- DL manuals

- Lastec

- Lawn Mower

- Articulator 325D

- Owner's Manual

Lastec Articulator 325D Owner's Manual

Summary of Articulator 325D

Page 1

Lastec articulator model 325d/425d owner's manual manual part number : man-325d lastec a division of wood-mizer products, inc. 7865 n county rd 100e lizton, indiana 46149 phone (317) 892-4444 fax (317) 892-4188 www.Lastec.Com.

Page 3

Table of contents page table of contents 325d/425d/odoc082800 iii section 1 to the owner 1-1 1.1 read this manual in its entirety before operating the articulator ......... 1-1 1.2 product registration..................................................................................... 1-1 1.3 laste...

Page 4

Table of contents section-page iv 325d/425d/odoc082800 table of contents section 3 initial set-up 3-1 3.1 assembly ...................................................................................................... 3-1 3.2 parking brake................................................................

Page 5

Table of contents section-page v 325d/425d/odoc082800 table of contents section 5 maintenance 5-1 5.1 every 8 operating hours.............................................................................. 5-1 5.2 first 25 operating hours ..................................................................

Page 6

To the owner read this manual in its entirety before operating the articulator to the owner 325d/425d/odoc082200 1-1 1 section 1 to the owner 1.1 read this manual in its entirety before operating the articulator do not allow anyone to operate the articulator without first reading and understanding t...

Page 7

To the owner lastec product warranty 1 1-2 lastec warranty/odoc100600 to the owner 1.3 lastec product warranty lastec, a division of wood-mizer products, inc. Warrants its new products to be free of defects in material or workmanship. This warranty is applicable only for the normal ser- vice life ex...

Page 8

To the owner component manufacturers’ warranties 1 1-4 325d/425d/odoc082200 to the owner 1.4 component manufacturers’ warranties some of the component parts of the model 325d/425d articulator are warranted by their respective manufacturers. These parts include: l kubota diesel engine l warner electr...

Page 9: Customer Profile Information

Company name company contact mailing address shipping address phone fax authorized company representative signature: detatch here detatch here detach here serial number: please check the box that most accurately describes your business: please check the box to your left if you would not allow lastec...

Page 10

Go to www.Lastec.Com for latest changes in this manual..

Page 11

Safety information warning symbols safety information 325d/425d/odoc082200 2-1 2 section 2 safety information 2.1 warning symbols following is a legend describing the warning symbols utilized throughout this manual, and the potential types of hazards which they indicate: the above illustrated symbol...

Page 12

Safety information safety guards and covers 2 2-2 325d/425d/odoc082200 safety information although these instructions have been compiled through extensive field experience and engineering data, some information presented herein may be general in nature due to unknown and/or varying operating conditi...

Page 13

Safety information preparational safety rules safety information 325d/425d/odoc082200 2-3 2 2.4 preparational safety rules l never operate the articulator when children are present. L always wear relatively tight and belted clothing to avoid entanglement in moving parts. Wear sturdy rough-soled work...

Page 14

Safety information operational safety rules 2 2-4 325d/425d/odoc082200 safety information 2.5 operational safety rules l never operate the articulator when children are present. L be sure that the parking brake is set before attempting to start the engine. L operate only in daylight or good artifici...

Page 15

Safety information maintenance safety rules safety information 325d/425d/odoc082200 2-5 2 slowly over rough ground. L disengage the blades, stop the engine, set the parking brake, and remove the key before dismounting the articulator or making any adjustments. L stop the articulator immediately upon...

Page 16

Safety information storage safety rules safety information 325d/425d/odoc082200 2-6 2 l keep the articulator engine area free of accumulated debris, fuel, or excess grease and oil to reduce fire hazard. L keep the articulator in good operating condition with all safety devices in place. L check the ...

Page 17

Initial set-up assembly initial set-up 325d/425d/odoc082200 3-1 3 section 3 initial set-up 3.1 assembly the model 425d articulator requires a minimum amount of assembly before operation. Follow the steps below to assemble the articulator: (you may find it easier to assemble the articulator while it ...

Page 18

Initial set-up parking brake 3 3-2 325d/425d/odoc082200 initial set-up 11. The deck lift cables are factory calibrated. The adjustment nuts on the deck 1 cable are locked into position during shipping, eliminating the need for adjustment after re-assem- bly. Simply install the cable into the mount p...

Page 19

Initial set-up fuel initial set-up 325d/425d/odoc082200 3-3 3 3.3 fuel the model 325d/425d articulator is equipped with an 8-gallon fuel tank, which is located behind the left fender. The articulator is shipped dry (no fuel) from the factory, so you will need to fuel the articulator before operating...

Page 20

Initial set-up fuel shut-off valve 3 3-4 325d/425d/odoc082200 initial set-up the left and right rear of the operator seat. Pull the release lever (located in the seat pan just below the lift handle) toward the lift handle. Lift the operator seat pan all the way for- ward, to its maximum position, un...

Page 21

Initial set-up air cleaner initial set-up 325d/425d/odoc082200 3-5 3 engine operator’s manual located at the back of this manual for the proper procedures. When operating in temperatures ranging from 32° - 77°f (0° - 25°c), engine oil should be mil-l-2104c or have properties of api classification cd...

Page 22

Initial set-up hydraulic fluid 3 3-6 325d/425d/odoc082200 initial set-up reserve tank is translucent, enabling easy viewing of the coolant level. The coolant level should fall between the “full” and “low” markings on the reserve tank. If the coolant level is low, add coolant prior to operation. If t...

Page 23

Initial set-up hydraulic pump adjustment initial set-up 325d/425d/odoc082200 3-7 3 3.10 hydraulic pump adjustment occasionally, you may need to adjust the hydraulic pumps to keep the drive wheels from creeping. Follow these procedures to adjust the pumps: 1. Lift the rear of the drive unit until the...

Page 24

Initial set-up gearbox 3 3-8 325d/425d/odoc082200 initial set-up orient roughly square to the frame. If, in order to adequately tension the belt, the pump pivots excessively past square, or comes into contact with any peripheral apparatus, you need to replace the belt. If the belt you are checking i...

Page 25

Initial set-up mower deck drive belt initial set-up 325d/425d/odoc082200 3-9 3 check both belts for visible wear or damage. If either belt appears excessively worn, damaged, cracked, weathered, or otherwise appears to pose an unsuitable or unsafe operating condition, replace it. The mower deck belt ...

Page 26

Initial set-up mower deck belts 3 3-10 325d/425d/odoc082200 initial set-up if you are unable to install a new belt with the idler system at its minimum stroke, it is likely you are installing the wrong size belt. Contact your lastec dealer for proper belt lengths for your articulator. Be sure that t...

Page 27

Initial set-up weight transfer springs initial set-up 325d/425d/odoc082200 3-11 3 be sure to replace all belt covers and hardware. 3.16 weight transfer springs it is important that the weight transfer system operating properly. The weight transfer springs help to lighten the mower deck by transferri...

Page 28

Initial set-up blades 3 3-12 325d/425d/odoc082200 initial set-up when replacing the jack stand, remember to tension the foot against the base of the con- trol panel in order to prevent excessive movement, wear, and noise. 3.18 blades the model 325d/425d articulator utilizes three/four individual 25”...

Page 29

Initial set-up steering control arms initial set-up 325d/425d/odoc082200 3-13 3 adjust the seat forward or back so that the operator can easily reach the control panel, steering control arms, and mower deck height adjustment pedal. 3.20 steering control arms check that both steering control arms are...

Page 30

Initial set-up mower deck height cable calibration 3 3-14 325d/425d/odoc082200 initial set-up by 1/4”, up to 4 1/2". The spacers which mark the 2", 3", and 4" deck height positions are knurled for quick identification. To adjust the deck height, push the deck height foot pedal (located to the outsid...

Page 31

Initial set-up tires & wheels initial set-up 325d/425d/odoc082200 3-15 3 adjusted, tighten both rear nuts to lock them into place. 8. To adjust the cable on the foot pedal, use the same procedure as the rocker. When standing in front of the foot pedal, turning the rear cable nuts counter-clockwise w...

Page 32

Initial set-up battery 3 3-16 325d/425d/odoc082200 initial set-up 3.26 battery the articulator utilizes a 12-volt battery. Ratings: ca@32°f=680; cca@0°f=540. The battery is located inside the covered utility box behind the right rear fender. To access, release the rubber latch on the back of the uti...

Page 33

Initial set-up engine initial set-up 325d/425d/odoc082200 3-17 3 tor should be called immediately when the accident occurs and "on-the-spot" medical attention given if possible. If a doctor cannot come to the scene of the accident immedi- ately, follow his instructions concerning actions to take. Do...

Page 34

Initial set-up hour meter 3 3-18 325d/425d/odoc082200 initial set-up into position. The arm should stay locked in this position even after discontinuing the pressure on the foot pedal. Once you have determined that the hydraulic deck lift arm is both lifting and locking the mower deck properly, slow...

Page 35

Initial set-up pre-operation equipment inspection checklist initial set-up 325d/425d/odoc082200 3-19 3 3.31 pre-operation equipment inspection checklist perform the following equipment inspection prior to each operation of the articulator. Q verify that the parking brake is set. Q check the fuel lev...

Page 36

Operating procedures starting the engine operating procedures 325d/425d/odoc082200 4-1 4 section 4 operating procedures 4.1 starting the engine upon completion of reading and understanding this manual in its entirety, reviewing all safety rules, completing the pre-operation inspection checklist, and...

Page 37

Operating procedures stopping the engine 4 4-2 325d/425d/odoc082200 operating procedures 17. If the engine does not start within 10 seconds, discontinue cranking by turning the key switch counter-clockwise to the off position. Repeat steps 1 through 3. If, after several attempts, the engine will sti...

Page 38

Operating procedures ground speed operating procedures 325d/425d/odoc082200 4-3 4 the upper right corner of the control panel) and the audible parking brake alarm are deac- tivated before attempting any travel with the articulator. In order to maneuver the articulator, you must first remove both ste...

Page 39

Operating procedures mower deck lift 4 4-4 325d/425d/odoc082200 operating procedures 4.5 mower deck lift before traveling to the cut site, lift the mower deck into transport position. To lift the mower deck into transport position, the engine must be running in order to activate the hydraulics. Be s...

Page 40

Operating procedures mower deck operation operating procedures 325d/425d/odoc082200 4-5 4 tension system takes up excess belt length or releases additional belt length as neces- sary during the up and down articulation of the decks. This allows the articulator to hold the contour of the ground with ...

Page 41: Section 5 Maintenance

Maintenance every 8 operating hours maintenance 325d/425d/odoc082200 5-1 5 section 5 maintenance along with completing the pre-operation equipment inspection checklist each time you operate the articulator, complete the following maintenance checklists at the indi- cated time intervals. 5.1 every 8 ...

Page 42

Maintenance first 25 operating hours 5 5-2 325d/425d/odoc082200 maintenance 5.2 first 25 operating hours l complete the 8 hour maintenance checklist. L change the hyrdraulic oil & filter. 5.3 first 50 operating hours l complete the 8 hour maintenance checklist. L change engine oil and filter. 1 5.4 ...

Page 43

Maintenance every 500 hours maintenance 325d/425d/odoc082200 5-3 5 5.8 every 500 hours l complete the 8, 50, 100, 200 & 400 hour maintenance checklists. L replace all bronze bushings. L inspect and re-pack all wheel bearings. L flush fuel tank. 1 l flush radiator. 1 l replace engine fan and alternat...

Page 44

Maintenance model 325d/425d articulator specifications maintenance 325d/425d/odoc082200 5-5 5 5.12 model 325d/425d articulator specifications mower deck deck configuration (325d / 425d) (3 / 4) articulating 25” mower decks, width (325d / 425d) 72” / 96” blades (325d / 425d) (3 / 4) 25” high-lift bla...

Page 45

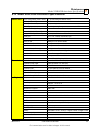

Maintenance doc082200 5-7 maintenance model 325d/425d articulator maintenance chart 5 5.13 model 325d/425d articulator maintenance chart e ver y 8 h our s fi rst 25 h ours fi rst 50 h ours e ver y 50 h our s e ver y 100 h our s e ver y 200 h our s e ver y 400 h our s e ver y 500 h our s e ver y 800 ...

Page 46

Maintenance 325d/425d electrical schematic maintenance 325d/425d/odoc082800 5-9 5 5.14 325d/425d electrical schematic battery 12vdc 50 30 starter fuel solenoid b ig l alternator pull 30 50 17 19 ac cb1 40a resettable str fuel alt glow plugs key switch sw1 19 30 ac 17 50 0 1 2 3 preheat off on start ...

Page 47: 425D Hydraulic Schematic

Maintenance 425d hydraulic system diagram maintenance 325d/425d/odoc082800 5-11 5 5.15 425d hydraulic system diagram 425d hydraulic schematic right motor left motor tank filter right pump dotted lines represent high-pressure lines left pump low-pressure cooler h1 h3 h4 h5 h6 h7 h8 h9 h10 h11 h12 h14...

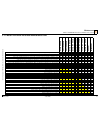

Page 48: Right

Maintenance 325d hydraulic system diagram maintenance 325d/425d/odoc082800 5-13 5 4.7 325d hydraulic system diagram 325d / 425d hydraulic schematic right motor left motor tank filter right pump dotted lines represent high-pressure lines left pump low-pressure cooler h1 h3 h4 h5 h6 h7 h8 h9 h10 h11 h...