Summary of Vostok 1

Page 1

1 use and maintenance vostok lever translation of the original instructions.

Page 2

2 index 1. Introduction pag. 19 1.1 using the manual pag. 19 1.2 warnings pag. 21 1.3 starting the coffee machine pag. 21 2. Technical characteristics pag. 21 3. Description of the machine pag. 22 3.1 legend pag. 22 4. Installation pag. 23 4.1 equipment provided pag. 23 4.2 water mains set-up pag. 2...

Page 3: 1. Introduction

3 1. Introduction before using the machine, carefully read all of the instructions contained in this machine. 1.1 using the manual this manual contains all information required for the installation, use and maintenance of the coffee machine. This manual is an integral part of the machine; always kee...

Page 4

4 • the user must be a responsible adult, who is expected to comply with local safety rules and accepted common sense procedures. For a proper and safe use of the machine, the operator must always comply with applicable accident prevention and other work safety and health regulations. • this applian...

Page 5: 2. Technical Characteristics

5 • acs-m&v s.R.L. Reserves the right to make any technical changes on the machine considered necessary without advance notice. 1.3 starting the coffee machine ambient temperature: 5 ÷ 45°c (drain the water system in case of frost) water pressure: 80 ÷ 800 kpa (0.8 ÷ 8.0 bar) noise level emitted by ...

Page 6

6 3. Description of the machine note: the terms used in this description will commonly be used throughout the following pages. 3.1 legend 1. Steam valve lever 2. Espresso coffee serving 3. Steam spout 4. Filter holding cup with handle 5. Hot water valve lever 6. Steam valve lever 7. Water spout 8. S...

Page 7: 4. Installation

7 4. Installation mandatory requirements : the operation of the lever for coffee brewing , it is extremely dangerous. In order to avoid the risk of harm to the operator is absolutely necessary, before driving the lever for any reason, make sure that: the filter holder cup is completely filled with t...

Page 8

8 provide an inspect able drainage pit on the floor connected with the sink drainage line, suitable for receiving the machine gravity drainage tube. The drain tube must be positioned so that the water flows out freely, without possibility for the pipe to clog up during the operation. 4.3 water softe...

Page 9: 5. Start-Up

9 fig.A connect the power cord to the electrical mains as shown in the attached diagram: 5. Start-up the coffee machine must be started by qualified technical personnel approved by acs-m&v s.R.L. Once the electric and hydraulic connections are completed, the user is urged to start the espresso coffe...

Page 10

10 fig.B fig. D fig. C 6.2 drawing steam a jet of steam, which can be used to foam milk or to heat other liquids, comes out of the steam drawing spout as follows: by raising or lowering the lever you attain the maximum flow (the lever stops in the maximum position. To stop the flow of steam, place t...

Page 11: 7. Routine Maintenance

11 7. Routine maintenance no panel or fixed guard of the frame may be removed from the machine to carry out the routine maintenance. Do not use harsh or harmful detergents such as alcohol, petrol or solvents to clean the coffee machine; use water and neutral detergents. Note: the daily cleaning oper...

Page 12: 9. Safety Devices

12 4) wash the components of the machine as described in the paragraph on routine maintenance. 5) cover the machine if necessary. 9. Safety devices 9.1 manual reset safety thermostat every boiler is equipped with a safety thermostat and is located next to the element unit and can be accessed by remo...

Page 13: 13. Problem Solving

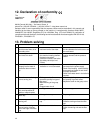

13 12. Declaration of conformity the manufacturer: m&v s.R.L. 80040 cercola (na) italy – via learco guerra, 9 phone/fax (+39) 081 5552428 – (+39) 081 0152417 – http://www.Mevsrl.Net declares under its own responsibility that the espresso coffee machine described in this manual and identified by the ...

Page 14

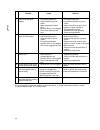

14 problem cause solution 9. Light cream (the coffee flows out of the spout rapidly) a. Coarse grinding b. Low pressing pressure c. Small quantity of ground coffee d. Water temperature below 90°c e. Sprinkler filter on unit clogged f. Filter holes widened (filter cup) a. Finer grinding b. Increase t...