- DL manuals

- Logic

- Spreader

- LDS120

- Operator's Manual

Logic LDS120 Operator's Manual

Summary of LDS120

Page 1

Lds120/120ds/240/360/700 operators manual wm1-lds120 lds – ground drive spreader.

Page 2: Index

Lds serial number: date of purchase: index section: description: page no: 1 introduction 1 hse information sheet 2 hse information sheet 3 2 in the interest of safety: do not 4 3 in the interest of safety: do 5 4 instruction & warning decals 6 5 transporting and lifting the lds 7 6 operating instruc...

Page 3: Introduction

1 with the purchase of your logic lds – ground drive spreader you have made an excellent choice. This machine should give first class service for a long time, if used correctly, and maintained as described in this manual. The ground drive spreader range is capable of spreading fertiliser as well as ...

Page 4: Terrain Vehicles (Atvs)

2 introduction this information sheet gives advice to users on how to use all terrain vehicles (atvs) safely with towed and mounted equipment. Plan the use of an atv carefully and take particular note of ground conditions and slopes, as these may vary considerably, depending on the terrain, weather ...

Page 5

3 mounted equipment atvs using mounted equipment are safer if the equipment has: a low centre of gravity. This improves stability; a gross weight within the limits the limits approved by the atv manufacturer; no dangerous projections to enquire the operator or bystanders; no forward projections whic...

Page 6

4 1. Do not – operate the lds without all the correct guards fitted. 2. Do not – touch any moving or rotating parts, during working conditions 3. Do not – operate the lds without suitable ear and eye protection 4. Do not – allow passengers. 5. Do not – operate the lds on excessively steep slopes. 6....

Page 7

5 1. Do – follow all manufactures guidelines. 2. Do – ensure all spectators are a min of 15 metres distance away when operating the spreader. The operator must continually check the working area, to avoid harming such third parties. 3. Do – carry out regular servicing and checks before use. 4. Do – ...

Page 8

6 instruction / warning decals 4 the above decals should be located on your lds – ground drive spreader. If any of the above decals are not located on your lds or are damaged in any way contact logic for some replacement decals before use..

Page 9: Transporting & Lifting

7 1. Check to see if the vehicle transporting the spreader can legally carry its weight (see manufactures plate on spreader for unladen weights) 2. Ensure the vehicle used to lift and transport the lds has the necessary lifting and loading capacity. Follow all vehicle manufactures guidelines for lif...

Page 10

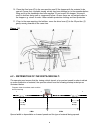

8 6.1 – before use check the following: 1. Ensure the tow ball on the vehicle is compatible with the spreader. 2. Check the operation of all controls (a). 3. Ensure the ride height is correctly set for the atv towing the spreader (b). Remove the fixing bolt and adjust the angle of the spreader to en...

Page 11

9 10. Place the flow lever (d) in the zero position and fill the hopper with the material to be spread. Ensure that a suitable towing vehicle has been hooked up to the spreader before filling and that the handbrake has been applied. Do not overfill the hopper; this could result in fertilizer being s...

Page 12

10 6.3 – vane regulation / adjustment: should the distribution prove to be uneven, the operator can remedy this by regulating the angle of all the vanes by adjusting the vanes to the different holes on the spreader disc. 6.4 – calibration (fertiliser) to precisely calibrate the spreader carefully re...

Page 13

11 6.5 – calibration charts lds120: calibrated at a speed of 15kph (kg/ha) setting 1 2 3 4 5 6 urea - 11.00 27.50 482.50 63.30 82.50 super - 19.30 44.00 77.00 112.80 140.30 dap - 19.30 35.80 57.80 79.80 104.50 calibrated at a speed of 20kph (kg/ha) setting 1 2 3 4 5 6 urea - 7.50 20.00 32.50 50.00 6...

Page 14

12 6.6 - lds120ds – calibration (salt) the logic lds120ds is capable of spreading dry white bagged de-icing salt only. All materials will vary slightly, depending on density and moisture, etc, even in bags, the same batch can vary. The following steps are intended as a guide only, and it is highly r...

Page 15

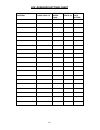

13 lds -spreader settings chart material towing vehicle operating speed (mph) spread width (m) feed gate setting.

Page 16: Maintenance

14 always empty the hopper before any maintenance is carried out 7.1 - daily 1. Check the condition of the engagement mechanism and grease daily. Use the following procedure, firstly engage the drive, and then pump grease into the nipple. 2. Check the condition of the spreader, if any parts need rep...

Page 17

15 7.2 - seasonal 1. Check the condition of the drive engagement lever and the plastic tube liner. 2. Check the wheel bearings for play and pack with grease every six months 3. Open the aperture and clean around the aperture blades and holes. 4. Periodically remove the agitator by removing the retai...

Page 18

16 8.1 – main frame and parts parts list: lds120 / lds120ds 8.

Page 19

17 8.2 - parts list main frame: lds120 / lds120ds item part number description qty 1 lds120-1001 frame 1 2 lds120-1002 drive axle 1 3 lds120-1003 easylock hub 1 4 lds120-1004 drive coupling 1 5 lds120-1005 bearing housing 1 6 lds120-1006 drive axle bearings 2 7 lds120-1007 key 1 8 lds120-1008 drivin...

Page 20

18 8.3 – spinner and hopper details: lds120 / lds120ds item part number description qty 1 lds120-1028 lid - lds120 1 2 lds120-1029 hopper – lds120 1 3 lds120-1030 agitator 1 4 lds120-1031 agitator bush 1 5 lds120-1032 lower shutter plate 1 6 lds120-1033 circlip 1 7 lds120-1034 spinner plate 1 8 lds1...

Page 21: Parts List: Lds 240/360

19 8.4 – main frame and parts parts list: lds 240/360 8.

Page 22

20 8.5 - parts list main frame: lds240/360 item part number description qty 1 lds240-1001 frame 1 2 lds120-1002 drive axle 1 3 lds120-1003 easylock hub 1 4 lds120-1004 drive coupling 1 5 lds120-1005 bearing housing 1 6 lds120-1006 drive axle bearings 2 7 lds120-1007 key 1 8 lds240-1002 driving wheel...

Page 23: Parts List: Lds240/360

21 8.6 – spinner and hopper details parts list: lds240/360 8 item part number description qty 1 lds240-1005 lid – lds240 1 2 lds240-1006 hopper – lds240 1 2 lds240-1006 hopper – lds360 1 lds360-1001 hopper extension – lds360 (not shown) 1 lds360-1002 hopper fixing bolt c/w nut & washer 6 3 lds120-10...

Page 24: Parts List: Lds700

22 8.7– drive assembly: lds700 8.8- main frame: lds700 8 7 6 9 11 12 13 14 1 2 3 4 5 20 19 18 17 16 24 15 21 22 23 10 parts list: lds700 8.

Page 25

23 8.9 – wheels and tyres: lds700 8.10 – spinner and agitator: lds700 29 28 27 26 25 33 32 31 30 35 34 36 37 38 39 40 41 42 43.

Page 26

24 8.11 - parts list: lds700 item part number description qty 1 lds700-1001 drive axle 1 2 lds120-1003 easylock hub 1 3 lds120-1004 drive coupling 1 4 lds120-1027 gearbox 1 5 lds120-1019 drive operating lever 1 6 lds700-1002 bearing housing 1 7 lds700-1003 driven sprocket 1 8 lds700-1004 tensioner 1...

Page 27

25 this logic manufacturing product is guaranteed against faulty workmanship and materials for a period of 6 months from the date of purchase. On engine-powered equipment, the engine manufactures guarantee will apply, any claims being subject to their terms and conditions. All claims must be made in...

Page 28

26 declaration of conformity 93 / 44 eec logic manufacturing ltd foundry industrial estate bridge end hexham northumberland product type: lds100 – vogal ground drive spreader covered by technical file number: ce – lds100 serial number: standards and regulations used: the supply of machinery (safety)...