Lattner Boiler Company Alkon 90 Installation And Servicing Manual - General Information

7

General Information

1.10 - GENERAL WARNINGS

This instruction manual is an integral and indispensable

part of the product and must be retained by the person in

charge of the appliance.

Please read carefully the instructions contained in this manual

as they provide important indications regarding the safe

installation, use and servicing of this appliance.

Keep this manual in a safe place for future reference.

The installation and servicing must be carried out in

accordance with the regulations in force according to the

manufacturer’s instructions and by legally competent

authorized persons.

The installations for the domestic hot water production

MUST be build, in their entirety, with materials (taps, pipes,

fittings, etc.) approved for drinkable water.

By a competent person, we imply a person who has a specific

technical qualification in the field of components for central

heating systems for domestic use, domestic hot water

production and servicing. The person must have the

qualifications foreseen by the current laws in force.

Bad or irregular servicing could compromise the safe

operation of the appliance, and could cause injury to persons,

animals or damage to property. The manufacturer shall not

be held liable for any such injury and/or damage.

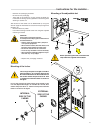

Before carrying out any cleaning or servicing turn off the

electrical supply to the boiler by means of the ON/OFF switch

and/or by means of the appropriate shutdown devices.

Do not obstruct the intake/outlet terminal ducts.

In the event of failure and/or faulty functioning of the appliance,

switch off the boiler. Do not attempt to make any repairs:

contact qualified technicians.

Any repairs must be carried out by LATTNER authorized

technicians and using only original spare parts. Non-

observance of the above requirement may jeopardize the

safety of the appliance.

To guarantee the efficiency and correct functioning of the

appliance it is indispensable to have the boiler serviced

annually by a qualified person.

If the boiler remains unused for long periods, ensure that any

dangerous parts are rendered innocuous.

Before putting again into service an appliance which has been

unused for a certain time, proceed to rinse the domestic hot

water circuit, making the water flowing for the time necessary

to draw the full content of the domestic circuit.

If the appliance is sold or transferred to another owner or if

the present user moves home and leaves the appliance

installed, ensure yourself that the manual always follows the

appliance so that it can be consulted by the new owner and/

or installer.

Only original accessories must be used for all appliances

supplied with optionals or kits (including electrical ones).

This appliance must be used only for the purposes for which

it has been expressively designed. Any other use shall be

considered incorrect and therefore dangerous.

1.9 - DISPOSAL

-

Dispose of the boiler packaging in an environmentally

sound manner.

-

Dispose of components of the heating system (e.g. boiler

or control device), that must be replaced in an environ-

mentally responsible manner.

1.8 -

TOOLS, MATERIALS AND

ADDITIONAL EQUIPMENT

For the installation and maintenance of the boiler you

will need:

-

Standard tools for space heating, gas and water fitting

-

Digital manometer that is capable of reading both positive

and negative pressures

-

Combustion analyzer

-

Digital multimeter

-

pH digital meter

-

Metric Allen wrenches

-

Metric socket wrenches

In addition, a handtruck with a fastening belt is useful.

Operating Limits of the boiler:

Max. boiler temperature: 176 °F (80 °C)

Max Allowable Working Temperature ASME: 200 °F

Max. Allowable Working Pressure ASME: 92 psi