Star manufacturing international 10 sunnen drive st. Louis, mo.63143-3800 part number: 2m-w740 ph: 314-781-2777 fax: 314-781-2714 rev a www.Star-mfg.Com november 5, 2009 installation, operation, maintenance and service instructions model: gcof-pp-nat.

This manual must be retained for future reference. Read, understand and follow the instructions and warnings contained in this manual. Danger potentially hazardous situation, which, if not avoided, could result in death. Warning potentially hazardous situation, which, if not avoided, could result in...

Ul file# mh19366 3 table of contents chapter page table of contents ............................................................................3 read first.........................................................................................4 equipment description ..................................

Ul file# mh19366 4 caution the oven weighs 500 lbs. For safe handling, installer should obtain help as needed, or employ appropriate materials handling equipment (such as a forklift, dolly, or pallet jack) to remove the unit from the skid and move it to the place of installation. Caution any stand, ...

Ul file# mh19366 5 caution keep floor in front of equipment clean and dry. If spills occur, clean immediately, to avoid the danger of slips or falls. Warning keep water and solutions out of controls. Never spray or hose control console. Caution most cleaners are harmful to the skin, eyes, mucous mem...

Ul file# mh19366 6 equipment description lang model: gcof-ppnatfd exterior construction the oven exterior dimensions are 40” (100 cm) wide, 32” (80 cm) high, 38” (95 cm) deep. The top, front, back, and sides are constructed of stainless steel with an aluminized bottom. The oven doors come standard w...

Ul file# mh19366 7 unpacking receiving the oven upon receipt, check for freight damage, both visible and concealed. Visible damage should be noted on the freight bill at the time of delivery and signed by the carrier's agent. Concealed loss or damage means loss or damage, which does not become appar...

Ul file# mh19366 8 installation warning installation of the unit must be done by personnel qualified to work with plumbing. Improper installation can cause injury to personnel and/or damage to equipment. Unit must be installed in accordance with all applicable codes. Notice the data plate is located...

Ul file# mh19366 9 installation cont’d leg pad adapter identify the front and rear leg adapters (the front adapters have two threaded inserts, the rear has four). Leg to adapter installation: install the leg’s threaded stud through the hole in the adapter labeled “c” with the bent flange of the adap...

Ul file# mh19366 10 installation cont’d ventilation and clearances standard minimum clearance from combustible construction is as follows. 4” from side 4” from back 6” from floor these ovens may be set directly, without legs, on a curbed base or non- combustible floor. If the oven is set without leg...

Ul file# mh19366 11 installation cont’d warning convection ovens installed with casters must have the following: a connector that complies with the standard for connectors for movable gas appliances ansi z21.69 latest edition, a quick disconnect that complies with the standard for quick disconnect d...

Ul file# mh19366 12 installation cont’d gas conversions 1. Disconnect oven from power and gas. 2. Remove bottom trim piece from oven (2 hex head bolts and 1 phillips screw). 3. Remove side panel from oven. 4. Disconnect black manifold pipe from 3/8” aluminum pipe at the furrel nut. 5. Remove two phi...

Ul file# mh19366 13 initial start up warning before lighting, use a soap and water solution to test all joints for gas leaks. Pre-power on after the oven is installed and connected to power & gas, prior to turning on, verify the following: the doors open and close freely. All racks are in the oven c...

Ul file# mh19366 14 operation control panel power switch. Light switch. Inspection light only. Push toggle switch to the up position to inspect product. Switch will automatically return to the off position. Alphanumeric display. Shelf select button. Press to select shelf which product will be placed...

Ul file# mh19366 15 operation cont’d typical operation sequence action result turn power switch to on. Control panel comes on, display says “select product or read/clear to program. Press a product button. Display says “product x preheating to xxx f”. Motor starts and oven begins preheating to the p...

Ul file# mh19366 16 operation cont’d hints & suggestions convection ovens constantly circulate air over and around the product. This strips away the thin layer of moisture and cool air from around the product allowing heat to penetrate more quickly. Cooking times can be shortened and cooking tempera...

Ul file# mh19366 17 operation cont’d loading when loading and unloading the oven, stage products and racks so the oven doors are opened for the least amount of time. Be sure that racks are level within the oven. Bent or warped pans can greatly affect the evenness of the cook or bake. If using baker’...

Ul file# mh19366 18 maintenance & cleaning warning keep water and solutions out of controls. Never spray or hose control console. Caution most cleaners are harmful to the skin, eyes, mucous membranes and clothing. Precautions should be taken to wear rubber gloves, goggles or face shield and protecti...

Ul file# mh19366 19 troubleshooting symptoms what follows is a chart of symptoms and possible causes to aid in diagnosing faults with the oven. Refer to the symptoms column to locate the type of failure then to the possible cause for the items to be checked. To test for a possible causes refer to th...

Ul file# mh19366 20 troubleshooting cont’d notice service on this or any other lang appliance must be performed by qualified personnel only. Consult your lang authorized service agent directory. You can call our toll free number 1-800-807-9054 or visit our website www.Star-mfg.Com for the service ag...

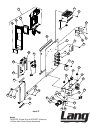

32 3 6 25 24 27 31 30 29 28 23 22 26 21 19 see detail a see detail b see detail c sk2348 rev . A 1/31/11 model: 1 2 4 5 8 7 9 10 11 14 15 16 17 13 12 20 18 34 33 gcod/f-pp & gcod/f-pt gas covection oven.

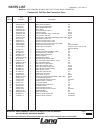

Model no: gcof-ppnatfd, gcod-pt-nat, gcof-pt-nat, gcof-ptnatmf/co commercial full size gas convection oven parts list september 1, 2011 rev a important: when ordering, specify voltage or type gas desired page include model and serial number of some items are included for illustrative purposes only a...

Detail a pilot burner assembly detail b cooling fan kit assy manifold assembly sk2310 rev. C 12/1/10 model: gcod/f-nat & gcod/f-lp detail a: gas covection oven pilot & manifold assy detail b: gcco cooling fan kit assy 1 2 5 6 7 available in assembly only 14 16 15 13 12 8 9 2 10 11 4 3 17 18 19 20 21...

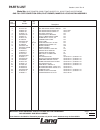

Model no: gcof-ppnatfd, gcod-pt-nat, gcod-pt-lp1, gcof-pt-nat, gcof-ptnatmf gas full size convection oven, pilot burner, manifold & cooling fan assembly parts list october 4, 2011 rev a important: when ordering, specify voltage or type gas desired page include model and serial number of some items a...

1 2 3 5 6 7 10 2 11 2 9 4 19 21 23 3 22 20 4 13 14 16 17 2 18 16 15 12 26 24 25 24 29 30 29 31 32 35 34 33 26 27 28 27 28 8 2 4 sk2346 rev. - 2/1/08 model: gccoppp (purple plus) & gccoppt (platinum) full size gas control panels assemblies detail c.

Model no: gcof-ppnatfd, gcod-pt-nat, gcof-pt-nat/lp, gcof-ptnatmf/co commercial full size gas convection oven control panel assy parts list september 1, 2011 rev a important: when ordering, specify voltage or type gas desired page include model and serial number of some items are included for illust...

Ul file# m h 1 9366 22 wiring diagram 120-v olt.

Ul file# m h 1 9366 23 wiring diagram 220/240-volt.