- DL manuals

- Mac Allister

- Lawn and Garden Equipment

- MBCP254 DUPLEX

- Operator's Manual

Mac Allister MBCP254 DUPLEX Operator's Manual

Summary of MBCP254 DUPLEX

Page 1

Brushcutter mbcp254 operator’s manual warning: read thoroughly the instruction booklet before using this machine duplex.

Page 2

English - en original instructions .....................................................................

Page 3

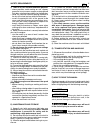

Ii 1 2 4 5 4 5 2 1 3 6 7 4 5 5 6 7 7 1 2 3 1 2 3 1 4 1 2 3 4 6 5 7 8 1 2 3 4 5 6.

Page 4

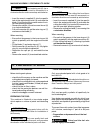

Ii 1 2 3 4 stop start run stop start run choke run 1 1 2 2 3 3 4 4a 5 6 2.2 1 2.4 2.3 2.1 2 8 7 9 1 1 0 1 4 1 3 1 15.

Page 5

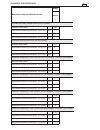

Iv 0,5 mm 1 1 2 3 2 30° a b c 30° 2 1 3 16 17 18 19 20 21 22 2 5 3 1 Ø 2,4 mm 2 x 3,0 m (118 in.) 4 6 120 mm (4,75 in.) 7.

Page 6

Iv.

Page 7

En introduction 1 dear customer, thank you for choosing one of our products. We hope that you will be completely satisfied with this machine and that it fully meets your expectations. This manual has been compiled in order to provide you with all the information you need to get acquainted with the m...

Page 8

En main components 1. Power unit 2. Drive tube 3. Cutting device a. Blade with 3 points b. Cutting line head 4. Cutting device guard 5. Front handgrip 6. Guard 7. Handlebar 8. Rear handgrip 9. Connection point (of the webbing) 10. Identification plate 11. Webbing a. Single belt b. Double belt 12. An...

Page 9: 2. Symbols

En 1) warning! Danger. The failure to use this machi- ne correctly can be hazardous for oneself and oth- ers. 2) read the instruction manual before using the machine. 3) if you are using the machine every day in nor- mal conditions, you can be exposed to a noise le- vel of 85 db (a) or higher. Wear ...

Page 10: 3. Safety Requirements

En a) training 1) read the instructions carefully. Become ac- quainted with the controls and the proper use of the machine. Learn how to stop the engine quickly. 2) only use the machine for the purpose for which it was designed, namely – cutting grass and non-woody vegetation, u- sing a nylon line (...

Page 11

3) take on a firm and well-balanced position: – where possible, avoid working on wet, slippery ground or in any case on uneven or steep ground that does not guarantee stability for the operator; – never run, but walk carefully paying attention to the lay of the land and any eventual obstacles; – ass...

Page 12: 4. Machine Assembly

The machine is supplied with some of the components disassembled and the fuel tank empty. Always wear strong work gloves to handle the cutting devices. Mount the components very carefully so as not to impair the safety and efficiency of the ma- chine. If in doubt, contact your dealer. 1. Completing ...

Page 13: 5. Preparing To Work

The fastening nut (5) has a left-hand thread and so must be unscrewed in a clockwise direction and screwed up anticlockwise. – insert the wrench supplied (2) into the specific hole in the angle transmission (3) and rotate the blade (1) by hand until the wrench enters the in- ner hole, blocking rotat...

Page 14

Periodically clean the petrol and fuel mixture containers to remove any eventual deposits. Refuelling never smoke whilst refu- elling and avoid inhaling the petrol fumes. Carefully open the tank top as pressure could have formed inside. Before refuelling: – shake the fuel mixture container well. – p...

Page 15

How to start - use - stop the engine 9 en 3. Press the primer device button (6) 3 or 4 times to prime the carburettor. 4. Hold the machine firmly on the ground with one hand on the power unit, in order not to lose control of the machine during startup (fig. 9). To prevent distortions, the drive tube...

Page 16: 7. Using The Machine

En 10 using the machine to respect people and the environment: – try not to cause any disturbance. – scrupulously comply with local regulations and provisions for the disposal of waste ma- terials after sawing. – scrupulously comply with local regulations and provisions for the disposal of oils, pet...

Page 17

En using the machine 11 • choosing the cutting device choose the most suitable cutting device for the job to be done, according to these general indications: – the 3-point blade is suitable for cutting brush- wood and small shrubs up to 2 cm in diameter; – the cutting line head can eliminate tall gr...

Page 18

Correct maintenance is essential to maintain the original efficiency and safety of the machine over time. During maintenance ope- rations: – remove the spark plug cap. – wait until the engine is sufficiently cold. – use protective gloves when handling the blades. – keep the blade protection device o...

Page 19

Sharpening the 3 point blade (fig. 20) use protective gloves. If sharpening is done without removing the blade, disconnect the spark plug cap. Sharpening must be done taking account of the type of blade and cutting edges, using a flat file and working all the points equally. The references for corre...

Page 20: 9. Troubleshooting

14 troubleshooting / technical specifications en 9. Troubleshooting 1) the engine will not start or will not keep running 2) the engine starts but is lacking in power 3) the engine runs irregularly and lacks in power when revved 4) the engine gives off an excessive amount of smoke – incorrect starti...

Page 21

Technical specifications 15 en maximum noise and vibration levels model mbcp254 operator ear noise pressure level (en iso 22868) with line cutter head db(a) 102 measurement uncertainty (2006/42/ec - en 27574) db(a) with 3-point blade db(a) measurement uncertainty (2006/42/ec - en 27574) db(a) measur...

Page 22: 11. Accessories

16 accessories en the table contains a list of all available acces- sories, indicating those which may be used on each machine, marked with the symbol “ ”. In consideration that the selection, application and usage of the acces- sory to be fitted in the variety of possible us- age are actions made s...

Page 24

171501145/0 en b&q plc. Chandlers ford, hants, so53 3le, united kingdom.