- DL manuals

- Lang

- Griddle

- G72T-JBX

- Installation, Operation And Maintenance Manual

Lang G72T-JBX Installation, Operation And Maintenance Manual

Summary of G72T-JBX

Page 1

Lang manufacturing company 6500 merrill creek parkway everett, wa 98203 rev. A2003 phone: 425-349-2400 fax: 425-349-2733 publication date – september, 2001 www.Langworld.Com © copyright 2001 gas griddle, jack in the box® installation, operation, & maintenance model: g72t-jbx & g72t-jbxl.

Page 2

This manual must be retained for future reference. Read, understand and follow the instructions and warnings contained in this manual. Danger potentially hazardous situation which, if not avoided, could result in death. Warning potentially hazardous situation which, if not avoided, could result in d...

Page 3: Table of Contents

Ul# mh19366 rev. A2003 3 table of contents chapter page table of contents ...................................................................................... 3 read first ........................................................................................................ 4 equipment descripti...

Page 4

Ul# mh19366 rev. A2003 4 important read first important caution the griddle is extremely heavy. For safe handling, installer should obtain help as needed, or employ appropriate materials handling equipment (such as a forklift, dolly, or pallet jack) to remove the unit from the skid and move it to th...

Page 5

Ul# mh19366 rev. A2003 5 important read first important notice never leave a chlorine sanitizer in contact with stainless steel surfaces longer than 10 minutes. Longer contact can cause corrosion. Notice service on this, or any other, lang appliance must be performed by qualified personnel only. Con...

Page 6: Equipment Description

Ul# mh19366 rev. A2003 6 equipment description lang model: lang model: g72t-jbx & g72t-jbxl exterior construction the griddle dimensions are 21” (53.34cm) high, 30” (76.20cm) deep, and width is dependent on the actual model number. Working height is 36” (91.44cm) to top of griddle plate. The griddle...

Page 7: Specification Sheet

Ul# mh19366 rev. A2003 7 specification sheet flue opening restraint griddle surface area 1656 sq. In. 3/ 4” npt gas inlet controler specifications for jack in the box 72” gas griddle on stand griddle model: g-72t-jbx grease drawers nat. L.P. Volts sides back bottom 162,000 162,000 120 5" 5" on stand...

Page 8: Specification Sheet

Ul# mh19366 rev. A2003 8 specification sheet flue opening restraint griddle surface area 1656 sq. In. 3/ 4” npt gas inlet controler specifications for jack in the box 72” gas griddle on 4” legs griddle model: g-72t-jbxl grease drawers nat. L.P. Volts sides back bottom 162,000 162,000 120 5" 5" on le...

Page 9: Unpacking

Ul# mh19366 rev. A2003 9 unpacking receiving the griddle upon receipt, check for freight damage, both visible and concealed. Visible damage should be noted on the freight bill at the time of delivery and signed by the carrier's agent. Concealed loss or damage means loss or damage, which does not bec...

Page 10: Installation

Ul# mh19366 rev. A2003 10 installation warning installation of the unit must be done by personnel qualified to work with plumbing. Improper installation can cause injury to personnel and/or damage to equipment. Unit must be installed in accordance with all applicable codes. Notice the data plate is ...

Page 11: Installation (Cont’D)

Ul# mh19366 rev. A2003 11 installation (cont’d) gas conversion 1. Disconnect grill from gas and power. 2. Remove 4 phillip screws holding front panel to grill. 3. Remove the front panel. 4. On the far left section, locate the pilot assembly and remove the two screws that hold it to the grill. 5. Fol...

Page 12: Initial Start Up

Ul# mh19366 rev. A2003 12 initial start up warning before lighting, use a soap and water solution to test all joints for gas leaks. Initial lighting procedure clean the preservative coating from the griddle plate and splashguard. Add a mild detergent to hot water and wash the griddle plate and splas...

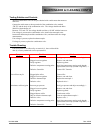

Page 13: Maintenance & Cleaning

Ul# mh19366 rev. A2003 13 maintenance & cleaning warning keep water and solutions out of controls. Never spray or hose control console. Caution most cleaners are harmful to the skin, eyes, mucous membranes and clothing. Precautions should be taken to wear rubber gloves, goggles or face shield and pr...

Page 14

Ul# mh19366 rev. A2003 14 maintenance & cleaning cont’d testing safeties and controls the pilot combination valve can only be checked with a multi-meter that measures mili-volts. Connect the mulit-meter to the top terminal of the combination valve marked “th/tp” and the body of the combination valve...

Page 15: Ncc Grill Controller

Ul# mh19366 rev. A2003 15 ncc grill controller description the grill controller reads the temperature of the cooking lanes then turns burners on and off as needed to archive the standard temperature on the grill surface. For the grill to function correctly, the controller must be set to the correct ...

Page 16

Ul# mh19366 rev. A2003 16 ncc grill controller (cont’d) cleaning as needed, wipe the surface of the controller with a damp towel to remove any dust, grease, or debris. Operating conditions • grill controller operating in the auto scan mode. • each section is set for the correct temperature. • indica...

Page 17

Ul# mh19366 rev. A2003 17 ncc grill controller cont’d adjusting to specifications (cont’d) adjusting grill calibration – weekly 1. Remove all items (press, covers, etc.) from the grill and do not cook on the grill for 5 minutes. 2. Enter the manual scan mode by pressing sel 3 times then the up arrow...

Page 18

Ul# mh19366 rev. A2003 18 ncc grill controller cont’d calibration ensures that the controller is reading the temperature information sent through each probe accurately. Perform calibration every two weeks. Important! Before beginning calibration: - ensure that grill has been on for 20 minutes. - che...

Page 19

Ul# mh19366 rev. A2003 19 ncc grill controller cont’d trouble shooting food safety and quality check 1. Destroy food if you suspect that it has been exposed to contamination (physical, biological, or chemical). 2. Destroy food if you suspect it has been exposed to temperatures that are too low or to...

Page 20

Ul# mh19366 rev. A2003 20 ncc grill controller cont’d trouble shooting (cont’d) symptom actions to take before calling for service no lights in the controller • conduct the food safety and quality check. • ensure the controller is turned on. • ensure the controller is plugged in. • ensure the circui...

Page 21

Ul# mh19366 rev. A2003 21 ncc grill controller cont’d warranty / servicing manufacturer ncc telephone no.: 1-800-323-2593 warranty 2 years for parts and labor simple repairs replacing the grill controller pick up a grill controller form the pos spares depot. Note: if not available through spares dep...

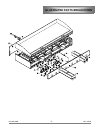

Page 22: Illustrated Parts Break Down

Ul# mh19366 rev. A2003 22 illustrated parts break down.

Page 23: Parts List

Ul# mh19366 rev. A2003 23 parts list item # part # description 1 40102-30 ncc console 2 41100-26 temperature sensor 3 80002-09-1 main burner 4 80201-06 pilot light right hand (sections 2,3,5, & 6) 5 80201-12 pilot light left hand (sections 1 & 4) n/s 80401-01 orifice, pilot, ng, .018 n/s 80401-03 or...

Page 24: Griddle Stand

Ul# mh19366 rev. A2003 24 griddle stand.

Page 25: Wiring Diagram

Ul# mh19366 rev. A2003 25 wiring diagram per section 1 2 3 4 5 6 controller plug temperature sensor th-tp tp th gas valve thermalpile.

Page 26: Warranty

Ul file #mh19366 rev. A2003 27 warranty lang manufacturing limited warranty to commercial purchasers* (domestic u.S., hawaii, & canadian sales only.) lang manufacturing equipment (“lang equipment”) has been skillfully manufactured, carefully inspected and packaged to meet rigid standards of excellen...