- DL manuals

- Lochinvar

- Water Heater

- ECOKNIGHT EKW116CE

- Installation manual

Lochinvar ECOKNIGHT EKW116CE Installation manual

Summary of ECOKNIGHT EKW116CE

Page 1

1 models ekw46ce ekw61ce ekw86ce ecoknight™ floor standing gas fired condensing circulating type water heater installation, commissioning, maintenance and user instructions installation manual_ecoknight 46-86_january2018.

Page 2

2 table of contents 1.0 introduction ...................................................................................................................................................................................................................... 4 2.0 safety guidelines............................

Page 3

3 17.4 commissioning the equipment ............................................................................................................................................................................. 62 17.5 temperature adjustment procedure .....................................................

Page 4

4 1.0 introduction the lochinvar ecoknight™range is a floor standing direct gas fired circulating type condensing water heater. The equipment comprises of stainless steel radial burner assembly and heat exchanger that permits fully condensing operation. Ecoknight™ water heaters must be used in con...

Page 5

5 2.0 safety guidelines read and understand the instructions read and fully understand all instructions before attempting to operate maintain or install the unit. Keep these instructions near the water heater for quick reference. This equipment must be installed by a competent person, registered wit...

Page 6

6 2.2 what to do if you smell gas warning if you smell gas no naked flames, no smoking! avoid causing sparks, do not switch on or off electrical equipment or lights open windows and doors shut off the main gas supply warn occupants and leave the building after leaving the building alert ...

Page 7

7 3.0 principal parts item description function note 1 stainless steel heat exchanger allows water to flow through specially designed coils for maximum heat transfer, while providing protection against flue gas corrosion. The coils are encased in a jacket that contains the combustion process. Not sh...

Page 8

8 3.1.2 principle parts shown, to be used with 3.1.1 front view all models rear view models ekw46ce-ekw61ce rear view models ekw86ce left side view models ekw86ce.

Page 9

9 4.0 technical data model number ekw46ce ekw61ce ekw86ce general data product i.D. Number ce 0063cq3351 classification ii 2h3b/p input (gross) kw 44 61.5 83.5 input (net) kw 39.6 55.4 75.2 recovery rate (44° Δt) l/hr 806 1153 1567 recovery rate (50° Δt) l/hr 709 1014 1379 heat generator seasonal ef...

Page 10

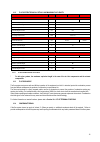

10 5.0 dimensions and clearance 5.1 dimensional drawings note full dimensional drawings showing connection sizes and positions are available from lochinvar technical support 5.1.1 d imensional drawing ekw46ce-ekw61ce 5.1.2 d imensional drawing ekw86ce, dimension unit model ekw46ce ekw61ce ekw86ce a ...

Page 11

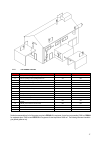

11 5.2 clearances 5.2.1 enclosure installation clearances ( mm ) 5.2.2 plant-room installation clearances ( mm ) 400 400

Page 12

12 6.0 general requirements the lochinvar ecoknight™ condensing water heater has been designed to operate trouble free for many years. These instructions should be followed closely to obtain the maximum usage and efficiency of the equipment. Read and understand the instructions read and fully unders...

Page 13

13 7.0 water quality 7.1 water quality /hard water water supply quality may adversely affect the efficiency performance and longevity of water heaters and hot water systems. Hard water may cause the formation of lime scale which will reduce operating efficiency and may cause early product failure. P...

Page 14

14 8.4 condensate drain the condensate drain is located on the left hand side of the water heater. It is fitted with a ½” pvc tee and union, this should be connected to an appropriate condensate drain, sloping continuously away from the water heater at an angle of at least 3 (50mm per metre). The ...

Page 15

15 10.0 flue system all versions of the ecoknight™ condensing water heater can be installed as either type b23 (fan assisted open flue) or c13, c33, c53 (room sealed) appliances. Only c13,c33,c53 flue systems are covered in any detail within this document, further information can be found in the eco...

Page 16

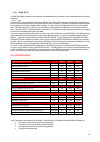

16 10.2 flue system technical details and maximum flue length model number ekw46ce ekw61ce ekw86ce flue data type b 23 nominal flue diameter mm 80+/-0.6 100+/-0.6 maximum flue gas temp °c 120 maximum equivalent length m 60 equivalent length 90 bend mm 1000 equivalent length 45 bend mm 500 flue g...

Page 17

17 10.4.1 flue terminal positions location description ekw46ce – ekw61ce ekw86ce a directly below an opening, air brick, opening windows etc. 300 2000 b above an opening, air brick, opening windows etc. 300 1000 c horizontally to an opening, air brick, opening windows etc. 300 1000 d below a gutter ...

Page 18

18 10.5 approved flue system for concentric and twin pipe flue systems only the lochinvar supplied m&g flue system must be used the approved flue system is not suitable for use external to the building. If external routes cannot be avoided, a flue system manufacturer should be consulted to supply a ...

Page 19

19 10.7 room sealed (type c) flue assembly in order to install the ecoknight™ water heater with a type c (room sealed) flue system a flue transition kit must first be installed, this kit is used for both c 13 (horizontal) and c 33 (vertical) flue systems. The information in this paragraph describes ...

Page 20

20 to install the flue connection to the ekw46ce – ekw61ce water heaters the following procedure should be followed: 1. Check you have all items shown in section 10.8.1 2. Check the flue temperature sensor (supplied with the water heater) is securely located into the hole on the exhaust transition. ...

Page 21

21 10.9 installation of transition kit to ekw86ce water heaters 10.9.1 flue transition parts ekw86ce depending upon the flue kit chosen either a vertical or horizontal concentric terminal will be included in the packaging with the transition kit, additional elbows, flue lengths etc. Are available as...

Page 22

22 to install the flue connection to the ekw86ce water heaters the following procedure should be followed: 1. Check you have all items shown in section 10.9.2. 2. Check the flue temperature sensor (supplied with the water heater) is securely located into the hole on the exhaust transition. If the fl...

Page 23

23 10.10 c13 concentric horizontal flue systems flue system specifications manufacturer muelink and grol (m&g) temperature class t120 flue gas material pp each concentric horizontal flue kit includes the items shown in the tables below item no ekwhf001 concentric horizontal flue assembly model...

Page 24

24 10.11 horizontal flue terminal installation when the water heater is installed as a type c 13 (horizontal concentric) appliance, the flue system should be installed as follows: 1. Determine the location of the flue terminal, taking into account minimum distances as detailed in section 10.4.1 and ...

Page 25

25 10.13 c 33 concentric vertical flue systems flue system specifications manufacturer muelink and grol (m&g) temperature class t120 flue gas material pp each concentric horizontal flue kit includes the items shown in the tables below item no ekwvf001 concentric vertical flue assembly models e...

Page 26

26 10.14 vertical flue terminal installation when the water heater is installed as a type c 33 appliance, the flue system should be installed as follows: 1. Confirm that the roof flashing is correct for the type of roof through which the terminal is to be installed. Section 10.14.1 2. Determine the ...

Page 27

27 10.14.3 g eneral concentric flue system installation guidelines the information in this section is for general guidance only and may not fully represent the installation on site do not drill and screw into flue system.

Page 28

28 max distance between brackets.

Page 29

29.

Page 30

30

Page 31

31 10.15 type c 43 (u duct) this appliance can operate on a u-duct common flue system. The maximum lengths for the interconnecting flue can be found in section 10.2. Concrete components of the u-duct must meet the requirements of bs en 1858. Model no. Nominal flue diameter mass rate @ 100% mass rate...

Page 32

32 when installing the water heater as a type c53 appliance, it should be noted that the terminals must not be installed on opposite sides of the building. If the flue temperature sensor is not fitted, the flue gas temperature may exceed the maximum temperature rating of the flue and can lead to sev...

Page 33

33 10.16.1 general twin-pipe installation guidelines the information in this section is for general guidance only and may not fully represent the installation on site.

Page 34

34.

Page 35

35.

Page 36

36 10.17 type b 23 (conventional flue with fan assistance) when the water heater is installed as a type b 23 appliance, the flue system should be installed in accordance with the flue manufacturer’s specific instructions. Item no ekwcf001 fan assisted open flue starter assembly kit contains componen...

Page 37

37 10.18 c63 certified flue systems in general, water heaters are certified with their own purpose supplied concentric or twin pipe flue systems, c 63 certified appliances allow the installer to use other flue systems when installing the water heater however, they must be of a suitable minimum stand...

Page 38

38 11.0 air supply the following information is based on single water heater installations only. If more than one water heater is being used, bs5440-2 or bs6644 (as appropriate) should be consulted to calculate the necessary requirements. 11.1 combustion ventilation when used as a type c (room seale...

Page 39

39 12.0 water connections 12.1 general adaptors are required to convert the ntp (male) thread on the heat exchanger to bsp (female). These adaptors can be found in the packing carton. The bsp section of the adaptor is indicated with blue paint. Ecoknight™ water heaters require a minimum flow rate an...

Page 40

40 12.2 open vented system arrangement the lochinvar ecoknight™ can be used in an open vented arrangement provided that a vent pipe in accordance with cp342, bs6644 or bs6700 as appropriate is fitted. The minimum static head requirement for an open vented system is 0.5 bar. 12.2.1 typical schematic,...

Page 41

41 12.3.2 expansion vessel sizing the following information is based on an inlet pressure of 3.5 bar and an expansion vessel efficiency of 0.45 using a standard 6 bar unvented kit. If the system will have different parameters a more detailed calculation will need to be made. V v = s v * e 0.45 where...

Page 42

42 12.5 primary pipework header sizing the pipework header between the ecoknight™ water heater(s) and lst(s) buffer vessels must be sized as per the guidance given in this section. Failure to use the correct size of pipe header will cause operational problems and potential early failure of the water...

Page 43

43 13.1 vessel temperature sensor single water heater installation each ecoknight™ is supplied with a vessel temperature sensor and sensor pocket. This must be fitted to the lst direct storage vessel supplied with the ecoknight™ water heater. This is installed within the vessel as close to the flow ...

Page 44

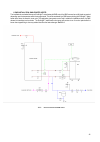

44 14.0 schematics 1.1 key for schematics lochinvar limited may provide technical advice and guidance to assist with best practice, optimisation and installation of lochinvar products; however, we will not be liable for any duties as designers under construction (design and management regulations 20...

Page 45

45 14.1 standalone installation, single water heater the installation shown below features an ecoknight™ water heater working on its own sensors only, the supplied tank sensor is installed within the sensor point on the lst direct storage vessel. This arrangement gives close temperature control and ...

Page 46

46 1.1 bms installation, single water heater the installation shown below features an ecoknight™ water heater with bms control, the bms can send an on/off signal as required depending upon the temperature within the storage vessel. This will be monitored by a bms sensor shutting the ecoknight™ water...

Page 47

47 14.2 installation, two water heaters with single vessel – alternate lead with strap-on sensor the installation shown below features two ecoknight™ water heaters working with a single tank sensor. The water heaters would be put into cascade - the supplied tank sensor is installed within the sensor...

Page 48

48 14.3 multiple water heaters with single vessel when multiple ecoknight™ water heaters are installed as shown below one water heater is designated as the leader water heater. The leader will decide how many member water heaters to activate and at what firing rate depending upon information receive...

Page 49

49 14.4 multiple water heaters with multiple lst direct storage vessels sometimes it may be necessary to install multiple lst direct storage vessels, for example to reduce the kw required meeting the demand or if a single larger vessel will not fit within the plant room. The vessels should be instal...

Page 50

50 15.0 electrical supply wiring external to the equipment must be installed in accordance with the i.E.E. Regulations and any local regulations that apply. Model normal supply voltage external fuse rating power consumption ekw46ce 230v ac 50 hz 1 ph 6.0 a 120 w ekw61ce 144 w ekw86ce 180 w 15.1.1 el...

Page 51

51 15.2.1 remote enabling there are three ways to enable the ecoknight™ water heater as follows; 1. Using night setback mode – this uses the ecoknight™ water heaters internal clock and can be used to program 7 stop times and 7 start times. Refer to section 21.1 for more intermittent control of the e...

Page 52

52 15.3 high voltage connector strip 15.3.1 high voltage connection strip the output across the 3 terminals should not exceed 190w per terminal. It is highly recommended these switched outputs are only used to switch suitable starter/overload relays on the pumps. Connection output notes primary 230v...

Page 53

53 pin connection output / input notes 1-2 alarm contacts volt free – close on alarm an internal volt free contact across pins 1 and 2 will close in the event of the heater locking out. This connection can be used by a bms to monitor the operation of the heater. 3-4 runtime contacts volt free – clos...

Page 54

54 15.5 electrical connections access to the high voltage and low voltage connection strips can be made by removing the appropriate knockouts on the back panel of the water heater. All connections should be secured using an appropriate cord anchorage. One cord anchor is supplied with the water heate...

Page 55

55 15.8 wiring diagram 15.8.1 wiring diagram.

Page 56

56 15.9 ladder diagram 15.9.1 ladder diagram.

Page 57

57 16.0 smart system control 16.1 general the lochinvar ecoknight™ uses the smart system control interface. The control panel display give information on set-up, system status and diagnostic data in words rather than codes. 16.2 smart system control panel 1 usb drive 2 pc connection 3 left select ke...

Page 58

58 16.4 saving parameters please note that the brackets ([]) denote screen status. 16.4.1 to save parameters and exit programming press the right select (save) key and then press the right select (home) key. 16.4.2 to enter a parameter and continue programming press the right select (save) key 1 tim...

Page 59

59 6 if flame is not detected after spark ends the control will perform a post-purge, then start another pre-purge cycle and try to light the water heater again. On the 145 model up the control will lock out after this second attempt on the 115 down a further four attempts will be made before the un...

Page 60

60 16.5 status display screens section display description a (water heater status bar) standby the unit has not received a call for heat start the unit has received a call for heat and is checking all safety circuits prepurge the unit has received a call for heat and has initiated a pre-purge period...

Page 61

61 section display description c(operational information) bms screen a. 0-10v bms in b. 0-10v bms out c. Bms address d. Bms control? E. Sys pump speed f. Blr pump out c. Dhw run time total dhw running time d. Dhw cycles total dhw demand cycles e. Power hours total time powered on f. Ignitions total ...

Page 62

62 17.0 commissioning and testing 17.1 electrical installation notes on the requirements for electrical installation are provided in section15.0: electrical supply. A schematic drawing of the control circuit is shown in figure 15.8. 17.2 gas installation for design see section 9.0: gas supply. See s...

Page 63

63 17.4.3 procedure for initial lighting if the unit is to operate on lpg refer to section 18.0 before proceeding 1. Ensure that the external gas-inlet appliance isolating valve, provided by the installer, is in the “off” position. 2. Press the power rocker switch, positioned on the back of the appl...

Page 64

64 17.7 pasteurisation if a pasteurisation cycle is to be used at a temperature raised above the standard set-point this can be achieved in one of three ways, the method chosen will depend on the frequency and monitoring required. Contact lochinvar technical support for further guidance. 1 use the b...

Page 65

65 18.2 conversion to lpg this process must be carried out in the order stated before the water heater is switched on. Failure to follow the following procedure may lead to non-warrantable damage to the water heater. The conversion must be carried out by a competent person certified for work on lpg ...

Page 66

66 18.3 lpg commissioning and testing the commissioning procedure on lpg is similar to that when the water heater is firing on natural gas. As such, the same procedure should be followed taking in to account the following information: 18.3.1 lpg pressure adjustment and combustion checks the lochinva...

Page 67

67 19.0 maintenance 19.1 general keep appliance area clear and free from combustible materials and flammable vapours and liquids. A competent person should check and ensure that the flue, its support and terminal, the ventilation to the boiler house, safety valve, drain, pressure gauge etc. Are in a...

Page 68

68 19.4 burner removal if it has been determined that the flame picture is unacceptable, the burner can be removed and cleaned using the following procedure: 1. Isolate the electrical and gas supplies to the heater. 2. Allow the water heater to cool down. 3. Disconnect the wiring connections to the ...

Page 69

69 19.7 refilling the system 1. Close the drain valve. 2. Open the cold-water inlet valve from the header tank or pressurisation unit to water heater system. 3. Working systematically towards the highest point in the system, open all bleed valves and allow any trapped air to escape. 4. Follow the li...

Page 70

70 20.0 smart system control settings 20.1 display panel access menu to access menus from the display panel, use the procedure shown below: only suitably qualified engineers should alter the settings and parameters within the ecoknight™ water heater. Incorrect settings could lead to operational prob...

Page 71

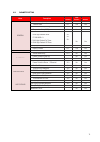

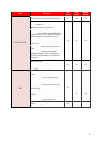

71 20.2 parameter setting menu description see user access installer section access general vacation mode (on/off) 21.1 yes yes time and date 21.1 yes yes software version (read only) 21.1 no yes temperature units (°c/°f) 21.1 yes yes dhw night setback offset 21.1 if dhw nsb > 0: 21.1 i. Dhw night s...

Page 72

72 menu description see section user access installer access control modes controlling sensor(outlet/system supply/inlet) 21.6 no yes cascade address 21.6 no yes if address = 0: maximum cascade outlet set point cascade offset cascade differential cascade type (l/l, eff) minimum on/off time minimum n...

Page 73

73 menu description see section user access installer access circulating pumps dhw pump delay 21.8 no yes dhw pump anti-seize delay 21.8 no yes service notification service notification months 21.9 no yes service notification running time 21.9 no yes service notification cycles 21.9 no yes reset ser...

Page 74

74 21.0 viewable and changeable control parameters before changing parameters, note the settings so that the unit can be returned to its origanal operating parameters. These can be uploaded to a usb for later use see 21.10.1. 21.1 general 21.1.1 vacation mode this parameter forces the dhw set points...

Page 75

75 21.1.7 night setback override any night setback on trigger currently active or scheduled within the next seven (7) days can be skipped. To skip a trigger, go to the night setback status screen and press the skip button. Rotate the navigation dial until the arrow (>) is next to the trigger you wis...

Page 76

76 21.4.2 tank set point differential when a tank sensor is installed, the tank temperature must drop this amount below the tank set point (dhw tank set point parameter) before the water heater turns back on. The installer can adjust this setting by accessing the tank set point differential paramete...

Page 77

77 21.6.3 maximum cascade set point this parameter determines the set point used by the individual water heaters in a cascade when a system sensor is connected to the leader water heater. When a water heater is commanded to fire by the leader water heater, it will attempt to achieve this temperature...

Page 78

78 21.6.10 alternate leader this parameter allows the member 1 water heater to automatically assume control of the cascade should it lose communication with the leader water heater. When programmed to yes, it is recommended that the member 1 water heater have its own set of external sensors installe...

Page 79

79 21.7.6 set point at maximum volts when programmed for bms control through the 0 - 10v bms input or through modbus/bacnet and the bms type is programmed as setpoint, the set point represented by the volts at maximum parameter is set by the set point at maximum volts parameter. The minimum value is...

Page 80

80 21.9 service notification 21.9.1 service notification in months when the water heater control determines that a scheduled service is due based on days of installation, the water heater display will turn yellow and a new status screen will appear informing the user that maintenance is required. Th...

Page 81

81 21.10 basic setup the basic setup menu contains the most frequently used parameters from the list above. See the descriptions above to set these parameters. 21.10.1 usb parameter files can be copied directly to and from a usb flash drive. When usb is selected from the main menu, the display will ...

Page 82

82 23.0 user instructions once the installation and commissioning is complete, the equipment owner or their representative should be made aware of the operation of the appliance and its safety devices. A practical demonstration should be given describing each functional step. Incorrect use may resul...

Page 83

83 23.4 smart system control 1 usb drive 2 pc connection 3 left select key 4 navigation dial 5 reset switch 6 right select key the information on the bottom of the display shows the functions of the two select keys on both corner, and the navigation dial in the centre. Menu left select key setpoints...

Page 84

84 23.6 maintenance see section 19.0 maintenance 23.7 air supply when installed as a conventionally flued appliance, the room in which the appliance is installed must be ventilated. Blocking these vents may lead to severe injury, serious property damage or death. The area in which the appliance is i...

Page 85

85 notes notes __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ ____________________________________...

Page 86

86 notes notes __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ ____________________________________...

Page 87

87.

Page 88

88.