- DL manuals

- Lawn-King

- Brush Cutter

- FW53E

- Original Instructions For Use

Lawn-King FW53E Original Instructions For Use

WARNING:

Read the instructions before using the product

Before initial start-up, please read through these operating instructions carefully

prior to using the machine. Keep the instructions safe and pass them on to any

subsequent user so that the information is always available.

Serial Number:

Translation of the original instructions for use

PETROL

BRUSHCUTTER

LK FW53E

Model FW53E

Summary of FW53E

Page 1

Warning: read the instructions before using the product before initial start-up, please read through these operating instructions carefully prior to using the machine. Keep the instructions safe and pass them on to any subsequent user so that the information is always available. Serial number: trans...

Page 2: Contents

2 contents contents intended use safety information symbols general description assembly operation maintenance and service troubleshooting storage disposal / environmental protection guarantee technical specifications ce 2 3 3 8 10 13 18 25 30 31 32 32 33 34.

Page 3: Warning!

3 when the thread reel is used, the motorized trimmer is suitable for cutting grass in the garden, along border edges and around trees or fence posts. When the metal cutting blade is used, the equipment cuts grass, weeds or light plant growth. The equipment is intended exclusively for private use. A...

Page 4

4 general safety information 1. Observe the surrounding conditions under which you are working. The motorized equipment produces toxic fumes as soon as the engine is running. These gases may be odourless and invisible. Therefore, never work with the equipment in enclosed or poorly ventilated spaces....

Page 5: Warning!

5 • always switch off the engine before filling. Always open the filler cap with care, so any excess pressure present can be relieved slowly and no fuel sprays out. The work with the equipment causes high temperatures on the housing. The equipment must therefore be allowed to cool before filling. Ot...

Page 6

6 caution! A certain residual risk, which cannot be eliminated, always remains even in the case of proper use of the tool. The following potential hazards can be derived from the type and design of the tool: • contact with the unprotected cutting head (cuts). • reaching into the scythe when it is ru...

Page 7

7 precautions to prevent recoil 12. The greatest care is required when extending the cutting thread. Risk of injury from cuts. After executing these processes, reassume the correct working position before switching on the equipment. 13. Do not use metallic cutting reels or saw blades. Note that the ...

Page 8: Symbols

8 on the equipment, there are information symbols. These convey important information about the product or information about its use. • caution: special safety measures are required when handing the equipment! • the entire operating instructions must be read and understood before use. Nonobservance ...

Page 9

9 10. Specification of the guaranteed sound power level lwa in db. 11. Maximum rotational frequency of the spindle. 12. Conforms to current standards. 13. Mix ratio 50:1, use only fuel mix 15. Gasoline is extremely flammable and explosive. Stop engine before refueling. 16. Exhaust gas contains carbo...

Page 10: General Description

10 general description 21 small cable clamps 22 multi-function control handle 23 carry ring for shoulder strap 1 5 3 2 4 6 7 8 9 23 22 21 12 10 11 13 20 19 18 17 16 15 14 pic 1 1 engine housing 2 fuel tank 3 starter handle with starter cable 4 choke lever 5 air filter cover 6 ignition cable 7 muffle...

Page 11

11 functional description the manually operated and portable motorized strimmer is driven by a combustion engine, which operates without interruption during the work. The power transmission is by means of a clutch disc, which transmits the output to the cutter via a centrifugal clutch at high speed....

Page 12

12 the equipment has an automatic double thread reel as the cutter as well as a metal cutting blade, which can be fitted optionally. In the cutting process, two nylon lines or four metal blades rotate about an axis vertical to the cutting level. To protect the user, the equipment has a protective de...

Page 13: Assembly

13 1. Turn counterclockwise to loosen handle adjustment knob (12) and take off top handle holder (32). 2. Place bike handle (11) in the handle slot, close bottom handle holder (29) with top handle holder (32). 3. Insert handle adjustment knob (12) through handle holder (32, 29), spring (30) and hand...

Page 14

Installing/removing the metal cutting blade wear protective gloves when handling the metal cutting blade. Dismantling the nylon head is described in the section on « installing/removing the nylon head ». 14 1 2 installing the metal blade guard (picture 5): 1. If applicable, unscrew the top (33b) and...

Page 15

15 check that the pin is removed from the hole on the gear housing before starting the engine. Removing the metal cutting blade (picture 6): 5. To lock the axle, push maintenance locking pin (25) sideways into the hole provided on the gear housing (19) and on the bottom flange (33a). 6. Unscrew the ...

Page 16

16 installing/removing the nylon head (picture 7): installing the guard: 1. Screw the guard (15) onto the metal blade guard (20) using the 3 screws and nuts (36) enclosed. Installing the nylon head : 2. Screw the nylon head (16) anticlockwise onto the cutting head holder by hand, as indicated in the...

Page 17

17 avoid direct skin contact with petrol and the inhalation of petrol fumes. Health hazard! The equipment is fitted with a two-stroke engine and therefore operated exclusively with a mix of petrol and two-stroke engine oil in the ratio 50:1. • use quality unleaded petrol with an octane rating of at ...

Page 18: Warning!

18 observe the following points in particular: • check the cutting tools for damage and wear. • correct installation of the cutting head • easy movement of all switches • secure sit of the spark plug connector. If the connector is loose, sparks can be formed and thus ignite any leaking fuel • ensure...

Page 19: Warning!

19 1. Fuel • level the engine before fueling. • open the fuel tank cap and fill the fuel tank with 50:1 gas/oil-mixed fuel. • pour slowly to avoid splash back” and allow air to escape from the fuel tank. • close the tank cap securely by turning it clockwise as far as it will do. Starting the engine ...

Page 20

20 note: • this engine is designed so that overflowed fuel due to pushing a priming pump is to be returned to the fuel tank. • there is no fear of flooding the engine, so push the priming pump enough times to get the engine started. Move the choke lever to the “closed” position. Move the throttle le...

Page 21: Warning!

21 warning! Releasing the starting rope suddenly may allow the rope to whip around and cause injury and/or damage the recoil starting mechanism. When starting the engine, firmly grasp the recoil starter grip; do not grasp the starter rope itself. Always control the rope as it rewinds into the housin...

Page 22

22 note • should the engine fail to start, do not try the recoil start many times with the choke lever to the “closed” position. This will cause the fuel to flood into the cylinder and make starting even more difficult. In this case, set the choke lever to the “open” position. And then, repeat the s...

Page 23

23 note: if adjustment is needed, if should be performed by your authorized kawasaki dealer. 10. Attach the equipment to the shoulder strap that has been put on (see chapter on “putting on the shoulder strap”). 11. To mow, hold the throttle lock (41) depressed and operate the throttle (42). 12. Stop...

Page 24

24 • do not work on a ladder. • work only on firm and stable bases. • always carry the equipment suspended by the shoulder strap or on the tube. Working with the nylon head • on small grass areas, hold the equipment at an angle of approx. 30° and turn evenly to the right and left with a semi-circula...

Page 25: Maintenance and Service

25 • when working, hold the cutting head over the ground and swing the equipment slowly to and fro in an even curve, like a line trimmer. • do not hold the cutting blade at an angle. • do not use the equipment to cut uncontrolled growth, undergrowth or scrub. • check the metal cutting blade regularl...

Page 26

26 7. Screw the nylon head (16) anticlockwise onto the drive shaft. 8. Trim the lines to approx. 13 cm in order to strain the engine less in the start and warm-up phase. Sharpening the line cutter engine maintenance: wear protective gloves to avoid cutting injuries. 1. Unscrew the line cutter (14) f...

Page 27

27 fuel tank cap service a breather passage is incorporated in the tank cap. If the breather passage is clogged, the fuel will not flow into the carburetor, causing problems with starting or running the engine. At the same time, make sure that the base of the breather assembly is fitted firmly into ...

Page 28

28 every 20 hours of operation 1. Pull the fuel filler out from the fuel tank. 2. Clean the fuel filter in a bath of high flash point solvent. 3. Dry the fuel filter and reinstall it into the fuel tank. Every 50 hours of operation 1. Switch off the equipment. 2. Take the spark plug cap with fingers,...

Page 29

29 6. Check the spark plug cap and reset it if necessary. The cap must be between 0.6mm and 0.7mm. To change the gap, bend only side-electrode, using a spark plug tool. 7. Install and tighten the spark plug to 14n.M(1.4kgf.M) 8. Fit the spark plug cap on the spark plug securely. 9. Pull up the spark...

Page 30: Troubleshooting

30 troubleshooting.

Page 31: Storage

31 general storage instructions • clean the equipment and accessories carefully before storage. • keep the equipment in a dry and dustproof place out of reach of children. • do not wrap the equipment in plastic bags, as damp and mould may form. • do not store the equipment on the protective cover; i...

Page 32: Guarantee

32 guarantee • we guarantee this equipment for 24 months. • the guarantee does not cover damage caused by natural wear, overloading or improper use. Certain components are subject to normal wear and not covered by the guarantee. These specifically include the: metal cutting blade, cutting line spool...

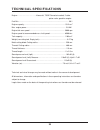

Page 33: Technical Specifications

33 engine……………………………kawasaki, tj53e forced air-cooled, 2 stoke piston valve, gasoline engine. Fuel mix........................................................................................................ 50:1 engine capacity............................................................................

Page 34

Ec declaration of conformity serial number : pls see front page we,company, gardif 60 ave de bruxelles z.A. De l’europe 77310 ponthierry france the undersigner, bruno van elslande, managing director, declare that the product petrol brush cutter: lawnking models lk fw53e - ref dbt911259 (model fw53e)...