- DL manuals

- Lochinvar

- Water Heater

- COPPER-FIN II CF-1261

- Designer's Manual

Lochinvar COPPER-FIN II CF-1261 Designer's Manual

Summary of COPPER-FIN II CF-1261

Page 1

Designer’s guide copper-fin ii ® water heater 4 0 0 , 0 0 0 – 2 , 0 7 0 , 0 0 0 b t u / h r.

Page 2

Dear specifier/project manager, at lochinvar, we have long recognized the importance of innovation to any product or service. Those who enter into business must also accept the challenge of meeting constantly changing needs. The designer’s guide you are now holding has been designed to make it more ...

Page 3: Table of Contents

L o c h i n v a r d e s i g n e r ’ s g u i d e c o p p e r - f i n i i w a t e r h e a t e r 6 1 5 - 8 8 9 - 8 9 0 0 1 codes . . . . . . . . . . . . . . . . . . . . . . . . .2 combustion & ventilation air . . . . . . . . .6 contaminants . . . . . . . . . . . . . . . . . . . .7 determining total “fr...

Page 4: Codes

Codes the equipment shall be installed in accordance with those installation regulations in effect in the local area where the installation is to be made. These shall be carefully followed in all cases. Authorities having jurisdiction shall be consulted before installations are made. In the absence ...

Page 5

The indoor units must be installed so that the ignition system components are protected from water (dripping, spraying, rain, etc.) during appliance operation and service (circulator replacement, control replacement, etc.). The appliance must be installed on a level, non-combustible floor. Concrete ...

Page 6: Special Location:

4 l o c h i n v a r d e s i g n e r ’ s g u i d e c o p p e r - f i n i i w a t e r h e a t e r 6 1 5 - 8 8 9 - 8 9 0 0 outdoor models require the installation of an optional vent cap. Instructions for placement of the vent cap are included in the venting section. Outdoor models must not be installe...

Page 7

L o c h i n v a r d e s i g n e r ’ s g u i d e c o p p e r - f i n i i w a t e r h e a t e r 6 1 5 - 8 8 9 - 8 9 0 0 5 (fig. 3) water heater equipment and control orientation. Operator interface panel gas connection drain left side operator interface panel burner inspection port front air inlet hot...

Page 8: Combustion & Ventilation Air

6 l o c h i n v a r d e s i g n e r ’ s g u i d e c o p p e r - f i n i i w a t e r h e a t e r 6 1 5 - 8 8 9 - 8 9 0 0 combustion & ventilation air provisions for combustion and ventilation air must be in accordance with section 5.3, air for combustion and ventilation, of the latest edition of the ...

Page 9: Contaminants

Area of one square inch for each 1000 btu (22cm 2 per kw) of input, but not less than 100 square inches (645 cm 2 ). If a single combustion air opening is provided to bring combustion air in directly from the outdoors, the opening must be sized based on a minimum free area of one square inch per 300...

Page 10

8 l o c h i n v a r d e s i g n e r ’ s g u i d e c o p p e r - f i n i i w a t e r h e a t e r 6 1 5 - 8 8 9 - 8 9 0 0 category i double wall vent (or equivalent) connectors and sized according to vent sizing tables (fan column) in the latest edition of the national fuel gas code. The category i ve...

Page 11: Venting Options

Must be consistent with the national fuel gas code z223.1 or in canada, the latest edition of cga standard b149 installation code for gas burning appliances and equipment. Venting options conventional venting a conventional venting system utilizes the natural buoyancy of the heated flue products to ...

Page 12

10 l o c h i n v a r d e s i g n e r ’ s g u i d e c o p p e r - f i n i i w a t e r h e a t e r 6 1 5 - 8 8 9 - 8 9 0 0 for this type of installation, it is best to use a draft control for each water heater located on the riser between the vent outlet and the breeching - location “a”. When this ris...

Page 13

Powered sidewall vent kits models cf401-751 utilize a powered vent cap which has a fan mounted inside the cap. The powered vent cap must be placed on an exterior wall. The powered sidewall vent cap and accessories are included in a venting kit, which must be furnished by lochinvar in accordance with...

Page 14

The combustion air supply system has specific vent material and installation requirements. The air inlet pipe connects directly to the water heater to supply combustion air. The combustion air inlet pipe will be a dedicated system with one air inlet pipe per water heater. The air inlet pipe must be ...

Page 15

Directaire ® vertical this vent system requires the installation of two pipes directly to the unit, one vertical pipe with a roof top termination for the flue products and one pipe for combustion air. The combustion air pipe may terminate horizontally with a sidewall air inlet or vertically with a r...

Page 16

14 l o c h i n v a r d e s i g n e r ’ s g u i d e c o p p e r - f i n i i w a t e r h e a t e r 6 1 5 - 8 8 9 - 8 9 0 0 the combustion air inlet cap must not be installed closer than 10 feet (3.05m) from an inside corner of an l-shaped structure. The vertical air inlet point for the combustion air ...

Page 17

The combustion air inlet pipe is a dedicated system with one air inlet pipe per unit. The air inlet pipe must be connected to the direct vent (dv) box adapter. The air inlet pipe must be sealed. Aire-lock tm horizontal direct vent kits the vent kit includes a dv box adapter; sidewall air inlet cap a...

Page 18: Outdoor Installation

16 l o c h i n v a r d e s i g n e r ’ s g u i d e c o p p e r - f i n i i w a t e r h e a t e r 6 1 5 - 8 8 9 - 8 9 0 0 lochinvar the installer supplies all vent pipe material. Combined air inlet points in most installations, the combustion air inlet pipe will be a dedicated system with one air inl...

Page 19: Gas Supply

The combustion air inlet of the outdoor cap must be located at least one foot (0.30m) above grade and above normal snow levels. The water heater must be at least 10 feet (3.05m) away from any forced air inlet and at least 3 feet (0.91m) outside any overhang. Do not install in locations where rain fr...

Page 20: Water Connections

A trap (drip leg) should be provided in the inlet gas connection to the water heater. A manual main gas shutoff valve is provided outside the jacket, upstream of the main gas valve. In canada, derated10% from 2,000 - 4,500 ft., over 4,500 ft. Derate must be in accordance with local authorities. Cons...

Page 21: Water Velocity Control

L o c h i n v a r d e s i g n e r ’ s g u i d e c o p p e r - f i n i i w a t e r h e a t e r 6 1 5 - 8 8 9 - 8 9 0 0 1 9 water velocity control important to ensure proper velocity through the heat exchanger, it is necessary to regulate the temperature rise across the heat exchanger from inlet to ou...

Page 22: Electrical Requirements

20 l o c h i n v a r d e s i g n e r ’ s g u i d e c o p p e r - f i n i i w a t e r h e a t e r 6 1 5 - 8 8 9 - 8 9 0 0 lochinvar acceptable water quality levels maximum water hardness = 25 grains minimum water hardness = 5 grains maximum total dissolved solids = 350 ppm range of acceptable ph = 7....

Page 23: A P P E N D I X A

2 0 0 5 e l m h i l l p i k e • n a s h v i l l e , t n 3 7 2 1 0 • 6 1 5 - 8 8 9 - 8 9 0 0 • f a x : 6 1 5 - 8 8 5 - 4 4 0 3 c o p p e r - f i n i i ® w a t e r h e a t e r p i p i n g d i a g r a m s a p p e n d i x a.

Page 24

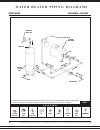

W a t e r h e a t e r p i p i n g d i a g r a m s piping diagram single heater - single tank building hot water supply lock-temp storage tank drain full port ball valve system pump system relief valve tee elbow union expansion tank check valve thermometer cold water supply building return inlet outl...

Page 25

Piping diagram single heater - two tanks full port ball valve system pump system relief valve tee elbow union expansion tank check valve thermometer l e g e n d building hot water supply lochinvar water heater cold water supply building return lock-temp storage tanks relief valve drain outlet inlet ...

Page 26

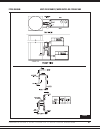

Full port ball valve system pump system relief valve tee elbow union expansion tank check valve thermometer l e g e n d piping diagram two temperature installation - single heater-single tank high temperature building return low temperature building return drain inlet outlet cold water supply 140 0 ...

Page 27

Piping diagram two heaters-single tank full port ball valve system pump system relief valve tee elbow union expansion tank check valve thermometer reducing tee reducing tee l e g e n d lochinvar water heater inlet inlet outlet outlet building return drain lock-temp storage tank cold water supply bui...

Page 28

Full port ball valve system pump system relief valve tee elbow union expansion tank check valve reducing tee reducing tee l e g e n d piping diagram two heaters-two tanks building return lochinvar water heater cold water supply lock-temp storage tanks drain gray shaded area represents common manifol...

Page 29

Piping diagram multi-stack frame w/water heaters and storage tank lit0396 l o c h i n v a r d e s i g n e r ’ s g u i d e c o p p e r - f i n i i w a t e r h e a t e r 615 - 8 8 9 - 8 9 0 0 a6.

Page 30

20 l o c h i n v a r d e s i g n e r ’ s g u i d e c o p p e r - f i n i i w a t e r h e a t e r 6 1 5 - 8 8 9 - 8 9 0 0 notes.

Page 32

Lochinvar corporation • lebanon, tn • 615-889-8900 / fax: 615-547-1000 www.Lochinvar.Com cf-dg-05 (reprint cf-dg-05 1/07) 11/07-printed in u.S.A..