- DL manuals

- Mabe

- Washer

- PTAN9150MWW

- Technical Service Manual

Mabe PTAN9150MWW Technical Service Manual

Summary of PTAN9150MWW

Page 1

1 technical service guide mabe canada robert gauthier training & technical support pub #10-man-aw-02 date: may 2011 new top load washer model number: ptan9150mww, ptan9250mws, ptan9350mws, ptan9450mws, ptan9455mgg.

Page 2: Important Safety Notice

2 important safety notice the information in this service guide is intended for use by individuals possessing adequate backgrounds of electrical, electronic, and mechanical experience. Any attempt to repair a major appliance may result in personal injury and property damage. The manufacturer or sell...

Page 3: Table of Contents

3 table of contents nomenclature……………………………………………………………………….. ……...…………………………....4 introduction………………………………………………………………………….. …………………………………...5 about the control panel…………………………………………………………… ……………………………….6,7,8 installation…………………………………………………………………………… …………………………………...9 washer warranty………………………………………...

Page 4: Location of Mini-Manual

4 2010 clothes care nomenclature washer location of mini-manual.

Page 5: Introduction

5 introduction feature current models new models wash action agitator impeller washer cover plastic plastic or glass wash temperatures 3 settings 3 to 5 settings + atc rinse system normal shower + deep rinse drive system transmission with sole- noid transmission with wax switch safety lid lock w/mec...

Page 6: About The Control Panel.

6 about the control panel. Quick start guide.

Page 7

7.

Page 8

8.

Page 9: Installation

Installation installation requirements drainage a vertical standpipe with an internal diameter of 1-1/2” (3.8 cm) is required. The standpipe height above the floor must be: minimum height: 36” (91,4 cm) maximum height: 96” (243,8 cm) insert the drain hose into the standpipe and secure it with the ca...

Page 10: Washer Warranty

Washer warranty.

Page 11

11 flow logic automatic drawer dispenser. Your washer is equipped with an automatic dispensing system, comprised of a drawer with 3 compartments: bleach detergent softener liquid bleach pour liquid bleach into the designated compartment with- out filling beyond the mark. Check clothing care labels f...

Page 12: Loading The Washer

12 loading the washer.

Page 13: Water Consumption

13 water consumption water level approx load size wash rinse total gal. Lt. Gal. Lt. Gal. Lt. Max level 12 — 16 lb 13.74 52 8.98 34 22.72 86 high level 9 — 11 lb 12.15 46 8.98 34 21.14 80 medium level 6 — 8 lb 10.30 39 6.08 23 16.38 62 cycle times programs wash final spin heavy soil 18 min. 10 min. ...

Page 14: Hydrosoft

14 hydrosoft tm infusor tm washer tips introduction hydrosoft tm model washers use an infusor tm , not a traditional agitator. Infusor wash technology provides excellent cleaning. Infusor models are energy star® qualified using only 23 gallons of water per (super) load compared to 48 gallons for a s...

Page 15

15 understand the consumer’s issue first 1. Lint do not overload the washer. Use the deep rinse option, adding more water, to reduce lint. 2. Not filling or low water level infusor models are designed to use less water and are energy star® qualified. During the wash cycle, water may not entirely cov...

Page 16

16 all models have the precisefill automatic load sensing feature. When precisefill is selected, the machine determines fill time by sensing the load size. The precise fill pressure switch minimum level setpoint. The lower level setpoint is attained at approximately 1 inch of water depth, at which p...

Page 17

17 6. Water temperature energy-star requirements dictate that even on a hot setting, the washer will mix in some cold water. If the home water supply pipes have a long run, are imbedded in a concrete slab, and/or the washer is used during the winter months, it may take longer for the first hot water...

Page 18: Wash Cycle Progression

18 wash cycle progression untangling drain intermediate spin washer executes pattern to set the clothes previous to agitation in or- der to improve wash performance. Washer agitates to determine water level matches clothes load and type of clothes. Water and detergent are admitted in this stage betw...

Page 19

19 wash cycle progression (cont.) level detection/ overload sensing takes 2 spins, measures time to reach a certain angle. Estimates if load is greater than 17 lbs or not. If load is greater than 17lbs, it bypasses the "load arrange- ment" phase and goes straight to the pre-fill portion. Clothes arr...

Page 20

20 load sensing washer agitates to determine if water level (as selected by con- sumer) is appropriate for actual load size and type of clothes. •after minimum water level is attained, washer senses if load is greater than 17lbs (impeller only goes back and forth). • basket is spin intermittently by...

Page 21

21 intermediate spin pattern consist of a series of speed ramps until maximum speed is reached. • 30 seconds after "minimum"** water level is reached, washer starts spinning basket doing 5 preliminary ramp ups to ensure load is properly distributed and safe to bring up to next spin level. • the 6th ...

Page 22

22 rinse fill shower rinse is the normal rinse cycle. However, in some instances the washer will go to a deep rinse instead: •when fabric softener is used and customer has selected the deep rinse option. •on certain cycles such as bulky items. •if the washer recognizes that a higher water level than...

Page 23: Shower Rinse Progression

23 shower rinse progression basket stop to 0 rpm clothes saturation (fresh water) rinse blocks complete? Drain & spin final spin end cycle water admission directly no 1 spin pattern “between rinse blocks”. Number of rinse blocks depends on selected load size: 2 blocks for small, med and large 3 bloc...

Page 24: Deep Rinse Progression

24 deep rinse progression clothes saturation (fresh water) drain & final spin end cycle water ad- mission directly waits until the basket stops completely. 1 basket stop to 0 rpm agitation fills with water up to level selected for main wash (or ad- justed by the washer. The water is injected on the ...

Page 25: Final Spin

25 final spin • washer start draining until "minimum" level is reached. • after level is reached, washer starts spinning basket, ramping up to 400 rpm • washer then slows down to 230 rpm, then ramps up to spin speed selected by consumer • if washer cannot reach desired spin speed, motor shut off unt...

Page 26

26.

Page 27: Component Locator Views

27 component locator views lid lock with quick release dispenser dispenser water valves hot water valves atc (temperature control) pressure sensor electronic board lid switch.

Page 28: Component Locator Views

28 component locator views speed sensor wax motor capacitor motor drain pump transmission.

Page 29

29 how to remove the control panel 1- remove the two screws behind the control panel. 2– lift back of console and tilt console towards machine front to free front 3 tabs..

Page 30: How To Remove Top

30 how to remove top remove the two screws behind the washer. Pull the back of the top up and forward to remove .. Disconnect the 2 connectors (1) (2) and remove the pressure switch hose to remove the top. Electronic control (pcb) the electronic control cover is held in place with plastic tabs. The ...

Page 31: Infusor Removal

31 infusor removal 1- remove the cap 2- remove the bolt 3- removing the infusor transmission removal note use a 3 ft by 3 ft floor protector under the washer to avoid damaging its components or the floor when separating the tub assembly from the cabinet. 1- remove the top (see page 24) 2- remove the...

Page 32

32 3- remove the tub cover 4- remove the tub nut use a tub wrench (wx5x1325 ) to remove the left hand thread tub nut. Same wrench used on a ge washer. Note: when re-assembling, use a hammer with the wrench to tighten the tub nut. Hand tighten with the wrench then ¼ of a turn using a hammer. 5- remov...

Page 33

33 note: the motor, pump and was motor can be service from the bottom without remov- ing the cabinet. The next step in removing the transmission (mode shifter), it is to remove the belt and the motor. The belt can be forced over the transmission pulley. 9 - remove the belt. (the belt can be forced o...

Page 34: Note:

34 note: 14- remove the pump to prevent it from getting damaged, it is held in pla- ce with 3 (1\4 “ screws) 15– remove the wax switch 16- remove 12 (3/8) bolts holding the transmission base to the outer tub. 17- once the base is removed, release the wire harness plastic retainer. Transmission remov...

Page 35: Atc Thermistor

35 atc thermistor the atc controls the water temperature selected by the customer. If the atc thermistor fails or harness is broken, the washer will still operate. The control will open just the cold water valve. At room temperature ( 20ºc) , the resistance should be approximately ~11kΩ. Resistance ...

Page 36

36 water valves & drain pump testing water valve • with harness disconnected the resistance value of any of the 4 water valve coils should be approximately 1kΏ • the water valve can also be tested with a 120 volt test cord. Testing drain pump • with harness disconnected the resistance value of the d...

Page 37: Wax Motor and Motor Sensor

37 wax motor and motor sensor testing wax motor • wax motor can be tested with a 120 volt test cord. • should take approximately 45 seconds to fully as described above. See page 48, 49 spin.

Page 38: Testing Motor

38 testing motor motor ccw cw line neutral direction switch is included in the electronic control board white yellow black motor measurement white – yellow = 10.2 Ώ white - black = 5.2 Ώ¶ yellow – black = 5.2 Ώ¶ j2.

Page 39: Wax Motor

39 wax motor driving pulley with the wax motor not energized, the washer is ready to spin. With the wax motor energized the washer is ready to agitate. Shifter shifter system agitate spin. 120 volts applied.

Page 40: Motor Sensor

40 motor sensor the speed sensor in the motor operates on a 10 vdc signal from the control board. The control board reads the pulses from the motor to determine proper operation. This signal can not be read with a conventional multi-meter while operating. Besides diagnostic error code mode – disconn...

Page 41: Lid Lock Step 1

41 3 5 4 2 neutral power locking pin does not drop as the cam prevents it from doing so. Lid lock step 1 step 1: • current is applied (120 volts ac) to terminals 4 and 2 (neutral) when any cy selected before pressing start. • this energizes the bi‐metal but does not lock as the cam prevents it from ...

Page 42: Lid Lock Step 2

42 lid lock step 2 press the start button to begin the wash cycle. Power is sent to terminal 3, activating the solenoid, turning the green cam 30 deg. Then locking pin falls in place, closing the circuit at terminal 5, sending a signal to the board that the lid is locked. This terminates power to te...

Page 43: Lid Lock Step 3

43 lid lock step 3 • lid remains locked until the end of the final spin (or until the pause button is pressed) and the motor has received feedback of 0 rpm from the speed sensor (hall effect sensor on motor). • to unlock the lid, the pcb sends pulses (usually 2) through terminal 3 to activate the so...

Page 44: Lid Lock Step 3 (Cont.)

44 lid lock step 3 (cont.) •if the pcb still detects power through terminal 5 after a few pulses, the pcb will emit a maximum of 5 pulses to disengage the contact and cut power through terminal 5. If this fails, the control will indicate a failure code f8 • unit will then attempt the sequence, a max...

Page 45: Off

45 how to check the program switch position function terminal 1-2 terminal 2-3 10 spin only 1100 Ω 9 quick wash 1000 Ω 100 Ω 8 off 900 Ω 200 Ω 7 bulky items 800 Ω 300 Ω 6 towels / linen 700 Ω 400 Ω 5 wool 600 Ω 500 Ω 4 delicates 500 Ω 600 Ω 3 jeans 400 Ω 700 Ω 2 colors 300 Ω 800 Ω 1 whites 200 Ω 900...

Page 46

46 how to check the selector switch position terminal 1-2 terminal 3-2 1 720 Ω 2 720 Ω 3 180 Ω 540 Ω 4 360 Ω 360 Ω 5 540 Ω 180 Ω.

Page 47: Wiring Diagram

47 wiring diagram.

Page 48

48 how to enter or exit to service mode 1. Unplug the washer. 2. Turn the cycles knob to position 6 3. Re-plug the washer pressing start/pause and options buttons at the same time for 3 seconds. Display will show “lll”. Service mode function 1. Once in the service mode, a technician can test each co...

Page 49

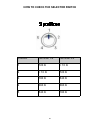

49 component testing (knob position).

Page 50

50 error and fault code warning and error codes a warning code appears when a failure has been detec- ted. After displaying a warning code for 30 seconds, the washer will attempt to resu- me the cycle. If the failure persists, the warning code will be shown once again. If the washer is able to resum...

Page 51: 1 2 3

51 how to check some components you can check different components from the plug underneath the top of the washer. 1- lift up the top. 2- unplug the main connection. 3- do the test. You can check the wax motor, drain pump, motor and the speed control. The readings obtained are resistances (Ώ). 1 2 3...

Page 52

52 water (level) pressure sensor water pressure sensor the sensor operates on low voltage dc which can be read from the control board connector j6. The voltage will increase from ~ 0 vdc (empty) to ~ 2.1vdc (full) across terminals 1 & 2, (beige to purple) . Terminals 2 & 3, (purple to black), will r...

Page 53: Circuit Board Connections

53 j5 j9 j3 j6 j10 j7 j4 jp2 jp1 j11 j2 circuit board connections 1 4 6 2 4 1 1 3 5 1 3 1 5 1 7 3 8 4 1 2 3 4 1 12 1 1 2 9 1 3 jp1 ( water valves) position connect to 1 softener valve 2 detergent valve 3 not used 4 lid lock 5 bleach valve 6 hot valve 7 not used 8 neutral jp2 (wax motor, lid lock, dr...

Page 54

54 circuit board connections (cont.) j6 (pressure sensor) position connect to 1 ground 2 signal 3 vdc j7 (spin switch) position connect to 1 vdc 2 signal 3 ground j9 (start/pause) position connect to 1 ground 2 vdc 3 select button 4 start / pause button 5 lid lock led 6 deep rinse led 7 wash led 8 r...