- DL manuals

- Lochinvar

- Water Heater

- F0600187510

- Installation And Service Manual

Lochinvar F0600187510 Installation And Service Manual

INSTALLATION AND SERVICE MANUAL

Save this manual for future reference.

W

WA

AR

RN

NIIN

NG

G: If the

information in this manual

is not followed exactly, a

fire or explosion may

result causing property

damage, personal injury or

loss of life.

– This appliance MUST

NOT be installed in any

location where gasoline or

flammable vapors are

likely to be present, unless

the installation is such to

eliminate the probable

ignition of gasoline or

flammable vapors.

WHAT TO DO IF YOU SMELL

GAS

• Do not try to light any

appliance.

• Do not touch any

electric switch; do not

use any phone in your

building.

• Immediately call your

gas supplier from a

neighbors phone.

Follow the gas

supplier’s instructions.

• If you cannot reach your

gas supplier, call the fire

department.

– Installation and service

must be performed by a

qualified installer, service

agency or the gas supplier.

W

WA

AR

RN

NIIN

NG

G: Do not use

this pool heater if any part

has been under water. The

possible damage to a

flooded pool heater can be

extensive and present

numerous safety hazards.

Any pool heater that has

been under water must be

replaced.

GAS HEATERS FOR COMMERCIAL

POOL APPLICATIONS

500,000 - 2,070,000 Btu/hr MODELS

Starting Serial #F0600187510

CPE-i&s-05

W

WA

AR

RN

NIIN

NG

G: Improper

installation, adjustment,

alteration, service or

maintenance can cause

property damage, personal

injury, exposure to

hazardous materials or

loss of life. Refer to this

manual. Installation and

service must be performed

by a qualified installer,

service agency or the gas

supplier. This pool heater

contains materials that

have been identified as

carcinogenic, or possibly

carcinogenic, to humans.

Summary of F0600187510

Page 1

Installation and service manual save this manual for future reference. W wa ar rn niin ng g: if the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life. – this appliance must not be installed in any location wher...

Page 2

Commercial pool heaters 2 t ta ab blle e o off c co on ntte en ntts s general product information . . . . . . . . . . . . . . . . . . . . . . . . .3 special instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 3

G ge en ne er ra al l p pr ro od du uc ct t iin nf fo or rm ma at tiio on n special instructions this manual supplies information for the installation, operation and servicing of this pool heater. Read and understand this manual completely before installing the pool heater. Installation and service ...

Page 4

• do not try to light any appliance • do not touch any electrical switch; do not use any phone in your building • immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions • if you cannot reach your gas supplier, call the fire department 6. This appliance is ...

Page 5

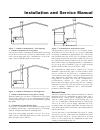

P pr ro od du uc ct t iid de en nt tiif fiic ca at tiio on n installation and service manual 5 figure 1b - optional vertical piping loop figure 1a - standard horizontal piping loop.

Page 6

Installation this pool heater meets the safe lighting performance criteria with the gas manifold and control assembly provided, as specified in the ansi z21.10.3/csa 4.3 standard for gas-fired water heaters. Locating pool heater 1. Maintain all clearances from combustible construction when locating ...

Page 7

Freeze protection although this pool heater is csa design certified for outdoor installations - such installations are not recommended in areas where the pool heater will be operated in the winter months and the danger of freezing exists. Proper freeze protection must be provided for outdoor install...

Page 8

Iin ns st ta al ll la at tiio on n continued caution: some pleated filters are too restrictive and could cause air flow problems. For convenience and flexibility, you can direct the combustion air inlet from either the back or right side of the pool heater. To arrange the combustion air inlet for si...

Page 9

Figure 7 – outside combustion air - two openings 2. Outside combustion air, using ducts you can direct outside combustion air to this pool heater using two air ducts to deliver the air to the mechanical room. Each of the two openings must have a minimum free area of one square inch per 2000 btu inpu...

Page 10

Iin ns st ta al ll la at tiio on n continued v ve en nt tiin ng g general information you must supply adequate combustion and ventilation air to this pool heater. You must provide minimum clearances for the vent terminal from adjacent buildings, windows that open, and building openings. Follow all r...

Page 11

Figure 12 – vent termination from flat roof 10' or less from parapet wall figure 13 – vent termination from flat roof more than 10' from parapet wall sidewall vent termination clearances and location locate the bottom of the vent terminal at least 12 inches (30cm) above grade and above normal snow l...

Page 12

Iin ns st ta al ll la at tiio on n continued combustion air inlet piping warning: locate and install the combustion air inlet cap correctly. Failure to do so can allow the discharge of flue products to be drawn into the combustion process. This can result in incomplete combustion and potentially haz...

Page 13

Figure 14 – sidewall combustion air inlet figure 15 – air inlet cap for sidewall termination to prevent recirculation of flue products from an adjacent vent cap into the combustion air inlet, follow all applicable clearance requirements in the latest edition of the national fuel gas code and/or can/...

Page 14

Iin ns st ta al ll la at tiio on n continued to the common air inlet. This exterior opening for combustion air must connect directly to the outdoors. The total length of the combined air inlet pipe must not exceed a maximum of 50 (15.2m) equivalent feet. Subtract 5 feet (1.5m) for each 90° elbow in ...

Page 15

Connect the flue vent directly to the flue outlet opening on the top of the pool heater. No additional draft diverter or barometric damper is needed on single unit installations with a dedicated stack and a negative draft within the specified range of 0.02 to 0.08 inches w.C. If the draft in a dedic...

Page 16

Iin ns st ta al ll la at tiio on n continued problems. The temperature of the flue products from a high efficiency pool heater may not be able to sufficiently heat the masonry structure of the chimney to generate proper draft. This will result in condensing of flue products, damage to the masonry fl...

Page 17

Figure 20 – vertical directaire installation with rooftop combustion air inlet vent kits warning: only use a sidewall air inlet cap supplied by the appliance manufacturer or a rooftop air inlet cap supplied by the vent manufacturer. Using any other air inlet cap for single-unit installations or usin...

Page 18

Iin ns st ta al ll la at tiio on n continued sidewall fan the sidewall fan can be mounted on the inside/outside (depending upon model) with a sidewall vent hood installed on the exterior wall. The sidewall fan and accessories are included in a venting kit provided by the appliance manufacturer. See ...

Page 19

Figure 22a – direct vent (illustration with sidewall vent and sidewall combustion air) figure 22b – sidewall venting warning: do not combine the flue from this unit with the vent from any other appliance. Do not combine flues from multiple appliances into a common vent. The flue from this unit must ...

Page 20

Iin ns st ta al ll la at tiio on n continued input kit* max. Vent vent max. Vent btu/hr (w/power length termination only length fan assy.) (500,000 - 750,000 btu/hr) 500,000 svk3006 100 ft. Svk3043 50 ft. 650,000 svk3008 100 ft. Svk3044 50 ft. 750,000 svk3008 100 ft. Svk3044 50 ft. 990,000 svk3053 1...

Page 21

For proper operation, a barometric damper is provided for horizontal directaire tm installations. The damper will help to ensure a draft between negative 0.04 to 0.08 inches w.C. Input btu/hr kit* 500,000 hdk3031 650,000 hdk3032 750,000 hdk3032 990,000 hdk3037 1,260,000 hdk3038 1,440,000 hdk3038 1,8...

Page 22

Iin ns st ta al ll la at tiio on n continued 90° elbow. Subtract 2.5 feet (0.7m) of equivalent length for each 45° elbow. Masonry chimney installation do not use a standard masonry chimney to directly vent the combustion products from this pool heater. To use a masonry chimney, the chimney must use ...

Page 23

In cold climates, use a type-b doublewall vent pipe or an insulated single wall pipe for combustion air. This will help prevent moisture in the cool incoming air from condensing and leaking from the inlet pipe. Caution: pool heaters that are shut down or will not operate may experience freezing due ...

Page 24

Iin ns st ta al ll la at tiio on n continued 2. On horizontal runs, do not install vent pipe with seams pointing down. Position vent pipe so that the seams are on the top side of the vent pipe. 3. Secure all joints with a minimum of three sheet metal screws or pop rivets. Apply aluminum foil duct ta...

Page 25

Vertical combustion air inlet clearances you must locate the air inlet termination elbow at least 12" (30cm) above the roof or above normal snow levels. If the air inlet cap is within a 10 foot (3.05m) radius of the flue outlet, the point of termination for the combustion air inlet cap must be at le...

Page 26

Iin ns st ta al ll la at tiio on n continued * these kits include an outdoor vent cap and gasket. Flue gas condensate can freeze on exterior walls or on the vent cap. Frozen condensate on the vent cap can result in a blocked flue condition. Some discoloration to exterior building or pool heater surf...

Page 27

2. Isolate the pool heater from the gas supply piping system by closing a manual shutoff valve during any piping system pressure testing that is equal to or less than 1/2 psig (3.5kpa). 3. Test all gas connections for gas leaks before placing the pool heater in operation. Gas piping to safely operat...

Page 28

Iin ns st ta al ll la at tiio on n continued figure 29 shows a typical pool heater gas train. Figure 29 – typical pool heater gas train drawing combination gas valves these pool heaters fire in a single stage of operation. Note: this pool heater incorporates a “soft start” feature which lights appro...

Page 29

13. Remove the manometer and related fitting from the “inlet” side of the gas valve, replace 1/8" hex plug in the gas valve and tighten. 14. Turn on the gas supply at the manual valve, turn on l.P. Gas at the tank if required. 15. Turn the power switch to the “on” position. 16. Turn the gas valve kn...

Page 30

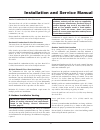

Iin ns st ta al ll la at tiio on n continued gas manifold pressure adjustment important: the gas valves are referenced to the fan pressurized chamber by a hose connected from the vent of the gas valve regulator to the chamber pressure tap located on the front inside portion of the jacket. Reference ...

Page 31

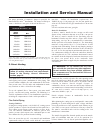

* net manifold pressure equals the measured manifold pressure minus the chamber pressure. See figure 31 to measure the net manifold pressure. Pool heater piping installation install piping from the filter system to the pool heater as shown in the pool heater piping diagrams. See figures 34 - 38. Min...

Page 32

Iin ns st ta al ll la at tiio on n continued note: if the wing nut underneath the valve actuator body is loose, retighten. 9. Reinstall the plastic actuator cover and secure with the screw loosened in step 2. 10. Place the valve cover (jkd6653) over the 3-way automatic bypass valve. Install the end ...

Page 33

Installation and service manual 33 figure 34 - heater is within 15 feet of pool piping figure 35 - heater is beyond 15 feet of pool piping.

Page 34

Commercial pool heaters 34 figure 36 - heaters are within 15 feet perpendicular of pool piping figure 37 - heaters are beyond 15 feet of pool piping iin ns st ta al ll la at tiio on n continued.

Page 35

Installation and service manual 35 relief valve this pool heater is supplied with a relief valve(s) sized in accordance with asme boiler and pressure vessel code, section iv. The relief valve(s) is installed in the vertical position and mounted in the hot water outlet. Place no other valve between t...

Page 36

Commercial pool heaters 36 iin ns st ta al ll la at tiio on n continued ensure that the pump installed on the pool heater will supply adequate flow to make the flow switch contacts and operate the pool heater. A water flow switch meets most code requirements for a low-water cut off device on applian...

Page 37

Installation and service manual 37 figure 39 - control panel component location drawing table–n terminal strip connection options the scenarios shown in figures 40 a - c represent typical terminal strip connection requirements. The terminal strips are located on the left side of the pool heater unde...

Page 38

Commercial pool heaters 38 iin ns st ta al ll la at tiio on n continued figure 40 (a-c) - terminal strip connection operation for your safety read before operating warning: if you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or los...

Page 39

39 figure 42 – on/off switch 8. Turn the manual gas cock clockwise to the “off” position. 9. Wait five (5) minutes to clear out any gas. If you smell gas, stop! Follow what to do if you smell gas in the safety information. If you don’t smell gas, go on to the next step. 10. Turn the manual gas cock ...

Page 40

Commercial pool heaters 40 operation continued figure 44 – vertical pool heater piping figure 45 – horizontal pool heater piping operating temperature control the pool heater is equipped with a microprocessor based adjustable digital temperature control to provide on/off operation. The temperature c...

Page 41

Installation and service manual 41 pool return sensor has been installed and connected, this will be the temperature of the water coming from the pool. By pressing the select key, the pool target is shown and the text target on the display. This is the pool temperature set point. By pressing the sel...

Page 42

Commercial pool heaters 42 operation continued hot surface ignition system hot surface igniter and ignition control module this unit has one ignition module and one hot surface igniter. Figure 47 – hot surface igniter figure 48 – hot surface ignition control module hot surface ignition control modul...

Page 43

Installation and service manual 43 access to internal control panel the control panel is accessed by turning the knurled knob located at the bottom center of the exterior control panel. Pull the panel out at the bottom. The door will tilt into unit until it comes free from the outer top. The outer c...

Page 44

Commercial pool heaters 44 operation continued operation and diagnostic indicators the control panel has up to six indicating and diagnostic lights to show all major steps of operation and control sensed malfunctions. There are display indicators on the operating temperature control that give status...

Page 45

Installation and service manual 45 chlorine residual is the chlorine remaining in the pool water after it is consumed in the process of destroying bacteria, algae and other oxidizable materials. Total alkalinity is the measurement of the total amount of alkaline chemicals in the water. Alkalinity co...

Page 46

Commercial pool heaters 46 operation continued pipe size requirements the pipe sizing chart provides the minimum pipe size for common manifold piping to ensure adequate flow. Circulating pump 1. This pool heater is factory supplied with a properly sized pump that circulates water between the pool he...

Page 47

Installation and service manual 47 high water temperature limit control this pool heater is equipped with a fixed setting, auto reset high water temperature limit control that is screwed into the outlet head in the heat exchanger. This temperature limit control has a maximum limit setting of 200°f (...

Page 48

Commercial pool heaters 48 cleaning and maintenance continued burner removal and cleaning 1. Turn “off” the main power to the pool heater. 2. Turn “off” the main manual gas shutoff to the pool heater. 3. Remove the front outer jacket panels. 4. Disconnect the manifold from the gas train using the un...

Page 49

Installation and service manual 49 combustion air fans both the 500,000 - 750,000 btu/hr models and the 990,000 - 2,070,000 btu/hr models use a fan-assisted combustion process. The 500,000 - 750,000 btu/hr models have one fan and the 990,000 - 2,070,000 btu/hr models use two fans to supply combustio...

Page 50

Commercial pool heaters 50 cleaning and maintenance continued if the air pressure switch does not make within 60 seconds from the time the fans turn on, the ignition module will go into a soft lockout period (approximately 5 minutes in duration) during which time the fans are turned off and the modu...

Page 51

Installation and service manual 51 energy saving recommendations 1. Keep the pool covered when not in use. This will cut heating cost, reduce water evaporation, conserve chemicals and reduce load on the filtering system. 2. Reduce pool thermostat to 78°f or lower. 3. Use an accurate pool thermometer...

Page 52

Commercial pool heaters 52 glossary power supply 120vac/60hz/1ph power connects to black (line) and white (neutral) wires located within an electrical wiring box located on the left side of the pool heater. A green chassis grounding wire is also provided for connection to earth ground. On/off rocker...

Page 53

Installation and service manual 53 prepurge (ignition module function) once the ignition module sees a 24vac input from its pressure switch, it runs the blowers for approximately 15 seconds in order to purge the combustion chamber of any unburned fuel/air mixture. Igniter warm-up and proving (igniti...

Page 54

Commercial pool heaters 54 wiring box connections.

Page 55

Installation and service manual 55 wiring box connections.

Page 56

Commercial pool heaters 56 ladder diagram.

Page 57

Installation and service manual 57 control box connections.

Page 58

Unit start up checklist ensure that the location and installation of the equipment is in accordance with the installation manual, all local installation requirements, and with the latest edition of the national fuel gas code, ansi 223.1 and/or can/cga-b149 installation code. 1. Measure the supply ga...

Page 59: View Menu Information

Advanced settings: by pressing the select key in the view mode while viewing the boiler Δt reading (or the supply sensor temperature if the pool supply sensor is connected), the boiler on hours will be displayed, indicated by the text boil on in the display. This is the total number of hours the poo...

Page 60

6/06-printed in u.S.A. Lochinvar corporation • 300 maddox simpson pkwy • lebanon, tn 37090 • 615-889-8900 / fax 615-547-1000 www.Lochinvar.Com.