- DL manuals

- Lancer

- Water Dispenser

- TOUCHPOINT SERIES 4800T

- Operation Manual

Lancer TOUCHPOINT SERIES 4800T Operation Manual

Lancer Corp.

6655 Lancer Blvd.

San Antonio, Texas 78219

800-729-1500

Technical Support/Warranty: 800-729-1550

custserv@lancercorp.com

lancercorp.com

Manual PN: 28-0931

NOVEMBER 2013

FOR QUALIFIED INSTALLER ONLY

TOUCHPOINT SERIES 4800T

Operation Manual

PN: 28-0931

“Lancer” is the registered trademark of Lancer © 2014 by Lancer, all rights reserved.

4800T

Summary of TOUCHPOINT SERIES 4800T

Page 1

Lancer corp. 6655 lancer blvd. San antonio, texas 78219 800-729-1500 technical support/warranty: 800-729-1550 custserv@lancercorp.Com lancercorp.Com manual pn: 28-0931 november 2013 for qualified installer only touchpoint series 4800t operation manual pn: 28-0931 “lancer” is the registered trademark...

Page 2

About this manual this booklet is an integral and essential part of the product and should be handed over to the operator after the installation and preserved for any further consultation that may be necessary. Please read carefully the guidelines and warnings contained herein as they are intended t...

Page 3

3 7. Unit dimensions................................................................................................................34-35 8. Illustrations and parts listings..................................................................................36 8.1 spare parts list 1.......................

Page 4

Touchpoint specifications 32.6" 33.4" 37.3" 23.0" 31.8" 9.4" dimensions width: 32.5 in (825 mm) depth: 33.7 in (856 mm) height: 37.3 in (947 mm) space required width: 41.3 in (1049 mm) depth: 38.5 in (978 mm) height: determined by manual filling requirements or ice maker mounting electrical 115vac/6...

Page 5

Pre-installation checklist before getting started each unit is tested under operating conditions and is thoroughly inspected before shipment. At the time of shipment, the carrier accepts responsibility for the unit. Upon receiving the unit, carefully inspect the carton for visible damage. If damage ...

Page 6

Warning/advertencia/avertissement ! The dispenser is for indoor use only. This unit is not a toy. Children should not be supervised not to play with appliance. It should not be used by children or infirm persons without supervision. This appliance is not intended for use by persons (including childr...

Page 7

Dispenser installation highlights this unit has been factory sanitized per lancer specifications. Listed below are six critical elements which will aid in a successful installation. 1. Fill water bath until water overflows from tank overflow tube. 2. The carbonator pump motor must be disconnected fr...

Page 8

Electrical warning/advertencia elÉctrica/ avertissement Électrique f check the dispenser serial number plate for correct electrical requirements of unit. Do not plug into a wall electrical outlet unless the current shown on the serial number plate agrees with local current available. Follow all loca...

Page 9

Automatic agitation/agitaciÓn automÁtica/ ! Units are equipped with an automatic agitation system and will activate unexpectedly. Do not place hands or foreign objects in the water bath tank. Unplug the dispenser during servicing, cleaning, and sanitizing. To avoid personal injury, do not attempt to...

Page 10

1. Installation 1.1 recieving the unit each unit is completely tested under operating conditions and thoroughly inspected before ship- ment. At time of shipment, the carrier accepts the unit and any claim for damage(s) must be made with carrier. Upon receiving units from the delivering carrier, care...

Page 11

1.4 selecting the location a. Select a level, well ventilated, accessible location away from direct sunlight (avoid) or overhead lighting (convenient to water, soda, and syrup lines and open type drain), a properly grounded electric supply and ensure sufficient clearance for air circulation. B. Suff...

Page 12

12 1.6 installing an icemaker (continued) a. Install the icemaker per manufacturer specifications. Points of consideration include drainage, ventilation, and drop zones. B. An adapter plate is required when installing an icemaker. Contact your sales representative or lancer customer service for more...

Page 13

1.8 connecting to electrical power (continued) a. Review the warnings. B. Route the power supply cord to a grounded electrical outlet of the proper voltage and amperage rating. C. Do not plug in the unit at this time. 1.9 connecting to water supply lines a. Use a sharp knife, razor blade, or tube cu...

Page 14

1.11 installation of the unit and pump deck (continued) j. Connect syrup supply lines to the 3/8 inch barb inlet fittings at the front of the unit. Reference plumbing diagram on front of unit. Primary syrup valve is s1. K. Connect the flavor injection lines to the barb fittings at the front of the u...

Page 15

15 g. Contact lancer warranty for the default pass-code or ask store manager if pass code was changed. H. During sanitizing, use only the manual pour button on each valve. I. Clean and sanitize the entire dispenser prior to proceeding. Follow sanitizing instructions in section 2..

Page 16

16 1.14 carbonator and syrup purging a. Ensure co2 supply is turned off. B. Ensure the pump deck is turned off. C. Open the relief valve until water comes out. Close the relief valve. D. Access the technician menu. E. To fill plain water and carbonated water lines, ensure a good flow of water is est...

Page 17

17 c. For each syrup and flavor adder module being used, tap the brand icon to open the brand library and reveal additional syrup brands for selection. D. Selecting the different tabs on the left side of the screen will reveal even more available brands. Tap back to return to technician menu. Contin...

Page 18

18 1.15 setting up brands (continued) e. Tap the desired syrup brand. Selected brand will become darker. Tap save to change assignment. Tap cancel to remove selection. F. Modify the dispense flow rate and w/o ice ratio if required. Ratios and dispense times will automatically be updated when changes...

Page 19

19 g. After completing changes, tap save to apply all changes made. Tapping cancel will undo all unsaved changes. 1.16 filling ice and setting ratio a. Fill unit with ice until the auger is covered. Push chute and check for ice delivery. B. Finish filling the unit with ice and install top cover (if ...

Page 20

20 1.17 other a. Pouring hot water into drain may cause the drain tube to collapse. Allow only luke warm or cold water to enter drain tube. B. Pouring coffee tea and similar substances into drain may cause the drain tube to become clogged with coffee or tea grounds, or other solid particles. C. If a...

Page 21

21 2.1 cleaning and sanitizing solutions (continued) nozzle sanitizing solution: prepare a chlorine solution (less than ph 7.0) containing 50 ppm chlorine with clean, potable water at a temperature of 90 – 110°f. Any sanitizing solution may be used as long as it is prepared according to manufacturer...

Page 22

22 2.4 cleaning and sanitizing beverage components - figal systems (continued) c. Turn key switch to service position. Using the technician menu, activate valve until water is dispensed. Note: to activate a valve, access the technician’s menu. Refer to ‘basic set up & user guide’ for instructions to...

Page 23

23 2.5 cleaning and sanitizing beverage components - bag-in-box systems note: extended lengths of product lines may require more time for flushing and rinsing lines than described below. A. Disconnect the syrup quick disconnect coupling from the syrup packages and connect the coupling to a bag valve...

Page 24

2.7 ice chute cleaning it is recommended to perform this procedure monthly, or more often if desired. Use the cleaning solution described above. An alternate solution of one part water to one part vin- egar may be used to remove water spots and calcium deposits. A. Turn off power to the dispenser. B...

Page 25

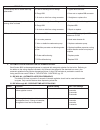

Trouble cause remedy multi media & advertising 3.1 advertising mode does not activate. A. Object too close to the proxim- ity sensor located on the front of the dispenser b. No videos uploaded c. Video input selection set to hdmi. D. Incorrect format. A. Remove object and ensure proper clearances ar...

Page 26

Trouble cause remedy touch screen & user interface 3.8 touch screen not responding to any touch inputs. A. Loose usb connection at touch screen or cpu. B. Cpu not reading touch screen usb. C. Improperly shutdown a. Ensure all touch screen connections are secure on touch screen and cpu. B. Disconnect...

Page 27

Trouble cause remedy ada 3.12 ada keypad does not respond to input a. Loose or improperly connected b. Malfunctioning ada board c. Malfunctioning ada membrane switch a. Check all cables are connected properly from the ada membrane switch to the ada control board. Ensure no exposed pins at connection...

Page 28

28 trouble cause remedy 4.1 touch screen responsive but no product dispensed when pour icon is touched from flavor selection/pour screen: no clicking can be heard from solenoid activation a. Unit is in “no dispense” mode b. Valve harnesses not connected properly c. Carbonator pump over pressurized n...

Page 29

29 trouble cause remedy 4.11 insufficient soda flow (carbonated drinks) a. Insufficient co2 supply pressure b. Shutoff on mounting block is not fully open c. Foreign debris in soda flow control d. Defective lfcv module a. Verify incoming co2 pressure is between 70-75 psi b. Open shutoff fully c. Rem...

Page 30

30 trouble cause remedy 4.17 water only dispensed, no syrup. Or syrup only dispensed, no water a. Syrup bib empty b. Water or syrup shutoff on mounting block not fully open c. Improper or inadequate water or syrup supply d. Co2 pressure to syrup pump too low e. Stalled or inoperative bib pump f. Kin...

Page 31

Trouble cause remedy 4.20 circuit breaker tripping a. Valve wire harness shorted to itself or faucet plate b. Controller pcb is bad c. Secondary wire harness has a short d. Power supply is bad a. Detect short by disconnecting valve harnesses from switch panel (4 25-pin harnesses and 4 9-pin harnesse...

Page 32

Trouble cause remedy 4.24 bib pump fails to restart after bag replacement a. Leak in discharge line or fittings b. Empty bib c. Air leak on inlet line or bag connector a. Tighten bib connector b. Clean out or replace bib connector c. Straighten or replace line 4.25 bib pump fails to stop when dis- p...

Page 33

33 6. Dispenser disposal to prevent possible harm to the environment from improper disposal, recycle the unit by locating an authorized recycler or contact the retailer where the product was purchased. Comply with local regulations regarding disposal of the refrigerant and insulation..

Page 34

34 7. Unit dimensions.

Page 35

35.

Page 36

36 8. Illustrations and parts listings 8.1 spare parts list 1 item part no. Description 1 82-4683 merchandiser assy, tp30 2 82-4515 panel,side, left,assy 3 82-4513 panel assy, side,right 4 82-4718 kit, spare parts, nozzle,tp 5 82-4682 splash plate assy, tp30 6 23-1627 cup rest, wire form, tp30 7 82-...

Page 37

37 8.2 spare parts list 2 item part no. Description 1 05-0999/02 lever, chute, ibd 2 19-0260/03 valve assy, lfcv,4.5 syr, blk, sc 3 19-0261/05 valve assy, lfcv, 4.5 soda, gry, s 4 19-0262/03 valve assy, lfcv, 0.2 inj, nat, sc 5 52-3416 power brick, 19v, 4.7a, 90w, touchpoint 6 52-3417 power brick, 1...

Page 38

38 8.3 spare parts list 3: control box assy item part no. Description 1 05-3101 standoff, #6-32x.5, nylon 2 05-3185 standoff, pcb, snap-lock, .375, nylon 3 05-3186 standoff, pcb, snap-fit, 1-3/8, nylon 4 13-0047 stdf .250 hartwell #hnst4-250-1 5 13-0209 wire saddle, rohs, w/arrowhead 6 52-3422 power...

Page 39

39 8.4 spare parts list 4: splash plate item part no. Description 1 21-0752 power cord, 16/3, sjt 2 52-3418 cable, usb, ada board, touchpoint 3 52-3429 cable, hdmi to dvi, touchpoint 4 52-3550 usb flash drive assy, update key, touchpoint 5 64-5065 pcb assy, ada, touchpoint.

Page 40

40 8.5 plumbing diagram.

Page 41

41 8.6 electronics diagram.

Page 42

Lancer corp. 800-729-1500 technical support/warranty: 800-729-1550 custserv@lancercorp.Com lancercorp.Com.