- DL manuals

- Lochinvar

- Water Heater

- SQUIRE SIT030

- Installation And Operation Manual

Lochinvar SQUIRE SIT030 Installation And Operation Manual

Installation & Operation

Manual

Models: SIT030 - SIT119

This manual must only be used by

a qualified heating installer / service

technician. Read all instructions

before installing. Perform steps in

the order given. Failure to comply

could result in severe personal

injury, death, or substantial property

damage.

WARNING

Save this manual for future reference.

SIT-I-O Rev H

CAUTION:

The heat transfer medium

must be water or other nontoxic fluid having

a toxicity rating or class of 1, as listed in

Clinical Toxicology of Commercial Products,

5th edition.

The pressure of the heat transfer medium

must be limited to a maximum of 30 PSIG by

an approved safety or relief valve.

Summary of SQUIRE SIT030

Page 1

Installation & operation manual models: sit030 - sit119 this manual must only be used by a qualified heating installer / service technician. Read all instructions before installing. Perform steps in the order given. Failure to comply could result in severe personal injury, death, or substantial prop...

Page 2: Hazard Definitions

2 hazard definitions the following defined terms are used throughout this manual to bring attention to the presence of hazards of various risk levels or to important information concerning the life of the product. danger warning caution caution notice danger indicates an imminently hazardous s...

Page 3

Installation & operation manual please read before proceeding installer – read all instructions before installing. Perform steps in the order given. Have this indirect water heater serviced/ inspected by a qualified service technician, at least annually. Failure to comply with the above could result...

Page 4: General Information

Installation & operation manual 1 general information the lochinvar sit series indirect water heater (fig. 1-1) is designed to generate domestic hot water in conjunction with a hot water boiler using forced boiler water circulation. This indirect water heater consists of a 316l stainless steel tank ...

Page 5: Pre-Installation

Installation & operation manual 5 2 pre-installation 1. The installation must conform to the instructions in this manual and all applicable local, state, provincial, and national codes, laws, regulations, and ordinances. Installations in canada must conform to b149.2 installation code. 2. Be certain...

Page 6: Boiler Side Piping

Installation & operation manual 6 multiple tank connections (boiler side) multiple tank installations must be done in the “reverse-return” manner. The reason for this is to create the same pressure drop (and therefore, the same flow) through the coil of each tank. The boiler manifold piping must be ...

Page 7: Boiler Side Piping

Installation & operation manual 7 solution boiler squire cold water in temperature / pressure gauge air separator ball valve (typical) union (typical) pressure relief valve drain point (typical) make up water boiler circulator backflow preventer pressure reducing valve pressure gauge expansion tank ...

Page 8: Boiler Side Piping

8 installation & operation manual solution boiler anti-scald mixing valve cold water in temperature / pressure gauge air separator ball valve (typical) union (typical) pressure relief valve drain point (typical) make up water hot water out boiler circulator backflow preventer pressure reducing valve...

Page 9: Boiler Side Piping

Installation & operation manual 9 knight boiler domestic hot water circulator backflow preventer pressure reducing valve pressure gauge anti-scald mixing valve cold water in temperature / pressure gauge air separator expansion tank ball valve (typical) union (typical) pressure relief valve drain poi...

Page 10: Boiler Side Piping

Installation & operation manual 10 3 boiler side piping knight boiler domestic hot water circulator temperature / pressure gauge union (typical) drain drain point (typical) hot water out boiler circulator pressure relief valve y-strainer (recommended) cold water in anti-scald mixing valve recirculat...

Page 11: Domestic Side (Tank) Piping

Installation & operation manual 11 4 domestic side (tank) piping basic domestic piping figure 4-2 on page 14 shows typical domestic water piping for a tank. The function of the components shown are as follows: a. Shut-off valves (recommended) - used to isolate the tank for servicing. B. Backflow pre...

Page 12: Domestic Side (Tank) Piping

12 installation & operation manual 4 domestic side (tank) piping temperature & pressure (t&p) relief valve for protection against excessive temperatures and pressure, install temperature and pressure protective equipment required by local codes. This equipment shall not be less than a combination te...

Page 13: Domestic Side (Tank) Piping

Installation & operation manual 13 notice verify that the combination temperature and pressure relief valve complies with local codes. If the combination temperature and pressure relief valve does not comply with local codes, replace it with one that does. Follow the installation instructions in thi...

Page 14: Domestic Side (Tank) Piping

14 installation & operation manual 4 domestic side (tank) piping expansion tank union (typical) shock arrestor shut-off valve shut-off valve backflow preventor shut-off valve shut-off valve anti-scald mixing valve drain ( field supply) recirculation pump to boiler from boiler check valve tank sensor...

Page 15: Wiring

Installation & operation manual 5 wiring indirect water heater sensor setup (knight boiler) label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. caution 1. Install the sensor inside the tank as depicted in fig. 5-1. 2. Connect th...

Page 16: Wiring

16 installation & operation manual 5 wiring indirect water heater controlled using aquastat and zone circulator / valve 1. Install aquastat to tank. Aquastat control (tst20016) can be ordered from your local lochinvar distributor. 2. Connect aquastat to the zone controller for the indirect water hea...

Page 17: Start-Up and Check-Out

Installation & operation manual 17 6 start-up and check-out 1. Make sure the system is free of leaks and that air is purged from the system. Caution fix any leaks found before proceeding further. Leakage from the boiler piping can result in severe damage to the boiler. 2. Many soldering fluxes conta...

Page 18: Maintenance

18 installation & operation manual 7 maintenance * make sure that the rest of the boiler and domestic water piping is free of leaks. * if there is an oil lubricated circulator in the system, make sure it is lubricated as called for by the circulator manufacturer. * make sure that the boiler is maint...

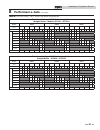

Page 19: Performance Data

Installation & operation manual 19 8 performance data squire indirect water heater i=b=r rating indirect water heater model number potable water volume gal. Heat source water volume gal. Standby heat loss f/hr continuous draw rating gal/hr first hour rating gal/ hr minimum heat output rate from heat...

Page 20: Performance Data

Installation & operation manual 20 8 performance data how to properly size your indirect water heater use the first hour rating (fhr) to properly size your indirect water heater. The first hour rating is the amount of hot water in gallons the heater can supply per hour (starting with a tank full of ...

Page 21: Performance Data

- installation & operation manual 21 first hour rating - 180°f boiler loop water (knight boiler - models sit030 - sit050) model sit030 sit040 sit050 circulator flow gpm 5 8 12 16 20 5 8 12 16 20 5 8 12 16 20 domestic outlet 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 ...

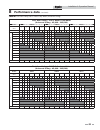

Page 22: Performance Data

Installation & operation manual 22 first hour rating - 180°f boiler loop water (universal sizing - 45,000 - 295,000 btu/hr) model sit030 sit040 sit050 circulator flow gpm 5 8 12 16 20 5 8 12 16 20 5 8 12 16 20 domestic outlet 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 11...

Page 23: Performance Data

Installation & operation manual 23 table 8d first hour rating 200°f boiler loop water (universal sizing) first hour rating - 200°f boiler loop water (universal sizing - 45,000 - 295,000) model sit030 sit040 sit050 circulator flow gpm 5 8 12 16 20 5 8 12 16 20 5 8 12 16 20 domestic outlet 115 140 115...

Page 24

Revision notes: revision a (eco c05265) initial release. Revision b (eco c05399) reflects the addition of the pressure drop chart and updates made to the performance data charts. Revision c (eco c05587) reflects the update of tables 3a and 3b (pressure drop charts) on page 6, table 4a on page 13, th...