- DL manuals

- Lochinvar

- Heat Pump

- LCGHP

- User Manual

Lochinvar LCGHP User Manual

Summary of LCGHP

Page 1

Installation, user and maintenance manual lcghp/lsghp powered by gas and renewable energies air-water gas absorption heat pump.

Page 2

Revision: a code: d-lbr724 this manual has been drawn up and printed by lochinvar; whole or partial reproduction of this manual is prohibited. The original is filed at lochinvar. Any use of this manual other than for personal consultation must be previously authorised by lochinvar. The rights of tho...

Page 3: Index Of Contents

Installation, user and maintenance manual – lcghp/lsghp 3 index of contents 1 preface 4 2 safety warnings ...

Page 4

1 preface 4 1 preface this installation, user and maintenance manual is a guide to the installation and operation of the air-water gas absorption heat pump "lcghp/lsghp". This manual is specifically intended for: ▶ final users for the operation of the appliance according to their own requirements; ▶...

Page 5

2 safety warnings installation, user and maintenance manual – lcghp/lsghp 5 2 safety warnings packing items (plastic bags, polystyrene foam, nails, etc.) must be kept out of the reach of children, as they are potentially dangerous. The appliance must only be used for the purposes for which it has be...

Page 6

2 safety warnings 6 damage due to aggressive substances in the air supply hydrocarbons containing chlorine and fluorine compounds, will increase corrosion. Make sure the air supply is free of aggressive substances. Acid condensate drain out the condensate produced during combustion as indicated in p...

Page 7

3 overview and technical features installation, user and maintenance manual – lcghp/lsghp 7 3 overview and technical features in this section you will find general information, hints on the operating principle of the appliance and its manufacturing features. This section also contains technical data...

Page 8

3 overview and technical features 8 initial activation procedure the complete procedure for the first start up of the appliance must be carried out by an authorized technician according to the instructions supplied by the manufacturer. To carry out entire procedure correctly, follow the instructions...

Page 9

3 overview and technical features installation, user and maintenance manual – lcghp/lsghp 9 3 3 technical manufacturing characteristics the appliance is supplied with the following technical manufacturing characteristics, control and safety components: ▶ steel sealed circuit, externally treated with...

Page 10

3 overview and technical features 10 lcghp-42lt lsghp-42lt power supply voltage v 230 type single phase frequency 50 hz supply 50 electrical power absorption nominal kw 0,83 (5) 0,90 (5) minimum kw 0,56 (5) - degree of protection ip x5d installation data sound power lw (max) db(a) 75,3 (8) 82,1 (8) ...

Page 11

3 overview and technical features installation, user and maintenance manual – lcghp/lsghp 11 lcghp-40ht lsghp-40ht hot water return temperature maximum heating °c 55 maximum for dhw °c 60 minimum in continuous operation (11) °c 30 hot water flow rate nominal l/h 3000 maximum l/h 4000 minimum l/h 140...

Page 12

3 overview and technical features 12 table 3 3 – ped data lcghp-40ht lcghp-42lt ped data components under pressure generator l 18,6 leveling chamber l 11,5 evaporator l 3,7 cooling volume transformer l 4,5 cooling absorber solution l 6,3 solution pump l 3,3 test pressure (in air) bar g 55 maximum pr...

Page 13

3 overview and technical features installation, user and maintenance manual – lcghp/lsghp 13 figure 3 2 – dimensions lcghp (low consumption ventilation) front and side views (dimensions in mm). Figure 3 3 – service plate a b hydraulic/gas unions detail legend g gas fitting Ø ¾” f b inlet water fitti...

Page 14

4 normal operation 14 4 normal operation in this section you will find all the indications necessary for the activation, regulation and control of operation of the appliance de- pending on the type of installation and control setup. ▶ type a: controlled by ccp (see figure 6.3 p. 31, detail ccp). ▶ t...

Page 15

4 normal operation installation, user and maintenance manual – lcghp/lsghp 15 ▶ by the s61 on-board controller; ▶ by the ccp/ddc (if present). The operating codes generated by the s61 controller are displayed on its screen and can also be viewed on the cci (if present) or ddc (if present). Operating...

Page 16

4 normal operation 16 description of menu of s61 controller the parameters and settings of the appliance are grouped in the menus shown on the controller’s display: table 4 1 – menu of electronic board menu menu description the display shows menu 0 view data (temperature, voltage, pump speed, ecc......

Page 17

4 normal operation installation, user and maintenance manual – lcghp/lsghp 17 7. In the same way: turn the knob to scroll through content (menus, parameters, actions), press the knob to select/confirm the content (access a menu, display/set a parameter, execute an action, quit or return to the previ...

Page 18

4 normal operation 18 5. To quit the menu, turn the knob clockwise until the "2. E" is displayed. Now press the knob to return to menu selection: "2.". 6. To exit the menu selection and return to the normal visualisation of the parameters of the appliance, turn the knob clockwise until "e" displays;...

Page 19

4 normal operation installation, user and maintenance manual – lcghp/lsghp 19 ▶ ascertain whether the appliance requires any maintenance operations (contact your authorised technical assistance centre or consult paragraph 7.2 p. 57); ▶ check that the water content of the plant is correct; if necessa...

Page 20

5 hydraulic installation 20 5 hydraulic installation in this section you will find all the instructions necessary for the hydraulic installation. Before realizing hydraulic system and gas supply for the appliance, the professionally qualified personnel is advised to read paragraph 3.1 p. 7, providin...

Page 21

5 hydraulic installation installation, user and maintenance manual – lcghp/lsghp 21 figure 5 1 – instruction for lifting the appliance can be installed at ground level, on a terrace or on a roof (if compatible with its “dimensions” and “weight”). The dimensions and weight of the appliance are given ...

Page 22

5 hydraulic installation 22 supports and levelling the appliance must be correctly levelled by placing a spirit level on the upper part. If necessary, level the appliance with metal shimming; do not use wooden spacers as these deteriorate quickly. Clearances and warnings position the appliance so as...

Page 23

5 hydraulic installation installation, user and maintenance manual – lcghp/lsghp 23 as other hydronic appliances, lochinvar heating systems operate with grid-water of good quality. In order to prevent any possible problem of operation or reliability caused by filling or top-up water, please refer to...

Page 24

5 hydraulic installation 24 ▶ plant filling system: if automatic filling systems are used, a seasonal check of the percentage of monoethylene glycol in the plant is recommended. For further information or technical support in this regard, contact lochinvar. The operations necessary for the first act...

Page 25

5 hydraulic installation installation, user and maintenance manual – lcghp/lsghp 25 figure 5 3 – position of condensate discharge and manual reset fumes thermostat a b d l legend a condensate discharge hose b fumes thermostat manual reset d corrugated hose the condensate discharge to the sewer must ...

Page 26

5 hydraulic installation 26 2. Fill the hydraulic circuit with clean water and add, if necessary, the proper quantity of monoethylene glycol according the minimum winter temperature in the installation site (see table 5.3 p. 26). 3. Check the filter on the return pipe for impurities; clean it if nec...

Page 27

5 hydraulic installation installation, user and maintenance manual – lcghp/lsghp 27 figure 5 4 – fume outlet a b c 5 8 programming of hydraulic parameters the operations described in this paragraph are necessary only if the appliance is not connected to a ddc or to a ccp. If the appliance is connect...

Page 28

5 hydraulic installation 28 the appliance functions by heating the water until it reaches the set-point temperature. At this point, if the power modulation is not active (parameter 181), it switches off. The temperature of the water goes down again until it reaches the temperature corresponding to "...

Page 29

6 electrical installation installation, user and maintenance manual – lcghp/lsghp 29 6 electrical installation this section illustrates the operations to perform for the correct electrical installation of the appliance, and contains electrical dia- grams that may be of use in the event of maintenanc...

Page 30

6 electrical installation 30 code description jp10 6-pole flame controller connector jp12 fumes sensor or generator fin sensor input jtag s61 controller programming connector main 230v (l, n) s61 controller power 230 v ac n.O. Contact pump contact, n.O. P7 (r, w, y, o) consent inputs p8 (gnd, l, h) ...

Page 31

6 electrical installation installation, user and maintenance manual – lcghp/lsghp 31 figure 6 3 – comfort control panel e accessory legend ccp comfort control panel components componing the ccp avs37 comfort control siemens rvs61 system controller and set-point cci comfort control interface plc prog...

Page 32

6 electrical installation 32 figure 6 4 – cci/ddc.

Page 33

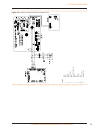

6 electrical installation installation, user and maintenance manual – lcghp/lsghp 33 6 1 electrical diagram of the appliance figure 6 5 – wiring diagram of the appliance with standard fan (lsghp) legend sch1 s61 circuit board sch2 w10 circuit board sch3 mod10 circuit board ter appliance power termin...

Page 34

6 electrical installation 34 figure 6 6 – wiring diagram of the appliance with low consumption fan (lcghp) legend sch1 controller s61 sch2 w10 circuit board sch3 mod10 circuit board ter appliance power terminal block cntbox flame controller pwrtr board transformer blw blower pmp hydraulic pump igntr...

Page 35

6 electrical installation installation, user and maintenance manual – lcghp/lsghp 35 figure 6 7 – electrical wiring diagram example of connection of appliance to 230 v 1 n - 50 hz electricity supply 6 3 type a (comfort control panel) this paragraph illustrates the operations to be performed when one...

Page 36

6 electrical installation 36 figure 6 8 – example of can bus legend a controller b-c-d appliance 1-4 terminal nodes 2-3 intermediate nodes terminal nodes and intermediate nodes what is the can bus cable the cable to be used must be suitable for can bus applications. The following table gives details...

Page 37

6 electrical installation installation, user and maintenance manual – lcghp/lsghp 37 figure 6 9 – can bus cable connection a a b c e d example of a single can bus cable connected to the board before working on the electrical panel of the appliance, make sure that power supply is off. 1. Cut a length...

Page 38

6 electrical installation 38 figure 6 10 – electrical wiring diagram legend sch electronic board gnd common data l data signal low h data signal high j1 jumper can-bus in board a detail case "terminal node" (3 wires; j1=jumper "closed") b detail case "intermediate node" (6 wires; j1=jumper "open") p...

Page 39

6 electrical installation installation, user and maintenance manual – lcghp/lsghp 39 the cci is equipped with a backup battery which retains the memory settings in case of power failure. The backup battery lasts approximately 7 years, after which time it must be replaced by an authorised technical a...

Page 40

6 electrical installation 40 figure 6 13 – connection of cci to 1 appliance legend sch s61 controller cci comfort control interface connection of cci to 1 appliance.

Page 41

6 electrical installation installation, user and maintenance manual – lcghp/lsghp 41 figure 6 14 – connection of cci to 3 appliances legend sch s61 controller cci comfort control interface connection of cci to 3 appliances.

Page 42

6 electrical installation 42 how to connect the comfort control panel you will need: the appliance disconnected from the electricity supply 1. The comfort control panel’s power cord must be type tipo fg7 3gx2.5mm 2 . The power supply is 230v ac 1n 50hz. 2. Cut a suitable length of cable. 3. The cabl...

Page 43

6 electrical installation installation, user and maintenance manual – lcghp/lsghp 43 figure 6 15 – wiring diagram for connection of wilo variable rate pumps legend ip bipolar pump power switch f fuse pm hot water circulation pump (primary circuit) pump signal 0-10v wire colours brown connect to -ve ...

Page 44

6 electrical installation 44 figure 6 16 – wiring diagram for hooking up the wilo variable rate pump powered by the unit wiring diagram for hooking up the wilo variable rate pump powered by the unit 6 4 type b (ddc) this paragraph illustrates the operations to be performed when one or more appliance...

Page 45

6 electrical installation installation, user and maintenance manual – lcghp/lsghp 45 as shown in table 6.2 p. 36, the can connection requires a can bus cable with 3 cores. If the cable available has more than 3 coloured wires, use the wires with the colours indicated in 6.2 p. 36 and cut the remaini...

Page 46

6 electrical installation 46 figure 6 17 – detail wires and jumpers j21 - terminal/intermediate node cci/ddc legend ddc cci/ddc j21 jumper can-bus in cci/ddc board a detail case "terminal node" (3 wires; j21=jumper "closed") b detail case "intermediate node" (6 wires; j21=jumper "open") h,l,gnd data...

Page 47

6 electrical installation installation, user and maintenance manual – lcghp/lsghp 47 figure 6 18 – cci/ddc - electric supply cci/ddc electric supply from external transformer. The following wiring diagrams show the connection of the ddc to 1 appliance (figure 6.19 p. 48) and 2 appliances (figure 6.2...

Page 48

6 electrical installation 48 figure 6 19 – connexion câble can bus for plants with one unit legend ddc direct digital control sch electronic board s61 j1 jumper can-bus in board s61 j21 jumper can-bus in board ddc a terminal nodes connection - (3 wires; j1 e j21 = "closed") h,l,gnd data signal wires...

Page 49

6 electrical installation installation, user and maintenance manual – lcghp/lsghp 49 figure 6 20 – connexion cable can bus for plants with more unit connexion câble can bus between one ddc and more unit how to connect the plant water circulation pump the control of the circulation pump from the elec...

Page 50

6 electrical installation 50 figure 6 21 – electrical wiring diagram example of pump/appliance electrical connection with 230 vac pump (with absorbed power of figure 6 22 – electrical wiring diagram example of pump/appliance electrical connection with 230 vac pump (with absorbed power equal or more ...

Page 51

6 electrical installation installation, user and maintenance manual – lcghp/lsghp 51 figure 6 23 – electrical wiring diagram legend sch circuit board j10 open jumper n.O. Contact n.O voltage free contacts ma unit terminal block l phase n neutral components not supplied pm water pump kp pump relay pt...

Page 52

6 electrical installation 52 ▶ make the electrical connection in such a way that the ground wire is longer than the live wires. In this way it will be the last wire to be pulled away if the mains cable should accidentally be pulled, and will thus guarantee the ground connection. Electrical safety is...

Page 53

6 electrical installation installation, user and maintenance manual – lcghp/lsghp 53 figure 6 25 – button connection for flame controller reset legend 1 w hit e 2 gr ey 3 or ange 4 gr een 5 yello w/black 6 black 7 yello w/gr een (gr ound) 8 br own 9 blue 10 yello w 11 violett e 12 pink pls reset but...

Page 54

7 initial activation and maintenance 54 7 initial activation and maintenance in this section you will find the following information: ▶ indications required by the authorized technical assistance centre (tac) in order to carry out the entire procedure of first start- up of the appliance. ▶ indicatio...

Page 55

7 initial activation and maintenance installation, user and maintenance manual – lcghp/lsghp 55 ▶ damages or failures of the appliance due to transportation or installation; ▶ smell of gas due to probable leaks from the plant itself and in any case all situations that are due to non-compliant plants...

Page 56

7 initial activation and maintenance 56 figure 7 1 – gas valve gas valve honeywell vk 4115v if the pressure measured by the pressure gage is not complying with the value reported in table 5.2 p. 24 (with a tolerance of ±15%), it is not possible to switch the appliance on! 5. Proceed with the regulat...

Page 57

7 initial activation and maintenance installation, user and maintenance manual – lcghp/lsghp 57 after 30 minutes, the appliance will automatically remove the thermal power override previously selected. To speed up, select and execute action "25" of menu 2. 11. Switch the appliance off. 12. Close the...

Page 58

7 initial activation and maintenance 58 scheduled maintenance operations to be performed at least one every two years check that the condensate discharge is clean √ *only in case the analysis of combustion products is non-compliant in section 5 p. 20 are reported suggestions related to the hydraulic...

Page 59

7 initial activation and maintenance installation, user and maintenance manual – lcghp/lsghp 59 figure 7 2 – gas changeover gas changeover legend a gas valve b o-ring c o-ring d gas nozzle e fixing screws f red silicon pipe g fixing screws h manual reset fumes thermostat.

Page 60

8 operating codes/troubleshooting 60 8 operating codes/troubleshooting 8 1 overview and operating codes/troubleshooting table 8 1 – table of operating codes generated by the s61 electronic board (firmware version 3.026) codes description trip conditions reset method e 400 fault on reset circuit of f...

Page 61

8 operating codes/troubleshooting installation, user and maintenance manual – lcghp/lsghp 61 codes description trip conditions reset method e 429 gas solenoid valve without electrical power code u_29 is active for more than 10 minutes (with flame controller unit on). Carry out appropriate checks. Re...

Page 62

8 operating codes/troubleshooting 62 codes description trip conditions reset method e 490 ambient temperature sensor defective interruption or short circuit of ambient tempera- ture sensor. Reset may be performed from the controller (or from the s61 board via menu 2, parameter 1). If the code persis...

Page 63

Declaration of conformity installation, user and maintenance manual – lcghp/lsghp 63 declaration of conformity figure 1 coscienza ecologica caring for the environment robur s.P.A. Tecnologie avanzate per la climatizzazione advanced heating and cooling technologies www.Robur.It robur@robur.It via par...

Page 64

Declaration of conformity 64 figure 2 coscienza ecologica caring for the environment robur spa tecnologie avanzate per la climatizzazione advanced heating and cooling technologies www.Robur.It robur@robur.It via parigi 4/6 24040 verdellino/zingonia (bg) italy t +39 035 888111 f +39 035 884165 d-fgl0...

Page 65

Declaration of conformity installation, user and maintenance manual – lcghp/lsghp 65 figure 3 coscienza ecologica caring for the environment robur spa tecnologie avanzate per la climatizzazione advanced heating and cooling technologies www.Robur.It robur@robur.It via parigi 4/6 24040 verdellino/zing...

Page 66

Declaration of conformity 66 figure 4 coscienza ecologica caring for the environment robur spa tecnologie avanzate per la climatizzazione advanced heating and cooling technologies www.Robur.It robur@robur.It via parigi 4/6 24040 verdellino/zingonia (bg) italy t +39 035 888111 f +39 035 884165 d-fgl0...

Page 68

Lochinvar ltd hight efficiency water heaters and boilers 7 lombard way, the mxl centre, banbury, oxon ox16 4tj t +44 (0) 1295 269981 f +44 (0) 1295 271640 sales@lochinvar.Ltd.Uk www.Lochinvar.Ltd.Uk revisione: a codic e: d -lbr724 14 med sdc 007 06/11/2014.