- DL manuals

- M&M

- Controller

- RWB series

- Manual

M&M RWB series Manual

Summary of RWB series

Page 1

M&m refrigeration, inc. Computer control system screw compressor control rwb series retro fit panel &.

Page 2

Standard screw compressor - rwb series m&m r efrigeration i nc . Copyright protection claimed includes all forms and matters now and hereinafter granted pro- tection by statutory or judicial law, including unlimited protection for screen images generated from the software programs. Such images inclu...

Page 3

M&m r efrigeration i nc . Revision history revision date change - 11/2002 inital release.

Page 4

Standard screw compressor - rwb series m&m r efrigeration i nc ..

Page 5: Table of Contents

M&m r efrigeration i nc . Iii table of contents table of contents chapter 1 ccs introduction associated documents.................................................................. 1-1 applicable compressor models.................................................... 1-1 chapter 2 general operating ove...

Page 6

Standard screw compressor - rwb series iv m&m r efrigeration i nc . Oil pressure calculations ......................................................... 3-3 oil level indication.................................................................. 3-3 starting the screw compressor...........................

Page 7

M&m r efrigeration i nc . V table of contents oil temperature regulation.......................................................... 3-17 liquid injection oil cooling (option).......................................... 3-17 single port liquid injection .....................................................

Page 8

Standard screw compressor - rwb series vi m&m r efrigeration i nc . Temperature setpoints.......................................................... 3-40 discharge temperature setpoints .................................... 3-40 oil temperature setpoints (without liquid injection) .... 3-41 oil temper...

Page 9

M&m r efrigeration i nc . Vii table of contents chapter 5 menu functions technical overview ...................................................................... 5-1 logon user ............................................................................... 5-1 logoff user..............................

Page 10

Standard screw compressor - rwb series viii m&m r efrigeration i nc . Password control ................................................................. 5-19 add/delete user .............................................................. 5-20 screen access levels ........................................

Page 11

M&m r efrigeration i nc . Ix table of contents word range write................................................................ C-12 error messages..................................................................... C-13 data formats.....................................................................

Page 12

Standard screw compressor - rwb series x m&m r efrigeration i nc ..

Page 13: Associated Documents

M&m r efrigeration i nc . 1-1 chapter 1 ccs introduction the compressor control system (ccs) is an advanced microprocessor- based control system designed for efficient and automatic control and mon- itoring of industrial refrigeration systems including screw compressors. The controller is composed o...

Page 14

Standard screw compressor - rwb series 1-2 m&m r efrigeration i nc ..

Page 15: Definitions

M&m r efrigeration i nc . 2-1 chapter 2 general operating overview the following sections will give the user an overview of the general operat- ing procedures for the ccs. Definitions ccs system manager is the person who will assign user passwords, access levels and screen access requirements. Curso...

Page 16: Keypad Functions

Standard screw compressor - rwb series 2-2 m&m r efrigeration i nc . Parameter is a system control value, which is displayed by the system or input by the user. Examples are suction pressure and high suction pressure alarm setpoint. Screen is a method of displaying information to the user. The syste...

Page 17

M&m r efrigeration i nc . 2-3 chapter 2: keypad functions stop the red stop key causes an immediate and orderly shutdown of a compressor. This key usually has no effect on master panels. Shift the shift key is used to switch control back and forth from the display area to the hot keys. This key may ...

Page 18: Main Screen Overview

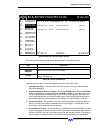

Standard screw compressor - rwb series 2-4 m&m r efrigeration i nc . Main screen overview the main screen is the name for a set of features common to all large character screens. The main screen is broken down into three areas: display area, hot keys, and title banner. The fol- lowing drawing shows ...

Page 19: Hot Key Selection

M&m r efrigeration i nc . 2-5 chapter 2: hot key selection hot key selection 1. Verify number next to a hot key is highlighted - one of the numbers next to a hot key should be highlighted and flashing. (this is not the same as having the hot key command highlighted.) if there are no numbers highligh...

Page 20

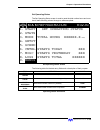

Standard screw compressor - rwb series 2-6 m&m r efrigeration i nc . Menu screens the menu screen is used to present the user with choices for various system operations. Menu screens are found throughout the ccs system. The following is an example of a menu screen. Menu screen the following table co...

Page 21

M&m r efrigeration i nc . 2-7 chapter 2: screen types menu selection procedures - menu options are chosen similar to hot key options. 1. Verify cursor control - verify that a menu option number is highlighted. If not use the shift key to transfer cursor control from the hot keys to the display area....

Page 22

Standard screw compressor - rwb series 2-8 m&m r efrigeration i nc . The following table contains a list of the active keys on a data entry screen and their func- tion. Data screen keys a data entry screen may contain both numerical input and selectable fields, which are identi- fied by different cu...

Page 23

M&m r efrigeration i nc . 2-9 chapter 2: screen types arrow keys - the arrow keys will accept the entered data and move the cursor to the next field. Errors - a flashing error message tells the user that the entered data is not within an acceptable range for the field. The user must clear the error ...

Page 24

Standard screw compressor - rwb series 2-10 m&m r efrigeration i nc . 3. Enter/arrow keys - locks in the numerical data and moves the cursor across to the units section of the field. 4. Verify cursor type - locate the ">" selection cursor next to the units section. 5. Enter - cycles between possible...

Page 25

M&m r efrigeration i nc . 2-11 chapter 2: screen types 3. “.” key - selecting the period (.) key puts the field into edit mode and allows the current contents of the field to be entered. 4. Arrow keys - allows you to move within a field to different charac- ters. 5. Number keys - these keys are used...

Page 26

Standard screw compressor - rwb series 2-12 m&m r efrigeration i nc . 4. Arrow keys - allows you to move within a field to different charac- ters. 5. Number keys - these keys are used to enter numbers into a char- acter. 6. Clear key - this key is used to clear the contens of the entire field. 7. En...

Page 27

M&m r efrigeration i nc . 2-13 chapter 2: screen types the following table contains a list of the active keys on a status screen and their function. Status screen keys confirmation screens a confirmation screen is used to ask the user to confirm a selection by answering a ques- tion. This screen usu...

Page 28

Standard screw compressor - rwb series 2-14 m&m r efrigeration i nc . The following table contains a list of the active keys on a confirmation screen and their function. Confirmation screen keys confirmation screen procedures number keypad - use the keypad to match your response with the numerical c...

Page 29

M&m r efrigeration i nc . 2-15 chapter 2: screen types the following table contains a list of the active keys on a momentary screen and their function. Momentary screen keys information screens information screens are used to display system data to the user. The information on these screens may be r...

Page 30

Standard screw compressor - rwb series 2-16 m&m r efrigeration i nc . Required to clear the error and enter a correct value. The data entry process is described in more detail in the data entry section. The following is an example of an access screen. Access screen the following table contains a lis...

Page 31

M&m r efrigeration i nc . 2-17 chapter 2: screen types log screens log screens are used to view recorded system information. The width and length of the log screens may be wider and longer than allowed by the lcd display area. The arrow and page keys can then be used to view the entire log. All syst...

Page 32: Alarms & Failures

Standard screw compressor - rwb series 2-18 m&m r efrigeration i nc . Alarms & failures the ccs continually monitors the system parameters and compares them to alarm and fail- ure setpoints to inform the operator of the system status. An alarm is intended to alert the operator that an undesirable co...

Page 33

M&m r efrigeration i nc . 2-19 chapter 2: alarms & failures active alarms & failures status screen the active function keys for this screen are described in the following table. Alarm & failure screen keys use the following steps to acknowledge and clear any alarms & failures. 1. Verify screen type ...

Page 34

Standard screw compressor - rwb series 2-20 m&m r efrigeration i nc ..

Page 35: Modes of Operation

M&m r efrigeration i nc . 3-1 chapter 3 compressor controls the following sections discuss the standard and optional features contained in the ccs screw compressor package. Modes of operation the screw compressor package has several modes of operation. The mode is changed by using the mode hot key a...

Page 36: Lubrication System

Standard screw compressor - rwb series 3-2 m&m r efrigeration i nc . Lubrication system the rwb screw compressor is designed to be self-lubricating. The oil being supplied to the compressor is at discharge pressure and the oil porting to all parts of the compressor is below discharge pressure. The n...

Page 37

M&m r efrigeration i nc . 3-3 chapter 3: starting the screw compressor oil pressure calculations the oil pressure and oil filter pressure values are computed using a combination of the oil pressure after filter, oil pressure before filter, and discharge pressure transducers. The following formulas a...

Page 38

Standard screw compressor - rwb series 3-4 m&m r efrigeration i nc . Allowed to start. If the slide valve position does not move below 5% within 5 minuets, the compressor will be failed on start slide position. Once the motor starts, the slide valve position is monitored while the compressor is comi...

Page 39

M&m r efrigeration i nc . 3-5 chapter 3: starting the screw compressor automatic mode in automatic mode the compressor can be started automatically based on suction pres- sure or process temperature. Automatic starting is enabled on the miscellaneous control screen under the misc hot key. Once the a...

Page 40

Standard screw compressor - rwb series 3-6 m&m r efrigeration i nc . Stopping the screw compressor the stopping sequence is as follows: 1. The motor is stopped. 2. Once the starter has disengaged the slide valve is moved to the fully unloaded posi- tion (below 5%). If the slide valve does not respon...

Page 41: Capacity Control

M&m r efrigeration i nc . 3-7 chapter 3: capacity control sequenced mode when the stop command is received from the master sequencer, the ccs will stop the screw compressor automatically and leave it on-line for sequenced operation. While stopped on-line, the compressor is available for sequencing a...

Page 42

Standard screw compressor - rwb series 3-8 m&m r efrigeration i nc . Control groups four groups of control setpoints can be defined for use with automatic capacity con- trol. Each setpoint group consist of a cut-in, cut-out, control, and low alarm and fail- ure setpoints. The control associated with...

Page 43

M&m r efrigeration i nc . 3-9 chapter 3: capacity control slowly to control parameter changes. While the control parameter is outside the band- width values the slide valve is continuously loaded or unloaded. Long pulse - this is the longest amount of time used to move the slide valve while loading ...

Page 44

Standard screw compressor - rwb series 3-10 m&m r efrigeration i nc . Time proportional control strategy diagrams load deadband unload deadband unload bandwidth load bandwidth control setpoint pressure difference below setpoint pressure difference above setpoint no slide valve movement no slide valv...

Page 45

M&m r efrigeration i nc . 3-11 chapter 3: capacity control remote capacity control i/o control when remote operation is desired using discrete i/o signals, and the compressor is in the remote mode, capacity control is performed using the remote load and remote unload inputs. The relationship of thes...

Page 46

Standard screw compressor - rwb series 3-12 m&m r efrigeration i nc . Network control when the network communications option is enabled, and the compressor is in the auto-remote mode, capacity control is performed using automatic capacity control. The control setpoint is selected using setpoint mess...

Page 47

M&m r efrigeration i nc . 3-13 chapter 3: capacity control current, the ccs informs the master sequencer that no further capacity increases are possible and additional compressors may be needed. Running in full load mode when the full load command is received the ccs disables all capacity control an...

Page 48

Standard screw compressor - rwb series 3-14 m&m r efrigeration i nc . Slide valve position ramp start limiting the slide valve position ramp start feature has been provided to limit capacity increases after the compressor starts. The operator can define the minimum positions to start ramp- ing, the ...

Page 49: Setpoint Scheduling

M&m r efrigeration i nc . 3-15 chapter 3: setpoint scheduling unload solenoid configuration the unload solenoid for the a -series compressors has two configurations, in the original configuration, the solenoid is normally closed, energized to unload the com- pressor. In later versions, the unload so...

Page 50

Standard screw compressor - rwb series 3-16 m&m r efrigeration i nc . Variable vi slide stop control vi refers to the volumetric ratio of the screw compressor. The vi is computed by taking the ratio of the volume of gas when compression begins to the volume of gas when discharge begins. In a fixed v...

Page 51: Oil Temperature Regulation

M&m r efrigeration i nc . 3-17 chapter 3: oil temperature regulation oil temperature regulation the oil temperature in the oil separator is regulated when the screw compressor is stopped. The temperature is maintained above the oil heater setpoint with a deadband of +5 degrees. When the compressor i...

Page 52: Power Fail Restart

Standard screw compressor - rwb series 3-18 m&m r efrigeration i nc . Power fail restart the operator can define a power fail restart time from the miscellaneous time setpoint screen. If the ccs is reset manually or due to a loss of power the down time is calculated and com- pared to this setpoint. ...

Page 53: Economizer Control (Option)

M&m r efrigeration i nc . 3-19 chapter 3: economizer control (option) economizer control (option) the economizer control option provides an intermediate pressure port located between the primary suction and discharge ports on the screw compressor. The economizer solenoid out- put is used to control ...

Page 54: Operational Procedures

Standard screw compressor - rwb series 3-20 m&m r efrigeration i nc . Operational procedures the operator interface for the screw compressor is performed using lcd, keypad, and the fol- lowing nine hot keys: • start • stats • mode • setpt • sched • cntrl • misc • logs • menus the following sections ...

Page 55

M&m r efrigeration i nc . 3-21 chapter 3: operational procedures the following screen is an example of one of the possible momentary screens that may appear after answering yes to the start confirmation screen. The possible momentary screens will vary depending on the individual system configuration...

Page 56

Standard screw compressor - rwb series 3-22 m&m r efrigeration i nc . Stats hot key the stats hot key will allow the user to return quickly to the main status screen. The operator may select the compressor status screen or the compressor graphics screen as the default main status screen. The quit ke...

Page 57

M&m r efrigeration i nc . 3-23 chapter 3: operational procedures manual control of the slide valve is discussed in the capacity control section and alarms and failures are discussed in the alarm/failure section of this manual. The following table lists the various parameters displayed on the screw s...

Page 58

Standard screw compressor - rwb series 3-24 m&m r efrigeration i nc . System current state the left-most highlighted status banner section displays the current state of the system. The following is a table with a brief description of possible system states. System state mode area the middle highligh...

Page 59

M&m r efrigeration i nc . 3-25 chapter 3: operational procedures alarm & failure area the right most highlighted status banner section displays the alarm and failure status of the system. When a new alarm or failure occurs, this area will flash from highlighted to non-highlighted to inform the opera...

Page 60

Standard screw compressor - rwb series 3-26 m&m r efrigeration i nc . Energy status screen the energy status screen displays the motor current and the computed energy con- sumption information. Energy status screen the following table lists the various parameters displayed on the screen. Energy stat...

Page 61

M&m r efrigeration i nc . 3-27 chapter 3: operational procedures operating hours screen the operating hours status screen allows the operator to view the compressor’s cur- rent running hours since its last start and the total number of hours the system has been in operation since installation in add...

Page 62

Standard screw compressor - rwb series 3-28 m&m r efrigeration i nc . Variable vi status screen the variable vi status screen displays information pertaining to the variable vi con- trol option. Variable vi status screen the following table lists the parameters displayed on the variable vi status sc...

Page 63

M&m r efrigeration i nc . 3-29 chapter 3: operational procedures economizer status screen (option) the economizer status screen displays information pertaining to the economizer control option. This screen is only present if the economizer control option is enabled. Economizer status screen the foll...

Page 64

Standard screw compressor - rwb series 3-30 m&m r efrigeration i nc . Active alarms & failures status screen the active alarms & failures status screen displays the system's current alarms/fail- ures. This screen will be the initial screen displayed by the system when an alarm or failure first becom...

Page 65

M&m r efrigeration i nc . 3-31 chapter 3: operational procedures auto-start warning screen the auto-start warning screen is displayed anytime the screw may be automatically started. The user can return to the system default status screen by pressing the quit key or cycle through all the status scree...

Page 66

Standard screw compressor - rwb series 3-32 m&m r efrigeration i nc . Mode hot key the mode hot key allows the operator to select the system's operational mode. When the mode hot key is selected, a menu screen displays the available modes contained on the system. This menu screen could have up to si...

Page 67

M&m r efrigeration i nc . 3-33 chapter 3: operational procedures remote mode the remote mode is only available if the remote option is enabled. It is primarily used for systems where another control system is responsible for starting, stopping, and capacity control. Remote mode uses an external remo...

Page 68

Standard screw compressor - rwb series 3-34 m&m r efrigeration i nc . Setpt hot key the setpt hot key allows the user to access a set of menu options used to set the sys- tems various setpoints . Setpt menu diagram pressure setpoints the pressure setpoints menu allows the user adjust the various pre...

Page 69

M&m r efrigeration i nc . 3-35 chapter 3: operational procedures suction pressure control data entry screen the following table lists the data entry fields on the screen and a description of their purposes. Suction pressure control data definitions suction pressure day mm/dd/yy hh:mm:ss control grou...

Page 70

Standard screw compressor - rwb series 3-36 m&m r efrigeration i nc . High suction pressure setpoints the high suction pressure alarm and failure setpoints are not scheduled and are active regardless of which group is in control. High suction pressure setpoints screen the following table lists the d...

Page 71

M&m r efrigeration i nc . 3-37 chapter 3: operational procedures discharge pressure setpoints the discharge pressure setpoints screen is used to set the discharge pressure control parameters for high alarm, limiting, and ramp conditions discharge pressure setpoints data entry screen the following ta...

Page 72

Standard screw compressor - rwb series 3-38 m&m r efrigeration i nc . Oil pressure setpoints the oil pressure setpoints screen allows the operator to set acceptable ranges for the oil pressure parameter to allow the ccs to identify when the value is out of range. An example of the screen is shown be...

Page 73

M&m r efrigeration i nc . 3-39 chapter 3: operational procedures oil filter pressure setpoints the oil filter setpoints screen allows the operator to set an acceptable range for the oil filter pressure as shown in the following example. Note: the displayed oil pressure is a computed value. The compu...

Page 74

Standard screw compressor - rwb series 3-40 m&m r efrigeration i nc . Temperature setpoints the temperature setpoints menu allows the user to set temperature related set- points described in the following sections. Discharge temperature setpoints the discharge temperature setpoints screen allows the...

Page 75

M&m r efrigeration i nc . 3-41 chapter 3: operational procedures oil temperature setpoints (without liquid injection) the oil temperature setpoints screen allows the operator to set acceptable ranges for the screw oil temperature and oil sump temperature regulation. Oil temperature setpoints screen ...

Page 76

Standard screw compressor - rwb series 3-42 m&m r efrigeration i nc . Oil temperature setpoints ( with liquid injection) the liquid injection option adds two additional setpoint to the oil temperature set- point screen. An example of the optional oil temperature setpoint screen is as fol- lows. Scre...

Page 77

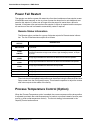

M&m r efrigeration i nc . 3-43 chapter 3: operational procedures process temperature control group the process temperature control group screen is used to setup the process temperature control parameters when the process temperature control option is enabled. Process temperature control groups the f...

Page 78

Standard screw compressor - rwb series 3-44 m&m r efrigeration i nc . High process temperature selection the high process temperature setpoints screen is only visible when the process temperature control option is enabled. High process temperature setpts the following table lists the parameter displ...

Page 79

M&m r efrigeration i nc . 3-45 chapter 3: operational procedures motor current setpoints the motor current setpoints screen is used to set the motor current control parame- ters for high alarm, limiting, and ramp conditions. Motor current setpoints data entry screen the following table lists the dat...

Page 80

Standard screw compressor - rwb series 3-46 m&m r efrigeration i nc . Slide valve setpoints the slide valve setpoints screen allows the operator to set acceptable ranges for minimum slide valve position as shown in the following example. Slide valve setpoints screen the following table lists the dat...

Page 81

M&m r efrigeration i nc . 3-47 chapter 3: operational procedures sched hot key the scheduling function allows the user to create and modify schedules to control the changing of suction pressure setpoints based on the day of the week and time of day. The following sections will describe the various s...

Page 82

Standard screw compressor - rwb series 3-48 m&m r efrigeration i nc . Active group the active group screen allows the user to select the current active group. This set- ting will be active until a scheduling change or the operator modifies it. An example of the screen is shown below. Active group sc...

Page 83

M&m r efrigeration i nc . 3-49 chapter 3: operational procedures active schedule the active schedule screen allows the user to change the current active daily sched- ule. This setting will be active until a scheduling change or the user modifies it. An example of the screen is shown below. Active sc...

Page 84

Standard screw compressor - rwb series 3-50 m&m r efrigeration i nc . Weekly schedule the weekly schedule screen is used to define which of the seven available daily schedules is to be assigned to each day of the week as shown in the following exam- ple screen. Weekly schedule screen the following t...

Page 85

M&m r efrigeration i nc . 3-51 chapter 3: operational procedures schedule 1 to schedule 7 the seven daily schedules all have a standard format allowing the user to select up to 8 schedule changes per day. The following example shows the standard for- mat for all seven of the daily schedules. Daily s...

Page 86

Standard screw compressor - rwb series 3-52 m&m r efrigeration i nc . Cntrl hot key the cntrl hot key allows the user to access a set of menu options used to set the sys- tems control features. Cntrl menu diagram suction pressure control setpoints the suction pressure control setpoints screen allows...

Page 87

M&m r efrigeration i nc . 3-53 chapter 3: operational procedures the following table lists the data entry and information fields on the screen and a description of their purposes. Suction pressure control setpoints definitions process temperature control setpoints the process temperature control set...

Page 88

Standard screw compressor - rwb series 3-54 m&m r efrigeration i nc . The following table lists the data entry fields and a description of their purposes. Process temperature control setpoints definitions economizer control setpoints (option) the economizer control screen is only visible when the ec...

Page 89

M&m r efrigeration i nc . 3-55 chapter 3: operational procedures the following table lists the data entry fields and a description of their purposes. Economizer control status definitions variable vi setpoints (option) the variable vi control screen provides setpoints for vi control. Variable vi con...

Page 90

Standard screw compressor - rwb series 3-56 m&m r efrigeration i nc . Misc hot key the miscellaneous control screen provides setpoints and controls for various system parameters. Miscellaneous control screen the following table lists the data entry fields and a description of their purposes. Miscell...

Page 91

M&m r efrigeration i nc . 3-57 chapter 3: operational procedures logs hot key the logs hot key is fully described in chapter 4, logging functions. Menus hot key the menus hot key is fully described in chapter 5, menu functions..

Page 92

Standard screw compressor - rwb series 3-58 m&m r efrigeration i nc ..

Page 93

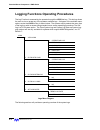

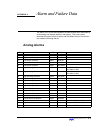

M& r efrigeration i nc . 4-1 chapter 4 logging functions the ccs records the systems parameters and conditions for later use in a set of logs. Each log has a limit on the number of entries that it can store, so as the log fills-up the oldest entries are replaced by the most recent ones. The system m...

Page 94

Standard screw compressor - rwb series 4-2 m&m r efrigeration i nc . Logging functions technical overview the following sections will discuss the overall function of each of the five standard logs as well as the optional kw and system logs. Operations log the operations log displays a list of the sy...

Page 95

M&m r efrigeration i nc . 4-3 chapter 4: logging functions technical overview kw log (optional) the kw log is an optional daily log included when the kw monitoring option is included in the system. It is used to record the periodic totals for demand kw, peak demand, and daily, weekly, monthly and ye...

Page 96

Standard screw compressor - rwb series 4-4 m&m r efrigeration i nc . Logging functions operating procedures the log function is accessed by the operator through the logs hot key. This hot key allows the user to view or erase any of the systems available logs. A diagram of the available menu options ...

Page 97

M&m r efrigeration i nc . 4-5 chapter 4: logging functions operating procedures operations and trend logs the operations and trend logs typically store the same parameters. The only difference is the time interval at which entries are made. The logs will also indicate which parame- ters have caused ...

Page 98

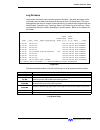

Standard screw compressor - rwb series 4-6 m&m r efrigeration i nc . Alarm and failure logs the alarm and failure logs are records of the system alarm and failure conditions. The screen format is the same for both logs, except for the type column. Alarm log page the alarm and failure logs will conta...

Page 99

M&m r efrigeration i nc . 4-7 chapter 4: logging functions operating procedures user log the user log is a record of the last 50 user logons for the system. The following is an example of a typical user log screen. User log page the user log will contain the data described in the following table for...

Page 100

Standard screw compressor - rwb series 4-8 m&m r efrigeration i nc . Kw log (optional) if the option is supported by your system configuration, data for kw usage is entered in the optional kw log daily at midnight and can be reviewed by accessing the kw log function. Below is an example of a kw log ...

Page 101

M&m r efrigeration i nc . 4-9 chapter 4: logging functions operating procedures clear logs the clear logs function is typically not available to the user. A special one-time password is required from m&m to access this function. Please contact the m&m service depart- ment if you desire to clear the ...

Page 102

Standard screw compressor - rwb series 4-10 m&m r efrigeration i nc ..

Page 103: Technical Overview

M&m r efrigeration i nc . 5-1 chapter 5 menu functions the menus hot key allows the user to access miscellaneous screens that do not fall under one of the other hot key categories. The system supports the following four additional menus: • logon user • logoff user • diagnostics • setup technical ove...

Page 104

Standard screw compressor - rwb series 5-2 m&m r efrigeration i nc . Diagnostics menu the diagnostics menu option permits the user to view basic information about the sys- tem. The information can then be used to readily troubleshoot problems when they occur. Most of the screens available under this...

Page 105

M&m r efrigeration i nc . 5-3 chapter 5: technical overview override discrete i/o (option) the override discrete i/o screen allows the user to set the state of certain discrete outputs. It also allows the user to simulate certain discrete inputs to an active or inac- tive state. This feature is for ...

Page 106

Standard screw compressor - rwb series 5-4 m&m r efrigeration i nc . Static sensor calibration static calibration is performed to reset or restore sensor calibration values after a hardware, software or factory configuration change. The previous dynamic cali- bration results are shown on the static ...

Page 107

M&m r efrigeration i nc . 5-5 chapter 5: technical overview initialization the initialization menu selection under the setup group allows the user to reset the system or restore factory setpoints. Power fail reset choosing power fail reset causes the software to restart using current setpoints as if...

Page 108: Operational Procedures

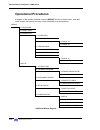

Standard screw compressor - rwb series 5-6 m&m r efrigeration i nc . Operational procedures a diagram of the screens available under the menus hot key is shown below. Note that some screens are optional and may not be accessible on all compressors. Additional menus diagram menus 1. Logon user 2. Log...

Page 109

M&m r efrigeration i nc . 5-7 chapter 5: operational procedures logon user to log onto the system the user selects the logon user option and enters the appropriate user password. Once a password is accepted the system allows access according to the restrictions preset by the ccs system manager. Belo...

Page 110

Standard screw compressor - rwb series 5-8 m&m r efrigeration i nc . Diagnostics the diagnostics menu option permits the user to view and in some cases alter basic infor- mation about the system. The menu selections include viewing system information, view- ing io, analogs, and dip switches; and vie...

Page 111

M&m r efrigeration i nc . 5-9 chapter 5: operational procedures system information the system information screen is used to provide the user with the system options and software configuration status. An example of a system information screen is shown below. System information screen the following ta...

Page 112

Standard screw compressor - rwb series 5-10 m&m r efrigeration i nc . View discrete i/o the view discrete i/o screens are information screens used for viewing purposes only as shown in the following example. Discrete i/o rack 1a screen . Discrete i/o rack 1b screen the following table lists the vari...

Page 113

M&m r efrigeration i nc . 5-11 chapter 5: operational procedures view analogs the view analog inputs screen can be viewed by the operator and will be displayed on a screen similar to the following example. Screen type - information analog inputs screen the following table lists the various parameter...

Page 114

Standard screw compressor - rwb series 5-12 m&m r efrigeration i nc . View dip switches the screen shown below is an example of the view dip switches screen used for ver- ifying the position of the dip switches on the microprocessor board. Note: dip switches should only be adjusted by qualified pers...

Page 115

M&m r efrigeration i nc . 5-13 chapter 5: operational procedures view network comm the view network comm screen allows the user to monitor the status of the system's communication links. The screen shown below is an example of a view network comm screen. Communications status screen the following ta...

Page 116

Standard screw compressor - rwb series 5-14 m&m r efrigeration i nc . Override discrete i/o the override discrete i/o screens allow discrete inputs and outputs to be simulated whenever the compressor is stopped (some channels are not assigned). Any overrid- den channels will be restored to normal wh...

Page 117

M&m r efrigeration i nc . 5-15 chapter 5: operational procedures setup the setup menu allows the user to perform miscellaneous setup changes, which are used to configure the system. The menu selections include set time date, calibrate sensors, password control, initialization, and configuration. Set...

Page 118

Standard screw compressor - rwb series 5-16 m&m r efrigeration i nc . Set date & time the set date & time screen allows the user to change the date, clock mode or time of day for the system. The clock mode gives the user the ability to display time in 24 hour or 12 hour modes. An example of the scre...

Page 119

M&m r efrigeration i nc . 5-17 chapter 5: operational procedures calibrate sensors the calibrate sensors menu allows the user to adjust the range of sensor inputs. There are two types of calibration, dynamic and static. Dynamic calibration is used primarily for accurate calibration of sensor inputs ...

Page 120

Standard screw compressor - rwb series 5-18 m&m r efrigeration i nc . Dynamic sensor calibration dynamic sensor calibration is described more fully in the technical overview section of this chapter. Dynamic sensor calibration screen the following table lists the data entry fields and a description o...

Page 121

M&m r efrigeration i nc . 5-19 chapter 5: operational procedures static sensor calibration static sensor calibration is described more fully in the technical overview sec- tion of this chapter. Static sensor calibration screen the following table lists the data entry fields and a description of thei...

Page 122

Standard screw compressor - rwb series 5-20 m&m r efrigeration i nc . Add delete user screen and the screen access level screen which are discussed in the following sections. Password control screen add/delete user the add/delete user screen will allow for the addition or deletion of a user. This fu...

Page 123

M&m r efrigeration i nc . 5-21 chapter 5: operational procedures the following table lists the data entry fields and a description of their purpose. Add/delete user definitions screen access levels screen access authorization levels are selected for various screen sections using the screen access le...

Page 124

Standard screw compressor - rwb series 5-22 m&m r efrigeration i nc . Initialization the initialization menu selection under the setup group includes power fail reset and set factory config. These screens are discussed further in the following sec- tions. Initialization screen m & m refrigeration 8:...

Page 125

M&m r efrigeration i nc . 5-23 chapter 5: operational procedures power fail reset selection of this initialization option causes the software to restart using the cur- rent setpoints as if a power failure occurred. When the user selects power fail reset, a confirmation screen will be displayed askin...

Page 126

Standard screw compressor - rwb series 5-24 m&m r efrigeration i nc . Set factory config this selection allows the user to reset the system to factory default values. When the user selects the set factory config menu option a confirmation screen will be displayed asking the user to verify that he wi...

Page 127

M&m r efrigeration i nc . 5-25 chapter 5: operational procedures configuration the configuration menu selection allows the user to setup various basic system parameters for the display and operation of the compressor. These parameters are usually setup once and never change. Configuration screen m &...

Page 128

Standard screw compressor - rwb series 5-26 m&m r efrigeration i nc . Display the display setup screen allows the user to configure the display units, default status screen, and the compressor model for use in displaying the proper graph- ics image. Display screen the following table list the data e...

Page 129

M&m r efrigeration i nc . 5-27 chapter 5: operational procedures communication setup the following table is a sample communications setup screen for df1 and mod- bus communications. Communications screen the following table list the data entry fields and a description of their purpose. Communication...

Page 130

Standard screw compressor - rwb series 5-28 m&m r efrigeration i nc . Motor configuration the following table is a sample motor configuration screen. Motor configuration screen the following table list the data entry fields and a description of their purpose. Motor configuration definitions note: ch...

Page 131

M&m r efrigeration i nc . 5-29 chapter 5: operational procedures set operating status the set operating status screen is used to reset the total runtime hours and num- ber of starts following a board change or software update. Set operating status screen the following table list the data entry field...

Page 132

Standard screw compressor - rwb series 5-30 m&m r efrigeration i nc ..

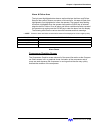

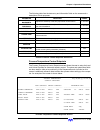

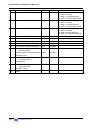

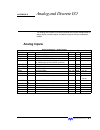

Page 133: Analog Alarms

M&m r efrigeration i nc . A-1 appendix a alarm and failure data the alarm and failure data appendix provides a table which describes all of the analog and discrete alarms in the system. The level column describes the type of alarm or failure and the default column lists the fac- tory setpoint for an...

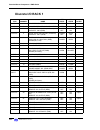

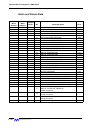

Page 134

Standard screw compressor - rwb series a-2 m&m r efrigeration i nc . 21. Low oil pressure alarm m,d,hw series = 22 psig s series = 15 psig a series = 15 psig with pump a series = 50 psig without pump 22. Low oil pressure fail m,d,hw series = 20 psig s series = 10 psig a series = 10 psig with pump a ...

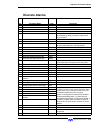

Page 135: Discrete Alarms

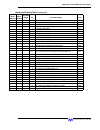

M&m r efrigeration i nc . A-3 appendix a: discrete alarms discrete alarms no. Parameter name level comments 1. Memory initialized alarm 2. Frame overrun alarm 3. Timer allocation fail 4. Ram size failure low fail indicates a hardware problem with the ram chip. 5. Power low reset fail the power has d...

Page 136

Standard screw compressor - rwb series a-4 m&m r efrigeration i nc . 36. Vi sensor oil level float spare fail fail a series and rwb: vi sensor hx series: oil level float all others: spare 37. Oil flow switch oil level float spare fail fail a series: oil flow switch rwb: oil level float all others: s...

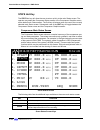

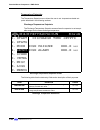

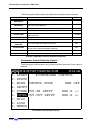

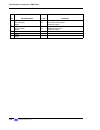

Page 137: Analog Inputs

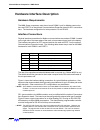

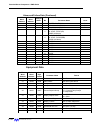

M&m r efrigeration i nc . B-1 appendix b analog and discrete i/o the analog and discrete i/o section identifies the channel assignments for sensor inputs, control outputs, and status inputs for various compressor models. Analog inputs screw compressor - analog inputs type channel name range units se...

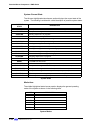

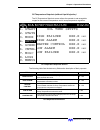

Page 138: Discrete I/o Rack 1

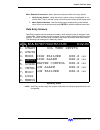

Standard screw compressor - rwb series b-2 m&m r efrigeration i nc . Discrete i/o rack 1 type channel name off state on state notes output 1 compressor motor off on output 2 main or pre-lube oil pump motor off on output 3 slide valve load sol (all others) capacity 100% (rdb) closed off open on outpu...

Page 139

M&m r efrigeration i nc . B-3 appendix b: discrete i/o rack 1 notes: input 26 remote unload (all others) remote 100% capacity (rdb) off off on on option input 27 remote start/stop off on option input 28 remote setpoint select a off on option input 29 remote setpoint select b off on option output 30 ...

Page 140

Standard screw compressor - rwb series b-4 m&m r efrigeration i nc ..

Page 141: Introduction

M&m r efrigeration i nc . C-1 appendix c communication protocols introduction the hardware interface and software protocol are defined for per- forming serial communications with the m&m screw compressor computer control system (ccs). Two open protocols are defined in this document, modbus rtu and a...

Page 142

Standard screw compressor - rwb series c-2 m&m r efrigeration i nc . Hardware interface description hardware requirements the m&m screw compressor uses the on-board comm 1 port for modbus communica- tions and port 2 on the optional communications expansion board for df1 communica- tions. The hardwar...

Page 143

M&m r efrigeration i nc . C-3 appendix c: hardware interface description the following pin-outs apply to the comm 0 port of the plc/5-60 programmable controller. Pin rs-232c rs-422a rs-423 pin rs-232c rs-422a rs-423 1 c.Gnd c.Gnd c.Gnd 14 not used txd.Out send com 2 txd.Out txd.Out + txd.Out 15 3 rx...

Page 144

Standard screw compressor - rwb series c-4 m&m r efrigeration i nc . Message addressing each compressor is required to have a unique address referred to as the unit number. The unit number is initially set using dip switch sw1 on the main microprocessor board. However, the actual unit number can be ...

Page 145

M&m r efrigeration i nc . C-5 appendix c: hardware interface description.

Page 146

Standard screw compressor - rwb series c-6 m&m r efrigeration i nc ..

Page 147

M&m r efrigeration i nc . C-7 appendix c: software interface description software interface description protocol overview all communications with the m&m screw controller is on a request-response basis. The main computer is the “master” and the m&m controller is the “slave”. All messages will origin...

Page 148

Standard screw compressor - rwb series c-8 m&m r efrigeration i nc . Modbus protocol description all transactions will be performed using the modbus rtu transmission mode. All mes- sages will be terminated with a two-byte crc-16. The modbus ascii transmission mode is not supported. The default softw...

Page 149

M&m r efrigeration i nc . C-9 appendix c: software interface description preset single register the preset single register function code (0x06) is used to change the contents of a single register within the m&m controller. Any register within the control message and setpoint messages may be changed ...

Page 150

Standard screw compressor - rwb series c-10 m&m r efrigeration i nc . Note: 0x80 has been added to the function code. The following error codes are supported: unit address 0x?? Function code 0x90 error code 0x03 crc 0x?? Hex code error code definition 01 illegal function. The function code in the me...

Page 151

M&m r efrigeration i nc . C-11 appendix c: software interface description df1 protocol description all df1 transactions will be performed with the m&m controller acting as a slave unit on the network (peer-to-peer communications are not supported). All messages are termi- nated with a one-byte bcc c...

Page 152

Standard screw compressor - rwb series c-12 m&m r efrigeration i nc . Protected typed logical write the following elements are required to access the data in the control message and setpoint messages using the protected typed logical write command. Control com- mands and setpoints may be written ind...

Page 153: Data Formats

M&m r efrigeration i nc . C-13 appendix c: data formats error messages the df1 protocol provides for the return of error codes in the event of a data error within a correctly formatted message block. When the m&m controller detects an error within a read or write message, the message response will c...

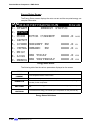

Page 154: Status Message Description

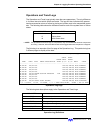

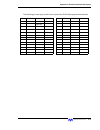

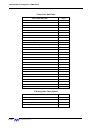

Standard screw compressor - rwb series c-14 m&m r efrigeration i nc . Status message description the status message is a read-only message containing analog, discrete, alarm and state data. Note: some data in the status message may not apply to your particular compressor, depending on optional equip...

Page 155

M&m r efrigeration i nc . C-15 appendix c: status message description discrete input and outputs df1 word address modbus word address hex byte offset bit parameter name input/ output active state n10: 19 40020 0026 0 compressor motor output high 1 main or pre-lube oil pump motor (option) output high...

Page 156

Standard screw compressor - rwb series c-16 m&m r efrigeration i nc . Alarm and failure data df1 word address modbus word address hex byte offset bit parameter name level n10: 21 40022 002a 0 high suction pressure fail 1 high suction pressure alarm 2 low suction pressure alarm 3 low suction pressure...

Page 157

M&m r efrigeration i nc . C-17 appendix c: status message description alarm and failure data (continued) df1 word address modbus word address hex byte offset bit parameter name level n10: 23 40024 002e 0 memory initialized alarm 1 frame overrun alarm 2 timer allocation fail 3 ram size failure low fa...

Page 158

Standard screw compressor - rwb series c-18 m&m r efrigeration i nc . Alarm and failure data (continued) equipment data df1 word address modbus word address hex byte offset bit parameter name level n10: 25 40026 0032 0 master shutdown fail 1 ecp comm shutdown fail 2 df1 comm shutdown fail 3 vi senso...

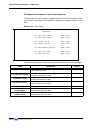

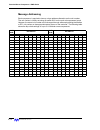

Page 160

Standard screw compressor - rwb series c-20 m&m r efrigeration i nc . Compressor state table vi display state table (option) screw state definition value anti cycle 0 stopped 1 starting 2 running 3 loading 4 unloading 5 limited - motor current 6 limited - slide valve position 7 limited - discharge p...

Page 161

M&m r efrigeration i nc . C-21 appendix c: status message description last screw start status table economizer mode table (option) last start status value start disabled, anti-cycle timer running 0 start disabled, screw failed 1 start disabled, screw already running 2 start disabled, start already i...

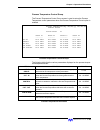

Page 162: Control Message Description

Standard screw compressor - rwb series c-22 m&m r efrigeration i nc . Control message description the control message is a read/write message containing fields to start and stop the compres- sor, change the compressor mode, and change the control setpoint group number. The contents of the control me...

Page 163

M&m r efrigeration i nc . C-23 appendix c: control message description network in control command the network in control command is used to allow the network to enable or disable itself from controlling the system. When set to zero, the contents of the remainder of the con- trol message, the suction...

Page 164

Standard screw compressor - rwb series c-24 m&m r efrigeration i nc . Set compressor mode command the set compressor mode command is used to change the current active mode of the compressor. Normally, only the remote and auto-remote modes are used by the mas- ter. Remote mode, when the network is in...

Page 165

M&m r efrigeration i nc . C-25 appendix c: control message description set economizer mode command the set economizer mode command is used to change the current active mode of the economizer but only when the economizer option is installed and the compressor is in remote or auto-remote modes. Manual...

Page 166

Standard screw compressor - rwb series c-26 m&m r efrigeration i nc . Suction pressure setpoint message description the suction pressure setpoint message is a read/write message used to display or change the four suction pressure control group setpoints. Suction pressure setpoints may be read or wri...

Page 167: Description

M&m r efrigeration i nc . C-27 appendix c: process temperature setpoint message description process temperature setpoint message description the process temperature setpoint message is a read/write message used to display or change the four process temperature control group setpoints. This command i...

Page 168

Standard screw compressor - rwb series c-28 m&m r efrigeration i nc ..