Summary of PSXH47EFWW

Page 1

Dryer psxh47efww 07-man-dr-02.

Page 2: Table of Contents

2 table of contents important safety notice 3 specification 4, 5 component resistances 6 functiontest sequence 7, 8, 9 electronic control board circuits 10 drive motor circuit 11, 12 temperature sensing circuit 13 heating circuit 14 drying time 15 troubleshooting 16, 17, 18 error code chart 19, 20 t...

Page 3: Important Safety Notice

3 important safety notice the information in this presentation is intended for use by individuals possessing adequate backgrounds of electrical, electronic, and mechanical experience. Any attempt to repair a major appliance may result in personal injury and property damage. The manufacturer or selle...

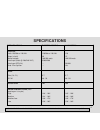

Page 4: Specifications

4 specifications specifications electric models gas models electrical volts 120/208 or 120/240 amps (circuit) motor wattage heat input (watts @ 208/240 vac) heat input (btu/hr.) auto. Elec. Ignition 120/208 or 120/240 30 160-350 watts 3200/4500 --- --- 120 15 160-350 watts --- 20,000 yes drum size (...

Page 5: Specifications (Cont.)

5 specifications (cont.) specifications electric models gas models dimensions (inches) height (stack models) width depth 36” 27” 28.5” 36” 27” 28.5” vent capability** 4-way 3-way port opening (sq. In.) 235 235 ** electric dryers can be vented four ways: through back, bottom, right or left side. ** g...

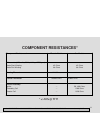

Page 6: Component Resistances*

6 component resistances* component resistances* electric models gas models drive motor (120 volts, 60 hz, 1/4 h.P. 1725 rpm) motor start winding motor run winding 4.5 ohms 3.8 ohms 4.5 ohms 3.8 ohms heating element 12.8 ohms control thermistor 50,000 ohms 50,000 ohms burner assembly ignitor secondar...

Page 7: Function Test Sequence

7 function test sequence this is a functional test for the dryer. To activate this mode, perform the following steps: 1. Turn the cycle selector knob to the 12 o’clock position. 2. Press and hold the select and pause cancel buttons simultaneously for 6 seconds. 3. Immediately after, press and hold t...

Page 8

8 function test sequence (cont.) 4 turns drive motor runs; heat source is off. A. When the temperature selector is rotated, there should be a key beep with each setting. B. When the dryness key is pressed, all the dryness level leds should light. C. When the options or select key is pressed, all the...

Page 9

9 function test sequence (cont.) 6 turns drive motor runs; heat source is on. Drying led is lit. Control thermistor reading is displayed. ** to exit test mode, press and hold the select and pause cancel buttons simultaneously for six seconds or disconnect power from dryer. Dryer will be reset for re...

Page 10

10 electronic control board circuits line l1 is applied to the control board at pin 1 of the eight pin plug and neutral on pin 2 of the eight pin plug. The control board receives inputs from: • the selector switch, the temperature switch and the push buttons which program the control; • the contact ...

Page 11: Drive Motor Circuit

11 drive motor circuit when power is connected to the dryer, line l1 is applied through the thermal limiter (a non-resettable fuse mounted on the rear wall of the dryer) to the com terminal of the door switch. When the door is closed the com terminal is connected to terminal no of the door switch. F...

Page 12: Drive Motor Circuit (Cont.)

12 drive motor circuit (cont.) when the motor is not turning, the start winding and the run winding are connected in parallel. When the contacts of relay rl1 are closed, with the dryer door closed, line l1 and neutral voltage is applied across both the start and run windings of the drive motor. With...

Page 13: Temperature Sensing Circuit

13 temperature sensing circuit the temperature in the dryer is controlled by the control thermistor and the electronic control board. The control thermistor, mounted in the blower fan housing, is a negative coefficient thermistor that decreases in resistance as the temperature increases. The electro...

Page 14: Heating Circuit

14 heating circuit the electronic control board applies power to the heating circuit through the contacts of heater relay rl2. When the electronic control senses the temperature in the drum is below the programmed temperature, it closes the contact of rl2. This applies line l1 power to the high limi...

Page 15: Drying Time

15 drying time the amount of drying time is determined in one of two ways. A fixed amount of drying time is determined by turning the selector knob to one of the fixed drying times. The auto dry cycles a variable amount of time determined by the size of the load, the amount of moisture in the clothe...

Page 16: Troubleshooting

16 troubleshooting service error codes the electronic controls of the dryer have self diagnostics codes built in that cover most product failures. When a failure occurs, the dryer stops or pauses. The control will beep and flash the status lights to tell the customer that a failure has occurred. To ...

Page 17: Troubleshooting (Cont.)

17 troubleshooting (cont.) the four indicator lights of drying, cool down, extra care and clean lint filter will flash the number of times for the first digit of the code after the e, and the start indicator light will flash the number of times for the second digit after the e. The code is obtained ...

Page 18: Troubleshooting (Cont.)

18 troubleshooting (cont.) note: a letter appearing in the code stands for a number higher than nine. A = 10 b = 11 c = 12 d = 13 e = 14 f = 15 example code e4a: the first digit would be 4 and the second digit would be 10. If this code would appear on a dryer, the four indicator lights would blink f...

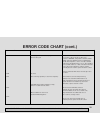

Page 19: Error Code Chart

19 error code chart error code fault condition action e 10 e 11 e 12 e 24 e 25 communication failure – eeprom communication failure - problem with communication or memory did not check, one has become corrupted communication failure - memory shorted control thermistor open control thermistor clear c...

Page 20: Error Code Chart (Cont.)

20 error code chart (cont.) error code fault condition action e4a e 5b e 68 e 8c e af the drying time has exceeded program time for that cycle. No heat. One of the keys (buttons) is stuck closed (active). High limit thermostat has tripped too many times in a certain amount of time. Microcontroller h...

Page 21: Troubleshooting Flow Charts

21 troubleshooting flow charts electric dryer completely inoperative. Note: always check wiring to the components. Note: if a fault code is displayed, the dryer will not operate. Defective door switch. Defective thermal limiter. No yes yes refer to error code chart. Does the control beep or the led ...

Page 22

22 longer than normal drying times. (possible e 4a) longer than normal drying times. Are the clothes wetter than normal when removed from the washer? Yes check washer spin cycle. No is the vent restricted? Yes clear vent. No is the blower motor running at full speed? No replace motor. Yes is the dry...

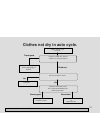

Page 23

23 clothes not dry in auto cycle. Tested good. Failed test. No yes checks good. Checks bad. Clothes not dry in the auto cycle. Using the function test, do the 3 o’clock test. (refer to page 4.) check that the dryer is level or slightly tipped forward. Are the sensor bars clean? Clean bars. Check the...

Page 24

24 drive motor runs but dryer does not heat. 0 50,000 ohms +/-10% drive motor runs but dryer not heat. Check the resistance of the control thermistor at room temperature. Defective thermistor. Program the dryer for a normal cycle with high temp and touch start. Measure the voltage drop between the t...

Page 25

25 mabe confidential and proprietary information-not for public disclosure. January 2007.