- DL manuals

- Legend

- Indoor Fireplace

- DV36

- Owner's Manual

Legend DV36 Owner's Manual

Summary of DV36

Page 1

Owners manual of direct-vent gas fireplace dv36(ng) legend fireplace co.,ltd a b c d e f mm 1248 942 873 993 420 445.

Page 2: Installers Guide

2 installers guide - do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance. - what to do if you smell gas • do not try to light any appliance. • do not touch any electrical switch. • do not use any phone in your building. • immediately call...

Page 3

3 safety and warning information note: not intended for fireplace insert. Do not modify this appliance. Do not place articles on or against this appliance. Do not use or store flammable materials near this appliance. Do not spray aerosols in the vicinity of this appliance while it is in operation. D...

Page 4

4 table of contents safety and warning information ................................................ ……………..3 section 1: approvals and codes .............................................……………….5 appliance certification................................................................... ……………..5 instal...

Page 5

5 1 approvals and codes appliance certification the legend fireplace models discussed in this installers guide have been tested to certification standards. Certification model: dv36 type: direct vent gas fireplace heaters standard: as4553-2008 installation codes this fireplace shall be installed onl...

Page 6

6 report to your dealer any parts damaged in shipment particularly the condition of the glass. Do not install any unit with damaged, incomplete, or substitute parts. The vent system components and trim doors are shipped in separate packages. The gas logs are packaged separately and must be field ins...

Page 7

7 factory-built fireplace chases should be constructed in the manner of all outside walls of the home to prevent cold air drafting problems. The chase should not break the outside building envelope in any manner. This means that the walls, ceiling, base plate and cantilever floor of the chase should...

Page 8

8 step 2. Framing the fireplace fireplace framing can be built before or after the fireplace is set in place. Framing should be positioned to accommodate wall coverings and fireplace facing material. Unit assembly prior to installation the top facing support, the side nailing strips and the 2 top st...

Page 9

9 step 3. Installing the vent system a. Vent system approvals this model is approved to use flo-met direct vent components and terminations .Approved vent system components are labeled for identification. The pipe is tested to be run inside an enclosed wall. There is no requirement for inspection op...

Page 10

10 flue outlet settings horizontal flue configuration: fully open vertical flue configuration: baffle set to 28mm open (flue termination @ 4.5m above floor level)* vertical flue configuration: baffle set to 32mm open (flue termination @ 2.5m above floor level)* *flue outlet opening was measured from...

Page 11

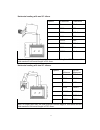

11 horizontal venting with one 90º elbow. Options v minimum h maximum a 0 914.4 b 304.8 1524 c 609.6 2438.4 d 914.4 3048 e 2438.4 3048 f 2743.2 2438.4 g 3048 1524 h 3352.8 914.4 note: for longer pipe runs, the total minimum vertical length is 3352.8mm and the total maximum horizontal length is 914.4...

Page 12

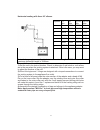

12 horizontal venting with three 90º elbows. Options v1 min h1 max v1+v2 min h1+h2 max a 0 609.6 609.6 914.4 b 304.8 914.4 1219.2 1219.2 c 609.6 914.4 1828.8 1524 d 914.4 914.4 2438.4 1828.8 e 1219.2 1219.2 3048 2133.6 f 1524 1524 3352.8 2438.4 g 1828.8 1828.8 3657.6 2743.2 h 2133.6 2133.6 3962.4 30...

Page 13

13 direct vent zero clearance top exit vertical flue kit installation instructions this flue kit has been manufactured in accordance with as5601 2002.To ensure safety this flue kit must be installed as outlined in these instructions. Heater and flue clearancs from combustible walls and framing must ...

Page 14

14 5) mark the wall for a 254x254mm square hole. The center of the square hole should line up with the centerline of the horizontal pipe. Cut and frame the square hole in the exterior wall where the vent will be terminated. Note: a) the horizontal run of vent must be level, or have a 6.35mm rise for...

Page 15

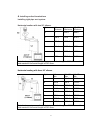

15 b. Installing vertical terminations installing rigid pipe vent system: horizontal venting with two 90º elbows. Options v1 minimum h maximum v1+v2 minimum a 0 914.4 609.6 b 304.8 1524 914.4 c 609.6 1828.8 1219.2 d 914.4 2133.6 1524 e 1219.2 2438.4 1828.8 f 1524 2743.2 2133.6 note: for longer pipe ...

Page 16

16 1) maintain the 32mm clearances (air spaces) to combustibles when passing through ceilings, walls, roofs, enclosures, attic rafter, or other nearby combustible surfaces. Do not pack air spaces with insulation. Check the "venting arrangement" section for the maximum vertical rise of the venting sy...

Page 17

17 the upper half of the flashing is installed under the roofing material and not nailed down until the chimney is installed. This allows for small adjustments. 6) continue to assemble pipe lengths. Note: if an offset is necessary in the attic to avoid obstructions, it is important to support the ve...

Page 18

18.

Page 19

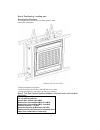

19 step 4. Positioning, leveling, and securing the fireplace the diagram below shows how to properly position, level, and secure the fireplace. • place the fireplace into position. • level the fireplace from side to side and from front to back. • secure the fireplace to the framing by nailing or scr...

Page 20

20 step 6. The gas supply line gas line installation the gas line is brought through the right of the appliance. The gas valve is situated on the right hand side of the unit and the gas inlet is on the right hand side of the valve. The gas line connection may be made of rigid pipe, copper pipe (if y...

Page 21

21 pilot adjustment periodically check the pilot flames. Correct flame pattern has three strong blue flames:1 fl owing around the thermopile, 1 around the thermocouple and 1 fl owing across the burner (it does not have to be touching the burner). Note: if you have an incorrect flame pattern, contact...

Page 22

22 s.I.T. Valve description step 7. Gas pressure requirements pressure requirements for legend gas fireplaces are shown in the table below. Pressure natural gas inlet gas pressure 1.13kpa manifold pressure 0.87kpa caution: ensure that the wires do not touch any hot surfaces and are away from sharp e...

Page 23

23 caution: label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing. Step 8. Finishing the following diagram shows the minimum vertical and corresponding maximum horizontal dimensions of firepla...

Page 24

24 hearth extensions step 9. Position brick panels, logs, log ember and glowing material and remote control. Brick panels (optional panel models may be installed in different manner) 1) undo the bottom 2 door latches and open and remove glass door. Remove logs. Note: the logs must not be in the unit...

Page 25

25 positioning the logs.

Page 26

26 the logs have been packed separately, refer to thefollowing pics to position the log ember, the glowing material and log set. If sooting occurs, the logs might need to be repositioned slightly to avoid excessive flame impingement. If logs are broken do not use the unit until they are replaced. Br...

Page 27

27 note: please make sure the log do not cover the holes on burner pan, and make sure the log set could not obstruct the flame, if not, the sooting will soon deposit. Installation of standard flush door the standard flush door comes with a black frame. To install the frame, simply hook the top door ...

Page 28

28 the receiver. Install the receiver and its cover in the wall. Switch the remote receiver to "remote" mode. The remote control is now ready for operation. Warning: if the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons in order to a...

Page 29

29 lighting procedure the legend fireplace are equipped with electric spark ignitor box. Important: to ignite and reignite the pilot, you must first open the bottom louver. Important gas on/off knob cannot be turned from "pilot" to "off" unless it is partially depressed. Note: if appliances fails to...

Page 30

30 the lighting plate instructions.

Page 31

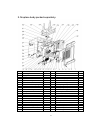

31 4 maintaining and servicing your fireplace part list: warning: servicing shall be carried out only by authorized personnel. A set of dv36 includes the unit and the log set packed separately. 1. Standard log set includes 6 pcs of log from a to f, one for each..

Page 32

32 2. Fireplace body packed separately. No name qty no name qty 1 bottom grill 1 22 side and back frame 1 2 top grill 1 23 spacer 1 3 front frame 1 24 air box outside guider part2 1 4 mesh frame 1 25 air box assembly 1 5 glass assembly 1 26 side standoff 8 6 glass frame 1 27 inner exhausting base 1 ...

Page 33

33 cleaning and maintenance make sure the gas valve knob is in the “off” position. Wait at least five (5) minutes before starting maintenance. Fireplace must be cold before starting maintenance. Venting system a qualified agency should examine the venting system annually. Cleaning glass caution let ...

Page 34

34 troubleshooting standing pilot ignition symptom possible cause action 1. Spark ignitor will not light pilot. A. Wire disconnected. B. Defective ignitor. C. No gas or low gas pressure. D. Batteries not fitted or batteries flat. A. Open door and check to make sure wire is connected to ignitor. B. C...

Page 35

35 to the thermopile, adjust pilot flame. C. Check thermopile wire connections to make sure all are tight and that the thermopile is fully inserted into pilot assembly. Check thermopile with a millivolt meter. Connect leads to tp and tp/th terminals on the control valve. If meter reading is below 32...

Page 36

36 troubleshooting general troubleshooting symptom possible cause action 1. Glass soots a. Smoke occur in flame a. Position the ceramic fibre log set correctly, make sure the log set could not obstruct the flame 2. Flame burn blue and lifts off burner (ghosting) a. Insufficient oxygen being supplied...

Page 37

37 limited lifetime warranty policy lifetime warranty one year warranty the following components are warranted for 1 year to the original owner, subject of proof of purchase: all component of the direct vent gas fireplace basic warranty legend warrants the components and materials in your gas applia...