- DL manuals

- Landice

- Treadmill

- 8700 Series

- Service Manual

Landice 8700 Series Service Manual

1

111 Canfield Avenue

•

Randolph, New Jersey 07869

•

1-800-LANDICE

•

FAX 973-927-

0630

8700-Series

Home and Commercial Treadmill

Diagnostic and Service Manual

2001

This guide covers all 8700 series treadmills manufactured from

1993 – 2000.

HOME TREADMILLS – 8700 SPRINT 1-4 / PRG / SST

NOTE: Early HOME treadmills listed as: 8700R & 8700P are the same as the LTD models.

The only difference was the warranty coverage.

LTD / 110V UNITS – 8700R (

REGILAR NO PROGRAMS

) / P (

WITH PROGRAMS

) / PT1 / PT2

CLUB / 220V UNITS – 8700R (

REGILAR NO PROGRAMS

) / P (

WITH PROGRAMS

) / PT1 / PT2

Version M/C.1

For Technical Service Call 1-(800)-LANDICE

Summary of 8700 Series

Page 1

1 111 canfield avenue • randolph, new jersey 07869 • 1-800-landice • fax 973-927- 0630 8700-series home and commercial treadmill diagnostic and service manual 2001 this guide covers all 8700 series treadmills manufactured from 1993 – 2000. Home treadmills – 8700 sprint 1-4 / prg / sst note: early ho...

Page 2

2 service manual ver m/c.1 page 2 table of contents section 1- introduction page 3 how to use this manual page 4-5 landice warranty and policy page 6 tools needed for repairs section 2- installation page 7-9 safety warnings page 10-13 membrane panel identification section 3- - parts identification p...

Page 3

3 how to use this manual this manual is designed to help service technicians in the installation, maintenance, or repair of landice 8700 model treadmills. It covers terminology, installation, tools needed, diagnostics, removal and replacement of parts, estimated time of repairs, warranty forms, wiri...

Page 4

4 landice warranty and policies parts our policy requires that all defective parts be returned to landice. All warranty parts will be billed to the dealer at dealer cost. Landice will credit this invoice upon receipt of defective parts. Landice will pay the freight to send out any defective parts. I...

Page 5: Treadmill Warranty Summary

5 september 1, 2001 treadmill warranty summary treadmill parts all defective parts must be delivered to landice (freight prepaid) where they will either be repaired or replaced at landice's discretion. This warranty does not cover cosmetic damage, damage due to acts of god, accident, misuse, abuse, ...

Page 6

6 recommended tools for servicing landice treadmills 1. Deep socket set 3/8 drive with ratchet and extension: must have 3/8, 7/16, 1 /2, 5/16, 9/16 socket. 2. Combination wrench set: must have 3/8, 7/16, 1 /2, 5/16, 9/16 3. #1, 2, and 3 philips head screwdriver (or electric screwdriver) 4. #1, 2, an...

Page 7: Warning:

7 important operating safety instructions warning: failure to observe the following operating instructions can result in serious injury! 1 if you are suffering from any illness, condition, or disability which affects your ability to run, walk or exercise, do not use this product without consulting y...

Page 8: Danger

8 danger to reduce the risk of electric shock, always unplug the treadmill from the electrical outlet immediately after using. Always unplug the treadmill before cleaning or removing the motor cover. Warning to reduce the risk of burns, fire, electric shock, or injury to persons: 1 treadmill should ...

Page 9

9 200 - 250 volt treadmills (15 amp dedicated line) treadmills marked 200-250 vac are intended for use on a circuit having a nominal rating more than 120v and are factory-equipped with a specific cord and plug to permit connection to a proper electric circuit. Make sure the product is connected to a...

Page 10

10 8700 standard membrane models that used this membrane: 8700, 8700-r, 8700-ltd, 8700-ltd-vfx, 8700-club, 8700-club-vfx production time frame: 1991-1999 electronics: standard 110v scr (220v scr for club units), commercial motor pan. See wiring diagram. Settings used in: home and commercial (ltd’s a...

Page 11

11 8700 ep/pt membrane models that used this membrane: 8700ep, 8700-pt production time frame: 1991-1993 electronics: standard 110v scr (220v scr for club units), commercial motor pan. See wiring diagram. Settings used in: home and commercial key features: closed loop treadmill (w/ speed sensor) safe...

Page 12

12 8700 pt2 membrane models that used this membrane: 8700-pt2, 8700-club-pt2 production time frame: 1994-1998 electronics: standard 110v scr (220v scr for club units), commercial motor pan. See wiring diagram. Settings used in: home and commercial key features: closed loop treadmill (w/ speed sensor...

Page 13

13 8700 programmable membrane models that used this membrane: 8700-prg, 8700-prg-vfx, 8700-club-prg production time frame: 1996-1999 electronics: 8700-prg used sprint-3 electronics, 8700-prg-vfx used sprint-4 electronics, 8700-club-prg used 220v pwm commercial motor pan. See wiring diagrams. Setting...

Page 14

14 section 3 – parts identification item part# m sr p n ote treadbelt 70046 $326.00 treadbelt - xl 70157 $381.00 slider d eck (n on-v fx) 70033 $208.75 slider d eck - xl (n on-v fx) 70156 $258.35 vfx d eck 70218 $200.00 v fx deck s pacer 70219 $9.00 2 per tread v fx d eck slat 70215 $25.05 3 per tre...

Page 15

15 m em brane panel - sp rint3/4 70190 $167.00 m em brane panel - 8700pr g 70195 $225.45 m em brane panel - s st 70171 $225.45 m em brane panel - nm a (c rt,pr t) 70191-nm a $210.42 velcro c ircle 70096 $0.85 velcro strip 70095 $5.00 d ri ve r oller a ssem bly 70036 $215.75 m ust order w / cv-18-2 s...

Page 16

16 w ireless pulse o ption "pulse kit" 71017 $167.00 extender kit m isc $25.05 r ecei ver kit 70074/m isc $125.25 pulse b el t/transm itter 70072/70073 $108.55 pulse recei ver 70074 $100.20 extender c able 71009 $16.70 r ight angle adapter 71010 $8.35 isolation leakage o ption m isc $167.00 isol ati...

Page 17

17 8700 comercial motor pan components.

Page 18

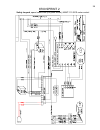

18 8700 commercial lower wiring schematic.

Page 19

19 led (light emitting diode) configurations: scr lower board the scr lower board is designed with diagnostic led lights. The led’s are color coded according to their specific function. Green indicates a properly operating treadmill; the green lights should always be on when power is supplied to the...

Page 20

20 c. Lim (red) – the c.Lim or current limit led should never come on. This diagnostic light is used to determine the condition of the treadbelt and deck. The scr board has a built-in amp meter. When the treadbelt belt and deck system wears, the amperage will increase. When this amperage reaches its...

Page 21

21 8700 home sst vfx, prg vfx, sprint vfx closed loop (speed sensor).

Page 22

22 8700 sst, prg and sprint vfx treadmill all vfx treadmills utilize closed loop speed control. All treadmills listed as vfx in the warranty database use a speed sensor..

Page 23

23 led lights on pwm the pwm lower board is designed with two diagnostic led lights. The led’s are color coded according to their specific function. Led 1 (red) – this indicates a high current draw similar to the c.Lim led on our scr lower control board. Led 1 will only light if there is high curren...

Page 24

24 led (light emitting diode) configurations: relay board the relay board is designed with diagnostic led lights. The led’s are color coded according to their specific function. Green indicates a properly operating treadmill; the green lights should always be on when power is supplied to the treadmi...

Page 25

25 8700 sst, prg and sprint 3, non vfx treadmill all non vfx treadmills utilize open loop speed control and no relay boards. Sprint 3 treadmills have push button controls.

Page 26

26 8700 sprint 2 safety lanyard, speed control dial (not push button), kbwt-110 scr motor control.

Page 27

27 8700 sprint 1 – lower wiring schematic no safety key, speed control dial (not push button), kblc-118 motor control board.

Page 28

28 8700 sprint 1&2 upper wiring schematic.

Page 29

29 section 4- servicing landice treadmills definitions 12 vdc power supply (transformer) this transformer converts ac power to dc power. It provides low voltage current for the upper display board. This component is found on treadmills with pwm motor control boards. It is incorporated into the scr m...

Page 30

30 side frame covers these sit on top of the frame rails and keep deck in place. They also form the base for the traction strip. Ir potentiometer the ir pot is located on the pwm motor control board and is used to adjust the time it takes the pwm to react to a load or amperage spike. It normally req...

Page 31

31 treadbelt this is the surface the user walks on. It rides over the deck and rollers. Upper display board this controls information from the membrane panel and face plate. It then transmits it to the relay board on home models and the scr on club or ltd models. Uprights one on either side, they ho...

Page 32

32 testing components 12 vdc power supply measure across the input terminals for ac line voltage (120/220vac). Measure across the output wires for dc voltage (9.0vdc to 18.0vdc is acceptable). If you confirm proper input voltage (ac) and have no output voltage (dc) the dc power supply must be replac...

Page 33

33 elevation motor using your voltmeter measure the input voltage (ac) to the elevation motor. Secure the black (negative) meter probe to a good chassis ground. Place the red meter probe on the red wire in the elevation harness. Press the elevation down key and you should get 120 /220vac. Place the ...

Page 34

34 terminals with your voltmeter. You should measure 120/220vac across these terminals. The dc voltage comes out of the scr board (going to the drive motor) across two output terminals marked mtr+ and mtr-. Confirm dc voltage out by measuring across these two terminals with your voltmeter. You shoul...

Page 35

35 common symptoms symptom: treadbelt feels like it’s slipping or grabbing when walked on. Possible cause: loose drive belt or treadbelt. Adjust as per manual. Remember to adjust only till slipping stops. Do not overtighten possible cause: worn treadbelt and/or deck. If treadbelt or deck is worn it ...

Page 36

36 5. Tighten drive roller until star washer bites into aluminum frame, start treadmill, and adjust tracking. If belt is straight then put on motor cover. If belt is still not straight, go to #6. 6. If there is improvement and there is still room to move drive roller adjustment bolt, continue to adj...

Page 37

37 ir potentiometer adjustments, pwm only: ir = i (amperage) r (resistance) the ir potentiometer that is located next to the max speed potentiometer on the pwm motor control board is used to adjust the time it takes the pwm to react to a load or amperage spike. When the user steps onto the treadbelt...

Page 38

38 speed calibration: sprint 4/prg/sst closed loop (speed sensor) 1. Enter the o.L.S. Mode (open loop speed) by pressing “fast” and “start” simultaneously. 2. Adjust the max speed first. Bring the set speed to 12mph. Let actual speed stabilize. 3. Adjust the max potentiometer on the pwm motor contro...

Page 39

39 removal and replacement of components 1. Before beginning any removal or replacement of components unplug power cord from wall. 2. Make a note of serial number, model (l7, l8, home, ltd, or club) and type (sport, pro, cardio, crt, or executive). Landice tracks all information from this serial num...

Page 40

40 12 vdc transformer replacement (home treadmills only) observe the proper polarity when installing a new dc power transformer. Catastrophic damage can occur to the upper display board electronics if the dc polarity is reversed. 1. If your dc transformer has color coded fast-on (push on) connectors...

Page 41

41 membrane panel 1. Remove control panel end caps from upright assembly. 2. Remove membrane panel and display board assembly by releasing velcro. 3. Disconnect upper wire harness from display board. 4. Remove screws securing display to membrane panel. 5. Install new membrane panel. Face plate (repl...

Page 42

42 elevation motor 1. Remove elevation motor. A. Remove all weight from the elevation assembly by placing a suitably strong object under the under motor pan (toolbox) so that the wheels are in the air. B. Disconnect elevation motor harness from lower board or lower harness. C. Disconnect the elevati...

Page 43

43 to enter diagnostic mode: turn off the treadmill. Sprint-1 & 2 (press display & turn knob to the on position simultaneously) sprint-3 & 4 (press display & start simultaneously) sst & prg (press up & start simultaneously) club & ltd (press display & start simultaneously) to calibrate the potentiom...

Page 44

44 elevation leg assembly 1. Remove plastic motor cover. 2. Remove set screws (2) holding elevation motor to elevation leg assembly. 3. Remove elevation pins from elevation gear nut. 4. Carefully turn treadmill onto its side to gain access to elevation leg mounting brackets. 5. Remove screws from mo...

Page 45

45 drive roller/front roller 1. Release all treadbelt tension. 9/16" bolts on rear roller. 2. Remove drive belt from drive motor. Release tension on drive motor tensioning hook (7/16" nut located underside of motor pan). Pivot motor towards treadbelt and slide drive-belt off. 3. Remove (2) philips h...

Page 46

46 noises many times a treadmill will tell you what’s wrong with it by the noises it makes. We strongly recommend the use of an automotive stethoscope. Service tip: treadmill making noise but can’t tell from where. Solution: must isolate all moving parts. 1) unplug treadmill. 2) disconnect drive bel...

Page 47

47 6. Is there excess slip cote? If you see slip cote oozing from sides of belt or off end of deck remove belt and wipe down deck, belt, and rollers. 7. Is it a commercial treadmill? Landice uses a stiffer belt on club models to increase treadbelt life. These stiffer belts make more noise and are co...

Page 48

48 visual clues the following is a breakdown of things to look for when troubleshooting these components. Decks- check for wood showing through black phenolic. Check for ridges or cupping of deck especially in front middle of deck. Both of these indicate that deck should be replaced or reversed if o...

Page 49

49 voltage tests variance in voltage affects treadmill performance. Here is how to trace the voltage into and out of the 8700 series treadmill. Confirm incoming voltage: 120/220 vac where the line cord attaches to treadmill. It could be; relay board, lower scr board, terminal block or lower harness....

Page 50

50 diagnostic guide error codes ls or l5- loss of signal. See flowchart for ls pages 55,56,62,63 os or o5- an os or 05 error indicates a treadmill o ver s peed condition. This occurs when the actual treadbelt speed is faster than the desired selected speed. There is a potential for this to occur und...

Page 51: 8700 Series Treadmill

51 8700 series treadmill diagnostic troubleshooting guide 8700 ltd 8700 club.

Page 52

52 configuration mode step 1) turn machine off, press "up" and "start" at the same time, and let go. Step 2) to select between english (mph) and metric (kph) units, press the "display" button. To enable/disable the pulse option, press "pause". The pulse led will light when enabled.(*must purchase wi...

Page 53: Treadmill Maintenance

53 treadmill maintenance treadbelt tracking, tensioning and maintenance danger !! Lethal voltages and moving parts capable of causing serious injury are exposed when the drive housing cover is removed. Under no circumstances should drive housing cover be removed except by a landice factory authorize...

Page 54

54 plug treadmill into wall outlet. Is green +12v lamp on the motor control board lit? Upper display fails to light when start is pressed. 1. No power from outlet. 2. Loose wire from line cord to motor control board. 3. Blown slow-blow fuse on motor control board. Part # mda-20 (110v), mda-15 (220v)...

Page 55

55 plug treadmill into wall outlet and press start. Display lights up; treadbelt does not move “l5 / ls error” is red serial lamp on the motor control board lit? Is the yellow rlc lamp on the motor control board lit? 1. Unplug the treadmill from its l 2. Walk on the belt manually. (push belt) 3. Doe...

Page 56

56 press start button. Is yellow spd lamp on the motor control board lit? Display lights up, treadmill moves; speed will not increase; "l5" error. 1. Disconnect the speed sensor from the motor control board. 2. Is the yellow spd lamp on the motor control board still lit? Is speed sensor aligned squa...

Page 57

57 place the treadmill in diagnostic mode: display lights up; fails to respond to other buttons. 1. Remove the saftey lanyard. 2. Turnoff the treadmill. 3. Hold the display and start key simultaneously and then release them as soon as the display lights up. 7.1 1. Replace display board. Part # 70076...

Page 58

58 elevation system failure; "po" error. Grade pot out of calibration or failed. Recalibrate pot. Go to page 9. P/n 71013 does the treadmill go up when up is pressed and down when down is pressed in this mode? Remove the 6 pin elevation connection from the lower control board. Is either the yellow d...

Page 59

59 elevation potentiometer calibration enter diagnostic mode: 1. Press off to turn treadmill off. 2. Hold start and display at the same time, then release the buttons when the treadmill lights up. Calibrate the elevation potentiometer: 1. Visually confirm treadmill is level. (0% grade) 2. The potent...

Page 60: 8700 Series Home Treadmill

60 8700 series home treadmill diagnostic troubleshooting guide 8700 sprint 4 –vfx (s/n 7-36898 and up) 8700 sst – vfx (s/n 7-43807 and up) 8700 prg – vfx (s/n 7-43825 and up).

Page 61

61 upper display board fails to light when start is pressed. Is the ac pwr light on the relay board lit? 1.Plug a lamp into the wall outlet to confirm it is live. 2.Check line cord condition and connections. 3.Unplug treadmill and use a multimeter to check the fuse. If it is bad, swap with a spare m...

Page 62

62 check speed sensor alignment. It should be within 1/16" of the flywheel and parallel to the flywheel. Is it out of position? Unplug 3 wire speed sensor connector from relay board. Check for pushed pins or loose wires. Any found? Unplug 12 wire upper harness connector from relay board. Check for p...

Page 63

63 display lights up,treadbelt does not move,l5 error. 1.Press fast & start simultaneously. 2.Press fast until 2.0mph is displayed. Does the four digit display window read safe? Is the green led2 light on the pwm motor control board lit? 1. Check blue (l1) and white (l2) wires from relay board to mo...

Page 64

64 elevation system not functioning or po (pot out) error code displayed in the two digit speed window. Enter the diagnostic mode. (see pages 12, 13, or 14) does the elevation system work properly? Proceed with recalibrating elevation potentiometer, page 8. Unplug 6 pin elevation motor connector fro...

Page 65

65 elevation potentiometer calibration enter diagnostic mode: 2. Power up treadmill in diagnostic mode: sprint – press display & start simultaneously. Sst & prg – press manual & start simultaneously. Calibrate the elevation potentiometer: 1. Visually confirm treadmill is level. (0% grade) 2. The pot...

Page 66: 8700 Series Home Treadmill

66 8700 series home treadmill diagnostic troubleshooting guide 8700 sprint 3 8700 prg 8700 sst.

Page 67

67 "8700 sprint 3" treadmill display board - new design the 8700 sprint 3 will consist of a new display board mounted in the upright. It will communicate to the high power relays and kbwt motor control board located at the bottom of the treadmill via 12-conductor, 22-gage cable. Motor control: a dc ...

Page 68

68 reed switch a read switch mounted on the display board shall be used to detect the presence of a magnet attached to a safety lanyard. In the event the magnet is removed. The four-digit display shall read "safe" and power to be removed from all relays. Mechanical buttons. (6) mechanical buttons id...

Page 69: 8700 Series Home Treadmill

69 8700 series home treadmill diagnostic troubleshooting guide 8700 sprint 1 8700 sprint 2.

Page 70

70 symptom upper display does not light up. Check position of safety key.* yes check for 120 vac between points no ac 1. Check fuse on motor control 13 and 14 on terminal block. Board, replace if necessary yes a. Check 20 amp in-line fuse (mounted to motor pan) * 2. Check for loose connections on te...

Page 71

71 * applies to sprint 2 only. Symptom display erratic; speed and elevation controls work. Does the display function normally, except for an yes re - calibrate elevation potentiometer incorrect (or unchanging) according to the instructions in appendix 2. Elevation readout? If the potentiometer canno...

Page 72

72 symptom display lights up,treadbelt 1. Check on / off switch on does not turn. Speed control panel. Does the relay "click" when no 2. Check wiring between on / off the treadmill is switched on? Switch and relay(wiring harness) yes 3. Replace relay. Check for 120 vac between l1 and l2 terminals on...

Page 73

73 yes 1. Check wiring between motor control board,filter choke and drive motor. 2. Check for broken choke or shorted capacitor. 3. Check voltage going to motor directly at points 3 and 4 on terminal block. Check voltage output on the kb-tsm at points a+ and a-. If motor has input voltage but does n...

Page 74

74 2. 120 vac between (yellow) and (white) wires when the "down"switch is engaged,and 0 vac when the switch is disengaged. Yes no incorr ect readin gs replace elevation motor. 1. Check elevation switch for continuity. 2. Check wiring. Appendix 1: sprint 1 speed calibration *see sprint 2 wiring schem...

Page 75

75 max min ir cl step 2: turn machine on, increase speed until 1.2 mph shows on display, then slowly decrease speed just until the display shows exactly 1.0 mph. Step 3: adjust "min" pot on kblc-118 until belt speed is between 0.95 - 1.00 mph using a tachometer or 8.8 - 9.3 rpm counting belt revolut...

Page 76: Tracking and Tensioning

76 display” button to switch the treadmill on. Use the "select display" button to switch into elevation mode (both the "time" and "distance" led’s will be lit). Step 3: lower the treadmill until it is level (o% elevation). Step 4: turn the elevation potentiometer until "168" (* 153 sprint 2) shows i...

Page 77: Check Drive Belt Tension

77 maintenance of their treadmills. The following illustrates how to tension the treadbelt and drive belt. Check drive belt tension drive belts are pretensioned before the treadmill leaves the factory. Adjustments are only necessary when drive belt is slipping during use. To test for tightness: 1. R...

Page 78

78 speeds (2-3 mph) until you are comfortable making adjustments. Faster speeds will cause the adjustments to take effect quicker (5-6 mph). Example: treadbelt tracks to the right: a. Turn treadmill on, and bring speed up to 4.0 mph. B. Using a 9/16" wrench, tighten the right-hand adjustment bolt 1/...

Page 79

79 commercial treadmills once a week 1. Wipe down display with soft cotton cloth and mild soap and water. Cloth should be damp not wet. Once a week or as needed. 2. Wipe down handrails and traction strips with soft cotton cloth and mild soap and water. Cloth should be damp not wet. Once a week or as...

Page 80

80 brush to remove dirt trapped in treadbelt surface. A damp (not wet!) sponge can be used to finish the cleaning process. Institutional drive motor maintenance yearly institutional maintenance: replace the drive motor brushes. Failure to do so will result in premature drive motor failure. 1. Unplug...

Page 81

81 5v led definition 20 picture 18 troubleshooting 54 12 vdc power supply definition 29 picture 21-22 removal/replacement 40 troubleshooting 61 testing 32, 49, 70 capacitor definition 29 picture 17-18 removal/replacement 39 troubleshooting 55 wiring 18 ce error code 50 choke (inductor) definition 29...

Page 82

82 picture(motor pan) 17, 21 removal/replacement 41 testing 32 troubleshooting 47-48 drive motor brushes maintenance 32 removal/replacement 41 troubleshooting 35, 36, 47, 55, 63 drive roller w/sheave definition 29 removal/replacement 45 troubleshooting 35, 46, 77 elevation leg assembly definition 29...

Page 83

83 fuses 54, 61, 70 ir potentiometer definition 30, 37 adjustments 37, 74 troubleshooting 36 l5 (ls) error code 50 troubleshooting 55, 56, 62, 63 led lights scr 19-20 pwm 23 relay 24 maintenance 53, 78, 79 membrane panel definition 30 picture 10, 11, 12, 13 removal/replacement 41 testing 33 troubles...

Page 84

84 testing 34 troubleshooting 24, 61, 63 wiring 22 safety lanyard definition 30 troubleshooting 52, 57, 68, 70 scr motor control board definition 30 led lights 19-20 picture 17 removal/replacement 39 testing 33-34 troubleshooting 54, 55, 56, 58 wiring 18 slipcote lubricant definition 30 use 78-79 tr...

Page 85

85 testing 34 uprights (frame) definition 31 upper wire harness definition 31 troubleshooting 49, 54, 61, 70 voltage specifications 7-9 testing 49.