- DL manuals

- Lochinvar

- Water Heater

- 000 - 500

- Installation & Service Manual

Lochinvar 000 - 500 Installation & Service Manual

Installation & Service Manual

Models: 90,000 - 500,000 Btu/hr

This manual supplies information for the

installation, operation, and servicing of the

appliance. It is strongly recommended that this

manual be reviewed completely before proceeding

with an installation. Perform steps in the order

given. Failure to comply could result in severe

personal injury, death, or substantial property

damage.

WARNING:

Save this manual for future reference.

CFA-I-S Rev A

Summary of 000 - 500

Page 1

Installation & service manual models: 90,000 - 500,000 btu/hr this manual supplies information for the installation, operation, and servicing of the appliance. It is strongly recommended that this manual be reviewed completely before proceeding with an installation. Perform steps in the order given....

Page 2

2 hazard definitions the following defined terms are used throughout this manual to bring attention to the presence of hazards of various risk levels or to important information concerning the life of the product. Danger warning caution caution notice danger indicates an imminently hazardous situati...

Page 3

3 installation & service manual please read before proceeding notice this is a gas appliance and should be installed by a licensed electrician and/or certified gas supplier. Service must be performed by a qualified service installer, service agency or the gas supplier. Warning if the information in ...

Page 4

4 installation & service manual please read before proceeding warning to minimize the possibility of serious personal injury, fire, or damage to your appliance, never violate the following safety rules: 1. Boilers and water heaters are heat producing appliances. To avoid damage or injury, do not sto...

Page 5

5 ratings maximum allowed working pressure is located on the rating plate. Notice installation & service manual copper-fin i=b=r rating model number note: change “n” to “l” for l.P. Gas models. Input mbh (note 4) min max gross output mbh (note 1) net i=b=r ratings water, mbh (note 2) cbn315 158 315 ...

Page 6

6 ratings installation & service manual notes: 1. Copper-fins require special gas venting. Use only the vent materials and methods specified in the installation and service manual. 2. The copper-fin is orificed for operation up to 2000 feet altitude. The ap pli ance will be derated 4% per 1000 feet ...

Page 7

7 installation & service manual the copper-fin - how it works... 1. Control panel cover the control panel cover provides access to the thermostat, ignition module, and transformer. 2. Drain port (not shown) location from which the heat exchanger can be drained. 3. Flue outlet the flue outlet allows ...

Page 8

Installation & service manual 8 models cwn270 front view model cwn399 (inside unit) model cwn399 front view model cwn270 (inside unit) the copper-fin - how it works... 3 1 10 9 11 5 21 15 16 22 6 12 8 4 14 23 7 13 1 3 10 16 15 21 5 11 9 6 7 13 23 4 22 14 12 8.

Page 9

9 installation & service manual the copper-fin - how it works... (continued) model cbn500 (inside unit) model cbn500 front view models cbn399 (inside unit) model cbn399 front view 3 1 20 10 16 15 11 9 5 6 12 8 14 22 23 4 7 3 1 20 10 16 15 5 11 9 6 12 4 14 8 7 23 22.

Page 10

10 installation & service manual 1 determine unit location notice clearances from combustible construction are noted on the appliance rating plate. Location of unit 1. Locate the appliance so that if water connections should leak, water damage will not occur. When such locations cannot be avoided, i...

Page 11

11 installation & service manual 1 determine boiler location figure 1-3_ combustion air direct from outside combustion and ventilation air requirements for conventionally vented appliances provisions for combustion and ventilation air must be in accordance with the latest edition of the national fue...

Page 12

12 1 determine boiler location installation & service manual 4. If a single combustion air opening is provided to bring combustion air in directly from the outdoors, the opening must be sized based on a minimum free area of one square inch per 3000 btu/hr (7 cm 2 per kw). This opening must be locate...

Page 13

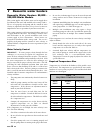

1 determine boiler location (continued) 13 installation & service manual table - 1b minimum recommended combustion air supply to equipment room input btu/hr *outside air from 2 openings directly from outdoors *outside air from 1 opening directly from outdoors, in 2 *outside air from 2 ducts delivere...

Page 14

14 installation & service manual 2 venting the distance of the vent terminal from adjacent build ings, windows that open and building open ings must comply with the latest edition of the national fuel gas code, ansi z223.1, in canada, the latest edition of cga standard b149 in stal la tion code for ...

Page 15

2 venting (continued) 15 installation & service manual locate appliance as close as possible to a chimney or gas vent. Avoid long horizontal runs of the vent pipe, 90° el bows, reductions and restrictions. Horizontal por tions of the venting system shall be supported to prevent sagging. Horizontal r...

Page 16

16 2 venting installation & service manual vertical vent termination clearances figure 2-2_ vent termination from peaked roof 10' or less from ridge figure 2-4_ vent termination from flat roof 10' or less from parapet wall figure 2-3_ vent termination from peaked roof more than 10' from ridge figure...

Page 17

2 venting (continued) 17 installation & service manual masonry chimney installation a masonry chimney must be properly sized for the installation of a gas fired appliance. Venting of an appliance into a cold or oversized masonry chimney can result in op er a tion al and safety problems. Exterior mas...

Page 18

18 2 venting installation & service manual automatic vent damper this heating boiler is design certified for use with the automatic vent damper (fig. 2-7) part number printed on the boiler’s rating plate. A vent damper is optional on heating boilers above 360,000 btu/hr. Automatic vent dampers are n...

Page 19

19 installation & service manual 3 gas connections gas supply verify that the appliance is supplied with the type gas spec i fied on the rating plate. This appliance is orificed for operation up to 2000 feet altitude. The ap pli ance will be derated 4% per 1000 feet above 2000 feet el e va tion. Con...

Page 20

20 3 gas connections installation & service manual table - 3e multiple appliance installations gas piping size chart nominal iron pipe size inches length of pipe in straight feet maximum capacity of pipe in thousands of btu/hr per hour for gas pressures of 13.5 inches water column (0.5 psig) or less...

Page 21

3 gas connections (continued) 21 installation & service manual apply wrench to flange only when flange is used apply wrench from bottom of gas control to either shaded area when flange is not used figure 3-2_ wrench 8. For l.P. Gas, consult your l.P. Gas supplier for expert installation. Important u...

Page 22

22 installation & service manual checking gas supply pressure gas valve manometer gas supply pressure union figure 3-4_ gas supply pressure 1. Turn the power “off” at the main dis con nect switch. 2. Turn gas valve control knob(s) to the “off” position. 3. The 500,000 btu/hr model will have two gas ...

Page 23

3 gas connections (continued) 23 installation & service manual combination gas valves wiring terminals pressure regulator adjustment (under cap screw) inlet pressure tap gas control knob pilot outlet outlet pressure tap pressure regulator adjustment (under cap screw) inlet pressure tap red reset but...

Page 24

24 4 hydronic piping installation & service manual relief valve figure 4-1_ relief valve - cbn315-500 this appliance is supplied with a relief valve(s) sized in accordance with asme boiler and pressure ves sel code, section iv (“heating boilers”). The re lief valve(s) is mounted directly into the he...

Page 25

4 hydronic piping (continued) 25 installation & service manual a water flow switch meets most code re quire ments for a low-water cut off device on boil ers requiring forced cir cu la tion for operation. Low water cutoff (if equipped) a hot water boiler installed above radiation level must be provid...

Page 26

26 4 hydronic piping installation & service manual 9. Inspect the liquid level in the expansion tank. The system must be full and under normal operating pressure to ensure proper water level in the expansion tank. Ensure that diaphragm type ex pan sion tanks are properly charged and not water logged...

Page 27

4 hydronic piping (continued) 27 installation & service manual hot water pip ing must be supported by suitable hangers or floor stands, not by the boiler. Copper pipe systems will be subject to considerable expansion and con trac tion. Rigid pipe hangers could allow the pipe to slide in the hanger r...

Page 28

28 4 hydronic piping installation & service manual pump installation and main te nance: the boiler circulating pump must be purchased lo cal ly. For installation and maintenance information on the circulator pump, refer to the pump man u fac tur ers in struc tion package included with the pump. The ...

Page 29

4 hydronic piping (continued) 29 installation & service manual low temperature bypass requirements this piping is like a primary/secondary boiler installation with a bypass in the secondary boil er piping. Inlet water temperatures below 140°f (60°c) can excessively cool the prod ucts of combustion r...

Page 30

30 4 hydronic piping installation & service manual primary / secondary piping expansion tank air separator pressure reducing valve back flow preventer ball valve (typical) union (typical) pressure relief valve flow check valve (typical) boiler temperature / pressure gauge pressure gauge drain drain ...

Page 31

4 hydronic piping (continued) 31 installation & service manual figure 4-5_ single boiler - primary / secondary with low temperature bypass expansion tank air separator pressure reducing valve back flow preventer ball valve (typical) union (typical) pressure relief valve flow check valve (typical) bo...

Page 32

32 4 hydronic piping installation & service manual primary / secondary piping figure 4-8_ multiple boilers zoned with circulators expansion tank air separator pressure reducing valve back flow preventer ball valve (typical) pressure relief valve (typical) flow check valve (typical) indirect dhw tank...

Page 33

5 electrical connections 33 installation & service manual this appliance is wired for 120 vac service. The appliance, when installed, must be electrically ground ed in accordance with the requirements of the authority having jurisdiction or in the absence of such re quire ments, with the latest edit...

Page 34

34 5 electrical connections installation & service manual pump wiring for a heating boiler the heating boiler circulating pump must be pur chased locally. The max i mum load for the pump switched by the internal pump relay must not exceed 1 hp. The current draw for a field installed 120 vac pump mus...

Page 35

5 electrical connections (continued) 35 installation & service manual locating temperature control remove the control panel door on the front of the unit in order to locate and access the temperature control. Temperature control settings remove the control panel door on the front of the unit unless ...

Page 36

36 5 electrical connections installation & service manual temperature control sensors this is a two-stage temperature control (m9/f9) that controls the burner ignition and pump functions. This temperature controller can measure up to three different sensor inputs, depending upon how the unit is set ...

Page 37

5 electrical connections (continued) 37 installation & service manual installation of a remote sensor (boiler application) 1. Turn off the main electrical power and the main manual gas shutoff to the appliance. 2. Remove the side access panel from the appliance to gain access to the thermostat. 3. L...

Page 38

38 5 electrical connections installation & service manual shutdown the shutdown knob specifies the outdoor air lockout temperature at which the control would prevent the unit from operating. Outdoor air max (o.A. Max) the o.A. Max knob allows a reset up to the maximum outdoor air temperature specifi...

Page 39

5 electrical connections (continued) 39 installation & service manual manual reset high water temperature limit control (standard fixed settings on boilers and water heaters with optional adjustable settings) water heaters are supplied with a fixed setting, manual reset high water temperature limit ...

Page 40

40 6 start-up installation & service manual initial start-up follow the lighting instructions on the label applied to the appliance. A. On water heaters and boilers with the system pump delay option, the operating temperature control will energize the pump relay which energizes the pump on a call fo...

Page 41

6 start-up (continued) 41 installation & service manual lighting instructions 1. Stop! Read the safety information (page 40). 2. Remove the control panel door. 3. Set the thermostat to the lowest setting (off). 4. Turn off all electrical power to the appliance. 5. Turn the gas control knob on the ga...

Page 42

42 6 start-up installation & service manual 10. Use the loop end of the wire lighting wand, shipped with the instruction pack age, to hold the match and reach the pi lot. An access slot is provided in the lower front jacket panel, beside the burner, to insert the lighting wand and match to the pilot...

Page 43

6 start-up (continued) 43 installation & service manual lighting instructions for spark ignition pilot models (f9/m9) models 90,000 through 500,000 btu/hr input for your safety read before operating warning if you do not follow these instructions exactly, a fire or explosion may result causing prope...

Page 44

44 6 start-up installation & service manual to turn off gas to appliance 1. Set the thermostat to the off position. 2. Turn off all electric power to the appliance if service is to be performed. 3a. 90,000 - 135,000 and 399,999 - 500,000 btu/hr models, rotate the gas control knob on the gas valve cl...

Page 45

6 start-up (continued) 45 installation & service manual 6. Shut-down and draining - if for any rea son, the appliance is to be shut off, the following precautionary measures must be taken: (a) shut off gas supply. (b) shut off water supply. (c) shut off electrical supply. (d) drain the unit complete...

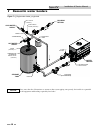

Page 46

46 7 domestic water heaters installation & service manual domestic water heaters 90,000 - 500,000 btu/hr models this section applies only to those units used to sup ply direct fired domestic hot water and installed with a storage tank(s). The use of a properly sized pump and the control of water vel...

Page 47

7 domestic water heaters (continued) 47 installation & service manual water chemistry the required temperature rise and the standard pump sizing are based on the heating of potable water with chemistry within the specified limits. Caution should be used when heating water softened to less than 5 gra...

Page 48

48 installation & service manual 7 domestic water heaters figure 7-1_ single water heater_single tank flow check valve (typical) expansion tank thermometer cold water supply hot water supply building return drain temperature & pressure relief valve (typical) flow switch water heater circulator stora...

Page 49

49 installation & service manual 7 domestic water heaters (continued) figure 7-2_ single water heater_multiple tank flow check valve (typical) ball valve (typical) expansion tank thermometer cold water supply hot water supply building return drain (typical) temperature & pressure relief valve (typic...

Page 50

50 7 domestic water heaters installation & service manual figure 7-3_ multiple water heater_single tank thermometer hot water supply drain temperature & pressure relief valve (typical) flow switch ( typical ) water heater circulator ( typical) storage tank water heater union (typical) ball valve (ty...

Page 51

7 domestic water heaters (continued) 51 installation & service manual minimum pump performance based on heating potable water with a hardness of 8 to 25 grains per gallon and total dissolved solids not exceeding 350 ppm. See “water chemistry”, page 47. Btu/hr input gpm ft. Hd. 90,000 - 500,000 30 8 ...

Page 52

52 installation & service manual 7 domestic water heaters caution setting the temperature selector to high er settings provides hotter water, which in creas es the risk of scald injury. The manufacturer recommends the use of a prop er ly sized thermostatic mixing valve to supply do mes tic hot water...

Page 53

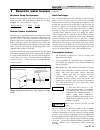

53 installation & service manual 7 domestic water heaters (continued) figure 7-8_ relief valve - water heater figure 7-9_ water flow switch, water heater relief valve relief valve flow switch flow this appliance is supplied with a relief valve sized in accordance with asme boiler and pressure ves se...

Page 54

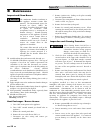

54 installation & service manual 8 maintenance and annual startup service technician (see the following pages for instructions) general: • address reported problems • inspect interior; clean and vacuum if necessary; • check for leaks (water, gas, flue) • examine venting system • check system water p...

Page 55

8 maintenance (continued) 55 installation & service manual follow the service and maintenance procedures given throughout this manual and in component literature shipped with the appliance. Failure to perform the service and maintenance could result in damage to the appliance or system. Failure to f...

Page 56

56 8 maintenance installation & service manual check expansion tank 1. Expansion tanks provide space for water to move in and out as the heating system water expands due to temperature increase or contracts as the water cools. Tanks may be open, closed, diaphragm or bladder type. See section 4 - hyd...

Page 57

Installation & service manual 8 maintenance (continued) 57 check all wiring 1. Inspect all wiring, making sure wires are in good condition and securely attached. Check control settings 1. Adjust settings if necessary. See section 5 - electrical connections for adjustment procedures. 2. Check setting...

Page 58

58 8 maintenance installation & service manual avoid breathing dust and contact with skin and eyes. • use niosh certified dust respirator (n95). This type of respirator is based on the osha requirements for cristobalite at the time this document was written. Other types of respirators may be needed ...

Page 59

8 maintenance (continued) 59 installation & service manual p. Check “v” baffles on top of the heat ex chang er. Remove and clean if necessary. Q. Remove soot from the heat exchanger with a stiff bristle brush. Soot may also be re moved from the heat exchanger by washing thoroughly with detergent and...

Page 60

8 maintenance 60 installation & service manual important upon completion of any testing on the gas system, leak test all gas connections with a soap solution while main burners are operating. Im me di ate ly repair any leak found in the gas train or re lat ed components. Do not operate an appliance ...

Page 61

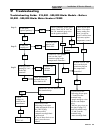

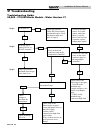

9 troubleshooting 61 installation & service manual troubleshooting guide: 315,000 - 500,000 btu/hr models - boilers 90,000 - 500,000 btu/hr water heaters f9/m9 step 1: step 2: step3: is the spark ignitor sparking? No yes check continuity on the spark cable. Check for 24 vac on the 24v terminal (gray...

Page 62

9 troubleshooting 62 installation & service manual step 1: step 2: step 3: is the pilot lit? Yes is the gas valve getting 24vac to the mv terminal? Yes check gas pressure and make sure the gas valve knob is on no check gas pressure. Check the pilot assembly and thermocouple. Clean the thermocouple a...

Page 63

10 diagrams 63 installation & service manual schematic diagram - f1 unit 90,000 - 270,000 btu/hr models wiring diagram - f1 unit 90,000 - 270,000 btu/hr models.

Page 64

10 diagrams 64 installation & service manual schematic diagram - f9 unit 315,000 - 399,999 btu/hr models wiring diagram - f9 unit 315,000 - 399,999 btu/hr models.

Page 65

65 installation & service manual 10 diagrams (continued) schematic diagram - m9 unit 315,000 - 399,999 btu/hr models box depicts optional items 120v line 120 neutral ground 24vdc relay circulation pump mot 120v transformer 24v cn1-1 operator cn1-2 1 low water 2 cutoff 5 vent damper 3 r w thermostat ...

Page 66

66 schematic diagram - f9/m9 unit 500,000 btu/hr models wiring diagram - f9/m9 unit 500,000 btu/hr models 10 diagrams installation & service manual.

Page 67

67 notes.

Page 68

Revision a (eco #c06290) initial release. Cfa-i-s rev a 09/10