- DL manuals

- Landa

- Pressure Washer

- MHP4 30324E

- Operator's Manual

Landa MHP4 30324E Operator's Manual

Summary of MHP4 30324E

Page 1

® 8.913-925.0-t 09/18/17 mhp 3000 & 3500 series hot water -gasoline powered - diesel/oil heated operator’s manual pressure washer models: mhp4 30324e 1.110-501.0 mhp4 35324e 1.110-503.0 mhp4 35224e 1.110.502.0 for the landa dealer nearest you, consult our web page at www.Landa.Com.

Page 2

2 landa mhp operator’s manual 8.913-925.0 - t machine data label.

Page 3

3 table of contents machine data label . . . . . . . . . . . . . . . . . . . . . . . . . . 2 table of contents . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 how to use this manual . . . . . . . . . . . . . . . . . . . . . 4 safety introduction & safety information . . . . . . . . . . . . ....

Page 4

4 how to use this manual this manual contains the following sections: • how to use this manual • safety • operations • maintenance • parts list the how to use this manual section will tell you how to find important information for ordering correct repair parts. Parts may be ordered from authorized d...

Page 5

5 safety introduction & safety information thank you for purchasing this pressure washer. We reserve the right to make changes at any time without incurring any obligation. Owner/user responsibility: the owner and/or user must have an understanding of the manufacturer’s operating instructions and wa...

Page 6

6 safety important safety information warning: to reduce the risk of injury, read operating instructions carefully before using. 1. Read the owner's manual thor- oughly. Failure to follow instruc- tions could cause malfunction of the machine and result in death, serious bodily injury and/or property...

Page 7

7 safety warning: risk of injury. Hot surfaces can cause burns. Use only designated gripping areas of spray gun and wand. Do not place hands or feet on non-insulated areas of the pressure washer. 12. Transport/repair with fuel tank empty or with fuel shut-off valve off. Caution: hot discharge fluid....

Page 8

8 safety 21. Do not allow acids, caustic or abrasive fluids to pass through the pump. 22. Never run pump dry or leave spray gun closed longer than 1-2 minutes. 23. Machines with shut-off spray gun should not be operated with the spray gun in the off position for extensive periods of time as this may...

Page 9

9 operations component identification pump — delivers a specific gpm to the high pressure nozzle which develops pressure. Spray gun — controls the application of water and detergent onto cleaning surface with trigger device. Includes safety latch. Detergent valve — allows you to siphon and mix deter...

Page 10

10 operations assembly instructions step 1: attach a 5/8" water supply hose to inlet connector. Minimum flow should be 5 gpm. Step 4: check oil level on sight glass on side of pump. Oil should be visible one-half way up sight glass (sae 10w-40 non-foaming). The oil level can also be checked by using...

Page 11

11 operations operating instructions step 1: read operator’s manual before operating. Before installing nozzle, turn on water supply and run machine allowing water to flush through the system until clear. Pull wand coupler collar back, insert desired pressure nozzle into coupler, then secure by push...

Page 12

12 operations detergents and general washing techniques warning: some detergents may be harmful if inhaled or ingested, causing severe nausea, fainting or poisoning. The harmful elements may cause property damage or severe injury. Step 1: use detergent designed specifically for pressure washers. Hou...

Page 13

13 operations shutting down and clean-up step 1: remove detergent suction tube from container and insert into one gallon of fresh water. Open detergent valve, pull trigger on spray gun and siphon water for one minute. Step 4: turn off water supply. Step 2: turn burner switch off and continue sprayin...

Page 14

14 maintenance storage caution: always store your pressure washer in a location where the temperature will not fall below 32°f (0°c). The pump in this machine is susceptible to permanent damage if frozen. Freeze damage is not covered by warranty. 1. Stop the pressure washer, squeeze spray gun trigge...

Page 15

15 maintenance the areas around the landa washer should be kept clean and free of combustible materials, gasoline and other flammable vapors and liquids. The flow of combustion and ventilating air to the burner must not be blocked or obstructed in any manner. Maintenance and service unloader valves ...

Page 16

16 maintenance fuel control system these machines utilize a fuel solenoid valve located on the fuel pump to control the flow of fuel to the combus- tion chamber. This solenoid valve, which is normally closed, is activated by a flow switch when water is flowing through it. When an operator releases t...

Page 17

17 maintenance for higher altitudes, the air band opening may need to be increased; for lower altitude, the .Air band may need to be decreased. For higher humidity, the air band opening may need to be increased; for lower relative humidity, the .Air band may need to be decreased. For higher ambient ...

Page 18

18 maintenance this pressure washer was produced with the best available materials and quality craftsmanship. However, you as the owner, have certain responsibilities for the correct care of the equipment. Attention to regular preventative maintenance procedures will assist in preserving the perform...

Page 19

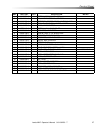

19 maintenance oil change record check pump oil level before first use of your new power washer. Change pump oil after first 50 hours and every month or 500 hours thereafter. Use sae 10w-40 non-foaming oil. Date oil changed month/day/year estimated operating hours since last oil change date oil chan...

Page 20

20 maintenance troubleshooting problem possible cause solution low operating pressure faulty pressure gauge install new gauge. Insufficient water supply use larger garden hose; clean filter washer at water inlet. Old, worn or incorrect spray nozzle match nozzle number to machine and/or replace with ...

Page 21

21 maintenance problem possible cause solution burner will not light (continued from previous page) clogged burner nozzle clean as required. Thermostat faulty or slow engine speed increase engine rpm to increase voltage. Flow switch malfunction remove, test for continuity and replace as needed. Flow...

Page 22

22 maintenance problem possible cause solution water temperature too hot incoming water to machine warm or hot lower incoming water temperature. Fuel pump pressure too high call local landa dealer for proper fuel pressure. Fuel pump defective replace fuel pump. Detergent line sucking air tighten all...

Page 23

23 maintenance problem possible cause solution pump noisy air in suction line check water supply and connections on suction line. Broken or weak inlet or discharge valve springs check and replace if necessary. Excessive matter in valves. Check and clean if necessary. Worn bearings check and replace ...

Page 24

24 notes landa mhp operator’s manual 8.913-925.0 - t.

Page 25: Parts

25 parts parts landa mhp mhp4 30324e 1.110-501.0 mhp4 35324e 1.110-503.0 mhp4 35224e 1.110-502.0 landa mhp operator’s manual 8.913-925.0 - t.

Page 26

26 control panel landa mhp operator’s manual 8.913-925.0 - t 10 2 3 4 5 6 7 8 9 11 12 13 14 15 16 17 21 8 22 8 22 18 24 1 19 23 19 (reversed view) 19 8 6 23 24 20

Page 27

27 landa mhp operator’s manual 8.913-925.0 - t control panel ref part no. Qty description notes 1 9.802-771.0 3 screw, 10/32" x 3/4" bh soc 2 8.912-711.0 1 box, mhp electrical, welded 3 9.802-530.0 1 rectifier, bridge, mb156, 12 vdc, 30 amp 4 9.802-470.0 2 relay, p & b/vf41f11, 12 vdc, 40 amp 5 8.91...

Page 28

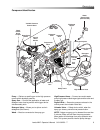

28 landa mhp left landa mhp operator’s manual 8.913-925.0 - t ex po se d pu ll eys a nd bel ts c an ca us e in ju ry pre cauc io n/ av er ti ss eme nt w ar ni ng ex po se d p ul le ys an d be lt s c an c au se in ju ry pre ca uc io n/a ve rt is se me nt w arn in g to ta nk 1 65 2 3 13 7 6 4 5 32 85 ...

Page 29

29 landa mhp operator’s manual 8.913-925.0 - t landa mhp right 37 58 65 88 56 50 36 24 119 66 44 83 16 16 89, 90, 94 63 63 48 49 100 95 96 97 98 55 57 107 24 39 46 45 54 69 75 43 42 67 68 41 43 42 78 80 53 52 82 84 92 57 87, 90, 93 14 101 129 131 130 99 90 89 34 79 51 wheel kit (optional) for detail...

Page 30

30 landa mhp ref part no. Qty description notes 1 8.912-187.0 1 wrap, top (all) yellow1 - 8.912-192.0 1 wrap, top stainless steel 2 9.802-071.0 36" trim, 1/16”, black, 750 - b2 3 9.802-766.0 6 screw, 3/8” x 1" hx 4 8.717-424.0 1 insulation, gasket, skid, stackless top 5 8.911-304.0 1 exhaust, plate ...

Page 31

31 landa mhp operator’s manual 8.913-925.0 - t landa mhp ref part no. Qty description notes 39 - 1 pump see specifications page 40 8.750-299.0 1 unloader, vrt 3, 8 gpm @ 4500 psi 41 8.706-652.0 1 box, battery - 9.802-091.0 1 plate, battery box, small, polypro not shown 42 9.803-541.0 4 bolt, 5/16” x...

Page 32

32 landa mhp ref part no. Qty description notes 72 - - engine bushing see specifications page 73 - - pump bushing see specifications page 74 - - belt see specifications page 75 8.912-714.0 1 bracket, battery 76 8.912-715.0 1 belt guard (11,13,16 hp) 77 8.912-719.0 1 plate, face (11,13,16 hp) 78 9.80...

Page 33

33 landa mhp operator’s manual 8.913-925.0 - t landa mhp ref part no. Qty description notes 100 8.912-723.0 1 shield, heat, mhp 101 9.802-813.0 4 washer, 5/8", lock 102 8.706-797.0 1 nipple, 1/2" hex 103 8.706-844.0 1 tee, 1/2" female, pipe 104 8.724-844.0 1 switch, reed replacement, mv60 105 9.802-...

Page 34

34 detergent / float tank landa mhp operator’s manual 8.913-925.0 - t 22 17 20 21 16 11 22 23 13 14 15 19 18 10 5 4 3 1 2 2 26 25 12 30 30 29 24 9 optional wheel kit assembly 22 22 float tank option landa pump with float tank option detergent valve option 7 8 6 27 28.

Page 35

35 landa mhp operator’s manual 8.913-925.0 - t detergent / float tank ref part no. Qty description notes 1 8.707-317.0 1 valve/control, metering - 9.802-810.0 1 washer, 5/8" sae flat zinc not shown - 8.719-011.0 1 washer, 5/8" interval star zinc not shown 2 8.706-958.0 2 hose barb, 1/4" barb x 1/4" ...

Page 36

36 hose & spray gun ref part no. Qty description notes 1 9.802-166.0 1 coupler, 3/8" female - 9.802-100.0 1 quick coupler o-ring lg not shown 2 8.739-213.0 1 hose, 3/8" x 50', 2 wire tuff skin 3 4.775-054.0 1 easy! Force advanced kna 4 8.711-293.0 1 wand, vp, zinc (al 344) w/coupler, w/soap nozzle -...

Page 37

37 landa mhp operator’s manual 8.913-925.0 - t detergent injector ref part no. Qty description notes 1 9.802-216.0 1 injector, detergent, non adjust, #3 2 6.390-126.0 2 clamp, hose, .46-, .54 st 3 9.802-251.0 6 ft. Tube, 1/4" x 1/2", clear vinyl 4 8.707-057.0 1 strainer, 1/4", hose barb 3 2 1 4 2 9....

Page 38

38 specifications pump engine model model part # pulley pulley part # bushing bushing part # belt size/qty mhp4- 30324e lt4540 8.921-710.0 2ak84h 9.802-375.0 25mm 9.802-403.0 ax38 (2) mhp4- 35224e lt4540 8.921-710.0 2bk90 8.715-593.0 25mm 9.802-403.0 bx44 (2) mhp4- 35324e lt4540 8.921-710.0 2bk90 8....

Page 39

39 landa mhp operator’s manual 8.913-925.0 - t specifications engine (con’t) controls model belt part # model type part # pulley pulley part # bushing part# 4-30324e 9.802-410.0 gx340 (389cc) honda 8.750-578.0 2ak30 9.803-298.0 hx1" 5-11100 4-35224e 8.715-705.0 vanguard (570cc) briggs 8.754-819.0 2b...

Page 40

40 vrt3 unloader ref part no. Qty description notes 25 8.750-713.0 1 outlet fitting 18 8.750-712.0 1 knob, unloader - 8.750-709.0 - repair kit, vrt3, 2320/3630 psi - 8.750-710.0 - repair kit, vrt3, 4500 psi - - - (kit items: 3, 4, 6, 9-12, 21, 24) landa mhp operator’s manual 8.913-925.0 - t 8.750-29...

Page 41

41 landa mhp operator’s manual 8.913-925.0 - t vrt3 unloader unloader adjustment procedures 1. Remove lock nut (item 19). 2. Remove adjustment knob (item 18). 3. Loosen the two (2) nuts (item 15), move them upward on stem (item 8) until you see 4 or more threads below the nut. 4. Re-attach adjusting...

Page 42

42 mph series wayne “ehasr” burner landa mhp operator’s manual 8.913-925.0 - t.

Page 43

43 landa mhp operator’s manual 8.913-925.0 - t mph series wayne “ehasr” burner ref part no. Qty description notes 1 8.756-716.0 1 motor, 1/4 13.5vdc ametek 2 13121 1 motor cord cover 3 8.756-726.0 1 fan, 3.44"w x 5.25"d 5/16" bore 4 8.700-735.0 1 burner housing ehasr 5 9.107-507.0 1 ignitor, 12vdc, ...

Page 44

44 lt.2 series pump ref part no. Qty description notes 1 8.752-825.0 1 crankcase 2 - 3 plunger oil seal see kits table 3 - 3 o-ring Ø1.78 x 37.82 see kits table 4 - 3 pressure ring, 18mm see kits table 5 - 3 u-seal, 18mm see kits table 6 - 3 intermediate ring, 18mm see kits table 7 - 3 u-seal, 18mm ...

Page 45

45 landa mhp operator’s manual 8.913-925.0 - t lt.2 series pump ref part no. Qty description notes 19 - 6 valve seat see kits table 20 - 6 valve plate see kits table 21 - 6 valve spring see kits table 22 - 6 valve cage see kits table 23 8.752-830.0 8 hex screw 24 9.802-884.0 8 washer 25 9.803-182.0 ...

Page 46

8.913-925.0 • printed in u.S.A. ®.