- DL manuals

- Lauda

- Thermostat

- E 10 G

- Operating Instructions Manual

Lauda E 10 G Operating Instructions Manual

English

Version 08/2011 a1

YACE0088

LAUDA DR. R. WOBSER GMBH & CO. KG

Post office box 1251

97912 Lauda-Koenigshofen

Germany

Valid from:

Software Control System from Version 1.31.00

Software Protection System from Version 1.31

Cooling System Software 1.27

Phone: +49 9343/ 503-0

Fax: +49 9343/ 503-222

info@lauda.de

Internet

http://www.lauda.de

Operating Instructions

ECO GOLD

Heating and Cooling Thermostats with control head GOLD

Immersion thermostat

ECO GOLD

Heating thermostats

E 4 G, E 10 G, E 15 G, E 20 G, E 25 G, E 40 G,

ET 6 G, ET 12 G, ET 15 G, ET 20 G

Cooling thermostats

RE 415 G(W), RE 420 G(W), RE 620 G(W), RE 630 G(W),

RE 1225 G(W), RE 2025 G(W), RE 1050 G(W)

Summary of E 10 G

Page 1

English version 08/2011 a1 yace0088 lauda dr. R. Wobser gmbh & co. Kg post office box 1251 97912 lauda-koenigshofen germany valid from: software control system from version 1.31.00 software protection system from version 1.31 cooling system software 1.27 phone: +49 9343/ 503-0 fax: +49 9343/ 503-222...

Page 3

Eco gold 25/08/2011/ yace0088 table of contents 3 table of contents 1 safety ............................................................................................................................................................6 1.1 safety information .............................................

Page 4

Eco gold 4 table of contents 25/08/2011/ yace0088 8 maintenance ...............................................................................................................................................51 8.1 alarms, warnings and errors .............................................................

Page 5

Eco gold 25/08/2011/ yace0088 table of contents 5 e.2 creating and editing a program............................................................................................................95 e.3 starting the program ...................................................................................

Page 6: Safety

Eco gold 6 safety 25/08/2011/ yace0088 1 safety 1.1 safety information danger ! Type and source consequences of non-compliance • action 1 • action ... "danger" indicates an immediate dangerous situation which – if the safety requirements are ignored – may result in fatal or severe, irreversible inju...

Page 7

Eco gold 25/08/2011/ yace0088 safety 7 1.2 general safety read through the operating instructions carefully. They contain important information for working with this device. If you have any queries, please contact our service department (Ì 8.7). Follow all the directions in these operating instructi...

Page 8

Eco gold 8 safety 25/08/2011/ yace0088 1.3 special safety information the use of the thermostat is only admissible under the following conditions: • the siting surface must be impervious, flat, non-slip and non-combustible. Do not position the ther- mostat at the edge of the bench or table. • keep t...

Page 9: General Remarks

Eco gold 25/08/2011/ yace0088 general remarks 9 2 general remarks 2.1 description of the device this device is a laboratory thermostat. It is obtainable as: immersion thermostat (optionally with cooling coil), which is used for heating (and optionally for cooling) liquids. Heating bath and circulati...

Page 10

Eco gold 10 general remarks 25/08/2011/ yace0088 2.5 ec conformity the device conforms to the relevant fundamental requirements for safety and health of the following listed directives: lauda dr. R. Wobser gmbh & co. Kg postfach 1251 97912 lauda-königshofen germany − low voltage directive 2006/95/ec...

Page 11: Device Description

Eco gold 25/08/2011/ yace0088 device description 11 3 device description 3.1 device types heating thermostats the type designation of the lauda heating thermostats is composed of the prefix e for eco, the ap- proximate bath volume in liters and a g for the gold device variant. Example: e 10 g is a h...

Page 12

Eco gold 12 device description 25/08/2011/ yace0088 3.5 interface modules (accessories) the devices can be supplemented with further interface modules which are connected to the rear of the control head in two module slots (Ì 6.7) and are inserted. The following modules are currently available: 1. A...

Page 13

Eco gold 25/08/2011/ yace0088 operating and functional controls 13 4 operating and functional controls on the following pages the eco gold control head, the control panel and the heating/cooling thermostat device types are presented. Control head eco gold (can be used as immersion thermostat with sc...

Page 14

Eco gold 14 operating and functional controls 25/08/2011/ yace0088 control panel and display eco gold display control panel 1 expanded status display 5 soft keys, left and right 2 status display 6 enter key 3 display of the internal or external temperature value (t int or t ext ) 7 cursor keys (curs...

Page 15

Eco gold 25/08/2011/ yace0088 operating and functional controls 15 rear view of control head eco gold 1 usb interface 2 upper module receptacle approx. 51 mm x 27 mm for analogue, rs 232/485, profibus module and contact modules. 3 lower module receptacle approx. 51 mm x17 mm for pt100/libus module 4...

Page 16

Eco gold 16 operating and functional controls 25/08/2011/ yace0088 heating thermostats eco gold 1 cooling coil connections 2 pump connection: outflow and return (as standard only with e 4 g and et 15 g) 3 bath cover (as standard only with e 4 g) 4 four feet 1 rating label 2 mains connecting lead 3 b...

Page 17

Eco gold 25/08/2011/ yace0088 operating and functional controls 17 cooling thermostats eco gold 1 pump connection: outflow and return with m16 x 1 thread (stainless steel) 2 bath cover 3 front grip recess 4 ventilation grill (both sides) 5 front panel (removable without tools) 6 four feet 1 2 3 4 5 ...

Page 18

Eco gold 18 operating and functional controls 25/08/2011/ yace0088 1 rating label 2 connecting lead between the control head and cooling underpart 3 front grip recess 4 bath cover of cooling underpart (only with re 1050 g) 5 bath draining tap 6 bath drain point 7 ventilation grill 1 connections for ...

Page 19: Transport and Unpacking

Eco gold 25/08/2011/ yace0088 transport and unpacking 19 5 transport and unpacking keep your original packing of your thermostat for later transport. Danger ! Shipping damage electric shock hazard • check the device carefully for shipping damage be- fore putting into operation. • never operate the d...

Page 20

Eco gold 20 transport and unpacking 25/08/2011/ yace0088 standard accessories: catalogue num- ber quantity description included with thermostat hdq 132 1 bath cover e 4 e 4 g hdq 127 1 bath cover re 415, re 420 re 415 g and re 420 g hdq 128 1 bath cover re 620, re 630 re 620 g and re 630 g hdq 129 1...

Page 21

Eco gold 25/08/2011/ yace0088 before putting the device into operation 21 6 before putting the device into operation please note: − the device can be operated up to an ambient temperature of 40 °c. − a higher ambient temperature can have a negative effect on the cooling output of the thermostats use...

Page 22

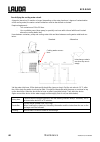

Eco gold 22 before putting the device into operation 25/08/2011/ yace0088 operation with cooling coil for the optional operation with the cooling coil (lcz 0720 and lcz 0721) mount the cooling coil as follows: cut the thread with the enclosed screw − cut the thread on the holed flange already before...

Page 23

Eco gold 25/08/2011/ yace0088 before putting the device into operation 23 assembly as immersion thermostat − place the bath vessel on a flat surface. − the control head is already screwed to the bath bridge. In the rear part of the bath there are two slots present on the bath edge. Guide the prongs ...

Page 24

Eco gold 24 before putting the device into operation 25/08/2011/ yace0088 assembly as cooling thermostat notice falling / toppling equipment property damage • do not tilt the cooling device during transport and never turn it upside down. − after transport, site the device in place where possible two...

Page 25

Eco gold 25/08/2011/ yace0088 before putting the device into operation 25 connection of the cooling water note that the following conditions apply for the connection of the cooling water supply: cooling water pressure (feed - outlet) max. 10 bar overpressure differential pressure (feed - outlet) min...

Page 26

Eco gold 26 before putting the device into operation 25/08/2011/ yace0088 6.2 connection of external consumers for heating thermostats a pump connection set is available as an accessory (Ì 9) for the connection of an external consumer. This pump connection set is included as standard with cooling th...

Page 27

Eco gold 25/08/2011/ yace0088 before putting the device into operation 27 − turn the pump output downwards for external bath circulation. − fit the hose section of the pump connection set onto the outflow elbow and place the pump connections in the position of the re- moved blind flange. − push the ...

Page 28

Eco gold 28 before putting the device into operation 25/08/2011/ yace0088 operation as circulation thermostat to ensure the greatest volume flow, with operation as a circula- tion thermostat ensure the shortest possible hose connections with the largest possible hose internal diameter. − connect a h...

Page 29

Eco gold 25/08/2011/ yace0088 before putting the device into operation 29 6.3 filling and emptying lauda accepts no liability for damage caused by the use of unsuitable heat transfer liquids (approved heat transfer liquids (Ì 6.4)). Caution ! Contact with heat transfer liquid when filling / draining...

Page 30

Eco gold 30 before putting the device into operation 25/08/2011/ yace0088 1 2 draining and changing the heat transfer liquid − switch off the thermostat and withdraw the mains plug. − allow the device and heat transfer liquid to cool down to or warm up to room temperature. − push a hose onto the bat...

Page 31

Eco gold 25/08/2011/ yace0088 before putting the device into operation 31 6.4 heat transfer liquids, cooling water and hoses note: − tap water is unsuitable for operation with the thermostat due to the calcium carbonate content. The bath vessel may calcify. − high purity water (from ion exchangers) ...

Page 32

Eco gold 32 before putting the device into operation 25/08/2011/ yace0088 a) approved heat transfer liquids lauda designation operating temperature range chemical designation viscos- ity (kin) viscosity (kin) at temperature fire point container size catalogue number °c mm²/s at 20 °c mm²/s °c 5 l 10...

Page 33

Eco gold 25/08/2011/ yace0088 before putting the device into operation 33 b) cooling water certain requirements are placed on the cooling water with regard to purity. Depending on the cooling water contamination, a suitable method of purification and/or treatment of the water must be employed. The c...

Page 34

Eco gold 34 before putting the device into operation 25/08/2011/ yace0088 risk to the environment due to oil contamination of the cooling water circuit with a leaky condenser there is the danger that refrigerating machine oil from the refrigerant circuit of the cooling thermostat can pass into the c...

Page 35

Eco gold 25/08/2011/ yace0088 before putting the device into operation 35 d) approved metal hoses in non-rusting stainless steel with union nut m16 x 1, inside diameter 10 mm type length (cm) temperature range °c application range catalogue number mc 50 50 10...400 with simple insulation for all lau...

Page 36

Eco gold 36 before putting the device into operation 25/08/2011/ yace0088 note: − the device mains plug is used as a mains disconnection component. The mains plug must be easily recognizable and easily accessible. − only connect units to sockets having a safety earth conductor (pe). No liability is ...

Page 37

Eco gold 25/08/2011/ yace0088 before putting the device into operation 37 − touch the bare earthed stainless steel back panel of the eco thermostat to discharge any electro- static charge. − remove the module from the packaging. − switch off the thermostat and withdraw the mains plug. − the plastic ...

Page 38: Operation

Eco gold 38 operation 25/08/2011/ yace0088 7 operation always follow this safety information: warning ! Control head drops into bath electric shock hazard • make sure that the control head mounting is securely joined to the bath. Warning ! Introduction of low-boiling liquid (e.G. Water into hot oil)...

Page 39

Eco gold 25/08/2011/ yace0088 operation 39 caution ! Bath overflow due to thermal expansion or immersion of objects burns, scalds, frostbite • take the volume of external consumers into account. • take into account the increase in volume with a rise in temperature. Caution ! Hot vapor formation / di...

Page 40: 1 S

Eco gold 40 operation 25/08/2011/ yace0088 7.1 switching on − switch on the device with the mains switch. An acoustic signal sounds. 1 s according to the adjacent display the software version numbers (depends on device type and options) appear for approx. 5 sec- onds. When making technical enquiries...

Page 41

Eco gold 25/08/2011/ yace0088 operation 41 7.2 menu structure with the soft keys you can select the following menu points with the gold control head: intern pt100 extern pt100 stage 6 extern analog stage 5 extern serial xp stage 4 extern usb tn stage 3 tv manual/auto stage 2 intern pt100 tv stage 1 ...

Page 42

Eco gold 42 operation 25/08/2011/ yace0088 continued from previous page menue online graph record start freeze graph 1 start setpoint value tset tint text setup tset tint programmer tset text interfaces section 8.2 tint text graph tint clock text standby tset mode displayed value sample time 2 s (ma...

Page 43

Eco gold 25/08/2011/ yace0088 operation 43 7.3 display representation the eco thermostats offer you intuitive menu guidance. In the following the possible window views and the symbols used are explained. 7.3.1 basic window the following information is displayed depending on the operating status: 3 2...

Page 44

Eco gold 44 operation 25/08/2011/ yace0088 examples of display representation: main menu in the main menu selected menu points are displayed inversely. The soft-key bar is shown in the lower region of the display. The following functions, for example, can be selected with the soft keys: esc you are ...

Page 45

Eco gold 25/08/2011/ yace0088 operation 45 7.3.3 entry window values are input using the entry window. In the entry window the following information is displayed: the first line contains the input parameter in short form (cf. Exam- ple: t set ). The parameter is located below this in plain text. Max...

Page 46

Eco gold 46 operation 25/08/2011/ yace0088 7.4 basic setup in this section the settings required for using the device as prescribed are summarized. For more exten- sive settings refer to the appendix. 7.4.1 setting the overtemperature switch-off point t max warning ! Overheating due to entering an i...

Page 47

Eco gold 25/08/2011/ yace0088 operation 47 7.4.2 setting the temperature set-point value − access to the main menu level is obtained by pressing the enter key . − select the menu point highlighted in color "set-point tem- perature" using the enter key . The entry window appears. The cursor below the...

Page 48

Eco gold 48 operation 25/08/2011/ yace0088 7.4.4 activating the "standby" operating state in the "standby" mode the pump, heater and chiller are switched off. The operating display remains active. There are two ways of selecting the "standby" mode: − 1. Activate "standby" by pressing (right soft key...

Page 49

Eco gold 25/08/2011/ yace0088 operation 49 7.4.5 defining temperature limits with this function the temperature limits til and tih are defined. If, for example, you are using water as the heat transfer liquid, +5 °c is practicable as the minimum temperature and +95 °c as the maximum temperature. − a...

Page 50: 08:32:46

Eco gold 50 operation 25/08/2011/ yace0088 7.4.6 setting the date and time. − access to the main menu level is obtained by pressing the enter key . − selection and confirmation of Æ clock Æ set time and date . The adjacent menu window appears. − the cursor flashes under the hours display. − change t...

Page 51: Maintenance

Eco gold 25/08/2011/ yace0088 maintenance 51 8 maintenance 8.1 alarms, warnings and errors alarms: alarms are relevant to safety. Pump, heating and chiller switch off. Warnings: warnings are normally not relevant to safety. The device continues to run. Errors: if a malfunction occurs, switch off the...

Page 52

Eco gold 52 maintenance 25/08/2011/ yace0088 when the bath temperature is located above the overtemperature switch-off point, a two-tone alarm sounds. "overtemperature" ap- pears in the display, the heater switches off on all poles and the pump and chiller are switched off via the electronics. − rec...

Page 53

Eco gold 25/08/2011/ yace0088 maintenance 53 before a longer unsupervised operation check the overtemperature protection: − slowly reduce t max as described in (Ì 7.4.5). The thermostat should switch off when the actual temperature is greater than t max . Alarm signaling (see above) must occur. − re...

Page 54

Eco gold 54 maintenance 25/08/2011/ yace0088 8.2 device status here, accumulated error messages as well as device and software data can be recalled. − access to the main menu level is obtained by pressing the enter key . − selection and confirmation of Æ setup Æ device status . The adjacent menu win...

Page 55

Eco gold 25/08/2011/ yace0088 maintenance 55 8.2.3 software version sw version − confirm with . Under the menu point sw version the appropriate software versions are displayed, depending on the device type and con- nected modules. 8.2.4 displaying and changing the device type type − confirm with . T...

Page 56

Eco gold 56 maintenance 25/08/2011/ yace0088 8.3 servicing follow all the safety information for cleaning and servicing the device. Caution ! Critical temperature of device parts, heat transfer liquid or accessories (hoses) burns, scalds, frostbite • bring the device parts, accessories and heat tran...

Page 57

Eco gold 25/08/2011/ yace0088 maintenance 57 8.3.2 servicing intervals to vdi 3033 device part mandatory for initial opera- tion and before any longer unsupervised operation, then with recommended frequency section remarks complete device external condition of device monthly heat transfer liquid ins...

Page 58

Eco gold 58 maintenance 25/08/2011/ yace0088 8.3.4 cleaning the condenser 8.3.4.1 air-cooled condenser the cooling circuit is largely maintenance-free. Remove dust and contamination from the condenser at regular in- tervals (depending on operating period and exposure con- ditions). − to do this, rem...

Page 59

Eco gold 25/08/2011/ yace0088 maintenance 59 8.3.4.2 water-cooled condenser to obtain the full cooling output, the sieve and water circuit should be cleaned at regular intervals. Cleaning the plug-in sieve for regular cleaning (depending on the degree of contamination of the cooling water) plug-in s...

Page 60

Eco gold 60 maintenance 25/08/2011/ yace0088 decalcifying the cooling water circuit at regular intervals of 3 months or longer (depending on the water hardness / degree of contamination of the cooling water) the water-cooled condenser must be decalcified or cleaned. Required equipment: − two contain...

Page 61

Eco gold 25/08/2011/ yace0088 maintenance 61 8.4 fault finding before you contact the lauda service constant temperature equipment (Ì 8.7), check whether you can rectify the problem yourself with the following instructions. In doing so, follow all this safety information: warning ! Live parts when f...

Page 62

Eco gold 62 maintenance 25/08/2011/ yace0088 8.5 disposal information the following applies to europe: disposal of the device may only be carried out by qualified specialists according to ec directive 303/2008/ec in con- junction with 842/2006/ec. The disposal is regulated by ec directive 2002/96/ec...

Page 63

Eco gold 25/08/2011/ yace0088 maintenance 63 8.6 taking the device out of service the device must be taken out of service by a specialist. Comply with the following safety information: caution ! Contact with hot / cold heat transfer liquid scalds, frostbite • bring the heat transfer liquid to room t...

Page 64

Eco gold 64 maintenance 25/08/2011/ yace0088 8.7 ordering replacement parts / lauda service when ordering replacement parts, please state the serial number (rating label); this helps to avoid queries and incorrect deliveries. The serial number is composed as follows, e.G. Lck1910-10-0001 lck19111 = ...

Page 65: Accessories

Eco gold 25/08/2011/ yace0088 accessories 65 9 accessories please take catalogue numbers for accessories from the following table. − immersion thermostats − heating thermostats − cooling thermostats − for all devices immersion thermostats accessories suitable for catalogue number cooling coil set (s...

Page 66

Eco gold 66 accessories 25/08/2011/ yace0088 cooling thermostats accessories suitable for catalogue number pump connection set (outflow and return nozzles) with fitting 13 mm (plastic) all cooling thermostats lcz 0716 for all devices accessories catalogue number upper module receptacle approx. 57 mm...

Page 67: Technical Data And Graphs

Eco gold 25/08/2011/ yace0088 technical data and graphs 67 10 technical data and graphs the figures were determined according to din 12876. Data applicable to all eco gold thermostats ambient temperature range °c 5 ... 40 relative humidity maximum relative humidity 80 % at 31 °c and decreasing linea...

Page 68

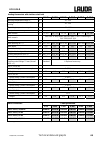

Eco gold 68 technical data and graphs 25/08/2011/ yace0088 immersion thermostats eco gold 230 v 220 v 115 v 100 v working temperature range °c 20…200 working temperature range with water cooling °c 20…200 operating temperature range °c -20…200 heater rating / power consumption kw 2.6/2.7 2.4/2.5...

Page 71

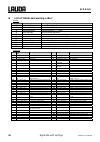

Eco gold 25/08/2011/ yace0088 technical data and graphs 71 cooling thermostats (1) re 415 g re 415 gw re 420 g re 420 gw re 620 g re 620 gw re 630 g re 630 gw working temperature - acc range* °c -15...200 -20…200 -20…200 -30…200 ambient temperature range °c 5...40 temperature accuracy k ±0.02 max. S...

Page 72

Eco gold 72 technical data and graphs 25/08/2011/ yace0088 cooling thermostats (2) re 1225 g re 1225 gw re 2025 g re 2025 gw re 1050 g re 1050 gw operating temperature, acc * °c -25…200 -25…200 -50…200 ambient temperature range °c 5...40 temperature accuracy k ±0,02 max. Storage temperature °c 43 wi...

Page 73

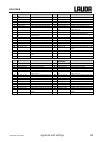

Eco gold 25/08/2011/ yace0088 technical data and graphs 73 pump characteristic eco gold 0 0,1 0,2 0,3 0,4 0,5 0,6 0 5 10 15 20 25 30 förderstrom [l/min] f ö rd erdru c k [ b ar] pumpenkennlinien gemessen mit wasser heating curve for eco gold heating thermostats with transparent bath 0 20 40 60 80 10...

Page 74

Eco gold 74 technical data and graphs 25/08/2011/ yace0088 heating curve for eco gold heating thermostats with stainless steel bath 0 50 100 150 200 00:00 00:20 00:40 01:00 01:20 aufheizzeit [h:min] badt em per atu r [° c] cooling curves for eco gold cooling thermostats abkühlkurven eco -60 -50 -40 ...

Page 75: Index

Eco gold 25/08/2011/ yace0088 75 11 index a accessories .........................................................65 acoustic signals ...................................................82 alarms......................................................51, 53, 86 ambient temperature .........................

Page 76

Eco gold 76 25/08/2011/ yace0088 programmer .........................................................93 prop_e ...............................................................100 proportional range .......................................98, 100 pump.......................................................

Page 77

Eco gold 25/08/2011/ yace0088 77.

Page 78

Eco gold 78 25/08/2011/ yace0088.

Page 79

Eco gold 25/08/2011/ yace0088 79.

Page 80: Appendix With Settings

Eco gold 80 appendix with settings 25/08/2011/ yace0088 appendix with settings.

Page 81: Other Settings

Eco gold 25/08/2011/ yace0088 appendix with settings 81 the adjustments described in this appendix are only intended for specially qualified personnel. A other settings a.1 resetting to factory settings − access to the main menu level is obtained by pressing the enter key . − selection and confirmat...

Page 82

Eco gold 82 appendix with settings 25/08/2011/ yace0088 a.2 setting the volume of the acoustic signals the eco gold thermostats sound alarms and faults as a two-tone acoustic signal. Warnings a signaled as a continuous tone, − access to the main menu level is obtained by pressing the enter key . − s...

Page 83

Eco gold 25/08/2011/ yace0088 appendix with settings 83 a.4 setting the display brightness the eco range of thermostats have a sensor which automatically adapts the display brightness ac- cording to the ambient light level. However, the automatic adaptation can be deactivated and the brightness set ...

Page 84

Eco gold 84 appendix with settings 25/08/2011/ yace0088 a.6 limiting the mains current consumption if your mains fusing is below 16 a, the current consumption can be reduced in steps from 16 a to 8 a. The maximum heating power is reduced correspondingly. Here, take into consideration whether other l...

Page 85

Eco gold 25/08/2011/ yace0088 appendix with settings 85 a.8 restoring the factory setting of the internal temperature sensor if the offset has been adjusted, the factory setting can be restored again. − access to the main menu level is obtained by pressing the enter key . − selection and confirmatio...

Page 86

Eco gold 86 appendix with settings 25/08/2011/ yace0088 b list of "alarm and warning codes" alarms alarm code meaning 1 low level pump pump runs too fast (low level) 2 low level pump low level in the float 3 overtemperature overtemperature (t > tmax) 4 pump blocked pump blocked (standstill) 5 connec...

Page 87

Eco gold 25/08/2011/ yace0088 appendix with settings 87 code 1xx safety sys- tem meaning code 2xx command meaning 1 can receive overf overflow during can reception 1 can receive overf overflow during can reception 2 watchdog reset watchdog reset 2 watchdog reset watchdog reset 5 heat 1 failed heater...

Page 88

Eco gold 88 appendix with settings 25/08/2011/ yace0088 code 6xx switch con- tacts meaning code 7, 8, 9, 10, 11, 16xx solenoid valve meaning 1 can receive overf overflow during can reception 1 can receive overf overflow during can reception 2 watchdog reset watchdog reset 2 watchdog reset watchdog r...

Page 89

Eco gold 25/08/2011/ yace0088 appendix with settings 89 c graphical display of temperature measurements − from the main menu window you access the graphics win- dow by pressing (display). The temperature traces are shown in different colors. T set set-point temperature (red) t int internal bath temp...

Page 90

Eco gold 90 appendix with settings 25/08/2011/ yace0088 with rec. Interval you define the time interval between re- corded temperature measurements (the values in brackets state the maximum recording time). The menu offers five options. With time axis you can define the temporal range over which the...

Page 91: External Control

Eco gold 25/08/2011/ yace0088 appendix with settings 91 with temperature limits you can display and manually input the temperature limits for the graphical display. − temp.Scale min displays current minimum value − temp.Scale max displays current maximum value when temp.Scale max or temp.Scale min (...

Page 92

Eco gold 92 appendix with settings 25/08/2011/ yace0088 connection of the external pt100 to lemo socket 10s contact 1 2 3 4 + + - - i u u i current path voltage path voltage path current path pt100 din en 60751 4-pole lemosa plug for pt100 connection (catalogue no. Eqs 022) note: only use screened c...

Page 93: Programmer

Eco gold 25/08/2011/ yace0088 appendix with settings 93 − access to the main menu level is obtained by pressing the enter key . − selection and confirmation of Æ setup Æ control Æ setpoint offset . The adjacent menu window appears. As well as diff.Set/actual value the currently set offset value is d...

Page 94

Eco gold 94 appendix with settings 25/08/2011/ yace0088 e.1 programming example the graph shows as an example the reprogram- ming of a set-point temperature trace. (cooling time dependent on device type, consumer, etc.) example seg. No. 2: · "reach 50 °c within 20 minutes" before ( ____ ) no. T end ...

Page 95

Eco gold 25/08/2011/ yace0088 appendix with settings 95 note: no time specification is possible in the start segment (no. 1). The temperature of the first segment is attained as quickly as possible in order to switch to segment 2 after reaching the set tolerance. E.2 creating and editing a program i...

Page 96

Eco gold 96 appendix with settings 25/08/2011/ yace0088 − you can quit the edit window at any time without changes using (esc). When the cursor is located on a segment number, using you return to the menu level of the programmer without changes. Note: no time specification is possible in the start s...

Page 97

Eco gold 25/08/2011/ yace0088 appendix with settings 97 e.3 starting the program − the submenu status appears by selecting and confirming Æ programmer Æ program 1 . − with the menu status you can carry out the following with the commands start start program hold hold program continue continue progra...

Page 98: Control Parameters

Eco gold 98 appendix with settings 25/08/2011/ yace0088 e.5 defining the number of program loops (loops) programs can be processed many times. − the submenu loops appears by selecting and confirming Æ programmer Æ program n . − select and confirm loops with or and . − enter the desired number with o...

Page 99

Eco gold 25/08/2011/ yace0088 appendix with settings 99 − access to the main menu level is obtained by pressing the enter key . − selection and confirmation of Æ setup Æ control Æ contr.Parameter Æ intern pt100 . The adjacent menu window appears. Apart from the control parameters the currently set v...

Page 100

Eco gold 100 appendix with settings 25/08/2011/ yace0088 f.2 external control variable the setting options illustrated in this section are only possible with a connected external temperature sen- sor or with an existing module (as activated as control variable in section d.1) for reading in the actu...

Page 101

Eco gold 25/08/2011/ yace0088 appendix with settings 101 − access to the main menu level is obtained by pressing the enter key . − selection and confirmation of Æ setup Æ control Æ contr.Parameter Æ extern pt100 . The adjacent menu window appears. Apart from the control pa- rameters the currently se...

Page 102

Eco gold 102 appendix with settings 25/08/2011/ yace0088 f.2.2 procedure for setting the control parameters for external control 1. Activating external control (Ì d.1). 2. Set the slave controller: 2.1. Parameter to auto ; xpf in dependence of: − check or adjust device type (Ì 8.2.4). − select heat ...

Page 103: Interface Modules

Eco gold 25/08/2011/ yace0088 appendix with settings 103 g interface modules g.1 menu structure of the modules from this overview all menu points which cannot be executed in practice are masked out. Off on no yes set-point temperature calibration external actual temperature factory calibration pump ...

Page 104

Eco gold 104 appendix with settings 25/08/2011/ yace0088 g.2 analog module analogue module (lauda catalogue no. Lrz 912) has two inputs and two outputs, which are brought out to a six-pole din socket to namur recommendation (ne28). The inputs and outputs can be set independently of one another as a ...

Page 105

Eco gold 25/08/2011/ yace0088 appendix with settings 105 connection of analogue inputs and outputs a six-pole round connector with screw lock and contact assignment according to din en 60130-9 or iec 130-9 are required. A suitable coupling plug is obtainable under the catalogue no. Eqs 057. View of ...

Page 106

Eco gold 106 appendix with settings 25/08/2011/ yace0088 alternatives for windows vista and windows 7: − download various freeware programs from the internet. − copy program "hyper terminal" from an old operating system. To do this copy hypertrm.Exe from c:\programs\windows nt and both of the dll fi...

Page 107

Eco gold 25/08/2011/ yace0088 appendix with settings 107 g.3.4 rs 485 protocol note the following aspects: − the interface operates with one stop bit, no parity bit and with eight data bits. − transfer speed alternatively: 2400, 4800, 9600 (factor setting) or 19200 baud. − the device address always ...

Page 108

Eco gold 108 appendix with settings 25/08/2011/ yace0088 g.4 usb interface important: first install the driver and then connect the thermostat to the pc. G.4.1 description the eco heating and cooling thermostats are equipped with a usb interface at the back of the control head. This enables the conn...

Page 109

Eco gold 25/08/2011/ yace0088 appendix with settings 109 2. Key continue 3. Key finish driver installation is installed g.4.3 connecting the thermostat to the pc if an eco thermostat is connected via the usb interface, it is automatically assigned to a free com port. The pc unambiguously identifies ...

Page 110

Eco gold 110 appendix with settings 25/08/2011/ yace0088 for the first time, after installation on the pc, a wizard opens to search for new hardware. Please fol- low the wizard instructions. 3. Key continue 4. Key continue this window is covered by the following window "hardware installation" (see b...

Page 111

Eco gold 25/08/2011/ yace0088 appendix with settings 111 5. Click on continue installation . 6. Click on the key finish . G.4.4 where is the eco virtual com port? The thermostat can be operated via conventional communication programs (e.G. Hyperterminal) as a com port. Further settings, such as baud...

Page 112

Eco gold 112 appendix with settings 25/08/2011/ yace0088 click on the tab with the mouse and then on the device manager ..

Page 113

Eco gold 25/08/2011/ yace0088 appendix with settings 113 g.5 commands and error messages applicable to the rs 232/485 interface module and to the usb interface g.5.1 interface write commands (data issued to the thermostat) command meaning out_pv_05_xxx.Xx specify external temperature via interface o...

Page 114

Eco gold 114 appendix with settings 25/08/2011/ yace0088 admissible data formats: -xxxx.Xx -xxxx.X -xxxx. -xxxx xxxx.Xx xxxx.X xxxx. Xxxx -xxx.Xx -xxx.X -xxx. -xxx xxx.Xx xxx.X xxx. Xxx -xx.Xx -xx.X -xx. -xx xx.Xx xx.X xx. Xx -x.Xx -x.X -x. -x x.Xx x.X x. X -.Xx -.X .Xx .X g.5.2 interface read comma...

Page 115

Eco gold 25/08/2011/ yace0088 appendix with settings 115 command meaning in_mode_02 standby operation: 0 = device on / 1 = device off. In_mode_03 keypad remote control unit command: 0 = released / 1 = locked. In_mode_04 setpoint offset source: 0 = normal/ 1 = ext. Pt/ 2 = ext. Analog/ 3 = ext. Seria...

Page 116

Eco gold 116 appendix with settings 25/08/2011/ yace0088 g.5.3 interface error messages error meaning err_2 incorrect entry (e.G. Buffer overflow) err_3 wrong command. Err_5 syntax error in the value. Err_6 impermissible value. Err_8 module or value not present. Err_30 programmer, all segments occup...

Page 117

Eco gold 25/08/2011/ yace0088 appendix with settings 117 g.6 contact module g.6.1 contact module lrz 914 with 1 input and 1 output contact module (catalogue no. Lrz 914) with connectors to namur ne28, with 1 output and 1 input on each of 2 din sockets. The inputs provide the following functions: − e...

Page 118

Eco gold 118 appendix with settings 25/08/2011/ yace0088 contact outputs and inputs output input − view of flanged plug (front) or coupling-socket solder side − max. 30 v; 0.2 a coupling socket catalogue no. Eqd 047 − view of socket (front) or solder side of plug − signal approx. 5 v, 10 ma, do not ...

Page 119

BestÄtigung / confirmation / confirmation formblatt / form / formulaire: unbedenk.Doc erstellt / published / établi: lsc Änd.-stand / config-level / version: 0.1 datum / date: 30.10.1998 lauda dr. R. Wobser gmbh & co. Kg pfarrstraße 41/43 tel: +49 (0)9343 / 503-0 d - 97922 lauda-königshofen fax: +49...