- DL manuals

- Lauda

- Thermostat

- Integral XT 150

- Operating instructions manual

Lauda Integral XT 150 Operating instructions manual

Operating instructions

Integral XT

Process thermostats

XT 150, XT 250 W, XT 280, XT 280 W, XT 350 W, XT 350 HW, XT 490 W,

XT 550, XT 550 W, XT 750, XT 750 S, XT 750 H, XT 750 HS,

XT 950 W, XT 950 WS, XT 1590 W, XT 1590 WS,

XT 1850 W, XT 1850 WS

High-temperature thermostats

XT 4 H, XT 4 HW, XT 8 H, XT 8 HW

Summary of Integral XT 150

Page 1

Operating instructions integral xt process thermostats xt 150, xt 250 w, xt 280, xt 280 w, xt 350 w, xt 350 hw, xt 490 w, xt 550, xt 550 w, xt 750, xt 750 s, xt 750 h, xt 750 hs, xt 950 w, xt 950 ws, xt 1590 w, xt 1590 ws, xt 1850 w, xt 1850 ws high-temperature thermostats xt 4 h, xt 4 hw, xt 8 h, x...

Page 3: Operating Instructions

Yawe0028 translation of the original operating instructions release 11/2016 h replaces release 06/2016 g6, 04/2016 g5, 01/2015 g4, 05/2013 g1, 02/2012 e3, 10/2011 d1, 08/2011 c4, 08/2011 c2, 05/2011 c1, 11/07/2009, 08/06/03/2008, 07/2007 valid from: software version of command (control panel) 3.38 s...

Page 5: Prefixed Safety Notes

Integral xt yawe0028 / 24/06/2016 prefixed safety notes 3 prefixed safety notes before operating the equipment please read carefully all the instructions and safety notes in section 1. If you have any questions please phone us! Follow the instructions on setting up, operation etc. This is the only w...

Page 6: Contents

Integral xt 4 contents yawe0028 / 24/06/2016 contents prefixed safety notes .................................................................................................................................... 3 1 safety information .......................................................................

Page 7

Integral xt yawe0028 / 24/06/2016 contents 5 7.6.3.2 permanently and automatic degassing ................................................................................... 54 7.6.4 topping up ..............................................................................................................

Page 8

Integral xt 6 contents yawe0028 / 24/06/2016 7.16.6 pump-motor supervision: dry running ........................................................................................... 109 7.17 rs232/rs485 i nterface ( only c ommand remote control or m odule ) ................................... 110 7.17...

Page 9: Safety Information

Integral xt yawe0028/ 11/11/2016 safety information 7 explanation of signs: danger: this sign is used where there may be injury to person- nel if a recommendation is not followed accurately or is disregarded. Note: here special attention is drawn to some aspect. May include reference to danger. Refe...

Page 10

Integral xt 8 safety information yawe0028 / 11/11/2016 device immunity emissions class customer power supply integral xt process thermostat single-phase and triple- phase devices type 2 in accordance with din en 61326-1 emissions class b in accordance with cispr 11 only for eu domestic connection va...

Page 11

Integral xt yawe0028/ 11/11/2016 safety information 9 do not put any heavy parts on the device. the operating personnel must wear suitable protective equipment. do not operate the device when leaks have been found; ventilate the siting room immediately. with pressure sensitive loads (e.G. Gl...

Page 12

Integral xt 10 brief operating instructions yawe0028 / 24/06/2016 2 brief operating instructions these brief instructions shall give you the possibility to operate the unit quickly. For safe operation of the unit, it is absolutely necessary to read carefully all the instruc- tions and safety notes! ...

Page 13

Integral xt yawe0028 / 24/06/2016 brief operating instructions 11 if instead, a warning or error message is displayed, then refer to section 7.16. 9. Fill device with heat transfer liquid and follow section 7.6. Use suitable heat transfer liquid (þ 6.2). The devices are rated for operation with non-...

Page 14

Integral xt 12 brief operating instructions yawe0028 / 24/06/2016 2.2 menu structure: command menu display sounds master sounds command language master mode autostart current consumpt. Pump settings graph clock programmer interfaces 1 control limits pump level pressure control start fill mode start ...

Page 15

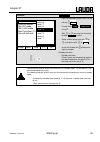

Integral xt yawe0028 / 24/06/2016 brief operating instructions 13 2.3 view of the device and connections integral xt 150 1 2 3 4 6 5 1 main switch 2 filling point for heat transfer liquid 3 interface section 4 mains cable 5 drain point m16 x 1 6 drain tap refer to page 19 for an illustrated side vie...

Page 16

Integral xt 14 brief operating instructions yawe0028 / 24/06/2016 integral xt 250 w 1 2 3 4 6 5 refer to page 19 for an illustrated side view of connections and taps..

Page 17

Integral xt yawe0028 / 24/06/2016 brief operating instructions 15 integral xt 350 hw and xt 950 w(s) 1 2 3 4 refer to page 20 for an illustrated side view of connections and taps..

Page 18

Integral xt 16 brief operating instructions yawe0028 / 24/06/2016 integral xt 280, xt 750 (s) und xt 750 h(s) 1 2 3 4 refer to page 20 for an illustrated side view of connections and taps..

Page 19

Integral xt yawe0028 / 24/06/2016 brief operating instructions 17 integral xt 490 w, xt 1590 w, xt 1590 ws, xt 1850 w, xt 1850 ws 1 2 3 4 refer to page 20 for an illustrated side view of connections and taps..

Page 20

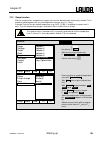

Integral xt 18 brief operating instructions yawe0028 / 24/06/2016 rear view xt 150/ xt 250 w from xt 280 1 2 1 overflow and venting for the equalizing container (all units) 2 switch for setting mains voltage and frequency (þ 2 and 9.4) (only xt 1850 w order no. Lwp 732; xt 1590 w order no. Lwp 742)....

Page 21

Integral xt yawe0028 / 24/06/2016 brief operating instructions 19 side view of connections (with xt 250 w as example) 1 2 3 4 1 exit cooling water connection r3/4” (only water cooled devices w). 2 entrance cooling water connection r3/4” (only water cooled devices w). 3 pump connector outflow m30 x 1...

Page 22

Integral xt 20 brief operating instructions yawe0028 / 24/06/2016 side view of connections and taps (with xt 350 hw as example) 1 2 3 4 5 6 7 8 1 pump connector outflow m30 x 1.5 (to the consumer) (xt 1850 w(s): m38 x 1.5). 2 pump connector return m30 x 1.5 (from the consumer) (xt 1850 w(s): m38 x 1...

Page 23

Integral xt yawe0028 / 24/06/2016 controls and functional elements 21 3 controls and functional elements control element: master control element: command remote control indication of an error message (red led flashes) control with ext. Temperature probe (green led lights) heating active (yellow led ...

Page 24: Device Description

Integral xt 22 device description yawe0028 / 24/06/2016 4 device description 4.1 environmental conditions the operation of the thermostats is only allowed under the following conditions as specified in en 61010-2-010:2003 and en 61010-1:2001: − indoor use. − altitude up to 2000 m above sea level. − ...

Page 25

Integral xt yawe0028 / 24/06/2016 device description 23 4.3 hydraulic circuit and vario pump the hydraulic circuit in the unit partly consists of a pipe system through which the temperature stabi- lizing liquid flows under pressure. The main components are: pipe system, equalizing tank (with no flow...

Page 26

Integral xt 24 device description yawe0028 / 24/06/2016 the safety system conforms to din en 61010-2-010. A dual-channel system is used in which two mi- cro-controllers monitor one another. Apart from the outflow temperature or temperature probe, there is a second safety temperature probe (pt100) fo...

Page 27

Integral xt yawe0028 / 24/06/2016 device description 25 4.8 interface modules (accessories) other interface modules can be inserted into two slots (refer to section 8). The following modules are currently available: 1. Rs232/485 interface module (order no. Lrz 913) with 9-pole sub-d socket. Electric...

Page 28: Unpacking

Integral xt 26 unpacking yawe0028 / 24/06/2016 5 unpacking falling down / tipping over of the device damage to property • do not tip the refrigerator and never place it upside down! + − if the device is overthrown or overturned on the shipping, log the fall and contact also the lauda service constan...

Page 29

Integral xt yawe0028 / 24/06/2016 unpacking 27 5.3 unpacking and packing with original transport packaging material 5.3.1 sector of application from integral xt 280 up to and including xt 1850 ws. There are two different sizes of transport pal- ettes, one for middle chassis (xt 280 / 350 / 550 / 750...

Page 30

Integral xt 28 unpacking yawe0028 / 24/06/2016 transportation board pallet recess on the pallet for the cooling water in and out connections. Pallet with transportation board in place. 5.3.5.2 packing the device align the wheels on the device length. Front side of the device front side of the device.

Page 31

Integral xt yawe0028 / 24/06/2016 unpacking 29 move transportation board underneath. The longer part of the board with end-to-end bar to the front side of the xt unit. Place transportation strips under both sides of the transportation board. Do not use chains! Lift the xt unit up and move it over th...

Page 32

Integral xt 30 unpacking yawe0028 / 24/06/2016 slip over the outer cardboard box. It is fixed by trans- portation board and pallet. Place the operating instructions of integral xt device on top of the device. First bring in the small distance cardboard (þ 5.3.5.1). The two beads shall be on the fron...

Page 33

Integral xt yawe0028 / 24/06/2016 unpacking 31 then place the large distance cardboard 90° rotated to the small distance cardboard. Close the outer cardboard box with retaining clips and adhesive tape..

Page 34

Integral xt 32 unpacking yawe0028 / 24/06/2016 secure the outer cardboard box twice on its larger and once on its smaller side. Stick on labels, markings and shock sensors! This unpacking instruction has to be placed prominent in a transparent plastic bag..

Page 35: Preparations

Integral xt yawe0028 / 24/06/2016 preparations 33 6 preparations falling down / falling over of the device on inclined plane / table edge crushing of the hands and feet • only position the device on level surfaces and not close to table edges. Falling down / tipping over of the device damage to prop...

Page 36

Integral xt 34 preparations yawe0028 / 24/06/2016 watercooled high-temperature thermostats: always connect cooling water cooling water connection is not established equipment damage (lasting damage to the high temperature valve) • the high-temperature thermostat has to be connect- ed to the cooling ...

Page 37

Integral xt yawe0028 / 24/06/2016 preparations 35 olives: − push a hose onto the hose olive. Secure hoses against slippage with the aid of hose clips etc. General notes: − always ensure the largest possible passages in the external circuit. For a hose cross-section that is too small à temperature gr...

Page 38

Integral xt 36 preparations yawe0028 / 24/06/2016 6.2 heat transfer liquids, cooling water and hoses filling, venting and degassing of heat transfer liquids (þ 7.6). Testing of the heat transfer liquid (þ 9.3.4). A) approved heat transfer liquids lauda designation tempera- ture range chem. Designati...

Page 39

Integral xt yawe0028 / 24/06/2016 preparations 37 important: danger of corrosion of the cooling water circuit due to water of unsuitable quality. • free chlorine (e.G. From disinfectants) and water containing chlorine lead to pitting in the cooling water circuit. • distilled, deionized or deminerali...

Page 40

Integral xt 38 preparations yawe0028 / 24/06/2016 c) hoses metal hoses in non-rusting stainless steel with union nut m30 x 1.5 internal width 20 mm hose type length (cm) temperature range °c field of application order number mxc 100s 100 -50 – 300 with special insulation for cold and hot areas for a...

Page 41: Starting Up

Integral xt yawe0028 / 24/06/2016 starting up 39 7 starting up 7.1 mains connection compare the rating on the name-plate (þ 9.5) with the mains voltage. Only valid for the usa: instructions for class a digital devices “this equipment has been tested and found to comply with the limits for class a di...

Page 42

Integral xt 40 starting up yawe0028 / 24/06/2016 switch on the main switch on the front panel: − the green led for "mains on" is lit, − and the unit starts its self-test. All display segments and symbols appear for about 1 s. − display of the current outflow temperature , − the pump starts provided ...

Page 43

Integral xt yawe0028 / 24/06/2016 starting up 41 − find cause of fault (þ 9.4) and, where necessary, top up missing liquid (þ 6.2). − press the enter key. − also press the key if unit has been switched off in the fault state. − no release is possible on command remote control! Command language − if ...

Page 44

Integral xt 42 starting up yawe0028 / 24/06/2016 7.4 key functions 7.4.1 general key functions and pilot lamps master enter key: − from the actual-value display at the main menu level, − activates input, display flashes, − saves input, display ceases to flash and menu point is left, − press for appr...

Page 45

Integral xt yawe0028 / 24/06/2016 starting up 43 command − enter key ("confirm selection") and go back one level. End − soft key function to confirm a selection or input and to return to the main display window. − escape key to quit a window without changes and to go back one level. − cursor keys fo...

Page 46

Integral xt 44 starting up yawe0028 / 24/06/2016 1. Basic window with the three most im- portant items of information: − t out , current outflow temperature, − t set , set point of the outflow temperature or external temperature, − information: heating / cooling. Here, heat- ing is taking place at 5...

Page 47

Integral xt yawe0028 / 24/06/2016 starting up 45 5. Process overview window − t out , current outflow temperature, − t set , setpoint, − t ext , current temperature on external probe (if connected), − controller to t out or t ext , the controlled value is shown large, − system pressure in the outflo...

Page 48

Integral xt 46 starting up yawe0028 / 24/06/2016 6. Window limits − t max , (þ 7.16.1), − t ih , t il (þ 7.10.2), − dynamic heating limit (þ 7.15.7.2), − max. Heating, cooling and smart cool (þ 7.15.7.1), − pictogram for degassing (þ 7.6.3). T max 185,00°c dynamic heat limit t ih (max) 202,00°c star...

Page 49

Integral xt yawe0028 / 24/06/2016 starting up 47 7.4.2 changing window information (command remote control) command display info you can adapt the information displayed by your command remote control to your re- quirements. For example, if you have not connected any temperature probe, you can exchan...

Page 50

Integral xt 48 starting up yawe0028 / 24/06/2016 7.4.3 locking the keyboard the keyboards of the master console and command remote control can be locked independently of one another. This is particularly advantageous when the thermostat is located in another room and the command remote control is us...

Page 51

Integral xt yawe0028 / 24/06/2016 starting up 49 command locking: − first press and then hold simultaneously pressed for 3 s. − the locking window appears. − hold both keys pressed until the pro- gress bar is completely filled. − then the display skips back into the pre- viously set screen mode, − t...

Page 52

Integral xt 50 starting up yawe0028 / 24/06/2016 7.5 level display the level display renders the current liquid level in the expansion vessel visible. Master le and 2 x − call level display le . − the current level indication is displayed (here 5 ). Command display in the various windows of the comm...

Page 53

Integral xt yawe0028 / 24/06/2016 starting up 51 7.6 filling, venting and degassing your integral xt has no bath which actively takes part in the temperature stabilization. There is however an expansion vessel which is filled with the liquid. The liquid passes to the external loads via the internal ...

Page 54

Integral xt 52 starting up yawe0028 / 24/06/2016 command filling mode the filling window appears automatically when the level is too low on switching on the device. It can however also be started manually: menu à pump à start filling mode . − fill with heat transfer liquid as described above up to l...

Page 55

Integral xt yawe0028 / 24/06/2016 starting up 53 − with devices up to 300 °c operating temperature range (h devices) switchover occurs alter- nately every 20 seconds between the individual hydraulic paths. When this happens, a long whirring sound is heard for about 5 seconds and the displayed pressu...

Page 56

Integral xt 54 starting up yawe0028 / 24/06/2016 − with this program the following parameters are automatically set: • the pump level is set to level 2. The pump level should only be changed when neces- sary (þ 7.9.3). • the heater power is reduced, round about 50 % (þ 7.15.7.1). • the cooling unit ...

Page 57

Integral xt yawe0028 / 24/06/2016 starting up 55 7.7 draining start draining − on the floor-standing device the drain taps and drain points are located on the right side of the housing, on the bench-top model they are on the front panel at the bottom right. − use the draining program so that the val...

Page 58

Integral xt 56 starting up yawe0028 / 24/06/2016 draining residues xt 150, xt 250 w after draining, liquid residues may still be located in the return hose. Proceed as follows: 1. Remove the return hose from the load. 2. Empty the residue from the hose into a con- tainer. 7.8 changing the heat trans...

Page 59

Integral xt yawe0028 / 24/06/2016 starting up 57 7.9 important settings 7.9.1 temperature setpoint setting the setpoint is the temperature which the thermostat should reach and maintain constant. Master (main level) set − press key until set (setpoint) appears. − press, display flashes. Or − enter t...

Page 60

Integral xt 58 starting up yawe0028 / 24/06/2016 command t set or t fix − or the soft key t set opens the setpoint window. − 123.45 is the setpoint which is still active. The upper and lower limit temperatures are displayed (device-specific values). There are three different possible entry methods: ...

Page 61

Integral xt yawe0028 / 24/06/2016 starting up 59 − select desired position with the cursor keys (black background). − with the soft key edit open the window shown on the left. − enter fixed temperature setpoint as de- scribed above and accept into the list with or cancel with . − select and accept v...

Page 62

Integral xt 60 starting up yawe0028 / 24/06/2016 master ext or − switches to the actual-value display of the external temperature probe (or to the actual value received from an interface module (þ 8)). − ext is lit in green next to the row of figures. − if no external pt100 probe is connected, -----...

Page 63

Integral xt yawe0028 / 24/06/2016 starting up 61 command pump level − open the device parameter menu via the soft key menu . − change from pump à pump level using . − with or you enter the illustrated window. Level 5 is active. − select another pump level with or and confirm with or end , − or quit ...

Page 64

Integral xt 62 starting up yawe0028 / 24/06/2016 7.9.4 pressure control alternatively to the 8 pump power levels, a mode with pressure control is provided which facilitates a very effective supply of pressure-sensitive glass reactors with a maximum permissible pressure rating. Command pressure contr...

Page 65

Integral xt yawe0028 / 24/06/2016 starting up 63 command max. Pressure [bar] 0.0 − open the device parameter menu with the soft key menu . − change from pump à to max. Pressure [bar] 0.0 . − the settings window opens. − enter the required maximum pressure. − if the set maximum pressure is exceed- ed...

Page 66

Integral xt 64 starting up yawe0028 / 24/06/2016 command control variable − open the device parameter menu with the soft key menu . − with the cursor keys, change further to: à control à control variable . − internal is currently active. − select other control variables (only dis- played when presen...

Page 67

Integral xt yawe0028 / 24/06/2016 starting up 65 7.9.7 current consumption from the mains if your mains fuse is rated below 16 a, the current consumption can be reduced in steps from 16 a to 10 a using this function. The maximum heating power is then, of course, also reduced accordingly. Take into a...

Page 68

Integral xt 66 starting up yawe0028 / 24/06/2016 7.9.8 setting the date and time (command remote control) command clock time date − open the device parameter menu via the soft key menu . − with the cursor keys continue to: à clock à set time − or to set date . − open the settings window with . − cha...

Page 69

Integral xt yawe0028 / 24/06/2016 starting up 67 7.9.9 display resolution setting (command remote control) the command remote control allows for different resolutions of the displayed temperature. Command display resolution − open the device parameter menu via the soft key menu . − with the cursor k...

Page 70

Integral xt 68 starting up yawe0028 / 24/06/2016 7.10 special settings 7.10.1 defining the type of start mode usually it is desirable that the thermostat carries on operating again after an interruption in the voltage supply. However, if for safety reasons you do not wish this, you can insert an int...

Page 71

Integral xt yawe0028 / 24/06/2016 starting up 69 7.10.2 defining temperature limits with this function it is possible to define a minimum and maximum outflow temperature in the range of which the device controls as a maximum. When the temperature limits are attained, the heater or the re- frigeratin...

Page 72

Integral xt 70 starting up yawe0028 / 24/06/2016 7.10.3 setpoint offset operating mode with this function it is possible to apply an offset value to the temperature provided by the external tem- perature probe or a module and then to use it as the setpoint. The heat transfer liquid temperature can, ...

Page 73

Integral xt yawe0028 / 24/06/2016 starting up 71 7.10.4 restoring works settings command works settings − open the device parameter menu via the soft key menu . − with the cursor keys continue to: à settings à works settings . − the window shown opposite appears. − master and then only control par. ...

Page 74

Integral xt 72 starting up yawe0028 / 24/06/2016 7.10.5 setting the volume of the acoustic signals the lauda integral xt thermostats signal alarms as a dual-tone acoustic signal and warnings as a continuous tone. Command sounds − open the device parameter menu via the soft key menu . − with the curs...

Page 75

Integral xt yawe0028 / 24/06/2016 starting up 73 − the temperature measurement device shows the true temperature value (with glass thermometers take the correction into account where applicable). − change the display in the adjacent win- dow to the true value with cursor or soft keys and accept with...

Page 76

Integral xt 74 starting up yawe0028 / 24/06/2016 7.10.8 entering the offset of the external temperature probe if a deviation is found during the check using a calibrated reference thermometer probe, e.G. From the lauda digical series, then the offset (the additive part of the characteristic) of the ...

Page 77

Integral xt yawe0028 / 24/06/2016 starting up 75 7.10.10 smartcool the chiller of the cooling thermostats is operated in the "automatic" operating mode as standard. Here, the cooling unit switches on or off automatically depending on the temperature and operating status. However, you can also switch...

Page 78

Integral xt 76 starting up yawe0028 / 24/06/2016 7.11 graphical display of temperature measurements (command remote control) command screen and graph − press the soft key screen a number of times as required until the graph re- corder window appears. − with the soft key graph you enter the menu for ...

Page 79

Integral xt yawe0028 / 24/06/2016 starting up 77 temp. Scale defines how the scaling is to be carried out: − automatic , by the program, or − manual in that you yourself define the limits with the next menu point. The minimum and maximum values for the graphical display are manually entered with tem...

Page 80

Integral xt 78 starting up yawe0028 / 24/06/2016 7.12 programmer almost any temperature/time profile can be created with the programmer. A desired bath temperature can be approached as quickly as possible or via a defined ramp. Furthermore, the pump level and the behavior of the switching outputs ca...

Page 81

Integral xt yawe0028 / 24/06/2016 starting up 79 + each program begins with the segment "start". It defines at which temperature seg- ment 1 is to continue the program. It is not possible to specify a time for the start segment. Edited program example (see dashed curve in the graph on previous page)...

Page 82

Integral xt 80 starting up yawe0028 / 24/06/2016 7.12.2 selecting and starting the program (start, hold, stop) here you will learn how to select and start a program that has already been created. If no program has been created see creating or modifying a program (edit) (þ 7.12.4). Command programmer...

Page 83

Integral xt yawe0028 / 24/06/2016 starting up 81 7.12.3 interrupting, continuing or terminating the program (hold, continue, stop) command programmer program 1 status − after a program has been started by pressing the key, the command op- tions hold or stop are shown. − here, with the aid of the key...

Page 84

Integral xt 82 starting up yawe0028 / 24/06/2016 7.12.4 creating or modifying a program (edit) here, there are the following functions: • entry of a program. • display of the program data of a saved program and modification of the segment data. • insertion or appending of a new segment. • deletion o...

Page 85

Integral xt yawe0028 / 24/06/2016 starting up 83 no t end °c time [h:m] tolerance start 30,00°c ------- 3,00°c 1 30,00°c 00:30 3,00°c pump menu end insert delete − in the "start" line enter in the field "t end °c" the temperature at which the se- quence is to start (default value is 30 °c). A time e...

Page 86

Integral xt 84 starting up yawe0028 / 24/06/2016 − a new segment is produced by moving the cell with the black background to a blank line with the cursor keys and then pressing the soft key insert . The values of the cell located above it are automatically copied. − if the field in the column t end ...

Page 87

Integral xt yawe0028 / 24/06/2016 starting up 85 − if the field in the column "pump" has a black background, the entry mode for the pump level is obtained by pressing the key . − with or select pump level 1 – 8 or ------- and confirm with . ------ stands for "no change to previous segment", i.E. Whe...

Page 88

Integral xt 86 starting up yawe0028 / 24/06/2016 7.12.5 defining the number of program loops (loops) command programmer program1 loops − if required, programs can be looped many times. − with and access the menu loops . − select the number of desired program loops. − press the key, set the required ...

Page 89

Integral xt yawe0028 / 24/06/2016 starting up 87 − the display of the programmed tempera- ture curve can be quit with or end . 7.12.7 obtaining information on a program (info) command programmer program1 info − continue with to info . − here, all information is displayed about the entered program se...

Page 90

Integral xt 88 starting up yawe0028 / 24/06/2016 7.12.8 optimization of the programmer the menu item “optimizing the programmer” in practice leads to a very good control behavior. Command prog. Optimization − open the device parameter menu via the soft key menu . − with the cursor keys continue to: ...

Page 91

Integral xt yawe0028 / 24/06/2016 starting up 89 7.13 ramp function with the ramp function temperature changes over any time period can be conveniently entered. This is especially advantageous with very low temperature changes (e.G. 0.1 °c/day). Example: from the current outflow temperature (e.G. 24...

Page 92

Integral xt 90 starting up yawe0028 / 24/06/2016 7.14 timer function / timer (command) using the timer function, the thermostat can carry out an action at a certain time or after a certain wait- ing period. Actions are: switching on the thermostat, entering the standby mode or one of the 5 pro- gram...

Page 93

Integral xt yawe0028 / 24/06/2016 starting up 91 − week plan à arrange takes you to the window shown on the left. − using the cursor keys , select the field which is to be filled in. − open the input dialog of the field with : select a time in the time fields and an action in the action field. − in ...

Page 94

Integral xt 92 starting up yawe0028 / 24/06/2016 + − low viscosity heat transfer liquids: e.G. Thin-bodied oil, water-glycol. − short hose connections with a large cross-section. The flow resistance is then low and a large amount of thermostatic medium can be pumped in a short time. In addition, the...

Page 95

Integral xt yawe0028 / 24/06/2016 starting up 93 7.15.2 configuration examples example 1, favorable configuration: − lauda integral xt 750 with connected metal double-shell vessel (20 l), − 2 x 2 m metal corrugated hose, 20 mm clearance (m30 x 1.5), − no by-pass, − oil lauda kryo 55, in temperature ...

Page 96

Integral xt 94 starting up yawe0028 / 24/06/2016 7.15.3 internal control variable (integral measurement probe) only read further here if you have no external temperature probe connected (and activated according to section 7.9.6 as control variable). The outflow controller compares the setpoint tempe...

Page 97

Integral xt yawe0028 / 24/06/2016 starting up 95 7.15.3.1 procedure for setting the control parameters for internal control 1. Choose a set of control parameters from the table of control parameters (þ 7.15.3.2). 2. Adjust the setpoint by 5 °c (5 k setpoint step change) and record the outflow temper...

Page 98

Integral xt 96 starting up yawe0028 / 24/06/2016 7.15.4 external control variable (external measurement probe) you only need to read further here if you have connected an external temperature probe or the actual temperature is read in from a module (and you have activated it as control variable acco...

Page 99

Integral xt yawe0028 / 24/06/2016 starting up 97 command control parameters − open the device parameter menu via the soft key menu . − with the cursor keys continue to: à control à control parameters à control parameters . − the adjacent window appears. Parameter endings: e = master controller, f = ...

Page 100

Integral xt 98 starting up yawe0028 / 24/06/2016 b) setting the master controller (external controller): experience has shown that the setting of the master controller demands much more time than the set- ting of the internal controller for a pure outflow temperature control. Many days may be necess...

Page 101

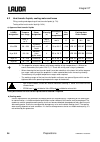

Integral xt yawe0028 / 24/06/2016 starting up 99 7.15.4.2 well-proven settings for control parameters and pump level for external control master controller (external controller) slave control- ler (internal con- troller) type of device heat transfer liquid exter- nal applic- ation kpe ep tne en tve ...

Page 102

Integral xt 100 starting up yawe0028 / 24/06/2016 command control parameter sets − open the device parameter menu via the soft key menu . − with the cursor keys continue to: à control à control parameters à control para. Sets . − the adjacent window appears. Set 1 to set 9. − select the desired set ...

Page 103

Integral xt yawe0028 / 24/06/2016 starting up 101 7.15.6 self adaption the function self adaption can be used to detect automatically the optimal control parameters for internal or external control. The self adaption can only be performed on a device with active cooling. This function is available f...

Page 104

Integral xt 102 starting up yawe0028 / 24/06/2016 − with the menu setpoint the set tem- perature for the test run can be set. The bath temperature will oscillate less than about ±15 kelvin around the set temperature. − change the display in the adjacent window and accept with . − with the menu ident...

Page 105

Integral xt yawe0028 / 24/06/2016 starting up 103 7.15.7 limiting the heating and cooling power 7.15.7.1 actuating signal limit with the actuating signal limit the maximum heating and / or cooling power can be limited. The setting occurs in percent of the maximum value. Command controller output lim...

Page 106

Integral xt 104 starting up yawe0028 / 24/06/2016 command dynamic heat limit − open the device parameter menu with the softkey menu . − with the cursor keys continue to: change à control à dynamic heat limit . − the window shown adjacent appears. Select with the cursor key start , end or set value a...

Page 107

Integral xt yawe0028 / 24/06/2016 starting up 105 7.16 alarms, warnings and errors the selfcheck assistant of your integral xt thermostat monitors more than 50 device parameters and triggers alarms, warnings or errors as appropriate. All warnings, alarms and errors are shown on the command remote co...

Page 108

Integral xt 106 starting up yawe0028 / 24/06/2016 + − not higher than 25 °c below the fire point of the heat transfer liquid used (þ 6.2). − the setting range is restricted to 5 °c above the upper limit of the working tempera- ture range ( tih þ 7.10.2). % ‰‰ − if the outflow temperature rises above...

Page 109

Integral xt yawe0028 / 24/06/2016 starting up 107 2. Display for leuel (low level) is shown when the expansion vessel contains too little liquid. 3. The red led above the fault triangle flashes. à heater switches off on both poles; à pump and refrigerating unit are switched off electronically. − rec...

Page 110

Integral xt 108 starting up yawe0028 / 24/06/2016 command over level handling − open the device parameter menu via the soft key menu . − with the cursor keys continue to: à settings à over level handling . − the shown window appears. − select the preferred parameter with or and confirm with . − see ...

Page 111

Integral xt yawe0028 / 24/06/2016 starting up 109 7.16.5 pump-motor supervision: overload or blockage % ‰‰ the selfcheck assistant monitors the vario pump: 1. Alarm sounds as dual-tone signal for pump-motor overload or blockage. 2. Display of bl0c signals blockage. 3. The red led above the fault tri...

Page 112

Integral xt 110 starting up yawe0028 / 24/06/2016 7.17 rs232/rs485 interface (only command remote control or module) 7.17.1 connecting cables and interface test rs232 computer thermostat signal 9-pin sub-d-socket 25-pin sub-d-socket 9-pin sub-d-socket signal ¬ - ¬ - ¬ - r x d 2 2 3 3 2 2 t x d t x d...

Page 113

Integral xt yawe0028 / 24/06/2016 starting up 111 example: transfer of setpoint 30.5 °c to the thermostat computer thermostat ”out_sp_00_30.5“crlf ð ï “ok“crlf 7.17.3 connecting cable rs485 thermostat 9-pin sub-d-socket contact data 1 data a (-) 5 sg (signal ground) optional 6 data b (+) + − use scr...

Page 114

Integral xt 112 starting up yawe0028 / 24/06/2016 example: transfer of setpoint 30.5 °c to the thermostat with address 15. Computer thermostat “a015_out_sp_00_30.5“cr ð ï “a015_ok“cr 7.17.5 write commands (data commands to the thermostat) command explanation out_pv_05_xxx.Xx external temperature to ...

Page 115

Integral xt yawe0028 / 24/06/2016 starting up 113 + − for ”_“ use also ” ” (blank character). − response from thermostat ”ok“ or in case of error ” err_x“ (rs 485 interface e.G. “a015_ok” or in case of error ”a015_err_x”.). Permitted data formats: -xxx.Xx -xxx.X -xxx. -xxx xxx.Xx xxx.X xxx. Xxx -xx....

Page 116

Integral xt 114 starting up yawe0028 / 24/06/2016 command explanation in_mode_00 master keyboard: 0 = free / 1 = locked in_mode_01 control: 0 = int. / 1 = ext. Pt100 / 2 = ext. Analogue / 3 = ext. Serial. In_mode_02 standby: 0 = unit on / 1 = unit off. In_mode_03 command remote control keyboard: 0 =...

Page 117

Integral xt yawe0028 / 24/06/2016 starting up 115 command explanation log_in_02 query of the start time from the data logger (reply: e.G. 20_14_12_20 => day 20, 14:12:20). Log_in_03 query of acquisition interval from the data logger (reply in seconds). + − for “_” use also “ ” (blank character). − t...

Page 118: Interface Modules

Integral xt 116 interface modules yawe0028 / 24/06/2016 8 interface modules 8.1 installing of modules the master and command can be supplemented with further interface modules. They will be simply insert- ed in 2 module cavities, at the front of the floor-standing device or at the right side of the ...

Page 119

Integral xt yawe0028 / 24/06/2016 interface modules 117 − plug on the bus connecting cable (red plug onto red socket). − insert the module and secure with the two cross-head screws. − connect the mains plug again and switch on the integral xt. + the plugs are protected against reverse polarity. The ...

Page 120

Integral xt 118 interface modules yawe0028 / 24/06/2016 8.2 menu structure for all modules all existing menu points are illustrated. However, the command remote control masks out menu points which cannot be executed. Further information can be found in the following sections. Input 1 input 2 input 3...

Page 121

Integral xt yawe0028 / 24/06/2016 interface modules 119 8.3 serial interfaces rs232/485 rs232/485 interface module (order no. Lrz 913) with 9-pole sub-d socket. Electrically isolated by optocoupler. With the lauda instruction set essentially compatible to the eco, ecoline, proline, inte- gral xt and...

Page 122

Integral xt 120 interface modules yawe0028 / 24/06/2016 connection of the analogue inputs and outputs a 6-pole round connector with screw locking and contact arrangement according to din en 60130-9 or iec 130-9 is needed. A suitable coupling plug can be obtained under order no. Eqs 057. View of the ...

Page 123

Integral xt yawe0028 / 24/06/2016 interface modules 121 − t ret is displayed in the process overview window. 8.5 contact module 8.5.1 contact module lrz 915 with three inputs and three outputs contact module (order no. Lrz 915) on 15 pole sub-d socket. With three relay contact outputs (changeover, m...

Page 124

Integral xt 122 interface modules yawe0028 / 24/06/2016 contact inputs and outputs − view of the socket from the plug side or of the plug on the solder side. − a suitable 15-pole sub-d plug can be obtained together with a suitable housing: order no. Eqm 030 and plug housing order no. Eqg 017. 8.5.2 ...

Page 125: Maintenance

Integral xt yawe0028 / 24/06/2016 maintenance 123 9 maintenance 9.1 cleaning 9.1.1 cleaning the surface of the device withdraw the equipment mains plug before cleaning. Cleaning can be carried out with water to which a few drops of surfactant (washing-up liquid) have been added and using a damp clot...

Page 126

Integral xt 124 maintenance yawe0028 / 24/06/2016 9.2.2 software version here, only the version of the control system in the master is displayed. Menu à settings à device status à software version . With the command remote control the versions of the control system ( control ), safety system ( safet...

Page 127

Integral xt yawe0028 / 24/06/2016 maintenance 125 9.2.5 fault memory (command remote control) for the analysis and localization of faults the command version includes a fault memory in which up to 46 fault and alarm messages are saved. Command error store menu à settings à device status à error stor...

Page 128

Integral xt 126 maintenance yawe0028 / 24/06/2016 9.2.7 heater info command operating info − open the device parameter menu via the softkey menu . − with the cursor keys, change further to: à settings à device status à heater info à display . Pump menu end t set t fix display device type sw verson s...

Page 129

Integral xt yawe0028 / 24/06/2016 maintenance 127 9.3 servicing and repair − withdraw the mains plug before all service and repair work. − repairs in the control section must be carried out only by specialists. − keep to service and maintenance intervals. If servicing does not occur at the stated in...

Page 130

Integral xt 128 maintenance yawe0028 / 24/06/2016 9.3.2 cleaning the condenser 9.3.2.1 air-cooled condenser in order that the full cooling power is available, the condenser of the cooling unit must be removed of dust – at one month intervals or longer, depending on the operating time and accumulatio...

Page 131

Integral xt yawe0028 / 24/06/2016 maintenance 129 9.3.2.2.2 decalcifying the water cooling circuit at regular intervals of 3 months or longer, the water-cooled condenser must be decalcified or cleaned. This depends on the hardness of the cooling water and the degree of soiling. Drain according to (þ...

Page 132

Integral xt 130 maintenance yawe0028 / 24/06/2016 9.3.3 fuses single-phase alternating current units xt 150 (lwp 112/512/812) up to xt 350 hw (lwp 119/519/819). In the event of an overload a circuit breaker interrupts the power supply. In an overload condition the circuit breaker may be manually res...

Page 133

Integral xt yawe0028 / 24/06/2016 maintenance 131 xt 350 w, xt 350 hw ul 533 ul 555 all except xt 150, xt 250 w, xt 350 w, xt 350 hw. Only xt 1850 w, xt 1850 ws: ul 555 (concealed, optional) ul 569 ul 555 ul 571 resp. Ul 558.

Page 134

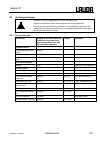

Integral xt 132 maintenance yawe0028 / 24/06/2016 list of the fuses in the devices from xt 490 w upwards: control fuse f3 à t 0a2 (slow blow) order no. Ees 069. Single-phase alternating cur- rent units order no. Circuit boards ul 533 (mains) ul 555-9 (power supply) for all devices --- f5/6/7 à t10a0...

Page 135

Integral xt yawe0028 / 24/06/2016 maintenance 133 three-phase alternating current units order no. Circuit boards ul 555-9 (power supply) ul 571 (heating) ul 563 (distributor 2) for all devices f5/6/7 à t10a0 (slow blow) eef 026 --- --- xt 280 lwp 334 208-220 v; 3/pe~60 hz f3, f4 à see table (þ 135) ...

Page 136

Integral xt 134 maintenance yawe0028 / 24/06/2016 three-phase alternating current units order no. Circuit boards ul 555-9 (power supply) ul 571 (heating) ul 563 (distributor 2) xt 750 lwp 320 208-220 v; 3/pe~60 hz f3, f4 à see table (þ 135) f1 to f6 à ff12a5 (extra quick blow) ees 015 --- xt 750 lwp...

Page 137

Integral xt yawe0028 / 24/06/2016 maintenance 135 three-phase alternating current units order no. Circuit boards ul 555-9 (power supply) ul 571 (heating) ul 563 (distributor 2) xt 1850 w lwp 532 400 v; 3/pe~50 hz f3, f4 à see table (þ 135) 2x ul 555 f1 to f6 à f10a0 (quick blow) ees 067 --- xt 1850 ...

Page 138

Integral xt 136 maintenance yawe0028 / 24/06/2016 mains pcb ul 555j j pcb heating ul 571 fuses for replacement bench-top device.

Page 139

Integral xt yawe0028 / 24/06/2016 maintenance 137 floor-standing device 9.3.4 testing the heat transfer liquid if the heat transfer liquid becomes contaminated or degenerated, it should be renewed. If required, the heat transfer should be checked for fitness for use (e.G. When changing the method of...

Page 140

Integral xt 138 maintenance yawe0028 / 24/06/2016 9.4 remedying faults before you contact the lauda service constant temperature equipment (þ 9.5), check whether the prob- lem can be remedied with the following instructions: a) process thermostats fault possible remedy device does not cool or only v...

Page 141

Integral xt yawe0028 / 24/06/2016 maintenance 139 master: warning message wxarn 332 command: low flow (cooling unit). (not enough flow in region of evaporator). (þ 7.15). 1. Check whether there is a blockage in the hy- draulic circuit (closed valves, pinched hose, dirt ...). à rectify cause. 2. Pump...

Page 142

Integral xt 140 maintenance yawe0028 / 24/06/2016 master: warning message wxarn 103 command: level too high (imminent excessive level in the expansion ves- sel). Master: alarm message al 6 command: level too high (excessive level in the expansion vessel) (þ 7.16.4). 1. Volume expansion during heatin...

Page 143

Integral xt yawe0028 / 24/06/2016 maintenance 141 b) high-temperature thermostats fault possible remedy master: alarm message cool flowx (equipment damage (lasting damage to the high temperature valve) ) 1. Cooling water temperature above 80 °c and longer than 8 seconds. à restore correct cooling wa...

Page 144

Integral xt 142 maintenance yawe0028 / 11/11/2016 9.5 service, ordering replacement parts and rating label when ordering spares please quote serial number (rating label). This avoids queries and supply of incorrect items. Rating label your contact for maintenance and support: lauda service constant ...

Page 145

Integral xt yawe0028 / 23/11/2016 maintenance 143 9.6 disposal information the following applies to europe: the disposal of the device is regulated by ec directive 2012/19/eu. 9.6.1 disposal of the refrigerant the device contains fluorinated greenhouse gases. The type and filling quantity can be rea...

Page 146: Accessories

Integral xt 144 accessories yawe0028 / 24/06/2016 10 accessories description application catalogue number lauda wintherm plus pc program. Control of the thermostat, online display of all values as a graph with free choice of time frame. Incl. Rs232 cable (2 m). Ldsm2002 t-piece connection for the in...

Page 147

Integral xt yawe0028 / 24/06/2016 accessories 145 interfaces and modules rs232/485 interface module digital communication, opera- tion of the lauda pc soft- ware wintherm plus (þ 7.17). Lrz 913 rs232 cable (2 m) thermostat-pc sub-d (9 pin. 9 pin). Eks 037 rs232 cable (5 m) thermostat-pc sub-d (9 pin...

Page 148

Integral xt 146 accessories yawe0028 / 24/06/2016 adapter m30 x 1.5 (according to din 3863 and din 3870) reduction m30 x 1.5 i to m16 x 1 a ud 660 reduction m30 x 1.5 a to m16 x 1 i hka 152 double nipple m30 x 1.5 eov 208 screw-in sleeve m30 x 1.5 a to g ¾‘‘a eov 194 flange adapter m30 x 1.5 a to di...

Page 149

Integral xt yawe0028 / 24/06/2016 accessories 147 metal thermostat hoses (þ 6.2) mxc 100s; 100 cm m30 x 15 i both ends; -50 to 300 °c lzm 081 mxc 200s; 200 cm m30 x 1.5 i both ends; -50 to 300 °c lzm 082 mxc 300s; 300 cm m30 x 1.5 i both ends; -50 to 300 °c lzm 083 metal thermostat hoses m 38x1.5 su...

Page 150: Technical Data

Integral xt 148 technical data yawe0028 / 24/06/2016 11 technical data eu conformity the device complies with the basic health and safety requirements outline in the directives listed below. N machinery directive 2006/42/ec n emc directive 2014/30/eu lauda dr. R. Wobser gmbh & co. Kg - pfarrstraße 4...

Page 151

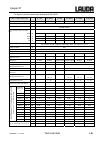

Integral xt yawe0028 / 11/11/2016 technical data 149 the figures have been determined according to din 12876. Table 1 process thermostats xt 150 xt 250 w xt 280 xt 280 w xt 350 w xt 350 hw operating temp./acc range °c -45 – 220 -45 – 220 -80 – 220 -80 – 220 -50 – 220 -50 – 300 ambient temp. Range °c...

Page 152

Integral xt 150 technical data yawe0028 / 11/11/2016 table 1 process thermostats xt 150 xt 250 w xt 280 xt 280 w xt 350 w xt 350 hw heater power / power consumption 230 v; 50 hz kw 3.5 / 3.68 3.5 / 3.68 --- --- 3.5 / 3.68 3.5 / 3.68 208-220 v; 3/pe~60 hz kw --- --- 2.9 / 7.0 2.9 / 7.0 --- --- 200 v;...

Page 153

Integral xt yawe0028 / 11/11/2016 technical data 151 table 2 process thermostats xt 490 w xt 550 xt 550 w operating temperature/acc-range °c -90 – 220 -50 – 220 -50 – 220 ambient temp. Range °c 5 – 40 humidity maximum relative humidity 80 % for temperatures up to 31 °c, decreasing linearly to 50 % r...

Page 154

Integral xt 152 technical data yawe0028 / 11/11/2016 table 2 process thermostats xt 490 w xt 550 xt 550 w heater power / power consumption 230 v; 50 hz kw --- --- --- 208-220 v; 3/pe~60 hz kw 5.7 / 9.5 --- --- 200 v; 3/pe~50/60 hz kw 5.3 / 8.6 --- --- 200 v; 50/60 hz kw --- --- --- 400 v; 3/pe~50 hz...

Page 155

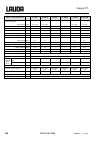

Integral xt yawe0028 / 11/11/2016 technical data 153 table 3 process thermostats xt 750 (s) xt 750 h(s) xt 950 w(s) xt 1590 w(s) xt 1850 w(s) operating temp.- acc range °c -50 – 220 -50 – 300 -50 – 220 -90 – 220 -50 – 220 ambient temp. Range °c 5..40 humidity maximum relative humidity 80 % for tempe...

Page 156

Integral xt 154 technical data yawe0028 / 11/11/2016 table 3 process thermostats xt 750 (s) xt 750 h(s) xt 950 w(s) xt 1590 w(s) xt 1850 w(s) heater power / power consumption 400 v; 3/pe~50 hz kw lwp 520: 5.3 / 7.8 lwp 522: 5.3 / 7.8 lwp 521: 5.3 / 7.8 --- lwp 532: 10.6 / 13.8 kw lwp 552: 8.0 / 9.7 ...

Page 157

Integral xt yawe0028 / 11/11/2016 technical data 155 fuses of the mains connection data mains connection xt 150 xt 250 w xt 280 xt 280 w xt 350 w xt 350 hw fu se : 230 v; 50 hz t16 a t16 a --- --- t16 a t16 a 208-220 v; 3/pe~60 hz --- --- t20 a t20 a --- --- 200 v; 3/pe~50/60 hz --- --- t20 a t20 a ...

Page 158

Integral xt 156 technical data yawe0028 / 11/11/2016 mains connection xt 1590 w xt 1590 ws xt 1850 w xt 1850 ws fu se : 230 v; 50 hz --- --- --- --- 208-220 v; 3/pe~60 hz --- --- --- --- 200 v; 3/pe~50/60 hz --- --- --- --- 200 v; 50/60 hz --- --- --- --- 400 v; 3/pe~50 hz --- t20 a t25 a t25 a 440-...

Page 159

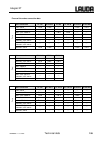

Integral xt yawe0028 / 11/11/2016 technical data 157 table 4 high-temperature thermostats xt 4 h xt 4 hw xt 8 h xt 8 hw operating temperature/acc-range °c 80 - 320 30 - 320 80 - 320 30 - 320 ambient temp. Range °c 5 - 40 humidity maximum relative humidity 80 % for temperatures up to 31 °c, decreasin...

Page 160

Integral xt 158 technical data yawe0028 / 11/11/2016 table 4 high-temperature thermostats xt 4 h xt 4 hw xt 8 h xt 8 hw surface loading (heater) 230 v; 50 hz w/cm² 6.1 6.1 --- --- 208-220 v; 3/pe~60 hz w/cm² --- --- 7.1 7.1 200 v; 3/pe~50/60 hz w/cm² --- --- 7.1 7.1 200 v; 50/60 hz w/cm² 4.6 4.6 ---...

Page 161

Integral xt yawe0028 / 24/06/2016 technical data 159 pump characteristics (pump level 1 – 8) integral xt xt 150, xt 250 w, xt 280, xt 280 w, xt 350 w, xt 350 hw, xt 490 w, xt 550, xt 550 w, xt 750, xt 750 s, xt 750 h, xt 750 hs, xt 950 w, xt 950 ws, xt 1590 w and xt 1590 ws measured with water pump ...

Page 162: Index

Integral xt 160 index yawe0028 / 24/06/2016 12 index a accessories .......................... 147 acoustic signals ......................72 activate standby ......................60 activating external control .......63 actuating signal limit ............ 103 alarms ....................................

Page 163

Integral xt yawe0028 / 24/06/2016 index 161 maintenance ........................ 123 max. Pressure [bar] 0.0 .......... 63 measurement display, graphical ............................................ 44 modules .......................... 25, 116 install ...................................... 116 n na...

Page 164

Integral xt 162 yawe0028 / 24/06/2016 intentionally left blank.

Page 165

BestÄtigung / confirmation / confirmation formblatt / form / formulaire: unbedenk.Doc erstellt / published / établi: lsc Änd.-stand / config-level / version: 0.1 datum / date: 30.10.1998 lauda dr. R. Wobser gmbh & co. Kg pfarrstraße 41/43 tel: +49 (0)9343 / 503-0 d - 97922 lauda-königshofen fax: +49...

Page 168

Lauda dr. R. Wobser gmbh & co. Kg p.O. Box 12 51 · 97912 lauda-koenigshofen · germany phone: +49 9343 503-0 · fax: +49 9343 503-222 e-mail: info@lauda.De · internet: www.Lauda.De.