- DL manuals

- Lawn-King

- Trimmer

- CBT911251

- Original Instructions For Use

Lawn-King CBT911251 Original Instructions For Use

1

PETROL

TRIMMER

Translation of the original instructions for use

WARNING: Read the instructions before using the product

Before initial start-up, please read through these operating instructions carefully

prior to using the machine. Keep the instructions safe and pass them on to any

subsequent user so that the information is always available.

Serial Number:

Summary of CBT911251

Page 1

1 petrol trimmer translation of the original instructions for use warning: read the instructions before using the product before initial start-up, please read through these operating instructions carefully prior to using the machine. Keep the instructions safe and pass them on to any subsequent user...

Page 2: Table Of Contents

2 dear customer, thank you for choosing one of our products. We hope that you will be completely satisfied with this machine and that it fully meets your expectations. This manual has been compiled in order to provide you with all the information you need to get acquainted with the machine and use i...

Page 3

3 1. Identification of main components main components 1. Power unit 2. Drive tube 3. Drive tube terminal 4. Cutting line head 5. Cutting device guard 6. Front handle 7. Rear handles with controls controls and refuelling 21. Engine stop switch 22. Throttle trigger 23. Throttle trigger lockout 24. Sp...

Page 4: 2. Symbols

4 2. Symbols on the equipment, there are information symbols. These convey important information about the product or information about the use. Caution: special safety measures are required when handing the unit! The entire operating instructions must be read and understood before use. Non -observa...

Page 5

5 12. Specification of the guaranteed sound power level lwa in db. 13. Caution! Hot surfaces – risk of burns! 14. Symbol on the choke lever lever in cold start position (start) lever in warm start position (run) 15. Symbol of fuel pump: press the fuel pump 10x before starting. 16. Mix ratio 40:1, us...

Page 6: 3. Safety Requirements

6 3. Safety requirements a) training 1) read the instructions carefully. Become acquainted with the controls and the proper use of the machine. Learn how to stop the engine quickly. 2) only use the machine for the purpose for which it was designed, namely - cutting grass and non-woody vegetation, us...

Page 7

7 2) warning: danger! Petrol is highly flammable: - keep the fuel in containers which have been specifically manufactured and homologated for such use; - never smoke when handling fuel; - slowly open the fuel tank to allow the pressure inside to decrease gradually; - top up the tank with fuel in the...

Page 8

8 c) operation 1) do not start the engine in a confined space where dangerous carbon monoxide fumes car collect. 2) mow only in daylight or good artificial light. 3) take on a firm and well-balanced position: - where possible, avoid working on wet, slippery ground or in any case on uneven or steel g...

Page 9

9 - if the machine starts to vibrate abnormally: find and remove the cause of the vibration immediately; - when the machine is not in use. D) maintenance and storage 1) keep all nuts, bolts and screws tight to be sure the equipment is in safe working condition. Routine maintenance is essential for s...

Page 10

10 f) how to read the manual certain paragraphs in the manual contain particularity significant information and are marked with various levels of highlighting with the following meaning: or these give details or further information on what has already been said, in the aim to prevent damage to the m...

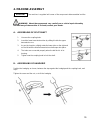

Page 11: 4. Machine Assembly

11 4. Machine assembly the machine is supplied with some of the components disassembled and the fuel tank empty. Warning! Mount the components very carefully so as slot to impair the safety and efficiency of the machine. If in doubt, contact your dealer. A. Assembling of split shaft 1. Unscrew the c...

Page 12

12 c. Assembling of plastic guard and of line cutter unscrew the plastic guard. Slide the plastic guard along the lower transmission shaft, up to the « u » part, provided for this purpose. Place the plastic guard on the « u » aligning its holes with those of the « u » part. Tighten the screw and tig...

Page 13: 5. Preparing To Work

13 5. Preparing to work checking the machine before starting work please: - check that ail the screws on the machine and the cutting device are tightly fastened; - check that the air filter is clean; - check that the protection devices are well fastened and working efficiently; - check the handgrips...

Page 14

14 for synthetic oil, add 2, 5% oil to gasoline (refer to indications of oil), it means 2, 5 cl of oil per 100 cl petrol. Preparation and preservation of the fuel mixture danger! Petrol and the fuel mixture are highly inflammable! - keep the petrol and fuel mixture in homologated fuel containers, in...

Page 15

15 danger! Never smoke whilst refueling and avoid inhaling the petrol fumes. Warning! Carefully open the tank top as pressure could have formed inside. Before refueling: shake the fuel mixture container well. Place the machine on a flat stable surface, with the fuel tank cap facing upwards. Clean th...

Page 16

16 6. How to start - use - stop the engine starting the engine warning! The engine must be started in an area at least 3 meters from where you refilled the fuel tank. Before starting the engine: - ensure that the protective cap on the line cutter has been removed. - place the machine firmly on the g...

Page 17: Warning!

17 • pour slowly to avoid splash back and allow air to escape from the fuel tank. • close the tank cap securely by turning it clockwise as far as it will do. Warning! Never fill the tank so the fuel level rises into the filler neck. If the tank is overfilled, heat may cause the fuel to expand and ov...

Page 18: Warning!

18 6. Hold the equipment firmly with one hand on the shaft tube. With the other hand, pull the starter cable several times on the starter handle until the engine starts. Pull the recoil starter grip slowly to engage the starter, and then give a short, quick pull. Caution! Do not pull the starter cab...

Page 19

19 8. Adjusting fuel adjustment the carburetor has been adjusted to the optimum fuel supply at the factory. Don’t reset the carburetor setting. Note: if adjustment is needed, if should be performed by your authorized dealer. 10. Attach the equipment to the shoulder strap that has been put on (see ch...

Page 20

20 • keep an eye on the cutting head. • never cut above shoulder height. • never replace the plastic cord with a steel wire – risk of injury and damage. • do not work on a ladder. • work only on firm and stable bases. • always carry the equipment suspended by the shoulder strap or on the tube. Worki...

Page 21: 7. Using The Machine

21 7. Using the machine to respect people and the environment: - try not to cause any disturbance. - scrupulously comply with local regulations and provisions for the disposal of waste materials alter sawing. - scrupulously comply with local regulations and provisions for the disposal of oils, petro...

Page 22

22 warning! The use of metal or rigid blades of any type with this machine is prohibited. Working techniques warning! Use only nylon lines. The use of metal lines plasticized metal lines and/or lines not suitable for the head can cause serious injuries and wounds. During use it is advisable to stop ...

Page 23

23 cutting near fences / foundations slowly approach the cutting line head to fences, posts, rocks, walls, etc. Without hitting them hard. If the line strikes a solid object it could break or become worn; if it gets tangled in a fence it could break abruptly. In any case, cutting around pavements, f...

Page 24

24 8. Maintenance and storage correct maintenance is essential to maintain the original efficiency and safety of the machine over time. Warning! During maintenance operations: - remove the spark plug cap. - wait until the engine is sufficiently cold. - never dispose of oils, fuel or other polluting ...

Page 25

25 - leave the filter to dry in the open air. - fit the filter element and the cover back on. Checking the spark plug periodically remove and clean the spark plug using a metal brush to get rid of any deposits. Check and reset the correct distance between the electrodes. Replace the spark plug and f...

Page 26

26 head line replacement follow the instructions for replacing the nylon line. 1- firmly hold the body of the cutting head and unscrew the bumper cover. 2- remove the empty spool. Remove the line remaining on the spool. 3- remove the spring. 4- clean the interior of the spool body carefully. 5- take...

Page 27

27 sharpening the line cutter - unscrew the two nuts and remove the line cutting knife from the guard. - let sharpen the cutting knife an authorized service workshop. - refit the knife on the guard. Extraordinary maintenance ail maintenance operations not foreseen in this manual must be performed ex...

Page 28

28 restarting work when you wish to start using the machine again: - remove the spark plug. - pull the starter rope a few times to eliminate excess oil. - check the spark plug as described in chapter "checking the spark plug". - prepare the machine as indicated in the paragraph entitled "preparing f...

Page 29: 9. Troubleshooting

29 9. Troubleshooting problem likely cause solution 1) the engine will not start or will not keep running incorrect starting procedure dirty spark plug or incorrect distance between the electrodes air filter clogged carburetion problems follow the instructions check the spark plug clean and/or repla...

Page 30: Guarantee

30 10. Disposal / environmental protection machinery does not belong in domestic waste. Do not allow used oil and petrol residues into the sewer system or drains. Dispose of used oil and petrol residues in an environmentally friendly way – take them to a disposal point. Take the equipment, accessori...

Page 31

31 11. Technical specifications engine ...................................................................................................... 2-stroke air-cooled capacity / power ...................................................................................... 29.7 cm 3 / 0.76 kw engine rotatio...

Page 32

Ec declaration of conformity serial number : pls see front page we,company, gardif 60 ave de bruxelles z.A. De l’europe 77310 ponthierry france the undersigner, bruno van elslande, managing director, declare that the product petrol trimmer: lawnking models lk prt3043 auto – ref. Cbt911251 (model prt...