- DL manuals

- Lang

- Oven

- GCCO-AP

- Service Manual

Lang GCCO-AP Service Manual

Summary of GCCO-AP

Page 1

Lang manufacturing company 6500 merrill creek parkway everett, wa 98203 phone: 1-800-224-5264 fax: 1-425-349-2733 www.Langworld.Com ©copyright 2000 service manual for the lang models: gcco-t, gcco-ap, gcco-sii, gcco-c, gcco-pp, gcco-pt,.

Page 2: Table of Contents

2 table of contents chapter page 1. Table of contents .......................................................................2 2. Read first........................................................................................3 3. Equipment description ................................................

Page 3

3 important read first important caution the oven weighs 500 lbs. For safe handling, installer should obtain help as needed, or employ appropriate materials handling equipment (such as a forklift, dolly, or pallet jack) to remove the unit from the skid and move it to the place of installation. Cauti...

Page 4

4 important read first important caution keep floor in front of equipment clean and dry. If spills occur, clean immediately, to avoid the danger of slips or falls. Warning keep water and solutions out of controls. Never spray or hose control console. Caution most cleaners are harmful to the skin, ey...

Page 5: Equipment Description

5 equipment description lang model: gcco gas full size convention oven exterior • the oven exterior dimensions are 40” (100 cm) wide, 32” (80 cm) high, 38” (95 cm) deep. The top, front, back, and sides are constructed of stainless steel with an aluminized bottom. • the oven doors come standard with ...

Page 6

6 equipment description cont’d • gcco-pt icon-driven (touch) panel allows for easy operation, also includes a manual override system. Day-part memory capabilities allow operators to “recall” the last daily selections automatically. Programmable up to 99 products, advanced baking capabilities include...

Page 7: Installation

7 installation receiving the oven upon receipt, check for freight damage, both visible and concealed. Visible damage should be noted on the freight bill at the time of delivery and signed by the carrier's agent. Concealed loss or damage means loss or damage, which does not become apparent until the ...

Page 8: Installation Cont’D

8 installation cont’d gas connection this appliance is manufactured for use with the type of gas indicated on the data plate. Contact the factory if the gas type does not match that which is on the data plate. All gas connections must be in accordance with local codes and comply with the national fu...

Page 9: Installation Cont’D

9 installation cont’d gas conversions 1. Disconnect oven from power and gas. 2. Remove bottom trim piece from oven (2 hex head bolts and 1 phillips screw). 3. Remove side panel from oven. 4. Disconnect black manifold pipe from 3/8” aluminum pipe at the furrel nut. 5. Remove two phillips screws holdi...

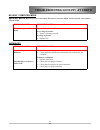

Page 10: Start-Ups

10 start-ups gcco-ap / gcco-c / gcco-pp / gcco-pt / gcco-sii / gcco-t convection oven start-up 1) verify connections at plug and terminal block 2) incoming gas - water column________ natural gas propane 3) incoming voltage l1______ 4) motor amp draw ______ 5) are programs correct? Yes no 6) verify a...

Page 11: Control Panel Gcco-T

11 control panel gcco-t time temp pulse fan hi-speed fan low-speed light on off power switch. Light switch. Inspection light only. Push toggle switch to the up position to inspect product. Switch will automatically return to the off position. Pulse fan switch. Pulse fan setting will only turn the fa...

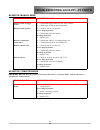

Page 12: Control Panel Gcco-Ap

12 control panel gcco-ap time temp pulse fan hi-speed fan low-speed light on off power switch. Light switch. Inspection light only. Push toggle switch to the up position to inspect product. Switch will automatically return to the off position. Pulse fan switch. Pulse fan setting will only turn the f...

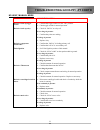

Page 13: Control Panel Gcco-Sii

13 control panel gcco-sii power switch. Light switch. Inspection light only. Push toggle switch to the up position to inspect product. Switch will automatically return to the off position. Pulse fan switch. Pulse fan setting will only turn the fan on when the oven is calling for heat. Dual speed swi...

Page 14: Control Panel Layout Gcco-C

14 control panel layout gcco-c light switch tier indicator: displays what tier (cycle) of a certain program is running. Shelf button: used to tell the oven which shelf the product is on. Power switch led display read/clear button: used as a programming key. Temperature button: press at any time to d...

Page 15: Control Panel Layout Gcco-Pp

15 control panel layout gcco-pp power switch. Light switch. Inspection light only. Push toggle switch to the up position to inspect product. Switch will automatically return to the off position. Alphanumeric display. Shelf select button. Press to select shelf which product will be placed. Product se...

Page 16: Control Panel Layout Gcco-Pt

16 control panel layout gcco-pt power switch. Light switch. Inspection light only. Push for light to come on. Light will automatically turn off. Alpha-numeric display. Arrow down button. Allows you to scroll down. Function keys. Keys are active when a program option is displayed on display. Cancel b...

Page 17: Programming Terms

17 programming terms control panel buttons 1 -0 product buttons. These are the buttons where the product programs are stored. Pressing a product button will heat the oven to the programmed temperature. A - e shelf buttons. The control is capable of timing each shelf individually. Pressing a product ...

Page 18: Programming Gcco-C

18 programming gcco-c programming action display turn the power switch on. If the oven is already on, turn it off and then back on. Enter quickly enter access code “r/c 1 6 2 7 3 8”. Do not hold the r/c button. Prod select a product number from 0-9. St: 00 select amount of time that product should s...

Page 19: Programming Gcco-C Cont’D

19 programming gcco-c cont’d gcco-c status display the status display informs the operator of the oven's status. It can be used as a countdown timer, shelf in use or internal oven temperature display during the cooking cycle (see gcco-c programming codes). The display informs the operator when the o...

Page 20: Programming Gcco-C Cont’D

20 programming gcco-c cont’d gcco-c programming codes below are codes, which will allow you to configure the display or aid in the operation, and troubleshooting of the oven. The readout must display "enter" before the computer will accept any programming code. If the readout displays any other word...

Page 21: Programming Gcco-Pp

21 programming gcco-pp action display turn the power switch on. If the oven is already on, press the read / clear key until the following screen is displayed. Select product or read/clear to program xx:xxpm xxxf enter access code “1 6 2 7 3 8”. A: set time b: set date c: program products d: next men...

Page 22: Programming Gcco-Pt

22 programming gcco-pt action display run oven time / date / program time date temp status step 1. Turn the power switch on. If the oven is already on, press the “cancel” key until the following screen is displayed. Step 2. Select: time / date / program. 12:00 01/01/01 325 standby action display dis...

Page 23: Programming Gcco-Pt Cont’D

23 programming gcco-pt cont’d action display step 5. Select: program products program products edit ready zone edit access code enable manual product configure time of day action display step 6. Select: create new product create new product edit product delete product edit product action display ste...

Page 24: Programming Gcco-Pt Cont’D

24 programming gcco-pt cont’d action display step 8. “select product name” is where you spell the name using the or to select each letter. Then select “enter” to move the cursor to the next space and select a new letter. Note: “appetizer a” is the name that must be replaced with the new product name...

Page 25: Programming Gcco-Pt Cont’D

25 programming gcco-pt cont’d action display select cooking curve 000 % use keys to select apple tier 1 temp: 320f time: 00:45:00 step 11. “select cooking curve”. Press or to select numbers, select “enter” to move the cursor to the next space. Cooking curve may be any number between 0 % and 100 %. E...

Page 26: Programming Gcco-Pt Cont’D

26 programming gcco-pt cont’d action display select pule rate 100 % use keys to select apple tier 1 temp: 320f time: 00:45:00 fan: hi cooking curve: 80 % step 13. “select pulse rate”. Press or to select numbers, select “enter” to move the cursor to the next space. 100 % is the default. If this okay,...

Page 27: Programming Gcco-Pt Cont’D

27 programming gcco-pt cont’d action display continue to next tier yes no use keys to select apple tier 1 temp: 320f time: 00:45:00 fan: hi rate: 100 % cooking curve: 80 % step 15. “continue to next tier”. The cursor automatically appears on “no”. Select “enter” or “accept” to end programming or mov...

Page 28: General

28 general operations convection ovens constantly circulate air over the product. This strips away the thin layer of moisture and cool air from the top of the product. Heat penetrates more quickly. Cooking times are shortened and cooking temperatures are usually reduced. To convert standard deck ove...

Page 29: General Cont’D

29 general cont’d one pan two pan three pan four pan five pan.

Page 30: Typical Operation

30 typical operation gcco-ap typical operation sequence action result turn power switch to on. Control panel heat call light comes on. Adjust proper temperature, between 140 & 450 degrees and allow to preheat up to 20 minutes. Oven begins heating. Open oven doors and insert product, set timer up to ...

Page 31: Typical Operation Cont’D

31 typical operation cont’d gcco-c typical operation sequence action result turn power switch to on. Control panel comes on, display says “88888” and then “enter”, motor starts. Press a product button. Display says “preht” (preheat), oven begins to heat to the programmed temperature. Beeper sounds b...

Page 32: Typical Operation Cont’D

32 typical operation cont’d gcco-pt typical operation sequence action result press the on switch. Control panel comes on, display says “lang, run oven, time date program. Select “run oven”. Display will show a list of product to choose. Select product button next to icon desired. Display says “prehe...

Page 33: Sequence of Operation Gcco-T

33 sequence of operation gcco-t power to oven light switch . 120/24-volt transformer energized. 24 volts to 6 (johnson control), th (channel products), and ground of spark module. Spark module begins sparking at pilot burner. 24 volts to pilot valve coil of combination gas valve. Pilot valve opens. ...

Page 34

34 sequence of operation gcco-sii power switch turned to “on” position. Power to oven light switch . 120/24-volt transformer energized. 24 volts to th, and ground of spark module. Spark module begins sparking at pilot burner. 24 volts to pilot valve coil of combination gas valve. Pilot valve opens. ...

Page 35: Sequence of Operation Gcco-C

35 sequence of operation gcco-c power switch turned to “on” position. Power to oven light switch. 120 volts to rows “a” and “b” of 24 pin terminal block. 120/24-volt transformer energized. 24 volts to rows “c” and “d” of 24 pin terminal block. 24 volts to common of back-up toggle switch. 24 volts to...

Page 36

36 sequence of operation gcco-pp/pt oven plugged in. 120 vac across “a” and “b” of 24 pin terminal block. 120 vac across common on light relay. 120 vac across common on cooling fan relay. 120 vac to control transformer (120 / 24-12) and component transformer (120 / 24). Power switched to “on” positi...

Page 37: Troubleshooting Gcco-T

37 troubleshooting gcco-t no motor probable cause corrective action defective power switch check power switch for normal operation. Replace as necessary. Defective transformer check transformer for normal operation. Gas supply turned off turn gas supply on and check for proper gas pressure. 5” water...

Page 38

38 troubleshooting gcco-t cont’d probable cause corrective action igniter continues to spark after pilot is lit check pilot for strong flame and good contact with sensor. Check sense wire for 12 to 13 micro amps on spark module. (johnson control spark modules use “#4” terminal and channel spark modu...

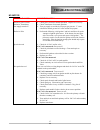

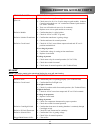

Page 39: Troubleshooting Gcco-Ap

39 troubleshooting gcco-ap no motor probable cause corrective action defective power switch check power switch for normal operation. Replace as necessary. Defective transformer check transformer for normal operation. Gas supply turned off turn gas supply on and check for proper gas pressure. 5” wate...

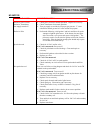

Page 40: Troubleshooting Gcco-Ap

40 troubleshooting gcco-ap probable cause corrective action igniter continues to spark after pilot is lit check pilot for strong flame and good contact with sensor. Check sense wire for 12 to 13 micro amps on spark module. (johnson control spark modules use “#4” terminal and channel spark modules us...

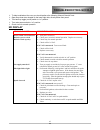

Page 41: Troubleshooting Gcco-Sii

41 troubleshooting gcco-sii no motor probable cause corrective action defective power switch check power switch for normal operation. Replace as necessary. Defective transformer check transformer for normal operation. Gas supply turned off turn gas supply on and check for proper gas pressure. 5” wat...

Page 42

42 troubleshooting gcco-sii cont’d probable cause corrective action igniter continues to spark after pilot is lit check pilot for strong flame and good contact with sensor. Check sense wire for 12 to 13 micro amps on spark module. (johnson control spark modules use “#4” terminal and channel spark mo...

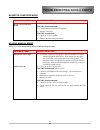

Page 43: Troubleshooting Gcco-C

43 troubleshooting gcco-c to help troubleshoot the oven you should perform the following “manual override” test: open drop down door located on the lower right side, directly below front panel. Turn back up toggle (on/off) switch to “on” position. Turn main power switch to “on” position. Check oven ...

Page 44

44 troubleshooting gcco-c cont’d probable cause corrective action no spark observed turn one on. Refer to wiring diagram and check for 24 vac at the th terminal on the spark module. If 24 vac is measured. Turn oven off: check large orange wire from igniter module to pilot burner for continuity, and ...

Page 45

45 troubleshooting gcco-c cont’d probable cause corrective action defective control transformer (12 vac). Check transformer for normal operation. Check primary coil for 120 vac and 154.1 Ω. Check secondary coil for no less than 10.5 vac and 1 Ω. If voltage is measured on primary: check for voltage o...

Page 46

46 troubleshooting gcco-c cont’d no fan-manual mode probable cause corrective action defective 120/24 vac transformer check for 24 vac on “c” and “d” of the terminal block. If 24 vac is not measured: turn off and: check secondary coil for 1 Ω. Check primary coil for 18.9 Ω. Replace transformer. If 2...

Page 47

47 troubleshooting gcco-c cont’d no motor computer mode probable cause corrective action no 24 vac on interface board check for 24 vac at tp4 to common (“d”). If 24 vac is not measured: confirm that back up relay is energizing. Replace if defective. If 24 vac is measured: check for 24 vac at tp5. Re...

Page 48

48 troubleshooting gcco-c cont’d probable cause corrective action no spark observed turn oven on. Refer to wiring diagram and check for 24 vac at the th terminal on the spark module. If 24 vac is measured, turn unit off and: check large orange wire from igniter module to pilot burner for continuity,...

Page 49

49 troubleshooting gcco-c cont’d no heat computer mode probable cause corrective action no 24 vac on interface board check for 24 vac at tp4 to ground. If 24 vac is not measured: check back-up switch for normal operation. If 24 vac is measured: check for 24 vac at tp6. Replace interface board if def...

Page 50

50 troubleshooting gcco-pp / -pt to help troubleshoot the oven you should perform the following “manual override” test: open drop down door located on the lower right side, directly below front panel. Turn back up toggle (on/off) switch to “on” position. Turn main power switch to “on” position. Chec...

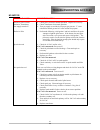

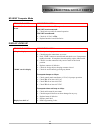

Page 51

51 troubleshooting gcco-pp / -pt cont’d no display probable cause corrective action defective power switch (-pp only) confirm that toggle switch is getting correct voltage. Check power switch for normal operation. Defective power switch output on circuit board (jp37) confirm that jp37 has 5vdc in th...

Page 52

52 troubleshooting gcco-pp / -pt cont’d no motor, manual mode probable cause corrective action defective back-up toggle switch confirm that toggle switch is in the “on” position. Check toggle switch for normal operation. Defective back-up relay check for 24vac at relay coil. If no voltage is present...

Page 53

53 troubleshooting gcco-pp / -pt cont’d no heat, manual mode probable cause corrective action defective back-up toggle switch confirm that toggle switch is in the “on” position. Check toggle switch for normal operation. Defective back-up relay check for 120vac at relay coil. If no voltage is present...

Page 54

54 troubleshooting gcco-pp / -pt cont’d no heat, computer mode important notice: before trying to trouble shoot “no heat in computer mode” confirm that the oven heats in “manual mode”. Probable cause corrective action defective output on cpu board check for 24vac at jp2 (while oven is calling for he...

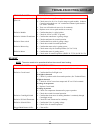

Page 55: Technical Data

55 technical data transformer resistance transformer input primary secondary output 120/24 volt 120 volt 18.9 Ω 1 Ω 24 volt 120/12 volt 120 volt 154.1 Ω 1 Ω 12 volt 24/24 volt 24 volt 2.7 Ω 3.4 Ω 24 volt contactor resistance contactor coil 3 pole 24 volt coil 6 Ω 2 pole 24 volt coil (p & b) (pp & pt...

Page 56: Technical Data Cont’D

56 technical data cont’d gas valve gas valve coil 24 volt input pv 28 Ω mv 28 Ω specifactions btu’s w/c model ng lp gas connection electrical conn. (single pahce) weight ng lp gcco 55,000 55,000 one 1/2” npt one 120 vac, 7.1a 500 lbs 5” 10” 2gcco 110,000 110,000 two 1/2” npt two 120 vac, 7.1a 1000 l...

Page 57: Technical Data Cont’D

57 technical data cont’d probe resistance temp resistance volt drop temp resistance volt drop 70 ° 556 Ω 1.11 290 ° 881 Ω 1.76 80 ° 569 Ω 1.14 300 ° 897 Ω 1.79 90 ° 583 Ω 1.17 310 ° 914 Ω 1.83 100 ° 596 Ω 1.19 320 ° 931 Ω 1.86 110 ° 610 Ω 1.22 330 ° 948 Ω 1.90 120 ° 623 Ω 1.25 340 ° 965 Ω 1.93 130 °...

Page 58: Technical Data Cont’D

58 technical data cont’d gcco-c model strapping the front control panel of the lang “purple” computer must be configured to match the model of oven it is being installed in. To configure the front control panel, you must change the arrangement of the strapping bars located at the bottom of the circu...

Page 59: Technical Data Cont’D

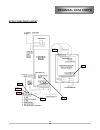

59 technical data cont’d gcco-c test point layout tp 2 tp 1 tp 3 tp 4 tp5 tp6 tp7.

Page 60: Technical Data Cont’D

60 technical data cont’d gcco-pp / -pt test point layout power yellow yellow yellow yellow yellow yellow gr e e n gr e e n gr e e n gr e e n gr e e n power or a n ge motor high red motor low bl u e steam gr e e n ecco / gcco lights gr e e n yellow yellow / red yellow brown brown purple plus power sw...

Page 61

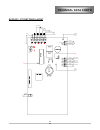

61 wireing diagram gcco-t.

Page 62

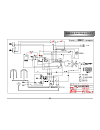

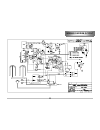

62 wiring diagram gcco-ap.

Page 63

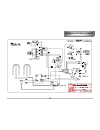

63 wiring diagram gcco-sii.

Page 64

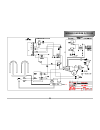

64 wiring diagram gcco-c.

Page 65

65 wiring diagram gcco-pp.

Page 66

66 wiring diagram gcco-pt.

Page 67: Parts List Gcco-T

67 parts list gcco-t description part no. Motor 1/3 hp 115/230 volt with momentary switch (before a-90068) 30200-15 motor 1/3 hp 115 volt 2 speed (after c-90069) 30200-35 micro switch, oven door 30301-02 switch, toggle, on-on 30303-06 switch, toggle, spring return 30303-16 thermostat safety 490 °f o...

Page 68: Parts List Gcco-Ap

68 parts list gcco-ap description part no. Motor 1/3 hp 115 volt 2 speed 30200-35 micro switch, oven door 30301-02 switch, toggle, on-on 30303-06 switch, toggle, spring return 30303-16 switch temperature control 12 position 140-450 °f 30304-16 thermostat safety 490 °f open 30401-09 terminal strip 3 ...

Page 69: Parts List Gcco-Sii

69 parts list gcco-sii description part no. Motor 1/3 hp 115/230 volt with momentary switch 30200-15 motor 1/3 hp 115 volt 2 speed 30200-35 micro switch, oven door 30301-02 switch, toggle, on-on 30303-06 switch, toggle, spring return 30303-16 thermostat safety 490 °f open 30401-09 terminal strip 3 p...

Page 70: Parts List Gcco-C

70 parts list gcco-c description part no. Motor 1/3 hp 115/230 volt with momentary switch (before x-90068) 30200-15 motor 1/3 hp 115 volt 2 speed (after v-90069) 30200-35 switch micro convection oven door 30301-02 switch toggle on-off 30303-06 switch toggle spring return 30303-16 thermostat safety 4...

Page 71: Parts List Gcco-Pp

71 parts list gcco-pp description part no. Motor 1/3 hp 115 volt 2 speed 30200-35 switch micro convection oven door 30301-02 switch toggle on-off 30303-06 switch toggle spring return 30303-16 thermostat safety 490 °f open 30401-09 thermostat 450 °f oven 30402-27 terminal block 24 position quick disc...

Page 72: Parts List Gcco-Pt

72 parts list gcco-pt description part no. Motor 1/3 hp 115 volt 2 speed 30200-35 switch micro convection oven door 30301-02 switch toggle on-off 30303-06 switch toggle spring return 30303-16 thermostat safety 490 °f open 30401-09 thermostat 450 °f oven 30402-27 terminal block 24 position quick disc...

Page 73

73 this page intentionally left blank.