- DL manuals

- M.T.H.

- Toy

- Proto-Sound 3.0

- Installation Manual

M.T.H. Proto-Sound 3.0 Installation Manual

Compatibility

This Proto-Sound 3.0 Diesel/Electric Locomotive Upgrade Kit is compatible with any

AC or DC Powered locomotive equipped with a DC can motor(s) and motor flywheel(s).

The locomotive must be large enough to house the electronics. The instructions herein are

generic in nature and will not provide the installer with specific installation details for

specific locomotives. Consult the individual item’s operator’s manual for specific

instructions on how to disassemble the locomotive prior to installing the upgrade kit.

WARNING:

This product is not covered by a warranty unless installed by an M.T.H.

Authorized Conversion Center.

DIESEL/ELECTRIC LOCOMOTIVE

UPGRADE KIT

INSTALLATION MANUAL

BETA EDITION

www.mthtrains.com

PLEASE READ BEFORE USE AND SAVE FOR REFERENCE

Summary of Proto-Sound 3.0

Page 1

Compatibility this proto-sound 3.0 diesel/electric locomotive upgrade kit is compatible with any ac or dc powered locomotive equipped with a dc can motor(s) and motor flywheel(s). The locomotive must be large enough to house the electronics. The instructions herein are generic in nature and will not...

Page 2: Table of Contents

Table of contents contents of the kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 upgrading multiple-unit diesels . . . . ....

Page 3: Contents Of The Kit

Contents of the kit a) proto-sound 3.0 board and plastic bracket aa) proto-sound 3.0 heat sink bracket kit b) mars/ditch (led) light (4) c) proto-coupler (2) cc) coupler insulator (2) d) backup light (led) e) marker lights (led) - red ee) marker lights (led) - green f) 40-pin chassis harness w/tach ...

Page 4

(g) headlight ce-2000006 (ff) tach reader bracket (27mm flywheel) (pictured below) ih-0000475 (fff) tach tape be-0000151 (h) speaker bf-0000034 ee) marker light (led) - green ce-2000003 (e) marker light (led) - red ce-2000004 (f) 40-pin chassis harness w/tach reader, vol. Pots, dcs/dcc switch bc-200...

Page 5

(i) recharging port hardware spacers (2) id-0000071 screw (2) ia-0000035 nut (2) ic-0000006 (r) speaker plug bc-0000008 (l) 6/32 x 6mm screws ia-0000027 (m) 6/32 nuts tp-ms00075 (j) interior lights (led) ce-2000007 (q) wire nuts bi-4500003 (k) overhead blinking light ce-2000008 (n) shrink tubing 12”...

Page 6: Required Tools

Required tools - soldering iron - esd safe work area - white thermally conductive grease - screw drivers, philips #2 & #00 - wire cutters - drill - drill bits (1/8”, 5/32”) - drill bit (3/8” or ½”) or de-burring tool - electrical tape - razor saw what is an esd ? As esd safe work area is an area set...

Page 7: Four-Motored Locomotives

Upgrading multiple-unit diesels this kit is designed for single diesel or electric locomotives only. There is no provision for wiring a coupler and/or back-up light into a dummy or non- powered trailing unit. Similarly, the kit does not provide a way to control powered trailing units. See the note b...

Page 8: Inspection & Review

Inspection & review before beginning the installation, inspect the engine to be upgraded and verify the following are in good working order: - pick-up rollers - motor w/flywheels - smoke unit (if equipped) - speaker mounting hardware - volume pot - coupler mounting hardware, “t” bar, spring, c-clip ...

Page 9: Proto-Sound 3.0 Upgrade

Preparing the chassis for the proto-sound 3.0 upgrade before you can install the proto-sound 3.0 components into your locomotive, any existing sound boards or reversing units must be removed. The proto-sound 3.0 kit contains all the necessary electronics your locomotive requires to operate. Some exi...

Page 10: Chassis

Installing the proto-sound 3.0 components onto the locomotive chassis once the existing electronic components have been removed from your locomotive, begin locating the best mounting position for the proto-sound 3.0 components. The major components are the proto-sound 3.0 board, proto-sound 3.0 heat...

Page 11

Mounting the proto-sound 3.0 board - remove the proto-sound 3.0 board (a) from the sealed anti-static bag - verify proto-sound 3.0 board is securely inserted into its plastic mounting bracket. - remove the speaker (h) from the protective packaging. Note: be careful not to damage the speaker cone - p...

Page 12: Cont’D

Mounting the proto-sound 3.0 board cont’d - once you have determined the best locations for mounting the proto- sound 3.0 board bracket (a), metal heat sink bracket (aa), mark the chassis floor locations using a pencil or silver marker so you can drill the holes in the proper locations. If necessary...

Page 13: Cont’D

Mounting the proto-sound 3.0 board cont’d - mount the plastic mounting bracket (a) containing the proto- sound 3.0 board using 2 of the screws (l) and nuts (m) - apply white thermally conductive grease to the bridge rectifier on the proto-sound 3.0 board. Mount the proto-sound 3.0 plastic mounting b...

Page 14

Installing the proto-couplers the proto-coupler installs in the same location as the original engine coupler. - install the proto-couplers (c) onto the existing locomotive trucks or coupler mount locations using the existing hardware. Be sure to route the coupler wire harness through the chassis flo...

Page 15: Coupler Installation

Coupler installation a plastic insulator, item cc in the parts list of your proto-sound 3.0 upgrade kit, has been included with the rest of your proto-sound 3.0 upgrade kit parts. Shown above is the coupler unassembled. Shown here is the insulator attached to the truck and coupler. Ensure that the p...

Page 16

Proto-sound 3.0 chassis wiring diagram proto-sound 3.0 upgrade kit installation guide - diesel/electric 16.

Page 17

Proto-sound 3.0 board connections proto-sound 3.0 upgrade kit installation guide - diesel/electric 8 pin 40 pin 17.

Page 18

Installing the chassis harnesses, speaker & smoke pot - attach 40 and 8-pin chassis harnesses to the proto-sound 3.0 board (a) noting that each plug is polarized and has a different number of pins. Take care to insert the correct plug into the correct connector on the proto-sound 3.0 board. See prev...

Page 19

Soldering speaker connections - solder the yellow and white wires (r) to the speaker (h) - connect speaker plug to harness plug (white) with yellow & white wires coming from the 40-pin chassis harness (s). Caution: if either wire shorts to the speaker frame, the proto-sound 3.0 electronics will be d...

Page 20: Installing The Volume Pot

- mount the vol pot in the 40-pin harness or solder the wires from the 40-pin chassis harness to the existing volume pot. Solder orange wire to the center terminal and purple wire to the terminal to the left of the center terminal. Note: volume pot not required for command operation. Leave wires sep...

Page 21

Installing tach reader bracket - based on the flywheel diameter (27 mm or 30 mm), install the tach reader mounting bracket (ff). The bracket is snapped into place on a mabuchi or similar motor by spreading it open and sliding it under the flywheel. It may be necessary to use tape or epoxy glue to ho...

Page 22

Mounting tach reader to tach reader bracket - insert the tach reader into the tach reader bracket. - the gap between the optical sensor and flywheel should be 0.5mm (0.022”)-1.5mm (0.060”); 0.75mm (.030”) is optimum. - if the gap is too large, decrease the tach reader space between reader and flywhe...

Page 23

Connecting motor, ground & pickup wires - solder the yellow and white wires from the 8-pin motor harness to the motors. As noted on page 9, observe the wire color code of the previous electronics to ensure both motors turn in the same direction. If the engine starts out in the reverse direction, you...

Page 24: Connecting Lights (Leds)

Proto-sound 3.0 upgrade kit installation guide - diesel/electric connecting lights (leds) - install the ditch, headlight, marker, mars, overhead blinking, cab interior, number board & back-up lightbulbs into the proper engine & wire harness locations as seen in the diagram on page 16. - on railking ...

Page 25

Connecting the proto-sound 3.0 harness to the smoke unit - soldering gray and green wires to the smoke unit fan motor. If the smoke unit motor terminals are hooked up backward, the impeller will spin in reverse and fail to pump out the smoke. When properly wired, most impellers should rotate clockwi...

Page 26: Cont’D

Critical step solder together the pads connecting the heating element to the circuit board as shown above. Make sure the heating elements are in parallel. You should measure 8 ohms across the pads. Failure to place the heating elements in parallel will permanently damage the proto-sound 3.0 board. C...

Page 27: Installation

Testing the proto-sound 3.0 upgrade installation - place the engine chassis on a test section of a track. - apply 12 volts of power (in conventional mode) to the engine. If you have a z4000 look at the current display. The engine should not draw more than 1.5 amps. If the engine draws more than 1.5 ...

Page 28

Before your upgraded locomotive will play locomotive sounds, the proto-sound 3.0 circuit board needs to be programmed with the appropriate proto-sound 3.0 file for your engine type. Programming can only be accomplished with the m.T.H. Dcs digital command system and the free dcs loader program. The l...

Page 29

Proto-sound 3.0 upgrade kit installation guide - diesel/electric refine your search results with these options step 1: the proto-sound 3.0 upgrade kit utilizes a proto-sound 3.0 diesel/electric board that uses proto-sound 3.0 sounds. To find a proto-sound 3.0 file, go to www.Mthtrains.Com and select...

Page 30

After adding the engine into the dcs system, name the engine on your dcs remote using the edit name feature proto-sound 3.0 upgrade kit installation guide - diesel/electric step 3: select the proto-sound 3.0 file from the results list. Right click and save the proto-sound 3.0 consumer package file i...

Page 31: Conventional Proto-Sound 3.0

Proto-sound 3.0 upgrade kit installation guide - diesel/electric conventional proto-sound 3.0 operation activating features throttle: to increase or decrease track voltage, and therefore train speed, turn the throttle control knob. Turning clockwise will increase voltage and speed, while turning cou...

Page 32

Proto-sound 3.0 upgrade kit installation guide - diesel/electric timing chart total time lapse: 1 seconds ½ press horn short & firm ½ sec. Pause ½ sec. Pause press bell short & firm press bell short & firm activating proto-sound® 3.0 conventional mode features proto-sound® 3.0 features are activated...

Page 33

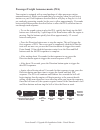

Proto-sound 3.0 upgrade kit installation guide - diesel/electric passenger/freight announcements (pfa) your engine is equipped with a sound package of either passenger station announcements or freight yard sounds that you can play when you pull into a station or a yard. Each sequence described below...

Page 34: Tips On Using Pfa

Proto-sound 3.0 upgrade kit installation guide - diesel/electric tips on using pfa • you can terminate pfa at any time by turning off power to the track for 15 seconds. • you do not have to be in forward to use pfa. At the conclusion of the full sequence, the train will pull away from the station or...

Page 35: Speed Control

Proto-sound 3.0 upgrade kit installation guide - diesel/electric m.T.H. Engines equipped with proto-sound® 3.0 have speed control capabilities that allow the engine to maintain a constant speed up and down grades and around curves, much like an automobile cruise control. You can add or drop cars on ...

Page 36: Automatic Sound Effects

Proto-sound 3.0 upgrade kit installation guide - diesel/electric automatic sound effects ® certain proto-sound 3.0 sound effects automatically play in programmed conventional mode conditions: • squealing brakes play any time the engine's speed decreases rapidly. • cab chatter plays at random interva...

Page 37

Troubleshooting proto-sound® 3.0 problems although proto-sound 3.0 has been designed and engineered for ease of use, you may have some questions during initial operation. The following table should answer most questions. If your problem cannot be resolved with this table, contact m.T.H. For assistan...

Page 38

Cab chatter lock-out volume fys remedy remedy remedy remedy sometimes the cab chatter sounds don’t play. I can’t get the engine to run after i power up the transformer. It sits still with the engine sounds running. The engine won’t lock into forward, neutral, or reverse. The sounds seem distorted, e...

Page 39

Fys remedy once in fys, the engine doesn’t go into reverse. When the fys enters its last sequence the bell automatically comes on. When fys is enabled, pressing the whistle and bell buttons has no effect. I push the direction button but the next sound clip in the sequence does not play or the engine...

Page 40: Limited 90-Day Warranty

Service & warranty information how to get service under the terms of the limited warranty when you suspect an item is defective, please check the operator's manual for standard operation and trouble-shooting techniques that may correct the problem. Additional information may be found on the m.T.H. W...