- DL manuals

- Landice

- Treadmill

- L Series

- Diagnostic And Service Manual

Landice L Series Diagnostic And Service Manual

Summary of L Series

Page 1

1 111 canfield avenue • randolph, new jersey 07869 • 1-800-landice • fax 973-927-0630 l-series home and commercial treadmill diagnostic and service manual 2003 version c/d.2 for technical service call 1-(800)-landice.

Page 2

2 service manual version c/d.2 page 2-3 table of contents section 1- introduction page 4 how to use this manual page 5-14 replica landice warranty cards and warranty policy page 15 service authorization form page 16 time allotted for repairs page 17-18 tools needed for repairs section 2- installatio...

Page 3

3 section 4 –servicing landice treadmills page 57-59 definitions of components page 60-62 testing components page 63-64 membrane panel bypass test page 65-68 common symptoms page 69-87 removal and replacement of components page 88-91 noises page 92 voltage tests page 93-94 diagnostics and error code...

Page 4

4 how to use this manual this manual is designed to help service technicians in the installation, maintenance, or repair of landice l7 and l8 model treadmills. It covers terminology, installation, tools needed, diagnostics, removal and replacement of parts, estimated time of repairs, warranty forms,...

Page 5

5.

Page 6

6 111 canfield avenue • randolph, new jersey 07869 • 800-landice • fax 973-927-0630 assignable lifetime home treadmill warranty landice, inc. Warrants all home treadmills sold into residential settings after june 1, 2002, as follows: treadmill frame lifetime treadmill parts lifetime wear items lifet...

Page 7: 5 Year / 5,000 Hour

7 111 canfield avenue • randolph, new jersey 07869 • 800-landice • fax 973-927-0630 5 year / 5,000 hour limited institutional warranty effective august 1, 2002, landice is pleased to offer an unprecedented 5-year / 5,000 hour warranty on our ltd series treadmills. To receive this warranty the treadm...

Page 8

8 111 canfield avenue • randolph, new jersey 07869 • 800-landice • fax 973-927-0630 5-year club treadmill warranty effective january 1, 2003, landice warrants all club series treadmills as follows: treadmill parts: 5-years all defective parts must be delivered prepaid to landice where they will be r...

Page 9

9 landice warranty and policies the service warranty covers installation of parts shown to be defective in material or workmanship. The selling dealer is responsible for labor for treadmills needing repairs. A service authorization (sa) number must accompany any service reimbursement request. Servic...

Page 10

10 pro-rate scale for wear items the following pro-rate scale applies to all wear items on landice l-series commercial treadmills. Wear period charge l7 treadbelt l7 deck l8/l9 treadbelt l8/l9 deck dealer price dealer price dealer price dealer price $204.00 $140.00 $259.00 $162.00 retail price retai...

Page 11

11 pro-rate scale for wear items the following pro-rate scale applies to all wear items on landice l-series commercial treadmills. L-series ltd treadmills sold after august 1, 2002 carry a 5-year parts warranty. Wear items are pro-rated as follows: up to 6 months – no charge 6-12 months – 80% off ye...

Page 12

12 service reimbursement policy: this is offered to all landice dealers as well as all authorized landice service providers. Landice covers our treadmills with a 1-year labor reimbursement policy. That means we will pay to fix our treadmill as long as it’s within one year from the date the treadmill...

Page 13

13 parts policy our policy requires that all defective parts be returned to landice. All warranty parts will be billed to the dealer at dealer cost. Landice will credit this invoice upon receipt of defective parts. It is the dealer's responsibility to return the defective parts to landice with a cop...

Page 14: Warranty Timetable

14 warranty timetable date frame parts labor home treadmills prior to 1994 5 years 1 year 1 year january 1, 1994 5 years 2 years 1 year july 15, 1996 lifetime 3 years 1 year july 15, 1998 lifetime 5 years 1 year september 1, 2001 lifetime lifetime 1 year june 1, 2002 legacy program introduced ltd tr...

Page 15

15 0 111 canfield avenue • randolph, new jersey 07869 • 1-800-landice • fax 973-927-0630 service claim form sa# dealer information: service dealer / dealer name: address city state zip phone( ) contact customer information name address city state zip phone( ) contact treadmill information model type...

Page 16: Time Allotted For Repairs

16 time allotted for repairs l-series treadmills work performed time allotted diagnosis at the time of repair 30 min remove and replace drive motor 30 min remove and replace drive belt 20 min remove and replace elevation motor 40 min (includes pot calibration) remove and replace upper board 15 min r...

Page 17

17 recommended tools for servicing landice treadmills 1. Deep socket set 3/8 drive with ratchet and extension: must have 3/8, 7/16, 1 /2, 5/16, 9/16 socket. 2. Combination wrench set: must have 3/8, 7/16, 1 /2, 5/16, 9/16 3. #1, 2, and 3 philips head screwdriver (or electric screwdriver) 4. #1, 2, a...

Page 18: Digital Multimeter

18 digital multimeter cont - electrical continuity the continuous flow of electricity, uninterrupted and unbroken. Use cont to check: fuses and wi re harnesses kΩ (kilo-ohms) - the electrical resistance of a component or conductor measured in ohms. You can check the conditi on of a potentiometer (a ...

Page 19

19 section 2 – installation important operating safety instructions warning: failure to observe the following operating instructions can result in serious injury! 1 if you are suffering from any illness, condition, or disability which affects your ability to run, walk or exercise, do not use this pr...

Page 20: Danger

20 danger to reduce the risk of electric shock, always unplug the treadmill from the electrical outlet immediately after using. Always unplug the treadmill before cleaning or removing the motor cover. Warning to reduce the risk of burns, fire, electric shock, or injury to persons: 1 treadmill should...

Page 21

21 danger! Improper connection of the equipment-grounding connector can result in a risk of electric shock. Check with a qualified electrician or serviceman if you are in doubt as to whether the product is properly grounded. Do not modify the plug provided with the product. If it will not fit in the...

Page 22: 220 Vac Club Treadmill

22 220 vac club treadmill 220v club electrical requirements: 220vac , 60 hz , 15 amp - dedicated circuit & ground plug - nema 6-15p (plug) receptacle - nema 6-15r (receptacle) above is diagram of plug configuration. 110 vac home, ltd, & club treadmill home, ltd, & 110v club electrical requirements: ...

Page 23: Assembly Instructions

23 how to install assembly instructions step 1 lay the treadmill on the ground. Using a razor blade knife cut the box just above the brass staples along all sides of the box. Do not cut through the center of the box, as you could hit the treadmill. Remove the box and discard. Step 2 the treadmill co...

Page 24

24 assembly instructions step 5 install side cover screw align the side frame cover beneath the end cap and install the phillips head screw. Tighten the phillips head screw until side cover aligns with endcap. Step 6 check drive belt tension check the tension on the drive belt by placing the drive b...

Page 25: Shifted In Shipping.

25 5. Remove the two screws on the back of the control panel using 5/32 allen wrench. 6. Place the reading rack in position on the back of the control panel. Be sure that the front edge of the reading rack overlaps the display panel. 7. If working alone, hold reading rack in correct position and ins...

Page 26

26 l-series treadmills general dimensions weight, l7 = approx. 280 pounds l8 = approx. 380 pounds l9 = approx. 380 pounds recommended clearance around unit for safe and functional operation in a home allow a minimum clearance of 18 inches on each side of the treadmill. Allow a minimum clearance of 4...

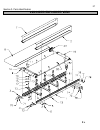

Page 27: L8/l9 Bed Exploded View

27 section 3- parts identification l8/l9 bed exploded view 18.

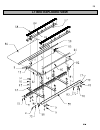

Page 28: L7 Bed Exploded View

28 l7 bed exploded view l series upright.

Page 29

29 l-series upright exploded view 112.

Page 30

30 l series motor pan exploded view 111.

Page 31

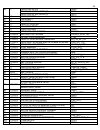

31 parts list for exploded view l7 & l8 treadmills note: always get version number for electronic components to insure compatibility. # model description part number 1 l8/l9 side frame (r) 70284 side frame (l) 70285 2 l8/l9 side frame cover(r) 70286 side frame cover(l) 70287 3 l8 bed endcap (r) 7029...

Page 32

32 30 l7/l8/l9 elevation motor (110v) 70088 elevation motor (220v) 70126 31 l7/l8/l9 elevation clevis 70049 32 l7/l8/l9 reading rack assembly 70346 33 l7/l8/l9 membrane panel(et) 70248 membrane panel(ct) 70310 membrane panel(pt) 70279 membrane panel(st) 70282 34 l7/l8/l9 display board(et) 70252 disp...

Page 33

33 58 l7 traction strip 70005 traction strip, wide (r) 70371 traction strip, wide (l) 70372 59 l7 deck spacer 70219 60 l7 treadbelt 70235 61 l7 vfx deck 70234 62 l7 take up roller 70237 63 l7 vfx deck post 70216 64 l7 drive roller 70236 65 l7 drive roller sheave cv-18-2 70 l7/l8/l9 bed end cap screw...

Page 34

34 103 l7/l8/l9 elevation potentiometer 71013 104 l7/l8/l9 elevation nut misc 105 l7/l8/l9 motor brush cap misc 106 l7/l8/l9 motor brush, 110v 70222 motor brush, 220v 70223 107 l7/l8/l9 motor brush holder misc 108 l7/l8/l9 speed sensor bracket 70067 109 l7/l8/l9 speed sensor 71007 110 l7/l8/l9 flywh...

Page 35

35 commercial motor pan (scr motor control board).

Page 36

36 l-series 110v commercial lower wire schematic.

Page 37

37 l-series 220v commercial lower wire schematic.

Page 38

38 led configurations: scr lower board the scr lower board is designed with diagnostic led lights. The led’s are color coded according to their specific function. Green indicates a properly operating treadmill; the green lights should always be on when power is supplied to the treadmill. Yellow indi...

Page 39

39 spd (yellow) – the spd led flashes on and off (relative to speed) when the speed sensor is operating properly. Grd (red) – the grd (grade) led should never come on. It illuminates only when the elevation potentiometer becomes out of calibration. Serial (red) – the serial led should never come on....

Page 40

40 l-series scr upper wire harness wiring diagram.

Page 41

41 l-series pwm motor pan (pwm motor control board) p w m l o w e r bo a r d re la y b o a r d 12 v d c t r a n s fo r m e r e l e v at io n m o t o r sp a r e f u s e dr iv e m o t o r fl y w h e e l sp ee d s e n s o r l ine c o rd el e va t io n n u t el e va t io n p o t e n io m et e r.

Page 42

42 l-series home motor pan wiring schematic.

Page 43

43 pwm voltage readings and paths l2 l1 a+ a- v+ p1 p2 a c v o lta g e i n pu t l 1 /l 2 = l in e v o lt a g e ( 110 /2 20) d c vo l t a ge o u t p u t a + /a - = d c v o lta ge o u t. V+ t o p 1 : c o nt in uous 6. 5 to 7. 0 v d c p2 t o p1 : v ari ab le fr o m 0 t o 7 v d c t he p w m m o to r co ...

Page 44

44 led configurations: pwm lower board the pwm lower board is designed with two diagnostic led lights. The led’s are color coded according to their specific function. Led 1 (red) – this indicates a high current draw similar to the c.Lim led on our scr lower control board. Led 1 will only light if th...

Page 45

45 relay board voltage readings and paths ac vo l t age i n p u t h o t / n e u t = l ine vol ta ge 110v a c n o ti c e: o nl y th e h o t le g is f u se d o n 110 v ol t tr ea dm il ls . A c v o l t a g e o u tp u t to d c t r an s f or m e r n e u t / h o t = l ine vol ta ge 110v a c ac v o l t ag...

Page 46

46 led configurations: relay board the relay board is designed with diagnostic led lights. The led’s are color coded according to their specific function. Green indicates a properly operating treadmill; the green lights should always be on when power is supplied to the treadmill. Yellow indicates a ...

Page 47

47 l-series home motor pan wiring schematic (pwm motor control board w/ relay assembly).

Page 48

48 pwm motor control board w/ relay assembly.

Page 49

49 l-series pwm upper wire harness wiring diagram.

Page 50

50 executive trainer lcd wiring schematic.

Page 51

51 l-series display control panels & features part 1 l-series sport trainer membrane models that use this membrane: l7-st, l8-st, l7-ltd-st, l8-ltd-st, l7-club-st, l8-club-st. (all l7’s before l7-03229 and all l8’s before l8-01478) production time frame: 1999 electronics: : pwm motor pan on all home...

Page 52

52 l-series display control panels & features part 2 l-series pro sports trainer faceplate models that use this faceplate: l7-pst, l8-pst, l7-ltd-pst, l8-ltd-pst, l7-club-pst, l8-club-pst, l9-club-pst(110v) & l9-club-pst(220v) production time frame: 2001-present electronics: : pwm motor pan on all h...

Page 53

53 l-series display control panels & features part 3 l-series cardio trainer membrane models that use this membrane: l7-ct, l8-ct, l7-ltd-ct, l8-ltd-ct, l7-club-ct, l8-club-ct, l9-club-ct(110v) & l9-club-ct(220v). Production time frame: 1999-present electronics: pwm motor pan on all home units, 110v...

Page 54

54 l-series display control panels & features part 4 l-series road runner membrane models that use this membrane: l7-rr, l8-rr production time frame: estimated to begin in december, 2001 electronics: pwm motor pan on all home units, see wiring diagrams. Settings used in: home key features: closed lo...

Page 55: ™

55 cardio trainer / executive trainer addendum accutrack contact heart rate monitoring system ™ the accutrack contact heart rate monitoring system™ can be used in place of the wireless chest strap to perform any of the following functions: • monitor your time in zone • control hrc programs • help yo...

Page 56

56 accessing diagnostic features on l-series treadmills note: the following information is for diagnostic and troubleshooting purposes and is meant to be used by authorized landice service technicians only and should not be made available to the general public. Executive trainer 1 - prev/3rd grey ci...

Page 57: Definitions

57 section 4- servicing landice treadmills definitions 12 vdc power supply (transformer) this transformer converts ac power to dc power. It provides low voltage current for the upper display board. This component is found on treadmills with pwm motor control boards. It is incorporated into the scr m...

Page 58

58 face plate this overlay is found on our sports trainer, pro sports trainer, and crt models and is screwed onto the upper display board. Frames (side) one on either side, these connect with the deck slats and motor pan to form the frame of the machine. Frame covers (side) these sit on top of the f...

Page 59

59 slipcoat lubricant recommended treadbelt lubricant for landice commercial treadmills speed sensor landice uses a magnetic speed sensor to receive accurate speed readings. Readings are taken directly from the flywheel on the motor and sent to the relay board or scr. Distance between the sensor and...

Page 60: Testing Components

60 testing components 1. Motor components drive motor: generation test – all landice drive motors (110 & 220) are direct current or dc. A dc drive motor can produce (generate) a dc voltage when it’s manually rotated. The dc output is linear to the speed the motor is rotated. To perform the “generati...

Page 61

61 elevation potentiometer remove the elevation pot from elevation motor but do not disconnect the brown, orange and blue wires. Using a digital voltmeter set to ohms ( Ω), place meter probes on the pot prongs with the (orange) and (brown) wires. You are measuring resistance so you do not need to ob...

Page 62

62 speed sensor the speed sensor can be checked for proper operation by entering the open loop speed mode. (see page 56) there is a yellow spd led mounted to either the relay board (home pwm models) or the scr board (ltd and club models). The light will flash on and off when you rotate the drive mot...

Page 63

63 membrane panel button codes code # executive trainer cardio trainer pro trainer pro sports trainer sport trainer 1 left 1 (top) manual start start start 2 left 2 programs n/a pause pause 3 left 3 cardio pause display display 4 left 4 (bottom) up display up program select fast 5 right 1 (top) down...

Page 64

64 pro trainer cardio trainer english metric english metric start stop pause disp+ disp- fast slow up down man prog cardio spare com shield (ground) on off pause disp+ disp- fast slow up down p1 p2 p3 p4 p5 ground static jump executive trainer jump jump.

Page 65: Common Symptoms

65 common symptoms symptom: treadbelt feels like it’s slipping or grabbing when walked on. Possible cause: loose drive belt or treadbelt. Adjust as per manual. Remember to adjust only till slipping stops. Do not overtighten possible cause: worn treadbelt and/or deck. If treadbelt or deck is worn it ...

Page 66

66 symptom: treadbelt is moving diagonally. If a belt is moving diagonally on the treadmill it can be corrected with the following steps: 1. Loosen the take up roller (both sides) 2. Take off the motor cover. 3. Loosen the drive roller adjustment bolt on the right side (opposite the sheave pulley). ...

Page 67

67 ir potentiometer adjustments, pwm only: ir = i (amperage) r (resistance) the ir potentiometer that is located next to the max speed potentiometer on the pwm motor control board is used to adjust the time it takes the pwm to react to a load or amperage spike. When the user steps onto the treadbelt...

Page 68

68 speed calibration: l-series pwm treadmills 1. Enter the o.L.S. Mode (open loop speed) by pressing “menu” and “start” simultaneously for executive trainers and “fast” and “start” for all other models. 2. Adjust the max speed first. Bring the set speed to 12mph. Let actual speed stabilize. 3. Adjus...

Page 69

69 removal and replacement of components 1. Before beginning any removal or replacement of components unplug power cord from wall. 2. Make a note of serial number, model (l7, l8, home, ltd, or club) and type (sport, pro, cardio, crt, or executive). Landice tracks all information from this serial num...

Page 70

70 choke- ltd and club only 1. Remove red wire. This connects choke to scr. 2. Remove purple wire. This connects choke to scr. 3. Reverse to install. Capacitor- ltd and club only 1. Remove white wire. This connects capacitor to scr. 2. Remove black wire. This connects capacitor to scr. 3. Remove pur...

Page 71

71 upper display board 1. Remove screws from upright on either side of display. 2. Remove caps from display. 3. Display is attached to upright with velcro. Pull from top of display to remove. 4. Remove membrane from display. 5. Disconnect main wire harness clip. (see diagram below) important:remove ...

Page 72

72 drive motor 1. Elevate treadmill to 15%. Unplug power cord. 2. Remove motor cover screws (4) 3. Disconnect white, green, and black wires from mcb. 4. If applicable remove green ground wire from frame. 5. Remove drive belt tension adjustment bolt by removing nut. Nut is located on bottom of motor ...

Page 73

73 2. Install new elevation motor. A. Remove your toolbox and set the treadmill on the ground. B. Align the elevation motor with the clevis mount and install the 3/8” diameter mounting pin. Insert the hitch pin. C. Reconnect the elevation motor wires. D. Enter diagnostic mode. (see page 56.) press t...

Page 74

74 elevation potentiometer calibration p/n #70088 110volt p/n #70126 220volt p/n #71013 note: elongated bracket holes are for potentiometer fine adjustment. Adjustment shaft elevation potentiometer elevation motor elevation nut enter diagnostic mode: press off to turn treadmill off. L-series et’s – ...

Page 75

75 elevation leg assembly 1. Remove motor cover screws (4 screws) and remove motor cover. 2. Remove set screws (2) holding elevation motor to elevation leg assembly. 3. Remove elevation pins from elevation gear nut. 4. Carefully turn treadmill onto its side to gain access to elevation leg mounting b...

Page 76

76 l8 1. Remove frame rail cap from left side (4 philips head screws) and rear (2 philips screws) 2. Remove end caps ( 2 philips head screws) 3. Remove 9/16 roller bolts (2 bolts). Note: see section on tracking and tensioning 4. Remove roller. 5. Reverse to install drive roller/front roller l7 1. El...

Page 77

77 display control package (dcp) installation 1. Attach heart rate control (hrc) module and bracket assembly to left upright leg. You will need to remove the control panel attachment screw in order to mount bracket. Next route the pulse bracket through the end cap bracket and reassemble it to the tr...

Page 78

78 installation of heart rate control components step 1: unplug the treadmill. Step 2: remove the left-hand control panel end cap. Step 3: remove the left-hand upright cover. Step 4: remove the membrane panel / display board assembly. Step 5: mount the heart rate receiver board & mounting bracket to...

Page 79

79 step 6: route the harness between the control panel end cap mounting bracket and the upright leg. Step 7: attach the hrc harness to the upper display circuit board. Step 8: re-secure the membrane panel / display board assembly to the upper control panel frame. Note: before assembling the rest of ...

Page 80: Hrc Troubleshooting

80 hrc troubleshooting the heart rate receiving hardware consists of two components, the receiver or pulse pcb (part #70283) and the pulse cable (part #70313). The pulse cable connects the pulse receiver to the upper display board. Before attempting to troubleshoot the “receiving portion” of the hrc...

Page 81

81 l7 medical rail field installation procedures tools needed for this installation: electric / battery powered drill drill bit size 5/16” & 1/4” open end / combination wrench size – 7/16 th allen wrench size – 3/16 th (should be included with hardware kit) 1. Turn treadmill on and elevate to 15% gr...

Page 82

82 l8 medical rail installation instructions 1. Insert the side rail into the upper rail clamp and tighten the bolts using a 3/16” allen wrench. 2. Fit the side rail to the bottom rail clamp. 3. Use a soft mallet to firmly set the rails inside the clamp..

Page 83

83 l8 medical rail installation instructions part 2 4. Again, use a 3/16” allen wrench to tighten the rail clamp bolts. 5. Line up the upright side covers and firmly snap them into place. 6. Place the plastic endcaps on the top corners of the control panel. Use the two small philips head screws stap...

Page 84

84 l9 hand rail installation instructions 1. Remove upright side covers. 2. Slide upright legs onto the three bolts on either side of the frame..

Page 85

85 l9 hand rail installation instructions part 2 3. Insert the fourth bolt (taped inside one of the upright legs) on either side of the frame. 4. Tighten the four bolts on each side using a 7/16” socket wrench. 5. Note: the two bottom holes on either side are unused on l9 models..

Page 86

86 l9 hand rail installation instructions part 3 6. Insert the side rail into the upper rail clamp and tighten the bolts using a 3/16” allen wrench. 7. Fit the side rail to the bottom rail clamp. 8. Use a soft mallet to firmly set the rails inside the clamp..

Page 87

87 l9 hand rail installation instructions part 4 9. Again, use a 3/16” allen wrench to tighten the rail clamp bolts. 10. Line up the upright leg side covers and firmly snap them into place. 11. Place the plastic endcaps on the top corners of the control panel. Use the two small philips head screws s...

Page 88: Noises

88 noises many times a treadmill will tell you what’s wrong with it by the noises it makes. We strongly recommend the use of an automotive stethoscope. Service tip: treadmill making noise but can’t tell from where. Solution: must isolate all moving parts. 1) unplug treadmill. 2) disconnect drive bel...

Page 89

89 4. On l7 models check that end cap is not mis-aligned. Re-align end caps so they are flush with side frame covers. If that doesn’t solve problem replace rear roller bolts. 5. Is belt rubbing on cross brace underneath treadmill? Sometimes these get bent during shipping. Bend back so belt will not ...

Page 90

90 decks and vfx - decks are solid pieces of wood with a phenolic coating that rest on the vfx cushioning system. 1. The deck can make a squeaking noise when the vfx hardware is not properly tightened or lubricated. You can test for this by bouncing on the deck when the machine is not running. 2. So...

Page 91

91 drive motors- 1. Motor brushes- a. Are they worn so that less than 3/8 of an inch is left? Replace brushes. B. Are they wearing on an angle? Check that brushes are seated correctly and that motor brush holder and spring are installed properly. 2. Commutator- a. Is it burnt, scratched, or scored? ...

Page 92: Voltage Tests

92 voltage tests variance in voltage affects treadmill performance 1. Confirm incoming line voltage: 120/220vac – pwm units: measuring between hot and neutral on relay board. Measuring between l1 and l2 wires on pwm board. Scr units: measuring between hot and neutral on scr board. For 115v and 230v ...

Page 93: Diagnostic Guide

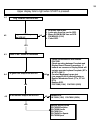

93 diagnostic guide to enter diagnostics l7 and l8- press and hold display key then press start key. L7 and l8 executive model only- press and hold menu key, then press start key. Error codes shown on display ls (can look like l5)- loss of signal. See flowchart for ls pages 63,64,69,70 os (can look ...

Page 94

94 finally, in the rarest of cases, on home treadmills, a faulty relay board can cause an os. To verify this, using a digital voltmeter, and with the treadmill turned on, measure the dc voltage between v+ and p1 on the pwm board. The reading should be between 6-7vdc. Also measure the dc voltage betw...

Page 95

95 l-series executive trainer error codes: the executive trainer software is designed with special error codes to display when experiencing a system failure. Here is a list of error codes, their meanings and diagnostics. Error code: safety shutdown / loss of signal ( with belt movement ) meaning: up...

Page 96

96 diagnostic mode: you must press the ok button in order to proceed with troubleshooting the elevation system failure. Error code: safety shutdown / over speed meaning: the actual belt speed is exceeding the user’s set speed. Example: user sets speed to 1.0mph, the actual belt speed registers 2.0mp...

Page 97

97 instructions for rebooting executive trainer software executive trainers with version 2.0 software or older (circa 12/2001). While the treadmill is off, you must hold down three (3) buttons simultaneously: 1. Prev 2. The third circular gray button down on the left side of the lcd screen. 3. Start...

Page 98

98 symptom: executive trainer lcd is too dim or too bright possible cause: needs to be adjusted follow setup menu to adjust contrast of lcd. If display is still bad (too bright / too dim), continue to step 1 step 1: a. Make sure that the power connector is securely connected from the lcd screen to t...

Page 99: L – Series Commercial

99 111 canfield avenue • randolph, new jersey 07869 • 800-landice • fax 973-927-0630 l – series commercial diagnostic flow charts l7, l8, & l9 executive trainer cardio trainer pro trainer pro sports trainer sport trainer technical support call 1-800-landice.

Page 100

100 plug treadmill into wall outlet. 1. No power from outlet. 2. Loose wire from line cord to scr. 3. Blown slow-blow fuse on scr. P/n mda-20 (110v) 4. Failed scr. Is green +12v lamp on the scr lit? 1. Check connections to wire harness. P/n 70251 2. Check mounting between faceplate and display board...

Page 101

101 plug treadmill into wall outlet and press start. Is "safe" displayed? Display lights up; treadbelt does not move; l5 error. 1. Red saftey lanyard is not in the correct position. 2. Replace display board. Is red serial lamp on the scr lit? Is the yellow rlc lamp on the scr lit? 1. Unplug the trea...

Page 102

102 press start button. Is yellow spd lamp on the scr lit? Display lights up; treadbelt moves; speed does not increase; l5 error. 1. Disconnect the speed sensor from the scr. 2. Is the yellow spd lamp on the scr lit? Is speed sensor aligned squarely and within a credit card's thickness from the flyw...

Page 103

103 elevation system failure; "po" error. Grade pot out of calibration or failed. Recalibrate pot. (see page 74) does the treamill go up when up is pressed and down when down is pressed in this mode? Remove the 6 pin elevation connection from the scr control board. Is either the yellow down lamp or ...

Page 104: L - Series Home Treadmill

104 111 canfield avenue • randolph, new jersey 07869 • 800-landice • fax 973-927-0630 l - series home treadmill diagnostic flow charts l7 & l8 executive trainer cardio trainer pro trainer pro sports trainer sport trainer technical support call 1-800-landice.

Page 105

105 upper display fails to light when start is pressed. Is the green ac pw r light on the relay board lit? 1. Plug a lamp into the wall outlet to confirm it it is live. 2. Check line cord condition and connection. 3. Unplug treadmill and use a multimeter to check the fuse. If it is bad, swap with a ...

Page 106

106 check speed sensor alignment. It should be within 1/16" of the flywheel and parallel to the flywheel. Is it out of position? Unplug 3 wire speed sensor connector from relay board. Check for pushed pins or loose wires. Any found? Unplug 9 wire upper harness connector from relay board. Check for p...

Page 107

107 upper display lights up but treadbelt doesn’t move: l5 error 1. Enter open loop speed mode. (see page 56) 2. Press fast until 12.0mph is displayed. Does four digit display window read safe? Is the green led2 light on the pwm lit? 1. Verify 110vac from blue (l1) and white (l2) wire from relay boa...

Page 108

108 elevation system not functioning or po (pot out) error code displayed in the two digit speed window. Enter the diagnostic mode. Does elevation system work properly? Proceed with re-calibrating elevation potentiometer. (pg. 74) unplug 6 pin elevation motor connector from relay. Which button or di...

Page 109: L - Series Home Treadmill

109 111 canfield avenue • randolph, new jersey 07869 • 800-landice • fax 973-927-0630 l - series home treadmill road runner diagnostic addendum l7 & l8 road runner technical support call 1-800-landice.

Page 110

110 l-series road runner lower wiring diagram.

Page 111

111 l-series road runner upper wiring schematic.

Page 112

112 road runner supplemental assembly instructions (follow these instructions in conjunction with step 10 on page 3 of your manual.) on the road runner, there are three wire harnesses that must be connected after the upright assembly is mounted to the frame of the treadmill. 1. The main harness (9 m...

Page 113

113 3. Route the cd changer harness behind the elevation motor, then around the back of the cd changer. 4. Insert the connector into the side of the changer. It will snap when properly connected. Examine all wires around the elevation motor and drive motor to be sure they will not contact any moving...

Page 114

114 road runner diagnostic addendum the following information should be used in addition to standard pwm diagnostic information when diagnosing the road runner. Software version display: -hold elevation lever in up position and turn key from off to pause. Version is displayed in main window. Reboot ...

Page 115

115 speed and grade diagnostics: -hold speed lever in the fast position and turn key from off to pause. -belt begins moving at minimum open loop speed. -speed and elevation levers function. -press time to view commanded grade (displays either up or down). -press distance to view actual grade. * this...

Page 116

116 sound only comes from one of the two speakers check speaker harness connections on the back of the display board. Swap the left and right connections. If the same speaker doesn’t play, the speaker is bad. If the other speaker doesn’t play, the display board is bad. Music doesn’t seem to play at ...

Page 117: Tracking and Tensioning

117 tracking and tensioning proper tensioning of the treadbelt and drive belt are necessary to insure smooth operation and long life for your treadmill. As these components may stretch as part of their normal break in period it is one of the few things we ask our customers to do in maintenance of th...

Page 118

118 treadbelt tracking the treadbelt is tracked by means of two adjustment bolts (9/16" wrench) located at rear of treadmill. By tightening the side the belt is closest to and loosening the opposite side by the same amount, you change the alignment of the rear roller without changing overall tension...

Page 119

119 example: treadbelt is tracking to the right hand side. Adjust right hand side of drive roller by moving it towards the front (motor side) of treadmill. The treadbelt will move towards the center. Recommended maintenance home models- vacuum around and underneath the treadmill on a monthly basis. ...

Page 120

120 slipcoat application instructions slipcoat lubricant is designed to reduce friction between t he treadbelt and deck. It is required for all institutional treadmills. Proper and timely application of slipcoat will prevent premature failures due to excessive wear and load. Items affected by inadeq...

Page 121

121 institutional drive motor maintenance yearly institutional maintenance: replace the drive motor brushes. Failure to do so will result in premature drive motor failure. 1. Unplug treadmill. 2. Remove motor brush caps (2). 3. Remove motor brushes and inspect. They should be replaced if 1/4 inch or...

Page 122

122 index description page number assembly instructions dcp (display control package 77 treadmill 23,24 medical handrails, l7 81 medical handrails, l8 82,83 medical handrails, l9 84-87 reading rack 25 accutrack contact heart rate 55 5v led defintion 39 picture 38 troubleshooting 92 12 vdc power supp...

Page 123

123 pro-rating 11 troubleshooting 38,39,65,66,88-90 diagnostic features accessing 56 diagnostic flow charts commercial units 99-103 home units 104-108 digital multimeter 12, 14 dimensions treadmill 26 display panels pictures of st,pt,ct,et 51-54 drive belt definition 57 picture 24, 30, 117 tensionin...

Page 124

124 picture 30,35,41 removal/replacement 72,73 testing 60 troubleshooting 38,46,90,103,108 wiring 36,37,42,47,74,110 elevation potentiometer calibration 74 definition 57 picture 74 testing 61 troubleshooting 39,103,108 error codes 93,94,101-103,106-108 face plate definition 58 removal/replacement 71...

Page 125

125 wiring 50 led lights scr 38, 39 pwm 44 relay 46 maintenance 119-121 medical rails installation-l7 81 installation-l8 82,83 installation-l9 84-87 membrane panel button codes 63 bypass test 63-64 definition 58 picture 51-54 removal/replacement 71 testing 62 troubleshooting 101 noises 88-91 o5 (os)...

Page 126

126 led lights 46 picture 41 removal/replacement 70 testing 61 troubleshooting 105-108 wiring 42,47 voltage 45 road runner installation (supplemental) 112, 113 troubleshooting 114-116 safety lanyard definition 58 troubleshooting 67,96,101,107 safety shutdown error code 95,96 (executive trainer only)...

Page 127

127 treadbelt cleaning 119,120 definition 59 picture 27,28 pro-rating 11 removal/replacement 75 tracking/tensioning 117, 118 troubleshooting 66,88,89,118 upper display board definition 59 executive trainer lcd wiring 50 picture 29 removal/replacement 71 troubleshooting 67,100,101,105,107,108 testing...