and will activate unexpectedly. • caution: do not place hands or foreign objects in the water bath tank. Unplug the dispenser during servicing, cleaning, and sanitizing. • caution: to avoid personal injury, do not attempt to lift the dispense...

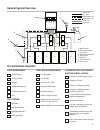

Page 5: General System Overview

5 general system overview pre-installation checklist syrup line co 2 line plain water line carb water line drain line electrical a. Water source b. Remote carbonator c. Floor drain d. Bib syrup containers e. Syrup pump f. Dispenser g. Electrical outlet h. Co 2 source b a c d d d d d d f g h e e e e ...

Page 6: Read This Manual

6 read this manual this manual was developed by lancer corporation as a reference guide for the owner/operator and installer of this dispenser. Please read this manual before installation and operation of this dispenser. Please see pages 13-17 for troubleshooting or service assistance. If the servic...

Page 7: Dispenser Installation

7 dispenser installation 1. Install the unit onto the counter. 2. Remove the bonnet from the dispenser by lifting up. 3. Remove the drip tray from the unit and connect the drain tube to the drain fitting located on the bottom. Secure drain tube with clamp provided in accessory kit. 4. Route the drai...

Page 8

8 installing remote syrup pumps - bag in box a b c a. Syrup pump b. Co 2 line c. Fitting d. Oetiker pliers d 1. Install bib rack and remote pumps according to manufacturers’ instructions. 2. Once pumps and bib rack are installed, measure and cut tubing to length between the pump co 2 inlets, then co...

Page 9: Installing Co

9 installing co 2 supply / dispenser setup do not turn on co 2 supply at this time before installing regulator, assure that a seal (washer or o-ring) is present in regulator attachment nut. ! Attention ! Warning - thread regulator nut on to tank, then tighten nut with wrench a. Co 2 regulator b. Out...

Page 10

10 adjust water flow rate & syrup / water ratio thewaterflowcanbeadjustedbetween1.25oz/sec (37 ml/sec) and 2.50 oz/sec (74 ml/sec) on all dispensing valves using the following procedures: note the refridgeration unit should have been running for at leastone(1)hourbeforeattemptingtosetflowrates onval...

Page 11: Maintenance

11 maintenance scheduled maintenance as needed • keep exterior surfaces of dispenser (include drip tray and cup rest) clean using a clean, damp cloth. Daily • remove each nozzle and diffuser from each valve and rinse well in warm water. Do not use soap or detergent. This will cause foaming and off t...

Page 12

12 cleaning and sanitizing solutions cleaning solution mix a mild, non-abrasive detergent (e.G. Sodium laureth sulfate, dish soap) with clean, potable water at a temperature of 90°f to 110°f (32°c to 43°c). The mixture ratio is one ounce of cleaner to two gallons of water. Prepare a minimum of five ...

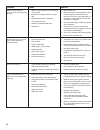

Page 13: Troubleshooting

13 troubleshooting trouble cause remedy water leakage around nozzle. 1. O-ring not properly installed above diffuser 2. O-ring is damaged or missing. 1. Install or replace o-ring correctly. 2. Replace o-ring. Leakage between upper and lower bodies. 1. Gap between upper and lower valve bodies. 2. Wor...

Page 14

14 trouble cause remedy water only dispensed; no syrup; or syrup only dispensed, no water 1. Water or syrup shutoff on mounting block not fully open. 2. Improper or inadequate water or syrup flow. 3. Bib supply too far from dispenser. 4. Co 2 pressure too low. 5. Stalled or inoperative bib pump 6. K...

Page 15

15 trouble cause remedy excessive foaming. 1. Incoming water or syrup temperature too high. 2. Co 2 pressure too high. 3. Water flow rate too high. 4. Nozzle and diffuser not installed. 5. Nozzle and diffuser not clean. 6. Air in bib lines. 7. Poor quality ice. 8. High beverage temperature. 1. Corre...

Page 16

16 trouble cause remedy compressor does not start (no hum), but gas cooler fan motor runs. 1. Compressor relay capacitors or overload malfunctioning. 2. Inadequate voltage. 3. Incorrect wiring. 4. Compressor malfunctioning. 1. Replace compressor relay capacitors or overload. 2. Measure voltage acros...

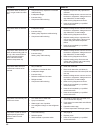

Page 17

17 trouble cause remedy circuit breaker tripping. 1. Valve wire harness shorted to itself or to faucet plate. 2. Pcb is bad. 3. Secondary wire harness is bad. 4. Transformer failure. 1. Detect short by disconnecting input fasten to keylock and single pin connector. Restore power if breaker doesn’t t...

Page 18

18 checking the normal pcb operation the electronic ice bank control (eibc) terminalblockhasaclinevoltageandshouldbecoveredwithtape.Tapeshouldcoverbareelectricalconnectionsto preventelectricalshock. ! Warning 1. Turn power off or insure that power has been disconnected from dispenser 2. Check condit...

Page 19: Dispenser Disposal

19 to prevent possible harm to the environment from improper disposal, recycle the unit by locating an authorized recycler or contact the retailer where the product was purchased. Comply with local regulations regarding disposal of the refrigerant and insulation. Dispenser disposal.

Page 20

20 cabinet assembly - high performance illustrations and part listings 3 29 2 1 32 31 7 6 11 8 9 10 27 16 33 34 23 24 22 18 20 19 21 13 15 17 15 14 12 5 37 25 26 36 35 4 6 30 28 8.

Page 21

21 item part no. Description 1 30-0636/02 wrapper, external 2 51-0568 trim, gray 3 04-0067 rivet 4 50-0173 insulation, tape, front 5 50-0178 insulation, top 6 50-0214 insulation, tape, sides 7 50-0118 insulation, tape, back 8 04-0082 nut, hex, 10-24, ss 9 30-0612 back, plate 10 04-0477 screw, 8 - 32...

Page 22

22 cabinet assembly - 1500e and pre-mix 27 23 5 4 6 4 7 2 32 12 33 34 35 22 1 24 12 12 30 31 12 20 19 12 13 11 26 21 3 28 11 8 29 14 17 18 16 15 14 10 9 25 6.

Page 23

23 item part no. Description 1 51-0744/01 wrapper, external 2 50-0173 insulation, tape, front 3 50-0178 insulation, top 4 50-0214 insulation, tape, sides 5 50-0118 insulation, tape, back 6 04-0082 nut, hex, 10 - 24, ss 7 42-0032 tank, foamed 8 04-0074 nut, clip 10 - 24 9 30-0624/01 front support pla...

Page 24: (Eibc) Pn: 82-2667; Usa Only

24 refrigeration deck assembly, r-134a, with lancer electronic ice bank control (eibc) pn: 82-2667; usa only w at er f lo w s fr o m ta nk o ve rf lo w t ub e. Fi ll w at er b at h un ti l -im po rt an t- w at er b at h fi ll h o le bl bl/w bl/w bl to junctio n bo x 39 37 (t o 32) 4 25 38 6 5 26 1 2...

Page 25

25 item part no. Description 1 30-5107 shroud, fan, bottom 2 30-5106 shroud, fan, top 3 04-0504 screw, 8 - 18 x 0.375 4 23-0985 condenser 5 47-0344 tube, process 6 23-0982 dryer/cap assy 7 25-0047 transformer, 115v/50-60hz 8 02-0041 seal 9 02-0040 seal, extrusion 10 11-0118 connector, ground 11 47-1...

Page 26: 240V/60Hz; Export Only

26 refrigeration deck assembly, r-134a, with lancer electronic ice bank control (eibc) pn: 82-2050e, 115v/60hz; pn: 82-2099e, 230v/50hz; pn 82-2048e, 240v/60hz; export only wa te r ba th fi ll h ol e -im po rt an t- fil l w at er ba th u nt il ta nk o ve rf lo w tu be . Wa te r fl ow s f ro m to tra...

Page 27

27 item part no. Description 1 30-5107 shroud, fan, bottom 2 30-5106 shroud, fan, top 3 04-0504 screw, 8 - 18 x 0.375 4 23-0985 condenser 5 47-0344 tube, process 6 23-0982 dryer cap assy 7 25-0048 transformer, 220v/50-60hz - 25-0047 transformer, 115v/50-60hz 8 02-0041 seal 9 02-0040 seal, extrusion ...

Page 28: Control Housing Connections

28 wiring diagram, electronic ice bank control (eibc), usa only control housing connections to valves 24 v leads ac power in agitator motor white black green kill switch jct compressor lancer ice bank control probe l relay s m m s fan motor c overload when starting unit or if current is interrupted,...

Page 29: Important

29 wiring diagram, electronic ice bank control (eibc), international only plumbing diagram - 5 valve and 6 valve key switch v a l v e s (5, 6, or 8) s1 s2 s3 b b b w w w s4 s5 b b s6 w w w b w w b b s7 s6 power cord bl 1500ced sym. G br usa only kill switch br b ribbed blk bl 16 15 7 8 b/w b b/w lin...

Page 30

Lancer corp. 800-729-1500 technical support/warranty: 800-729-1550 custserv@lancercorp.Com lancercorp.Com.