- DL manuals

- Larius

- Water Pump

- NOVA 45:1

- Operating And Maintenance Instructions Manual

Larius NOVA 45:1 Operating And Maintenance Instructions Manual

Summary of NOVA 45:1

Page 1

Opera ting and maintenance instr uctions opera ting and maintenance instr uctions english p a i n t s p r a y i n g e q u i p m e n t ii 2 g c iib t6 airless pneumatic pump ed. 007 11 - 11.

Page 2

Due to a constant product improvement programme, the factory reserves the right to modify technical details mentioned in this manual without prior notice. This manual is to be considered as an english language translation of the original manual in italian. The manufacturer shall bear no responsibili...

Page 3

1 nova 45:1/60:1 english s description for explosive areas ........P.9 disassembly of the pneumatic motor .P.12 disassembly of the pumping group .....P.17 exploded view for stainless steel pumping group .............................................P.20 exploded view for motor group .........P.22 exp...

Page 4: Working Principle

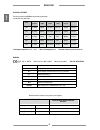

2 nova 45:1/60:1 english a b nova 45:1 3-7 bar (40-90 psi) 270 bar (3900 psi) 3/4" gas (m) 14 l/min (3,7 gpm) 4 60 1" conical gas (f) 57 kg 1110 mm pump feed air pressure maximum pressure of the product feed air inlet maximum delivery cycles per litre maximum cycles per minute material outlet weight...

Page 5

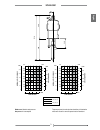

3 nova 45:1/60:1 english 1110 580 530 87 240 0 5 10 15 20 0 5 10 15 20 0 1 2 3 4 5 0 1 2 3 4 5 0 50 100 150 200 250 0 60 120 180 240 300 bar bar 500 1000 1500 2000 2500 3000 3500 4000 600 1200 1800 2400 3000 3600 4200 4800 0 800 1600 2400 3200 4000 0 20 40 60 80 100 120 140 160 0 600 1200 1800 2400 ...

Page 6

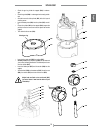

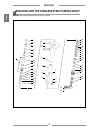

4 nova 45:1/60:1 english c description of the equipment pos. 1 2 3 pos. 4 5 6 pump feed air inlet pneumatic motor material outlet description fluid inlet fluid pumping group eyebolt for pump transport description anti-freeze system 1 3 2 6 4 5.

Page 7: Transport and

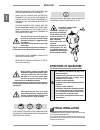

5 nova 45:1/60:1 english d e transport and unpacking • the packed parts should be handled as indicated in the symbols and markings on the outside of the packing. • before installing the equipment, ensure that the area to be used is large enough for such purposes, is properly lit and has a clean, smo...

Page 8: Typical Installation

6 nova 45:1/60:1 english connection between pump, flexible hose and spray gun before using the equipment. • always use the flexible hose supplied with standard kit. The use of any accessories or tooling other than those recommended in this manual, may cause damage or injure the operator. • the fluid...

Page 9: Setting-Up

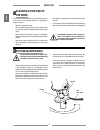

7 nova 45:1/60:1 english Ø266 Ø11 Ø240 45ϒ 45ϒ h1 h2 • make the compressed air flow into the pump. It is advisable to adjust air pressure to minimum necessary for its continuous working. • when the product chamber is full, pump will start working and stopping. Pump will start working again any time ...

Page 10: Cleaning At The End of

8 nova 45:1/60:1 english i cleaning at the end of the work by "cleaning at the end of the work" is meant the cleaning to carry out in case of use with a different product or if a long period of storage is foreseen. • stop the air supply to the pump. • dip the material pumping hose into the washing s...

Page 11: Problems and Solutions

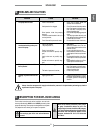

9 nova 45:1/60:1 english m problems and solutions solution cause problem • the pump does not start • accelerated working and no pres- sure of the pump • the pump works, but not sufficient flow of product • leakage of product from the wet cup • feed air not sufficient; • outlet product line clogged; ...

Page 12

10 nova 45:1/60:1 english technical features the main characteristics of nova series pneumatic piston pumps are indicated in the table below: marking ratio input pressure Ø air intake Ø material intake Ø material outlet Ø max working pressure max capacity 20:1 45:1 55:1 60:1 68:1 3 ÷ 6 bar 3 ÷ 6 bar...

Page 13

11 nova 45:1/60:1 english safety instructioins for onstallations in haz- ardous areas • the m.T. Cable of the above mentioned pumps must be grounded by means of an appropriate anti-loosening con- nection element. • the pipes used to connect suction and delivery must be metallic, or plastic with meta...

Page 14

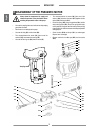

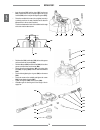

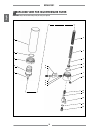

12 nova 45:1/60:1 english o disassembly of the pneumatic motor always close the compressed air supply and release the pressure in the plant before disas- sembling the pneumatic motor of the pump. • unscrew the coupling sleeve so as to disconnect the pumping group from the motor. • disconnect the air...

Page 15

13 nova 45:1/60:1 english • pull upwards the seat ( n17) so as to take out the valves ( n18) and the springs ( n19) (clean and/or replace the worn parts). • unscrew the lock nut ( n20) [take care of the washer ( n21)] by keeping the bush ( n22) blocked using a key. • extract the seat ( n17) from the...

Page 16

14 nova 45:1/60:1 english • turn counterclockwise the trip rod bearing ( n30) [take care of the washer ( n31)] and check the seal inside the screw ( n30) is undamaged. • take out the screws ( n32) [take care of the washers ( n33)] and remove carefully the cylinder ( n34) (do not bend it during extra...

Page 17

15 nova 45:1/60:1 english 1 mm • check the gas ring inside the support ( n39) is undama- ged. • check the gasket ( n40) is undamaged and correctly positio- ned. • coat the inner walls of the cylinder ( n41) with a thin layer of vaseline grease. • insert the motor piston ( n42) into the cylinder ( n4...

Page 18

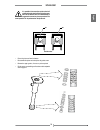

16 nova 45:1/60:1 english 46 mm 0,8 mm 0,8 mm • insert the springs ( n54) and the valves ( n55) into the seat ( n53). Position the seat on the pump support and lay the manifold ( n56) on the seat [do not forget the gasket ( n57)]. • fasten the manifold with screws (do not tighten) ensuring it is per...

Page 19

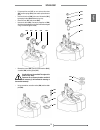

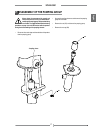

17 nova 45:1/60:1 english p disassembly of the pumping group always close the compressed air supply and release the pressure in the plant before disas- sembling the pumping group. If the product being used is toxic, it is suggested to follow the cleaning procedure on page 8 to avoid the contact with...

Page 20

18 nova 45:1/60:1 english • unscrew the suction valve. Clean and/or replace its parts, if necessary. • remove the split pin ( o3), loosen the nut ( o4) and unscrew the tie rod from the piston rod. • unscrew the packing nut ( o5). O4 o3 o5 tie rod.

Page 21

19 nova 45:1/60:1 english it is possible to increase the suction valve ball stroke placing the stop ball pin (o6) on the upper holes of the suction valve. This modification is suggested in case of very viscous products. The same operation can be performed on the piston rod. • extract the piston rod ...

Page 22

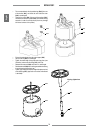

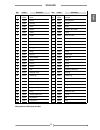

20 nova 45:1/60:1 english q exploded view for stainless steel pumping group warning: always indicate code and quantity for each part required. 1 2 3 4 5 6 8 9a 10 7 7a 7b 7c 9 9 11 12 13 14 16 19 2 17 18 20 9 8 22 24 26 28 15 29 10 9a 21 23 25 27 30 9a 9 9 9a 9.

Page 23

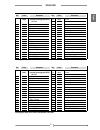

21 nova 45:1/60:1 english pos. Pos. Complete pumping group for nova 45:1 inox bush split pin sleeve o-ring tie rod nut cup complete with packing cup o-ring packing nut female ring teflon "v" gasket polyethilene gasket male ring pumping group housing filter fitting gasket sleeve bush piston rod stop ...

Page 24

22 nova 45:1/60:1 english r exploded view for motor group warning: always indicate code and quantity for each part required. 4 35 13 1 40 41 42 43 44 45 46a 46b 47 48 49 52 53 46 2 3 34 34 36 37 29 30 5 6 50 7 12 11 9 8 10 14 28 27 38 25 24 15 26 17 16 23 24 26 27 33 32 18 15 14 21 25 28 19 20 22 31...

Page 25

23 nova 45:1/60:1 english pos. Pos. Screw washer covering screw washer eyebolt support roller pin roller piston spring guide spring ring nut shock absorber washer lock nut washer bush rod guide screw leather ring seal copper washer valve housing spring o-ring travese reverse valve manifold plate pla...

Page 26

24 nova 45:1/60:1 english s exploded view for carbon steel pumping group warning: always indicate code and quantity for each part required. 1 2 3 4 5 6 8 10 7 7a 7b 7c 15 9 11 12 13 14 16 19 2 17 18 20 9 8 22 24 26 28 30 31 9 9 21 23 25 27 29 10 9 9 9 15 9.

Page 27

25 nova 45:1/60:1 english pos. Pos. Complete pumping group for nova 45:1 bush split pin sleeve o-ring tie rod nut cup complete with packing nut cup o-ring packing nut female ring leather "v" gasket male ring pumping group housing filter fitting gasket sleeve teflon "v" gasket piston rod stop ball pi...

Page 28

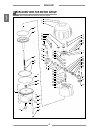

26 nova 45:1/60:1 english t exploded view for high pressure filter warning: always indicate code and quantity for each part required. 6 5 4 2 15 13 16 12 16 16 16 14 3 1 17 12 15 11 8 9 10 7.

Page 29

27 nova 45:1/60:1 english version inox nova 45:1/60:1 pos. Pos. Complete line filter filter base o-ring sieve fitting dowel sieve support filter sieve 30 mesh filter sieve 60 mesh filter sieve 100 mesh filter sieve 200 mesh screw intermediate fitting ring nut o-ring filter container fitting 3/8" - 3...

Page 30: Complete Handtruck

28 nova 45:1/60:1 english u complete handtruck pos. Complete handtruck wheels 95150 95154 code description 1 2 1 2.

Page 31: Air Group Complete

29 nova 45:1/60:1 english v air group complete pos. Pos. Air group complete elbow male female 1" -mf92 adapter 3/4 (nge 3/4) rapid coupling c/for rubber hose skg 25 rapid coupling 1"male female fitting (fb 3/4x19) hose tor/20nl 71n 19x29 reduction 1" -3/4" male female rapid coupling 8x17 rapid coupl...

Page 32: Accessories

30 nova 45:1/60:1 english z accessories code 11250: at 250 1/4" code 11200: at 250 m16x1,5 code 11000: at 300 1/4" code 11090: at 300 m16x1,5 piston gunstock filters code 11039: green (30m) - code 11038: white (60m) code 11037: yellow (100m) - code 11019: red (200m) code 11180: l91x 1/4" code 11120:...

Page 33

31 nova 45:1/60:1 english code 300: fast-clean base ue 11/16x16 fast-clean fast-clean tip nozzles code 07-20 07-40 09-20 09-40 11-20 11-40 13-20 13-40 13-60 15-20 15-40 15-60 17-20 17-40 17-60 19-20 19-40 19-60 21-20 21-40 21-60 23-20 23-40 23-60 25-20 25-40 25-60 27-20 27-40 27-60 27-80 29-20 29-40...

Page 34

32 nova 45:1/60:1 english code 95200: line filter code 98300: line filter inox high pressure hose 3/8" - m16x1,5 code 18063: 7,5 mt code 18064: 10 mt code 18065: 15 mt code 95055: suction system code 98055: suction system inox antistatic hose 3/16" - m16x1,5 code 6164: 5 mt code 55050: 7,5 mt code 3...

Page 35: L’Innovazione.

Paint spraying equipment l’innovazione. Quella vera..

Page 36

Airless pneumatic pumps 23801 calolziocorte - lecco - italy - via stoppani, 21 tel. (39) 0341/62.11.52 - fax (39) 0341/62.12.43 e-mail: larius@larius.Com - internet http://www.Larius.Com manufacturer: direct line tel. (39) 0341/621256 fax (39) 0341/621234 customers technical service vega airless art...