- DL manuals

- LC Packings

- Medical Equipment

- 161403

- User Manual

LC Packings 161403 User Manual

Summary of 161403

Page 1

D960r3 probot tm micro fraction collector user’s manual p/n 161403 www.Lcpackings.Com.

Page 2

Ii d960r3 user’s manual probot notice: the probot ™ micro fraction collector is covered by a limited warranty. A copy of this warranty is included with this manual. The customer is required to perform routine maintenance as described in the user’s manual on a periodic basis to keep the warranty in e...

Page 3

User’s manual probot d960r3 iii table of contents warranty vii liability viii instructions for returning instruments ix warnings xi safety precautions xi chapter 1 introduction 1-1 1.1 features of the probot ™ micro fraction collector 1-1 1.2 general design of the probot micro fraction collector 1-2...

Page 4

Table of contents iv d960r3 user’s manual probot 2.6.4 necessary steps to create and run the application 2-13 2.6.5 the main toolbar 2-14 2.7 µcarrier – first steps 2-15 2.7.1 launching µcarrier 2-15 2.7.2 using the predefined applications, trays and sample carriers 2-17 2.7.2 a loading a predefined...

Page 5

Table of contents user’s manual probot d960r3 v appendix a dosage module purge routine 1 a.1 overview 1 a.1.1 the step-by-step purge routine 1 appendix b peak collection in conjunction with chromeleon® software 1 b.1 overview 1 b.2 contact closure signals for peak detection with chromeleon 2 b.3 set...

Page 6

Table of contents vi d960r3 user’s manual probot [this page intentionally left blank].

Page 7

User’s manual probot d960r3 vii warranty lc packings (netherlands) bv, warrants that the products manufactured and sold by it to be free from defects in material and workmanship for normal use and service from the date of delivery to original purchaser for a period of one (1) year from the date of s...

Page 8

Warranty viii d960r3 user’s manual probot liability under no circumstances shall lc packings be liable for damage to persons or property. This warranty is the only warranty given by lc packings with respect to products and software provided with the products and is given in lieu of all other warrant...

Page 9

User’s manual probot d960r3 ix instructions for returning instruments before you return any item for repair, please contact the nearest lc packings office or its local distributor for instructions and obtain a return authorization number and the ‘health and safety form’ (if applicable). Pack the equ...

Page 10

Instructions for returning instruments x d960r3 user’s manual probot [this page intentionally left blank].

Page 11

User’s manual probot d960r3 xi warnings the danger sign, warning sign and the caution sign shown below are included in various locations in this manual. These signs provide the following information: danger danger: the information in a danger statement relates to a procedure, practice condition or a...

Page 12

Warnings and safety precautions xii d960r3 user’s manual probot 3) if a leak occurs, turn off power to the instrument and remedy the situation immediately. 4) all components of the system should be plugged into a common power line that is directly connected to a true ground. 5) always replace blown ...

Page 13: Declaration of Conformity

User’s manual probot d960r3 xiii declaration of conformity we lc packings nederland bv a dionex company abberdaan 114 1046 aa amsterdam the netherlands declare that our product probot ™ micro fraction collector is in confirmation with the following documents: # eec directives 89/392, incl. 91/368 an...

Page 14

Ce declaration xiv d960r3 user’s manual probot [this page intentionally left blank].

Page 15: Introduction

User’s manual probot d960r3 1-1 chapter 1 introduction 1.1 features of the probot ™ micro fraction collector the lc packings probot micro fraction collector is a robotic fraction collector that can be used to collect samples from a capillary hplc or cze system and deposit onto targets such as a mald...

Page 16

Introduction 1-2 d960r3 user’s manual probot 1.2 general design of the probot micro fraction collector the general configuration of the system (with sample deposition on a maldi target and the dosage module option) is presented in figure 1-1. X flow cell wa st e fi ll wa sh y z needle capillary µ- t...

Page 17

Introduction user’s manual probot d960r3 1-3 the following options are available for the probot: • manual control unit – allows for moving the sample table manually. • dosage module – the dosage module consists of a 4 way rotary valve with a syringe drive and a 100 µ l syringe. It can be used in dif...

Page 18

Introduction 1-4 d960r3 user’s manual probot 1.3 front view of probot light pencil light switch rotary valve leds µ-tee with needle power switch dosage module (optional) target x-y-z drive table adapter camera (optional) figure 1-2 front view probot - doors and needle cover removed 1.4 the manual co...

Page 19

Introduction user’s manual probot d960r3 1-5 1.5 rear view of probot power connector video out relay connector interlock connector rs-232 connector start connector analog in connector ttl in connector remote connector figure 1-4 rear view probot 1.6 control of the probot micro fraction collector the...

Page 20

Introduction 1-6 d960r3 user’s manual probot 1.7 about this manual this manual describes the lc packings probot micro fraction collector and includes the following information: chapter 2: installation and getting started describes how to install the probot and the µ carrier software. It includes the...

Page 21

User’s manual probot d960r3 2-1 chapter 2 installation and getting started 2.1 installation the instructions provided below are provided for installation of the lc packings probot micro fraction collector as part of the lc packings capillary hplc system or for installing the instrument as a stand-al...

Page 22

Installation and getting started 2-2 d960r3 user’s manual probot 2.1.1 location of probot in the laboratory the probot micro fraction collector should be installed in a facility with the following environmental conditions: • the temperature range should be maintained between 10 and 40 o c. The syste...

Page 23

Installation and getting started user’s manual probot d960r3 2-3 2.2 unpacking when the probot micro fraction collector is received, carefully unpack the unit and verify receipt of all components according to the packing list (some components include sub-packing lists). It is recommended that all pa...

Page 24

Installation and getting started 2-4 d960r3 user’s manual probot 2.3.1 removing the top cover to remove the top cover of the probot: a) remove the needle cover that covers the needle tee. B) remove the left door and right door by simply lifting them few centimeters (item 1; figure 2-1). 4 3 2 1 top ...

Page 25

Installation and getting started user’s manual probot d960r3 2-5 2.3.2 drive table safety brackets two safety brackets (two pieces of metal) are used to secure the drive table as shown in figure 2-3. To remove the drive table safety brackets: a) remove the top cover as described in section 2.3.1. B)...

Page 26

Installation and getting started 2-6 d960r3 user’s manual probot 2.4 installing the probot with the ultimate capillary hplc system the following section describes how to install the probot micro fraction collector as a component in the lc packings ultimate capillary hplc system. 2.4.1 electrical con...

Page 27

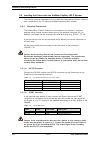

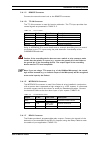

Installation and getting started user’s manual probot d960r3 2-7 2.4.1 c remote connector connect the manual control unit to the remote connector. 2.4.1 d ttl in connector the ttl in connector is used for fraction collection. The ttl input provides four control signals as presented in table 2-3. Tab...

Page 28

Installation and getting started 2-8 d960r3 user’s manual probot table 2-5 the relay cable output pin no. Color code description 1 brown relay 1, normally open 2 red relay 1, common relay 4 3 orange relay 1, normally closed 4 pink relay 2, normally open 5 yellow relay 2, common relay 3 6 green relay...

Page 29

Installation and getting started user’s manual probot d960r3 2-9 2.4.2 fluidic connections for fraction collection 2.4.2 a connecting the µ-tee for matrix addition the probot micro fraction collector should be installed as near as possible to the ultimate capillary hplc system. Since the µ-tee is lo...

Page 30

Installation and getting started 2-10 d960r3 user’s manual probot d) depending on your application, either connect the matrix tubing (section 2.4.2 b) or use the blind plug provided with the accessories to plug the third needle tee port. 2.4.2 b connecting the dosage module the dosage module (option...

Page 31

Installation and getting started user’s manual probot d960r3 2-11 2.5 software installation the following section describes the installation of the µ carrier software, version 2.0. Please refer to the ‘readme’ file provided on the µ carrier cd rom for additional information and updated instructions....

Page 32

Installation and getting started 2-12 d960r3 user’s manual probot 2.6 introduction to the µ carrier ™ software the following sections provide a basic introduction in the µ carrier liquid handling application designer software (v2.0) and information of how to setup and use the software. For more deta...

Page 33

Installation and getting started user’s manual probot d960r3 2-13 2.6.2 design of µcarrier the µ carrier liquid handling application designer software (v2.0) is built around the following three basic components: • the sample carrier – represents the target (e.G. A maldi target or a microtiter plate)...

Page 34

Installation and getting started 2-14 d960r3 user’s manual probot 2.6.5 the main toolbar the main toolbar (figure 2-7), which is presented in the upper left of the main window of µcarrier (figure 2-10) presents several buttons: figure 2-7 the main toolbar removes the tray and all tasks in the task l...

Page 35

Installation and getting started user’s manual probot d960r3 2-15 2.7 µcarrier – first steps 2.7.1 launching µcarrier when µcarrier is opened for the first time, the following window appears (figure 2-8): figure 2-8 the run a real device? Window a) choose the yes button if you want to control probot...

Page 36

Installation and getting started 2-16 d960r3 user’s manual probot figure 2-10 the main window of µ carrier with table if desired, µ carrier can be configured so that it does not show some the previous dialogs on each start. Select the options menu in the main window to open the options window (figur...

Page 37

Installation and getting started user’s manual probot d960r3 2-17 2.7.2 using the predefined applications, trays and sample carriers in addition to the predefined sample carriers and trays, µcarrier v2.0 provides ready-to-use applications for the most common used maldi ms instruments. These applicat...

Page 38

Installation and getting started 2-18 d960r3 user’s manual probot task list parameters of the selected task group definitions figure 2-13 application editor - application loaded all tasks of this application are loaded in the task list and the parameters of a selected task (row) are displayed in the...

Page 39

Installation and getting started user’s manual probot d960r3 2-19 2.7.3 alignment of the sample carriers the following procedure needs to be performed to define the exact position of the sample carriers on the table relative to the needle tip (including the ‘spotting height’). During this procedure ...

Page 40

Installation and getting started 2-20 d960r3 user’s manual probot c) follow the steps of the wizards by choosing the next button. The origin of the reference sample carrier will start to blink for a better identification. D) choose the ‘manual drive panel’ of µcarrier (section 2.8.5 a) or the ‘manua...

Page 41

Installation and getting started user’s manual probot d960r3 2-21 2.7.4 checking and modifying application parameters the next step is to check and/or modify the application parameters. After the application parameters have been checked/modified, the alignment of the sample carriers should be checke...

Page 42

Installation and getting started 2-22 d960r3 user’s manual probot f) to remove the group, make sure that it is not used as ‘collect group’ or ‘standby position’ in a task, e.G. ‘users’ must be ‘0’ (item 1, figure 2-17). Unselect if appropriate, and then use the delete group button. Note: there is no...

Page 43

Installation and getting started user’s manual probot d960r3 2-23 2.7.4 c checking/modifying the task parameters to check or modify the task parameters, select the task that needs to be checked in the task list. The task parameter box (e.G. Basic fractionation) will be presented in the application e...

Page 44

Installation and getting started 2-24 d960r3 user’s manual probot the time elapsed after the task was started exceeds this limit. In the case all spots have been processed, the run also stops. In both cases µcarrier will prepare the next task. The time per spot(s) is the actual spotting time. This t...

Page 45

Installation and getting started user’s manual probot d960r3 2-25 2.8 µcarrier – basics steps the following sections discus the basis steps of the µcarrier software. We show how to • create a new sample carrier using the sample carrier wizard – section 2.8.1. • create a new tray using the tray setup...

Page 46

Installation and getting started 2-26 d960r3 user’s manual probot 2.8.1 create a new sample carrier using the sample carrier wizard if the required sample carrier is not pre-defined, it has to be created. The sample carrier wizard assists you in creating a new sample carrier as well as modifying an ...

Page 47

Installation and getting started user’s manual probot d960r3 2-27 spot (well, vial). Based on this information the spot volume is calculated. In our example the shape is ‘circular’, the ‘diameter’ is 1.000 mm and the ‘height’ is 0.000 mm. Enter this data and confirm with the next button. Figure 2-23...

Page 48

Installation and getting started 2-28 d960r3 user’s manual probot figure 2-24 sample carrier wizard - sample carrier geometry f) now enter the number of spots in x and y direction (e.G. 24 by 24 in our example) and the distance (e.G. 1.45 mm) between the rows and the columns. The wizard automaticall...

Page 49

Installation and getting started user’s manual probot d960r3 2-29 figure 2-26 sample carrier wizard - completed h) either quit the wizard or continue to define or modify the next sample carrier. The sample carrier editor (figure 2-27) offers the same settings as the wizard, but all at the same scree...

Page 50

Installation and getting started 2-30 d960r3 user’s manual probot 2.8.2 create a new tray using the tray setup wizard if the required tray is not predefined, it has to be created. The tray setup wizard assists you in creating a new tray setup as well as modifying an existing one. A) open the tray ed...

Page 51

Installation and getting started user’s manual probot d960r3 2-31 figure 2-30 tray setup wizard – selecting a sample carrier e) if you want to place multiple carriers (of the same type) press the right mouse button, and then select the add multiple carriers .. ‘ option (figure 2-31). Enter the appro...

Page 52

Installation and getting started 2-32 d960r3 user’s manual probot f) if you want to add another sample carrier, or if you want to define a waste or a wash position, select the add another sample carrier option and repeat the steps above (figure 2-32). Figure 2-32 tray setup wizard – 6 sample carrier...

Page 53

Installation and getting started user’s manual probot d960r3 2-33 figure 2-33 tray editor with the 6 sample carriers b) click the add sample carrier icon and the list of sample carriers is presented in the browser pane. Select a carrier and wait until the preview is generated. C) double-click on the...

Page 54

Installation and getting started 2-34 d960r3 user’s manual probot 2.8.4 create a new application using the wizard depending on the requirements and complexity of a specific application, various parameters need to be defined to achieve the best performance. This can make it difficult for even an expe...

Page 55

Installation and getting started user’s manual probot d960r3 2-35 figure 2-35 the fractionation application wizard – welcome screen e) select the appropriate tray and choose next (figure 2-36). Figure 2-36 the fractionation application wizard – selecting a tray f) the ‘fraction control mode’ will be...

Page 56

Installation and getting started 2-36 d960r3 user’s manual probot figure 2-37 the fractionation application wizard – fraction control mode the following modes are available: • time – the fractionation is controlled by time. The intervals are specified in seconds and can be as low as 4 seconds. Time ...

Page 57

Installation and getting started user’s manual probot d960r3 2-37 • multiple injections, collect each run in a new group - multiple lc runs are collected in the same number of groups. Typically, one group refers to one sample carrier. A group can also use multiple carriers or multiple groups can be ...

Page 58

Installation and getting started 2-38 d960r3 user’s manual probot figure 2-39 the fractionation application wizard – lc parameters i) to add reagent (matrix) solution to the lc flow, select the add a reagent option in the ‘reagent addition’ screen of the fractionation application wizard . Choose if ...

Page 59

Installation and getting started user’s manual probot d960r3 2-39 figure 2-40 the fractionation application wizard – reagent addition specifications j) to specify the spots that should be used during the lc run, select a group from the list and frame the spots while keeping the left mouse pressed. O...

Page 60

Installation and getting started 2-40 d960r3 user’s manual probot k) select the pattern in which the spots are be used. Define the pattern for all groups and confirm all settings with the next button. Figure 2-42 the fractionation application wizard – standby position l) as the last step of the grou...

Page 61

Installation and getting started user’s manual probot d960r3 2-41 on default the probot table moves to its lowest position (0.0 mm) for all horizontal movements. This means, when moving from one spot to the next the table first moves down to its lowest position, and then it moves up upon arrival at ...

Page 62

Installation and getting started 2-42 d960r3 user’s manual probot figure 2-44 the fractionation application wizard – completed the last screen of the wizard (figure 2-44) offers three options. • align the sample carriers – select this option if no alignment was performed with the sample carriers bef...

Page 63

Installation and getting started user’s manual probot d960r3 2-43 figure 2-45 the application editor in the application editor you can modify the application by changing task parameters, deleting tasks or adding tasks. From the application editor the run can be started by clicking the run icon. Duri...

Page 64

Installation and getting started 2-44 d960r3 user’s manual probot 2.8.5 control the table position manually the robot table can be controlled either by drive control panel of the µ carrier software or by the manual control unit (optional, in conjunction with the µ carrier software only). Caution cau...

Page 65

Installation and getting started user’s manual probot d960r3 2-45 figure 2-48 the xyz robot module section b) choose the external button to control the position of the table manually with the manual control unit (figure 1-3 on page 1-4). C) to control the position of the table: • choose the x+ and x...

Page 66

Installation and getting started 2-46 d960r3 user’s manual probot the following section describes the procedure how to measure the dimensions of your sample carrier by using the manual control of the probot. A) using one of the remote control options, move the table so that the needle is positioned ...

Page 67

Installation and getting started user’s manual probot d960r3 2-47 2.8.7 default calibration and acceleration settings the setup of the calibration and acceleration parameters is important for a proper operation of the probot micro fraction collector (figure 2-49). In the case of a malfunction of the...

Page 68

Installation and getting started 2-48 d960r3 user’s manual probot [this page intentionally left blank].

Page 69: Maintenance and

User’s manual probot d960r3 3-1 chapter 3 maintenance and troubleshooting 3.1 overview this chapter provides information to assist in optimizing the performance of the probot ™ micro fraction collector and maintaining it in your laboratory. It includes the following material: • maintenance – describ...

Page 70

Maintenance and troubleshooting 3-2 d960r3 user’s manual probot 3.2 maintenance maintenance refers to a variety of activities that should be performed on a routine basis to optimize performance of the system. Many routine maintenance activities can be readily performed by the user. In some cases (e....

Page 71

Maintenance and troubleshooting user’s manual probot d960r3 3-3 3.3 replacing major components a variety of components on the probot micro fraction collector can be readily changed by the user as required to ensure that the instrument is maintained in optimal condition. In some circumstances the ana...

Page 72

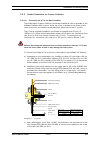

Maintenance and troubleshooting 3-4 d960r3 user’s manual probot 3.3.2 installing the video camera a camera kit (p/n 160590) which allows for easy monitoring of the needle and target(s) is available as an option. To install the video camera: a) locate the nut close to in the support bar to the µ-tee ...

Page 73

Maintenance and troubleshooting user’s manual probot d960r3 3-5 3 4 1 5 2 figure 3-3 replacing the syringe b) loosen the screw of the clamp that holds the syringe and turn the clamp by 90 degrees (item 3; figure 3-3). C) carefully lift the syringe and pull the plunger tip out of the spring clip. D) ...

Page 74

Maintenance and troubleshooting 3-6 d960r3 user’s manual probot c) remove the cover plate (items 4; figure 3-4). D) disconnect the connector of the dosage unit (figure 3-5). 1 figure 3-5 disconnecting the dosage module e) remove the two screws that hold the module (figure 3-6). Figure 3-6 removing t...

Page 75

Maintenance and troubleshooting user’s manual probot d960r3 3-7 to replace the fused silica needle fractionation needle: a) remove the fluidic connections on the upper and right µ-tee, remove the ground cable. B) unscrew the mounting screw (item 5, figure 3-2) and remove the µ-tee from the mounting ...

Page 76

Maintenance and troubleshooting 3-8 d960r3 user’s manual probot 3.3.6 replacing the standard needle to replace the hollow stainless steel needle (p/n 161375): a) remove the fused silica capillary from the needle tee and hollow needle. B) remove the needle cover to get access to the needle tee. C) lo...

Page 77

Maintenance and troubleshooting user’s manual probot d960r3 3-9 3.3.8 replacing the main fuse danger danger: disconnect the instrument from the electrical supply before inspecting/changing the fuse. Replace the blown fuse by a fuse of identical type and rating. To change the fuse: a) pull out the fu...

Page 78

Maintenance and troubleshooting 3-10 d960r3 user’s manual probot 3.4 troubleshooting troubleshooting refers to the determination of the cause of a problem. Since the probot micro fraction collector is typically incorporated into an hplc system, the first step is to determine if the problem is due to...

Page 79

Maintenance and troubleshooting user’s manual probot d960r3 3-11 3.5 spare parts lists 3.5.1 major items p/n description 160560 probot™ incl. Software, microdosage unit and manual control, without table 161467 probot™ incl. Software and manual control, without microdosage unit, without table 161374 ...

Page 80

Maintenance and troubleshooting 3-12 d960r3 user’s manual probot 3.5.3 spare parts p/n description figure 161402 light bulb for pen-light for probot standard needle tee 162158 probot™ needle tee for coaxial addition of matrix solution, incl. 3 fingertight fittings and screws 161375 standard needle f...

Page 81

Maintenance and troubleshooting user’s manual probot d960r3 3-13 rotary valve 161382 rotary valve for probot 161732 probot tubing kit 0.5 mm i.D. Tefzel tubing, 2 x 40 cm, 1x 15 cm, 1x 65 cm, incl. Fittings 163678 1/4-28 tube end fitting, knurled head, 1/16 peek housing 161093 door left, acrylic (wi...

Page 82

Maintenance and troubleshooting 3-14 d960r3 user’s manual probot 161401 table for compact disk for 1 cd 161392 table micromass for 6 rectangular targets 160580 table for nanospray needle holder n/a 160579 table for two well plates/micro titer plates 160577 table pvdf / pvdf, dual collect 160576 univ...

Page 83: Specifications

User’s manual probot d960r3 4-1 chapter 4 specifications 4.1 physical table movement x axis 195 mm y axis: 135 mm z axis: 95 mm table speed x axis: 0.250 to 20 mm/sec y axis: 0.250 to 10 mm/sec z axis: 0.125 to 10 mm/sec table positioning precision better than 20 µ m reference position all axes are ...

Page 84

Specifications 4-2 d960r3 user’s manual probot 4.3 electrical connections remote remote, x, y, z rs-232 9600 baud, 8 bit, 1 stop bit, no parity start remote start input ttl inputs ttl1 (peak start), ttl2 (peak end), ttl 3 (peak top), ttl4 outputs 4 relay outputs hv off hv switch off (safety feature ...

Page 85: Dosage Module Purge Routine

User’s manual probot d960r3 a-1 appendix a dosage module purge routine a.1 overview the dosage module (optional) is provided to add a reagent solvent (e.G. A matrix solution) to the mobile phase flow. The figures presented below are provided to describe the step-by-step procedure of how to remove ai...

Page 86

Appendix a a-2 d960r3 user’s manual probot to purge the dosage module: a) switch the rotary valve into the pump position, remove the syringe (figure a-2) and push the piston all the way forward to remove any air or solvent left. Refer to section 3.3.3 for more information about how to replace the sy...

Page 87

Appendix a user’s manual probot d960r3 a-3 wa st e fill au x reagent vials syringe drive dosage module pump fill purge rotary valve needle tee µ-tee or figure a-4 step 3 – purge the tubing d) switch the rotary valve back into the fill position, withdraw the reagent solvent and fill the syringe compl...

Page 88

Appendix a a-4 d960r3 user’s manual probot g) switch the valve into the purge position and purge again (figure a-6). Refill the syringe in the fill position. Wa st e fill sp are reagent vials syringe pump dosage module pump fill purge pump fill rotary valve needle tee µ-tee or figure a-6 step 5 – re...

Page 89: With Chromeleon® Software

User’s manual probot d960r3 b-1 appendix b peak collection in conjunction with chromeleon® software b.1 overview this appendix describes how to setup the probot ™ micro fraction collector for peak collection in conjunction with the chromeleon ® software. The peak detection capabilities of chromeleon...

Page 90

Appendix b b-2 d960r3 user’s manual probot b.2 contact closure signals for peak detection with chromeleon the following example uses three relay outputs of the ultimate micropump. The relay 1 (event output 7) will generate the ‘peak start’ signal while relay 2 (event output 8) will generate the ‘pea...

Page 91

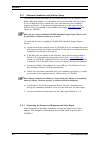

Appendix b user’s manual probot d960r3 b-3 b.3 setting up µ-carrier for peak collection the following sections describe how to setup the µ carrier (v2.0) software for peak collection. The probot micro fraction collector is controlled via external contact signals (start, ttl inputs). The detected pea...

Page 92

Appendix b b-4 d960r3 user’s manual probot to setup the fractionation task: a) set the collection control mode to external on the general tab (figure b-4). Figure b-4 general settings of the fractionation task b) enter the flow rate of the lc system and the calculated volume between the detector flo...

Page 93

Appendix b user’s manual probot d960r3 b-5 d) if you want µ carrier to prevent overfilling of the vessels, activate overfill control . The probot will then automatically move to the next fraction when the vessel is full (calculated by vessel volume and flow rate). E) for the remote start of µ carrie...

Page 94

Appendix b b-6 d960r3 user’s manual probot follow the steps a) – g) as discussed above except that you define one waste position rather than a group. The ‘type’ must be ‘reagent’. Figure b-8 the group editor b.4 electrical connections to control the ttl inputs of the probot (section 2.4.1 d) by the ...

Page 95

Appendix b user’s manual probot d960r3 b-7 masterpressure.Lowerlimit = 1.0 masterpressure.Upperlimit = 400.0 data_collection_rate = 2 timeconstant = 0.1 wait sampler.Ready injectmode = fullloop lowdispersionmode = off useairsegment = off useheadspace = off syringespeed = normal syringespeedfactor = ...

Page 96

Appendix b b-8 d960r3 user’s manual probot b.6 additional hints/troubleshooting for the proper handling of a fractionation task and to make sure that no peak is lost, it is important to calculate or measure the delay time between the flow cell of the detector (where the peak is detected) and the fra...

Page 97: Table Alignment Instructions

User’s manual probot d960r3 c-1 appendix c table alignment instructions c.1 overview this appendix provides information about how to check the alignment of the table of the probot ™ micro fraction collector and how to align it. Proper alignment is important to make certain that the distance of the f...

Page 98

Appendix c c-2 d960r3 user’s manual probot c.2 table alignment to check the table alignment (x and y), the manual control unit (in conjunction with the µ carrier software) is used to manually move the table. Before performing any check or aligning of the table, the probot instrument must be properly...

Page 99

Appendix c user’s manual probot d960r3 c-3 b) select manual device control from the tools menu or choose the manual device control button to open the ‘xyz robot module’ and ‘dosage module’ window (figure c-12). Figure c-12 the robot section c) select the external button to gain control of the probot...

Page 100

Appendix c c-4 d960r3 user’s manual probot c) move the table from one side to the other (x-direction) and check that the needle is centered above the groove and that the distance to the needle tip remains constant. D) move the table to the front and to the back (y-direction) and check that the dista...

Page 101

Appendix c user’s manual probot d960r3 c-5 4 3 do not unscrew use for alignment 5 6 figure c-15 aligning the y-direction note: do not loosen screw labeled ‘3’ in figure c-15 when you are removing screws 4 – 6. Loosening all screws at the same time may lead to a misalignment of the limiter switches o...

Page 102

Appendix c c-6 d960r3 user’s manual probot [this page intentionally left blank].

Page 103: The Vacuum Waste Removal

User’s manual probot d960r3 d-1 appendix d the vacuum waste removal option d.1 overview this appendix describes the features and usage of the vacuum waste removal option. This option is provided as a factory installed option only. If your probot micro fraction collector does not include this option,...

Page 104

Appendix d d-2 d960r3 user’s manual probot d.2 general design a lift magnet controls the position of the standard needle tee and the hollow stainless steel needle which guides the fused silica capillary. Depending on the position of the needle tee, the tip of the fused silica capillary is either ins...

Page 105

Appendix d user’s manual probot d960r3 d-3 d.3 setting up the probot the following sections describe the steps that are needed to setup and to adjust the probot to use the vacuum waste removal option successfully. D.3.1 electrical connections the start input is used to start the µcarrier application...

Page 106

Appendix d d-4 d960r3 user’s manual probot d.3.3 installing the fused silica capillary to install and adjust the fused silica capillary properly in the needle tee, follow the instructions below: a) depending on your application (e.G. Capillary or nano lc) use either the 30 µ m i.D. Fused silica capi...

Page 107

Appendix d user’s manual probot d960r3 d-5 d.4 setting up µcarrier and chromeleon ® the following sections provide basic information of how to setup µcarrier software to control the waste removal option properly. In addition, an example is provided which shows usage of this option in conjunction wit...

Page 108

Appendix d d-6 d960r3 user’s manual probot c) select the needledown button and that the stainless steel needle covers the tip of the fused silica capillary (figure d-1). D) calibrate all sample carriers (position and height) with the stainless steel needle in the down position (e.G. The fused silica...

Page 109

Appendix d user’s manual probot d960r3 d-7 e) set the ‘collection control mode’ to ‘external’. F) select the destination tab (figure d-8). Figure d-8 destination tab of the fractionate task g) set the ‘use special z –coordinate .. ‘ so that the needle tip rests 2 mm above the target. H) select the ‘...

Page 110

Appendix d d-8 d960r3 user’s manual probot d.5 listing of the chromeleon example program oven.Tempctrl = off pump.%a.Equate = "%a" %b.Equate = "%b" %c.Equate = "%c" %d.Equate = "%d" diameter = 300um length = 15cm stationaryphase = c18_3um_100a parkpercentage = disabled masterpressure.Lowerlimit = 0....

Page 111

Appendix d user’s manual probot d960r3 d-9 trigger peakend uv_vis_1 - 0.03, true=2.00 pump_relay_2.State = on pump_relay_2.Duration = 1.00 endtrigger 30.000 %b = 50 31.000 %b = 90 36.000 %b = 90 36.100 %b = 0 55.000 uv_vis_1.Acqoff pumppressure.Acqoff columnpressure.Acqoff pump.Flow = 4.000 %b = 0 %...

Page 112

Appendix d d-10 d960r3 user’s manual probot [this page intentionally left blank].

Page 113: Installing and Using The

User’s manual probot d960r3 e-1 appendix e installing and using the belkin ™ usb video adapter e.1 installation of the belkin ™ videobusii ™ image capture device this appendix describes the installation and the usage of the belkin usb video adapter. This adapter is included with the camera option (p...

Page 114

Appendix e e-2 d960r3 user’s manual probot e.2 software installation and µcarrier setup the following section describes how to install the drivers for the support of the belkin usb video adapter. The necessary drivers are provided with the µcarrier v2.0 cd rom and can be copied onto your hard disk u...

Page 115

Appendix e user’s manual probot d960r3 e-3 video input (yellow) bnc cable bnc to video adapter figure e-1 connection of the probot camera after connecting, switch on the probot and start µcarrier to check if the camera image is displayed. Note: the camera is powered by the probot. The probot must be...

Page 116

Appendix e e-4 d960r3 user’s manual probot e.2.2 saving a the current image or recording a sequence select the save button and enter a file name to save the current image (screenshot). The image will be stored as a bit map (‘bmp’ format). Select the play button and enter a file name to start recordi...

Page 117

Appendix e user’s manual probot d960r3 e-5 e.2.4 troubleshooting if no video image is visible, check the correct settings of µcarrier first. If the settings appear correct, check to see if the belkin videobusii device is installed properly. To check the µcarrier settings: a) start µ carrier 2.0, sel...

Page 118

Appendix e e-6 d960r3 user’s manual probot e.3 uninstall instructions note: the belkin videobusii device must be plugged in to uninstall it. Look for any question or exclamation marks in front of any of the selections, if you see one in front of ‘belkin’ or ‘unknown usb devices’, remove these select...