- DL manuals

- M.T.H.

- Toy

- Premier E94 Crocodile

- Operator's Manual

M.T.H. Premier E94 Crocodile Operator's Manual

Compatibility

This engine will operate on any

traditional O-Gauge track system,

including M.T.H.’s RealTrax® or

ScaleTrax™ or traditional tubular track.

The Hi-rail wheel version operates on

O-54 curves and the Scale wheel

version operates on 36” radius curves.

It is also compatible with most standard

AC transformers and DC power packs.

(See page 52 and 53 for a complete list

of compatible transformers, power

packs, and wiring instructions.)

PLEASE READ BEFORE USE AND SAVE

Premier E94 Crocodile

Electric

Engine

OPERATOR’S MANUAL

3

PFA

Passenger/Freight

Announcements

Summary of Premier E94 Crocodile

Page 1

Compatibility this engine will operate on any traditional o-gauge track system, including m.T.H.’s realtrax® or scaletrax™ or traditional tubular track. The hi-rail wheel version operates on o-54 curves and the scale wheel version operates on 36” radius curves. It is also compatible with most standa...

Page 2

This product may be protected by one or more of the following patents: 6,019,289; 6,280,278; 6,281,606; 6,291,263; 6,457,681; 6,491,263; 6,604,641; 6,619,594; 6,624,537; 6,655,640. ©2015, m.T.H. Electric trains®, columbia, md 21046 caution: electrically operated product: warning: when using electric...

Page 3

Set up checklist • lubricate engine • read all general maintenance instruction, starting on page 42 • apply power to run as described in the modes of operation section on page 9 unpacking you will notice that the packaging for the e 94 differs form previous mth packaging. That is because your e94 is...

Page 4

Automatic operating pantographs your mth electric type engine is equipped with automatic operating pantographs. The automatic operating pantographs must be unlatched before power is applied to the engine. To unlatch the pantographs, hold the base of the pantograph and gently pull up on the contact s...

Page 5

Command mode- automatic operation the pantographs can be operated automatically or manually when using the m.T.H. Dcs digital command system or dcc. The start up function must be initiated for the pantographs to operate in command mode. After the startup function has completed, the pantographs will ...

Page 6

Premier e94 crocodile electric engine 6 softkey operation for operating pantograph engines the new softkeys displayed when an operating pantograph engine is loaded into the remote are as follows (requires remote code version 3.10 or higher): mop (menu operating pantograph) when pressed it brings up ...

Page 7

Figure 7: lenz-style coupler figure 8: removing pin figure 9: pin coupler systems your engine comes equipped with the lenz-style coupler (see below). Also included is the fine scale european coupler. Pin to adjust the lenz-style coupler for more efficient operating of your locomotive while on the tr...

Page 8

Ps 3.0 enhancements ® here are some of the exciting changes incorporated into your new mth proto-sound 3.0 locomotives. More advanced features such as custom speed tables and advanced consisting can be found in the dcc section of this manual. Conventional (analog) ac/dc start-up/shut-down your new m...

Page 9

Loading engine firmware your new mth ps3.0-equipped o-gauge engine affords you the ability to load engine firmware. Loader version 2.30 or later will allow you to do this. Please refer to the loader program’s instructions for more details. So, as mth releases new features or updates you will be able...

Page 10

When power is first applied to the track, the locomotive will be silent for 1-20 seconds and the headlight will be on, indicating the super capacitors are charging (the super capacitors provide power to the sound system during direction changes or intermittent drops in track power due to dirty track...

Page 11

? proto-sound 3.0 conventional ac operating instructions ® activating proto-sound 3.0 conventional ac mode features throttle - to increase or decrease track voltage, and therefore train speed, turn the throttle control knob. Turning clockwise will increase voltage and speed, while turning counterclo...

Page 12: Push/road

? proto-sound 3.0 volume adjustment knob figure 10: manually adjusting the volume ® proto-sound 3.0 features are activated by sequences of bell and horn button pushes described below. Please read the full descriptions of each feature before using it. To use these buttons to activate features rather ...

Page 13: Push

Passenger/freight announcements (pfa) freight yard sounds that you can play when you pull into a station or a yard. Each sequence described below will play as long as it is left on, randomly generating sounds, but be sure to allow approximately 30 seconds between the button pushes described below to...

Page 14

? proto-coupler operation this locomotive is equipped with one or more coil-wound proto-couplers for remote ® uncoupling action. Because proto-couplers are controlled through the proto-sound 3.0 microprocessor, they do not require an uncoupling track section or modification to your layout to functio...

Page 15

M.T.H. Engines equipped with proto-sound 3.0 have speed control capabilities that allow the engine to maintain a constant speed up and down grades and around curves, much like an automobile cruise control. You can add or drop cars on the run, and the engine will maintain the speed you set. While the...

Page 16: Pull/road

Reset to factory default to override the settings you currently have assigned to the engine and reset it to its factory defaults, while in neutral tap the horn button quickly once, followed by five quick taps of the bell button, allowing approximately ½ second to lapse between each quick button pres...

Page 17

Automatic sound effects ® certain proto-sound 3.0 sound effects automatically play in programmed conventional mode conditions: • squealing brakes play any time the engine's speed decreases rapidly. • cab chatter plays at random intervals when the engine idles in neutral. • engine start-up and shut-d...

Page 18: Road

Dcs - digital command system while the acronyms are close, this is where the similarity ends between dcc and dcs. Yes they are both digital control systems. However, m.T.H. Dcs is not dcc. There are several proprietary versions of dcc on the market, but dcs is not one of them. M.T.H.'s dcs system is...

Page 19: Push

Premier e94 crocodile electric engine 19 rear engine in forward engine in reverse rear push rear engine in forward engine in reverse rear red (austrian version only) rear engine in forward engine in reverse rear r e d red (austrian version only) r e d red (austrian version only) r e d pull yard.

Page 20

Dcc - digital command control dcc is a popular digital command scheme wherein the track power is also a digital control signal. That is, using a dcc controller, you can communicate with multiple engines and have all of them moving at different speeds and in varying directions on the same track at th...

Page 21

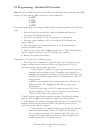

Bell/whistle (horn) f1 – bell to activate the bell press f1. To deactivate it, hit f1 again f2 – whistle (horn) to activate the whistle/horn, press f2. To shut it off either let off the f2 button or press and release it pfa f4 – pfa pfa in mth lingo stands for passenger/freight announcements. Your e...

Page 22

Lights f0 – headlight/taillight this toggles your headlight/taillight on and off. It will also override f19 and f20 (train/no-train and wrong direction running lights). When f0 is disabled your headlight, taillight, train/no-train indicators and wrong direction running lights are disabled as well. F...

Page 23

Grade crossing signal again, just like a real engine, you can trigger the grade crossing signal on your engine. This is two long, one short, one long whistle/horn blast. F11 – grade crossing signal pressing f11 twice (toggling on then off) will sound your crossing signal. Engine sounds f25 – engine ...

Page 24

F20 – road/pull this function will toggle between road and pull service. To see how toggling f20 will affect your lights please refer to page 18 and 19. F19 on and f20 on - road means: engine alone on the road both ends are active = on this should be default f19 on and f20 off - pull means: lights a...

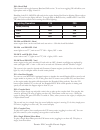

Page 25: Function Chart

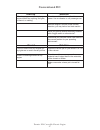

Function chart f0 f1 f2 f3 f4 f5 f6 f7 f8 f9 f10 f11 f12 f13 f14 f15 f16 f17 f18 f19 f20 f21 f22 f23 f24 f25 f26 f27 f28 headlight bell horn start-up/shut down pfa lights master volume front coupler rear coupler forward signal reverse signal grade crossing auto panto on/off front panto up/down rear ...

Page 26

Cv29 cv29 is the basic decoder setup cv that is used by all dcc decoder manufactures. So, if you are familiar with cv29 from other manufacturer's decoders mth's is no different. The most important part of cv29 is the ability to switch between long and short addressing. By default, cv29 on your mth p...

Page 27

Premier e94 crocodile electric engine 27 to change your engine's long address using pom: 1. Call up the current engine's address on your dcc handheld 2. Enter programming on the main on your dcc handheld 3. In this step you have to tell the mth engine that you want it to start looking at long addres...

Page 28

Premier e94 crocodile electric engine 28 lost or unknown engine address and the 55-55-55 address reset in some cases you may not remember or have somehow lost the engine address. Following the above feature or factory resets will allow you to recover an engine. The limitation to this is that for mos...

Page 29

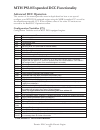

Premier e94 crocodile electric engine 29 mth ps3.0 expanded dcc functionality advanced dcc operation this section of the manual provides more in-depth detail on how to set up and configure your mth ps3.0-equipped engine using the nmra-standard cv’s as well as the manufacturer-specific cv’s. It also ...

Page 30

Premier e94 crocodile electric engine 30 factory default values for mth ps3.0 dcc configuration variables (cv’s) default value 1 2 3 4 5 7 8 11 17 18 19 21 22 23 24 25 29 49 50 51 52 53 54 56 57 63 64 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 105 106 3...

Page 31

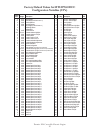

User-settable f-function list this feature allows you to take the 28 f-functions that currently reside in each mth proto-sound 3.0-equipped o-gauge engine and change the location of that function. For example: f4 is currently pfa and you'd like that placed down to f28 which is feature reset. The bel...

Page 32

The above list includes all f functions that an mth ps3 engine could have. You are free to change any of the above listed items to any f function position, 1-28. For example, if you your engine came from the factory without a smoke unit but you added one at a later date you could swap out any of the...

Page 33

Cv programming – marklin 6021 controller note: there are 4 dip switches on the back of the marklin 6021 controller. For mth engines you will want the dip switches set to the following: 1 - off 2 - on 3 - off 4 - off to enter programming mode using a marklin 6021 controller, perform the following ste...

Page 34

2. Briefly turn the speed knob counter clockwise to the direction change position. The headlight should shift to a short-short flash pattern. 3. Enter the units digit of the cv contents preceded by a zero. For the example of 128, enter 08. The state of the function led does not matter. Note: use 80 ...

Page 35

27 speed step mode maps directly to the 28 speed steps used in dcc but does not use the 28th speed step. It uses the odd steps on acceleration and the even steps on deceleration. 28 speed step mode maps directly to the 28 speed steps used in dcc when the new motorola format is used (dip switch 2 in ...

Page 36

Advanced consisting advanced consisting follows the nmra standards. Any values assigned to cv's 21-24 are ignored once the consist is removed (cv19 set to 0). Setting the msb (bit 7) of cv19 tells the engine that it is facing reverse in the consist setting cv21 and cv22 determine which f functions t...

Page 37

To set this consists up so that: • the headlight is on in the front engine when going forward, off when the consist is in reverse • the reverse light and headlight is off in the rear engine when the consist is going forward, headlight is on, reverse light is off when the consist is in reverse • the ...

Page 38

7. Set cv22 to a value of 2 to the rear engine's address to tell the rear engine that you want to control its fl control with the f0 button at the consist address. The engine will give you two horn blasts to announce that it received the cv change 8. Ensure f0 is deactivated at the rear engine's add...

Page 39

To do this: 1. Call up the front engine on your dcc system 2. To set the front engine to respond to the bell (f1), horn (f2), start-up/shut down (f3) and front coupler (f7) you will want to write a value of 71 to cv21. This is setting bits 0, 1, 2, and 6 on. A. Cv21's bits are shown in the table bel...

Page 40

Note: cv21 is only used when you have some value other than 0 written to cv19. If cv19 = 0 then the values of cv21, cv22, cv23, and cv24 are not used 1. Call up your middle engine (address 2 in the example) 2. Since you want to have the middle engine respond to f3 only then write a value of 4 (cv21,...

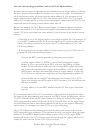

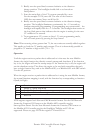

Page 41: Dcc Bit Value Decoder

So, in the above example you simply add up the values in the “decimal value” row – 128+64+0+16+8 +0+0+1 = 217. You would write 217 to the cv you were altering. The above applies to any cv. Also, if you have a cv that already has a value assigned that you do not want to alter but need to make additio...

Page 42

Maintenance lubricating and greasing instructions the engine should be well oiled and greased in order to run properly. Regularly lubricate all axles and pickup rollers to prevent squeaking. Use light household oil, such as that found in m.T.H.'s maintenance kit. Do not over oil. Use only a drop on ...

Page 43

Cleaning the wheels, tires, and track periodically check the locomotive wheels and pickups for dirt and buildup, which can cause poor electrical contact and traction and prematurely wear out the neoprene traction tires. Wheels and tires can be cleaned using denatured (not rubbing) alcohol applied wi...

Page 44

Traction tire replacement instructions your locomotive is equipped with two neoprene rubber traction tires on each powered truck block. While these tires are extremely durable, they may occasionally need replacement. 1. Locate the driver wheel set that has the traction tires. 2. Remove the bolt that...

Page 45

Starting up horn bell solution solution solution only my headlight comes on, nothing else. When i first turn the power on, the engine will not begin to run. The engine will not start after i press the direction button. I can't get the horn to blow when i press the horn button. I can't get the bell t...

Page 46

Volume solution the sounds seem distorted, especially when the horn or bell is activated. No sound ® proto-sound 3.0 volume is set too high. Turn the volume control knob on the bottom of the chassis counter-clockwise to reduce the volume. Volume is set too low, adjust volume control knob on the bott...

Page 47: Start-Up

Conventional dc start-up solution sound solution when i apply power to the track my engine doesn't do anything. No lights, no sound, no nothing. I have no sound from my engine, but my lights are on and it moves just fine. There's a crackling sound from my engine check to see if that section of track...

Page 48: Lights

One of my lights is out. None of my lights are on. The wrong direction or train/no train lighting is incorrect most likely you had been running the engine in dcc or dcs mode and toggled that light off. Put it back into one of those modes and turn that light back on. The engine will remember that whe...

Page 49: Start-Up

Dcc when i apply power to the track my engine doesn’t do anything. No lights, no sound. Did you press f3 yet? F3 on your dcc handheld will start your engine up. Check to see if that section of track has power. Use a voltmeter or a lit passenger car, not your tongue. Slide the engine a couple of feet...

Page 50: Lights

One of my lights is out. None of my lights are on. The wrong direction or train/no train lighting is incorrect. Check your f keys. F0 is the headlight (also controls the back-up light) and f5 will toggle the cab light could be the same reason as “one of my lights is out” is the engine getting power?...

Page 51: Start-Up

Dcs (remember, it's not dcc) when i press the whistle button on my dcs remote or dcs commander the whistle doesn't blow i have no sound on my engine, but my lights are on and it moves just fine there's a crackling sound from my engine when i run doppler i can hear the doppler shift but then the engi...

Page 52: Lights

One of my lights is out. None of my lights are on. The wrong direction or train/no train lighting is incorrect. Check that you haven't turned it off with the dcs controller. You have independent control over lights on your engine could be the same reason as “one of my lights is out” is the engine ge...

Page 53: Recommended Ac Transformers

Transformer compatibility and wiring chart proto-sound® 3.0 is designed to work with most standard ac transformers. The chart below lists the many compatible transformers. Note that many of the operational commands described in these instructions require a bell button, so if your transformer does no...

Page 54: Recommended Dc Transformers

Dc power supply chart transformer model min/max. Voltage power rating transformer type mrc controlmaster 20 0-20v 100-watt electronic ph hobbies ps5 ph hobbies ps10g 0-20v 0-20v 100-watt 180-watt electronic electronic bridgeworks magnum 15 bridgeworks magnum 200 bridgeworks magnum 1000 bridgeworks m...

Page 55

Premier e94 crocodile electric engine 55 additional features accessible with the dcs remote control system (additional equipment required) while conventional mode operation of a proto-sound® 3.0 engine yields wonderfully realistic sound and several train control features, command mode operation allo...

Page 56

Service & warranty information how to get service under the terms of the limited one-year warranty when you suspect an item is defective, please check the operator's manual for standard operation and trouble- shooting techniques that may correct the problem. Additional information may be found on th...