- DL manuals

- Loctite

- Dispenser

- 1390321

- Operation manual

Loctite 1390321 Operation manual

Summary of 1390321

Page 1

1 equipment operation manual loctite integrated semi-automatic dispenser dual channel with low level sensor part numbers 1390322, 0 – 1 bar 1390321, 0 – 7 bar.

Page 2: Table of Contents

2 table of contents 1. Please observe the following ..................................................................................................... 3 1.1 e mphasized s ections .........................................................................................................................

Page 3

3 1. Please observe the following 1.1 emphasized sections warning! Refers to safety regulations and requires safety measures that protect the operator or other persons from injury or danger to life. Caution! Emphasizes what must be done or avoided so that the unit or other property is not damaged. N...

Page 4

4 2.2 theory of operation the loctite ® integrated semi-automatic dispenser is connected to an external pneumatic supply. It regulates the adjusted dispensing pressure and controls the dispensing during the selected dispensing time. An uncovered bottle of loctite ® product is placed directly into th...

Page 5

5 caution! Pay attention if cyanoacrylate is dispensed – air in the feed line results in curing of the product! 2.3 items supplied - integrated semi-automatic dispenser, dual channel, 0-1 bar, order no. 1390322 or - integrated semi-automatic dispenser, dual channel, 0-7 bar, order no. 1390321 - foot...

Page 6

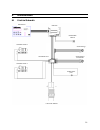

6 2.4 overall dimensions.

Page 7

7 2.5 control panel (front & back of controller) 1. Reservoir fitting 2. Valve pressure relief 3. Display 4. Mode switch 5. Right arrow switch 6. Manual switch for channel a 7. Low level error led light 8. Set switch 9. Up arrow switch 10. Manual switch for channel b 11. Enter switch 12. Main power ...

Page 8

8 3 . Technical data 3.1 specifications attribute value time range 0 – 99.99 seconds air input * clean, dry air not to exceed 125 psig (8.5 bar), and filtered with a maximum of 50 micron regulation range of the pressure regulator 1390322 0 – 2 bar (0 – 28 psi) 1390321 0 – 7 bar (0 – 100 psi) pressur...

Page 9

9 4. Installation 4.1 unpacking and inspection carefully remove the system from its shipping carton and inspect it for any signs of damage. Any damage should be reported immediately to the carrier. Refer to the list of supplied parts (see page 4) and compare to the contents. Report any missing or da...

Page 10

10 5. Operation 5.1 function of the control panel: switch (4): switching different mode as below cycle: run: auto > run: manual > run: continuous > set: time (auto) > set: delay (auto) > set: output > set: low level > set: lock-out switch (8) set the data in all “set: xxxx” mode. Switch (5): for par...

Page 11

11 5.2 xs1 connection signal: the system can be auto detecting when the footswitch(s) plug onto the system. Only xs1 channel a (master) footswitch plugged: the footswitch can control both output of channel a and channel b and start at the same time. Only xs1 channel b footswitch plugged: the footswi...

Page 12

12 5.6 run: continuous mode engage the footswitch(s) to start dispensing and hold until the dispensing cycle is complete. When the footswitch is released, the dispensing will end immediately. The display on the system will show the last dispensing time. If needed, press and to store the dispensing t...

Page 13

13 5.10 set: low level mode 1. Press , the setting for low level mode start to flash. 2. Press for switching between “off”, “lamp” and “lamp + stop”. 3. After completed setting, press to save and exit. Notice: off: only digital output from xs1 lamp: digital output from xs1 + led light on control pan...

Page 14

14 6. Troubleshooting symptom possible causes corrections the digital display does not light. - no power voltage present. - powers switch 12 in position o (off). - power adaptor with cord is defective. - control unit is defective check the power voltage. switch power switch to position i (on). ...

Page 15

15 7. Care and maintenance 7.1 care - occasionally the o-ring at the reservoir lid should be lubricated with the enclosed silicone grease. This will prolong the life of the o-ring. Notice: clean hands after application of grease to assure surfaces to be bonded are clean. Otherwise bonding might fail...

Page 16

16 8. Documentation 8.1 electrical schematic start switch main power switch main pcb start switch xs1 master power input jack solenoid valve a solenoid valve b low level sensor film switch secondary pcb.

Page 17

17.

Page 18

18 8.2 pin connections xs1 start via footswitch, additional empty signal and ready signal. Warning! Never connect external voltage on pin 1 or pin 9! Never short pins 3 and 4, nor 6 and 7 together, permanent board damage will result..

Page 19

19 9. Accessories, spare parts & system components sold separately loctite item number description accessories 985397 loctite ® air filter, regulator, gauge spare parts 8900064 reservoir tank fitting, ¼ inch npt x ¼ inch tubing 97201 footswitch 97972 ¼ inch o.D. Black pe teflon lined fluid feed line...

Page 20

20 equipment warranty for loctite® integrated semi automatic dispenser henkel expressly warrants that all products referred to in this instruction loctite ® integrated semi automatic dispenser (hereafter called “products”) shall be free from defects in materials and workmanship. Liability for henkel...