Lochinvar TNR-I&S-02 Installation & Service Manual

1

TNR-I&S-02

HIGH EFFICIENCY COMMERCIAL GAS WATER HEATER

TABLE OF CONTENTS

GENERAL INFORMATION ...................................................... 1

INSTALLATION .................................................................. 2

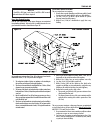

Locating The Water Heater ........................................... 2

Minimum Clearances ..................................................... 2

Venting ........................................................................ 6

Combustion Air Supply ................................................. 19

Water Connections ....................................................... 4

Gas Connections .......................................................... 14

GENERAL OPERATION ........................................................... 15

MAINTENANCE ..................................................................... 17

TROUBLESHOOTING GUIDE .................................................. 20

GENERAL INFORMATION

This gas-fired water heater is design certified by CSA International under

the American National Standard, Z21.10.3 (as indicated on the rating

plate) and CAN/CGA 4.3-M (as indicated on the rating plate) available

from CSA Standards Association, 178 Rexdale Blvd., Etobicoke, Ontario,

Canada M9W 1R3.

This water heater must be installed in accordance with local codes. In the

absence of local codes, it must be installed in compliance with the National

Fuel Gas Code (ANSI Z223.1-Latest Edition), or in Canada CAN/CGA B149.1

Natural Gas Installation Code (Latest Edition) or CAN/CGA B149.2 Propane

Installation Code (Latest Edition).

INSTALLATION & SERVICE MANUAL

WARNING

If the information in these instructions is not followed exactly, a

fire or explosion may result causing property damage, personal

injury or death.

WARNING

Keep clear of the combination temperature and pressure relief

valve discharge line outlet. The discharge may be hot enough to

cause scald injury. The water is under pressure and may splash.

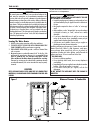

For protection against excessive temperatures and pressure, install

temperature and pressure protective equipment required by local codes,

but not less than a combination temperature and pressure relief valve

certified by a nationally recognized testing laboratory that maintains periodic

inspection of production of listed equipment or materials as meeting the

requirements of the Standard for Relief Valves and Automatic Gas Shutoff

Devices for Hot Water Supply Systems, ANSI Z21.22 and the Standard

CAN1-4.4 Temperature, Pressure, Temperature and Pressure Relief Valves

and Vacuum Relief Valves. The combination temperature and pressure

relief valve must be marked with a maximum set pressure not to exceed

the maximum working pressure of the water heater. The combination

temperature and pressure relief valve rating must not be less than the

hourly rating of the water heater.

Install the combination temperature and pressure relief valve into the

opening provided and marked for this purpose on the water heater.

Note: Some models may already be equipped or supplied with an installed

combination temperature and pressure relief valve. Verify that the

combination temperature and pressure relief valve complies with local

codes. If the combination temperature and pressure relief valve does not

comply with local codes, replace it with one that does.

Install a discharge line so that water discharged from the combination

temperature and pressure relief valve will exit within six (6) inches (15.2

cm) above, or any distance below the structural floor and cannot contact

any live electrical part. The discharge line is to be installed to allow for

complete drainage of both the combination temperature and pressure

relief valve and the discharge line. The discharge opening must not be

subjected to blockage or freezing. DO NOT thread, plug or cap the discharge

line. It is recommended that a minimum clearance of four (4) inches (10.2

cm) be provided on the side of the water heater for servicing and

maintenance of the combination temperature and pressure relief valve.

Do not place a valve between the combination temperature and pressure

relief valve and the tank!

TEMPERATURE & PRESSURE RELIEF VALVE

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

telephone in your building.

• Immediately call your gas supplier from a neighbor’s

telephone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

Use only vent terminals provided or factory authorized terminals for

venting this water heater.

This water heater is equipped with an adjustable thermostat to control

water temperature. Hot water temperatures required for automatic

dishwasher and laundry use can cause scald burns resulting in serious

personal injury and/or death. The temperature at which injury occurs

varies with the person’s age and the time of exposure. The slower

response time of disabled persons increases the hazards to them. NEVER

allow small children to use a hot water tap, or to draw their own bath water.

NEVER leave a child or disabled person unattended in a bathtub or shower.

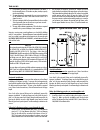

Failure to properly install the vent and air intake (if applicable) system

could result in property damage, personal injury, or death.

DANGER

DO NOT store or use gasoline or other flammable, combustible, or corrosive

vapors and/or liquids in the vicinity of this or any other appliance.

DO NOT install any damaged venting system components. If damage is

evident then please contact the supplier where the water heater was

purchased or the manufacturer listed on the rating plate for replacement

parts.

DANGER