- DL manuals

- MacDon

- Tractor

- 9250

- Operator's Manual

MacDon 9250 Operator's Manual

Summary of 9250

Page 1

9250/9350/9352 self-propelled windrower operator’s manual form 46584 issue 11/06 web rev_01 sugg. Retail: $25.00

Page 2

California proposition 65 warning diesel engine exhaust and some of its constituents are known to the state of california to cause cancer, birth defects, and other reproductive harm..

Page 3

Form # 46584 issue 11/06 web rev_01 1 introduction your new self-propelled windrower is designed to cut and lay in windrows, a wide variety of grain, hay and specialty crops. Windrowing allows starting the harvest earlier, protects the crop from wind damage, and gives you more flexibility in schedul...

Page 4

Form # 46584 issue 11/06 web rev_01 2 table of contents page introduction...........................................................................................................................................1 serial number locations .................................................................

Page 5

Form # 46584 issue 11/06 web rev_01 3 table of contents operation page transporting the windrower (continued) towing with a trailer ...............................................................................................................52, 53 towing without a trailer.............................

Page 6

Form # 46584 issue 11/06 web rev_01 4 table of contents page maintenance/service (continued) hydraulic system: header & reel lift cylinder control valve relief pressure .........................................................................................91 header & reel lift hydraulic schematic....

Page 7

Form # 46584 issue 11/06 web rev_01 5 serial number locations record the serial numbers in the space provided. Tractor: plate is located on left side of main frame, near rear corner. Diesel engine: plate is located on right side of block, beside injection pump. Note: when ordering parts and service,...

Page 8

Form # 46584 issue 11/06 web rev_01 6 safety safety alert symbol this safety alert symbol indicates important safety messages in this manual and on safety signs on the header. This symbol means: attention ! Become alert ! Your safety is involved ! Carefully read and follow the safety message accompa...

Page 9

Form # 46584 issue 11/06 web rev_01 7 safety safety signs • the safety signs reproduced below appear on the windrower at the locations listed. • keep safety signs clear and legible at all times. • replace safety signs that are missing or become illegible. • if original parts on which a safety sign w...

Page 10

Form # 46584 issue 11/06 web rev_01 8 safety safety signs (continued).

Page 11

Form # 46584 issue 11/06 web rev_01 9 safety general safety the following are general farm safety precautions that should be part of your operating procedure for all types of machinery. 1. Protect yourself. When assembling, operating and servicing machinery, wear all the protective clothing and pers...

Page 12

Form # 46584 issue 11/06 web rev_01 10 safety general safety (continued) 6. Wear close-fitting clothing and cover long hair. Never wear dangling items such as scarves or bracelets. 7. Keep hands, feet, clothing and hair away from moving parts. Never attempt to clear obstructions or objects from a ma...

Page 13

Form # 46584 issue 11/06 web rev_01 11 specifications tractor dimensions: weight (varies with tire size): - with naturally-aspirated (n/a) diesel engine ...............................................Approx. 7225 lbs. (3275 kg) - with turbocharged diesel engine .........................................

Page 14

Form # 46584 issue 11/06 web rev_01 12 specifications transmission: type ............................................................................................................................................ Hydrostatic displacement.................................................................

Page 15

Form # 46584 issue 11/06 web rev_01 13 specifications diesel engines: type ...................................................................................................... Cummins b 4.5na, 4 cylinder, 4-stroke cycle - turbocharged displacement .....................................................

Page 16

Form # 46584 issue 11/06 web rev_01 14 torque specifications tightening hydraulic o-ring fittings* 1. Inspect o-ring and seat for dirt or obvious defects. 2. On angle fittings, back the lock nut off until washer bottoms out at top of groove. 3. Hand tighten fitting until back-up washer or washer fac...

Page 17

Form # 46584 issue 11/06 web rev_01 15 operator's station symbol definitions the following symbols are used to depict functions or reactions at the various instruments and controls. Learn the meaning of these symbols before operating the windrower. - engine oil pressure - transmission oil pressure -...

Page 18

Form # 46584 issue 11/06 web rev_01 16 operator's station symbol definitions (continued) - conveyor speed - engaged - disengaged - header drive - header height - increase - decrease - reel height - deck shift - speed range control high low - on - bypass - header express down option - header tilt up ...

Page 19

Form # 46584 issue 11/06 web rev_01 17 operator's station caution: learn and practice safe use of controls before operating. Important: see your dealer if there are any instrument malfunctions. Operate windrower only if all instruments work properly. Mac-monitor the lcd display allows the operator t...

Page 20

Form # 46584 issue 11/06 web rev_01 18 g h j a si indicator operator's station mac-monitor: programming (continued) 4. Once the desired programming mode is displayed, enter the selection mode by pressing and holding switch (a) for more than 5 seconds. (at 5 seconds there will be an audible tone. Rel...

Page 21

Form # 46584 issue 11/06 web rev_01 19 operator's station operator presence system requires the operator to be seated in the seat in order to engage the header drive. Should the operator leave the seat with the header drive engaged, power is maintained to the header drive for 5 seconds, after which ...

Page 22

Form # 46584 issue 11/06 web rev_01 20 operator's station ignition switch the ignition switch (a) has three positions; off, run and start. The furthest counter-clockwise position of the key is off. Turn key fully clockwise to start. Holding key in this position will cause engine to crank. Release of...

Page 23

Form # 46584 issue 11/06 web rev_01 21 operator's station cab temperature controls note: for access to circuit breakers, relays, fuses and other electrical components in cab side console, remove panel on window side of console. Blower speed switch (a) - controls operation of blower. Four positions a...

Page 24

Form # 46584 issue 11/06 web rev_01 22 operator's station windrower controls variable ground speed control lever (a) controls windrower direction of movement and rate of speed. A neutral start switch prevents the starter from engaging unless this lever is in the neutral detent as shown and the steer...

Page 25

Form # 46584 issue 11/06 web rev_01 23 operator's station header controls header drive switch (a) - lift the guard to expose toggle switch. Push toggle switch forward to engage all header mechanical and hydraulic drives. Push guard down to disengage drives. Starter will not engage if switch is in th...

Page 26

Form # 46584 issue 11/06 web rev_01 24 operator's station header controls (continued) reel height switch (e) - press top of switch to raise reel and bottom to lower. Hold switch until reel reaches desired position. Note: for auger headers with hay conditioners equipped with hydraulic roll opener cyl...

Page 27

Form # 46584 issue 11/06 web rev_01 25 operator's station header controls (continued) cut height indicator (g) - the gauge on the lift linkage can be used to identify desired cut heights. With the center link (between tractor and header) in a mid-range position, the numbers on the gauge indicate app...

Page 28

Form # 46584 issue 11/06 web rev_01 26 operator's station seat adjustments operator weight & seat height adjustment - press knob (a) in to increase suspension stiffness and seat height. Pull knob out to decrease. Seat-back angle - pull up on lever (b), position seat back as desired, and release leve...

Page 29

Form # 46584 issue 11/06 web rev_01 27 operator's station operator amenities cup holder (a) – provided at side console. Cigarette lighter (b) ashtray (c) auxiliary power points (d) - two 12 volt power outlets are provided on backside of console. A cup holder b c lighter & ashtray d power points.

Page 30

Form # 46584 issue 11/06 web rev_01 28 operation your responsibilities as an owner/operator caution: 1. It is your responsibility to read and understand this manual and the header operator's manual completely before operating the windrower. Contact your dealer if an instruction is not clear to you. ...

Page 31

Form # 46584 issue 11/06 web rev_01 29 operation break-in period the windrower is ready for normal operation. However there are several items to check and watch out for during the first 100 hours, as follows: engine break-in: 1. Operate engine at moderate load, avoid extremely heavy or light loading...

Page 32

Form # 46584 issue 11/06 web rev_01 30 operation break-in period windrower break-in (continued): 8. Re-torque four walking beam pivot bolts (b) after the first 50 hours. Tighten to 265 ft. Lbs. (360 n·m.) note: for units with optional “behind-frame” weight package as shown, tighten hardware to 350 f...

Page 33

Form # 46584 issue 11/06 web rev_01 31 operation pre-starting checks: daily do the following each day before starting the engine: caution: 1. Clear the area of other persons, pets, etc. Keep children away form machinery. Walk around the windrower to be sure no one is under, on or close to it. 2. Rem...

Page 34

Form # 46584 issue 11/06 web rev_01 32 operation start-up procedure danger: avoid possible injury or death from a runaway machine. Do not start engine by shorting across starter terminals. Machine will start in gear and move if normal starting circuitry is bypassed. This machine has two safety devic...

Page 35

Form # 46584 issue 11/06 web rev_01 33 operation start-up procedure (continued) starting engine caution: be sure the area is clear of other persons, pets etc. Before proceeding. Temperature above 16° c (60° f): turn ignition key to start position until engine starts. Release key. If engine does not ...

Page 36

Form # 46584 issue 11/06 web rev_01 34 operation driving the windrower warning: · avoid driving the machine with header removed. Removing header decreases the weight on drive wheels, reducing steering control. · if necessary to drive machine with header removed, use transmission "field speed" range,...

Page 37

Form # 46584 issue 11/06 web rev_01 35 operation driving the windrower (continued) to drive forward: 1. After starting engine, release park brake. 2. Dual speed units: for field operation, set speed-range switch (a) to position l . For road speeds, set control to position h . 3. Slowly push throttle...

Page 38

Form # 46584 issue 11/06 web rev_01 36 operation driving the windrower (continued) to drive rearward: warning: back up slowly. Steering is opposite to normal when reversing. Hold steering wheel at the bottom and turn wheel in direction you want the rear of the machine to travel. 1. Move speed-range ...

Page 39

Form # 46584 issue 11/06 web rev_01 37 operation driving the windrower (continued) making a spin turn: hydrostatic steering gives the operator significantly more maneuverability than mechanical steering. Caution: be sure area is clear before making turns. Although tractor pivots "on the spot", ends ...

Page 40

Form # 46584 issue 11/06 web rev_01 38 operation stopping procedure to stop windrower: warning: do not move variable speed lever rapidly back to neutral. Operator may be thrown forward by sudden stop. Always wear seat belt when operating windrower. 1. To slow down and stop the windrower, slowly retu...

Page 41

Form # 46584 issue 11/06 web rev_01 39 operation leaving the windrower caution: before leaving the operator's seat for any reason: 1. Park on level ground if possible. 2. Be sure variable speed lever is in the neutral detent and steering wheel is locked in the straight-ahead position. 3. Engage the ...

Page 42

Form # 46584 issue 11/06 web rev_01 40 operation attaching the header 1. Choose an area that is as level as possible and set header stand (a) in the down position. 942 header, set 2 inch (50 mm) blocks under each end of cutterbar. 960 & 970 series headers, be sure header and tractor have been proper...

Page 43

Form # 46584 issue 11/06 web rev_01 41 operation attaching the header (continued) 6. Connect driveline to header drive shaft as follows: • open hinged shield at header drive shaft. • pull back spring loaded collar (g) on driveline yoke and slide yoke onto header shaft. Release collar, ensuring yoke ...

Page 44

Form # 46584 issue 11/06 web rev_01 42 operation attaching the header (continued) 9. Start engine. Activate header lift cylinders (switch on ground speed lever) to raise header fully. Stop engine and remove key. 10. Danger: to avoid bodily injury from fall of raised header, always engage header lift...

Page 45

Form # 46584 issue 11/06 web rev_01 43 operation adding rear weight important: the stability of the machine varies with different attachments, tractor options, terrain and operator’s driving technique. Install weight at rear of tractor to provide adequate machine stability. To determine the addition...

Page 46

Form # 46584 issue 11/06 web rev_01 44 operation adding rear weight (continued) to install weight bundle b2266 in rear tractor frame: 1. Install bolt (a) through welded nut in existing tractor weight (b) and start jam nut on bolt (a). 2. Insert weights (c) forward of welded pin (d) as shown, then mo...

Page 47

Form # 46584 issue 11/06 web rev_01 45 operation detaching the header 1. Activate header lift cylinders (switch on ground speed lever) to raise header fully. For units with header express down option, use switch on side console to bypass the feature. Lower the reel (second switch on lever). Stop eng...

Page 48

Form # 46584 issue 11/06 web rev_01 46 operation detaching the header (continued) danger: wait for all movement to stop. A rotating driveline can cause entanglement resulting in serious personal injury or death. 8. Disconnect driveline from header shaft as follows: • pull back spring-loaded collar o...

Page 49

Form # 46584 issue 11/06 web rev_01 47 operation operating the header correct operation reduces crop loss and allows cutting of more acres. The length of service you receive from your windrower depends upon thorough lubrication, and proper maintenance and adjustments. Caution: do not mount anything ...

Page 50

Form # 46584 issue 11/06 web rev_01 48 operation header angle header angle is adjustable by changing the length of the center link between header and tractor. Header angle adjustment ranges: 910, 920, 930 series headers: 8 ° to 16 ° 940 series headers: 6 ° to 13 ° 960 series headers: 13 ° to 21 ° 97...

Page 51

Form # 46584 issue 11/06 web rev_01 49 operation header levelling a 1/4 inch (6 mm) shim (a) is located on both sides of windrower lift linkage. If header is not level, adjust as follows: 1. Lower header onto a block so back of linkage lifts. 2. Remove hardware (b) on the high side of the header and...

Page 52

Form # 46584 issue 11/06 web rev_01 50 operation header flotation the following suggested header float settings are a starting point for normal conditions. Your specific requirements and conditions may require heavier or lighter float. Force required to lift the cutterbar off ground at each end of t...

Page 53

Form # 46584 issue 11/06 web rev_01a 51 operation transporting the windrower warning: do not drive windrower on a road or highway at night, or in conditions which reduce visibility, such as fog or rain. The width of the windrower may not be apparent under these conditions. Warning: avoid driving the...

Page 54

Form # 46584 issue 11/06 web rev_01 52 operation transporting the windrower towing the windrower on a trailer for transporting the windrower other than under its own power, a side mount trailer (a) carrying all four windrower wheels is recommended. Also acceptable are side mount trailers (b) where t...

Page 55

Form # 46584 issue 11/06 web rev_01 53 operation transporting the windrower towing the windrower on a trailer (continued) warning: when towing the windrower on a trailer (continued): 8. For model 9352/4952/2952/8152 tractors, when towing on a front or rear mount trailer, lock casters in a straight-a...

Page 56

Form # 46584 issue 11/06 web rev_01 54 operation transporting the windrower towing windrower without trailer the best method for transporting a disabled windrower is to haul it on a suitable trailer or flatbed. (see towing windrower on a trailer.) in emergency situations, for example, towing out of ...

Page 57

Form # 46584 issue 11/06 web rev_01 55 operation transporting the windrower towing windrower without trailer (continued) warning: when towing the windrower without a trailer: 3. For model 9352/4952/2952/8152 tractors, lock casters in a straight-ahead or straight- back position with l-pin (f). Secure...

Page 58

Form # 46584 issue 11/06 web rev_01 56 operation storage procedure do the following at the end of each operating season: caution: 1. Clean the windrower thoroughly. Never use gasoline, naphtha or any volatile material for cleaning purposes. These materials may be toxic and/or flammable. 2. Store win...

Page 59

Form # 46584 issue 11/06 web rev_01 57 maintenance/service service procedures caution: to avoid personal injury, before servicing machine or opening drive covers: 1. Fully lower header and reel. 2. Disengage header drive clutch. 3. Stop engine and remove key. 4. Engage park brake. 5. Wait for all mo...

Page 60

Form # 46584 issue 11/06 web rev_01 58 maintenance/service seat belt inspection and maintenance keep the operator and trainer seat belts in good condition as follows: 1. Keep sharp edges and items that can cause damage away from the belts. 2. From time to time, check belts, buckles, retractors, teth...

Page 61

Form # 46584 issue 11/06 web rev_01 59 maintenance/service fuels, fluids and lubricants diesel fuel use grade no. 2 - d fuel, as defined by astm designation: d 975 for diesel fuels. Note: when temperature is very cold, the use of a mixture of no. 1 and no. 2 diesel fuel is permitted for a short peri...

Page 62

Form # 46584 issue 11/06 web rev_01 60 maintenance/service fuels, fluids and lubricants (continued) engine oil sae 15w40 complying with sae specs for api class sj and ch-4 engine oil minimum. High grade oil would be api ci-4sk or api ci-4. Power wheel gear lubricant & bevel gear box lubricant use is...

Page 63

Form # 46584 issue 11/06 web rev_01 61 maintenance/service greasing the windrower tractor see "fuels, fluids and lubricants" for recom- mended greases. The following greasing points are marked on the windrower by decals showing a grease gun (a), and grease interval (b) in hours of operation. Use the...

Page 64

Form # 46584 issue 11/06 web rev_01 62 maintenance/service greasing the windrower tractor: 50 hours (continued) caster pivots: (a) - two fittings model xx50/xx40 tractors a header drive pulley (b) - one fitting b c header clutch pivot (c) - one fitting h d transmission driveline u-joints (d) - two f...

Page 65

Form # 46584 issue 11/06 web rev_01 63 maintenance/service greasing the windrower tractor: 200 hours or annually h caster wheel hub bearings (h) - two fittings.

Page 66

Form # 46584 issue 11/06 web rev_01 64 maintenance/service engine caution: never operate engine in a closed building. Proper ventilation is required to avoid exhaust gas hazards. Keep the engine clean. Straw and chaff on a hot engine are a fire hazard. Never use gasoline, naphtha or any other volati...

Page 67

Form # 46584 issue 11/06 web rev_01 65 maintenance/service diesel engine lubricating oil check engine oil level daily on dipstick. See "fuels, fluids and lubricants" section for recommended oil type. Important: never operate the engine with the oil level below the "l" (low) mark or above the "h" (hi...

Page 68

Form # 46584 issue 11/06 web rev_01 66 maintenance/service diesel engine lubricating oil changing engine oil and filter (continued) 6. Install the new filter. Turn the filter onto the mount until the gasket contacts the filter head. Tighten the filter an additional 1/2 to 3/4 turn by hand. Important...

Page 69

Form # 46584 issue 11/06 web rev_01 67 maintenance/service diesel engine (continued) engine speed: engine maximum and low idle speeds are factory set to specifications listed on page 13. Important: do not remove any seals from injector pump; removal of seals will void engine warranty. If specified s...

Page 70

Form # 46584 issue 11/06 web rev_01 68 maintenance/service diesel engine engine speed (continued): turbo engine throttle rod adjustment throttle lever in cab should move fuel pump lever the full range between slow speed stop and full rpm stop without contacting the console at either end. To adjust, ...

Page 71

Form # 46584 issue 11/06 web rev_01 69 maintenance/service diesel engine: air intake system air cleaner important: do not run engine with air cleaner disconnected or disassembled. The air cleaner is equipped with a vacuator valve which removes dust continuously from the air cleaner housing. Check da...

Page 72

Form # 46584 issue 11/06 web rev_01 70 maintenance/service diesel engine: air intake system air cleaner cleaning filter elements (continued) 5. Using a dry element cleaner gun, clean element with compressed air. Hold nozzle next to inner surface, and move up and down pleats. Important: air pressure ...

Page 73

Form # 46584 issue 11/06 web rev_01 71 maintenance/service diesel engine: fuel system storing fuel • buy good quality, clean fuel from a reputable dealer. • proper fuel storage is critically important. Keep all dirt, water and other contaminants away from fuel. • avoid storing fuel over long periods...

Page 74

Form # 46584 issue 11/06 web rev_01 72 maintenance/service diesel engine: fuel system fuel sediment bowl inspect fuel sediment bowl daily for water or other contaminants. Bowl is located under tank. Clean as required. To clean: 1. Close valve (a) to shut off fuel. 2. Loosen nut (b) and remove bowl. ...

Page 75

Form # 46584 issue 11/06 web rev_01 73 maintenance/service diesel engine: fuel system fuel filters - diesel engine change fuel filters every 500 hours of operation. Note: 2004 and earlier models have two fuel filters, 2005 units have only one. To change: 1. Close valve (a) under fuel tank to shut of...

Page 76

Form # 46584 issue 11/06 web rev_01 74 maintenance/service diesel engine: fuel system fuel system air removal - diesel engine controlled venting of air is provided at the injection pump through the fuel drain manifold. Small amounts of air introduced by changing filters or injection pump supply line...

Page 77

Form # 46584 issue 11/06 web rev_01 75 maintenance/service diesel engine: fuel system fuel system air removal - diesel engine (continued) to bleed high pressure lines: warning: escaping fluid under pressure can penetrate the skin causing serious injury. When disconnecting diesel lines, have engine s...

Page 78

Form # 46584 issue 11/06 web rev_01 76 maintenance/service engine exhaust system muffler caution: to avoid burns, do not touch muffler when engine is running or before allowing sufficient cooling time after shut-down. For naturally-aspirated diesel engines: clean out muffler accumulation every 200 h...

Page 79

Form # 46584 issue 11/06 web rev_01 77 maintenance/service engine cooling system coolant level check coolant level daily at reserve tank (a). Check level when engine is cold. If tank is less than half full, add coolant to reserve tank (a), not to radiator. Important: use a 50/50 mix of clean, soft w...

Page 80

Form # 46584 issue 11/06 web rev_01 78 maintenance/service engine cooling system changing coolant coolant should be removed, and the system flushed and filled with new coolant every 2000 hours or 2 years. Procedure: caution: to avoid personal injury from hot coolant, do not turn radiator cap until e...

Page 81

Form # 46584 issue 11/06 web rev_01 79 maintenance/service engine cooling system screens and coolers radiator screen the radiator screen may be equipped with an automatic cleaning device which "vacuums" the screen by means of two rotors (a). If rotors fail to clean the screen adequately, remove plas...

Page 82

Form # 46584 issue 11/06 web rev_01 80 maintenance/service electrical system battery warning: · gas given off by battery electrolyte is explosive. Keep all smoking materials, sparks and flames away from batteries. · follow proper charging and boosting procedures given in this section. · ventilate wh...

Page 83

Form # 46584 issue 11/06 web rev_01 81 maintenance/service electrical system battery (continued) preventing battery damage 1. Be sure alternator connections are correct before cables are connected to battery. See "preventing alternator and regulator damage" in this section. 2. Carefully observe pola...

Page 84

Form # 46584 issue 11/06 web rev_01 82 attaching booster battery maintenance/service electrical system battery (continued) charging battery caution: · ventilate the area where batteries are being charged. · do not charge a frozen battery. Warm to 60 ° f (16 ° c) before charging. · do not connect or ...

Page 85

Form # 46584 issue 11/06 web rev_01 83 maintenance/service electrical system preventing alternator and regulator damage 1. Always disconnect battery ground cable when working with the alternator or regulator. 2. Never attempt to polarize alternator or regulator. 3. If wires are disconnected from the...

Page 86

Form # 46584 issue 11/06 web rev_01 84 maintenance/service electrical system lights and bulbs adjustable headlights the two front headlights can be adjusted up or down and to the right or left with adjustment screws (a). Adjust for maximum illumination while ensuring oncoming traffic cannot be blind...

Page 87

Form # 46584 issue 11/06 web rev_01 85 maintenance/service electrical system lights and bulbs (continued) caution: to avoid a slip and fall injury when replacing lamps at front of machine, remove header and use a step ladder, unless header has a traction surface across the back tube. Replacing head ...

Page 88

Form # 46584 issue 11/06 web rev_01 86 maintenance/service electrical system lights and bulbs (continued) replacing red tail light bulbs 1. Remove two screws (a). Remove plastic lens. 2. Replace bulb and reinstall plastic lens. Note: bulb trade #1157. Replacing amber light bulbs 1. Remove light (b) ...

Page 89

Form # 46584 issue 11/06 web rev_01 87 maintenance/service electrical system lights and bulbs (continued) replacing gauge light bulbs 1. Turn light switch and ignition key to off. 2. Remove six screws (three per side) from instrument panel (a). While pulling out on top of instrument panel, pull up u...

Page 90

Form # 46584 issue 11/06 web rev_01 88 maintenance/service electrical system circuit breakers checking in-cab circuit breakers for access to breakers, remove panel (g) on window side of right hand side console. These breakers will reset automatically after approximately one minute. See your dealer i...

Page 91

Form # 46584 issue 11/06 web rev_01 89 maintenance/service hydraulic system warning: avoid high pressure fluids. Escaping fluid can penetrate the skin causing serious injury. Relieve pressure before disconnecting hydraulic lines. Tighten all connections before applying pressure. Keep hands and body ...

Page 92

Form # 46584 issue 11/06 web rev_01 90 maintenance/service hydraulic system hydraulic oil change hydraulic oil every 2000 hours. Note for fleet owners: if you also operate an older macdon built windrower tractor with a production year ’99 or earlier, that unit’s hydraulic system will be filled with ...

Page 93

Form # 46584 issue 11/06 web rev_01 91 maintenance/service hydraulic system: header & reel lift cylinder control valve relief pressure control valve (a), located under the r/h tractor floorboard, directs hydraulic flow to the header lift cylinders, reel lift cylinders and the cylinder used to engage...

Page 94

Form # 46584 issue 11/06 web rev_01 92 maintenance/service header drive: hydraulics flow control block flow control block (a), located under cab near ground speed linkage, provides hydraulic power to the header. The block divides pump output of 19 gallons per minute (gpm) and controls the flow of oi...

Page 95

Form # 46584 issue 11/06 web rev_01 93 maintenance/service header drive bevel gear box lubricant the bevel gear box directs power from the main drive train to the header drive at the right side of the tractor. See “fuels, fluids and lubricants” for recommended lubricant. Check lubricant level as fol...

Page 96

Form # 46584 issue 11/06 web rev_01 94 maintenance/service header drive header drive belt: pulley fore-aft alignment fore-aft misalignment of pulleys can cause a belt failure where the backing band splits between v- belt sections, as shown at (a). Check and correct the pulley fore-aft alignment in t...

Page 97

Form # 46584 issue 11/06 web rev_01 95 maintenance/service header drive header drive belt: pulley vertical alignment vertical misalignment of front pulley can cause a belt failure where sections of the backing band are missing, as shown at (t). The missing sections will vary from 1/2 inch to 5 feet ...

Page 98

Form # 46584 issue 11/06 web rev_01 96 maintenance/service header drive header drive belt guides (continued) to adjust: 1. Stop engine and remove key from ignition. 2. Loosen hardware securing top guide (a), belt keeper (b) and lower guide (c). 3. Hold rear idler (d) down with 15/16 wrench to tighte...

Page 99

Form # 46584 issue 11/06 web rev_01 97 maintenance/service traction drive: hydraulics transmission oil pressure warning light and buzzer in cab will be activated when ignition switch is turned on if transmission oil pressure is below approximately 40 psi (275 kpa) for naturally aspirated engine and ...

Page 100

Form # 46584 issue 11/06 web rev_01 98 maintenance/service traction drive: neutral lock and steering checks danger: to prevent machine run- away: • stop engine before adjusting steering linkage or neutral interlock. • never rewire or misadjust neutral interlock so engine can be started with controls...

Page 101

Form # 46584 issue 11/06 web rev_01 99 maintenance/service traction drive: neutral lock and steering checks (continued) 3. Neutral lock adjustment bolts engagement: check the depth of engagement of the neutral lock adjustment bolts (b) on pintle arms (c). Minimum engagement is 3/8 inch (10 mm), that...

Page 102

Form # 46584 issue 11/06 web rev_01 100 maintenance/service traction drive: neutral lock and steering checks (continued) 6. Radius arm pivots: check the two pivots (a) and (c). At each pivot, torque inner nut (d) to 7 ft.Lbs. (10 n ⋅ m). Hold inner nut (d) with a wrench and tighten outer nut (e) aga...

Page 103

Form # 46584 issue 11/06 web rev_01 101 maintenance/service traction drive: neutral lock and steering troubleshooting any problem with the neutral lock and steering controls could be caused by loose, worn, or improperly adjusted parts as described in the preceding nine checks. Important: when servic...

Page 104

Form # 46584 issue 11/06 web rev_01 102 maintenance/service traction drive: neutral set-up procedure this procedure should be performed only after the nine preceding checks and adjustments have failed to solve the neutral lock/steering problem. This procedure will eliminate machine movement in neutr...

Page 105

Form # 46584 issue 11/06 web rev_01 103 maintenance/service traction drive: neutral set-up procedure (continued) 7. The following adjustment is designed to give the maximum clearance between the neutral lock adjustment bolts and the pintle arms without having the wheels turn. This results in easy lo...

Page 106

Form # 46584 issue 11/06 web rev_01 104 maintenance/service traction drive: ground speed lever friction device adjustment the ground speed lever friction device maintains lever position at the point in the forward/reverse slot where it was released by the operator. The friction device is located at ...

Page 107

Form # 46584 issue 11/06 web rev_01 105 maintenance/service traction drive: wheels and tires power wheels check lubricant level every 200 hours or annually. See "fuels, fluids and lubricants" for recommended lubricant. Note: the following tractor models have a 9 bolt rim mount power wheel: macdon 92...

Page 108

Form # 46584 issue 11/06 web rev_01 106 maintenance/service traction drive: wheels and tires (continued) drive wheel bolts at first use, or when a wheel is removed, check drive wheel bolt torque according to the following schedule: • every 15 minutes on the road or 60 minutes in the field until torq...

Page 109

Form # 46584 issue 11/06 web rev_01 107 maintenance/service traction drive: wheels and tires tire inflation make a visual check daily that tires have not lost pressure. Under-inflation of drive tires can cause side wall cracks. Once a year, measure tire pressure with a gauge. Maintain the pressures ...

Page 110

Form # 46584 issue 11/06 web rev_01 108 maintenance/service traction drive: park brake for models 9250/9350, 4940/4950, 2940/2950, 8140/8150 the park brake is applied when brake lever (a) is locked in the up position. Adjust park brake after the first 10 hours of operation and every 100 hours therea...

Page 111

Form # 46584 issue 11/06 web rev_01 109 a b park brake adjustment d c e reposition brake link on bracket at half-wear stage f adjust brake link hardware g c 3/8” (10 mm) maintenance/service traction drive: park brake models: 9352, 4952, 2952 and 8152 the park brake is applied when brake lever (a) is...

Page 112

Form # 46584 issue 11/06 web rev_01 110 maintenance/service cab air system warning: the air conditioning system is pressurized. Improper servicing may cause refrigerant to penetrate eyes and skin or cause burns. Special equipment and procedures are required to service the air conditioning system. Se...

Page 113

Form # 46584 issue 11/06 web rev_01 111 maintenance/service cab air system return air filters clean return air filters every 100 hours, more often in dusty conditions. To clean: 1. Remove filter covers at both sides of cab rear wall by removing two nuts (a). 2. Remove foam filter elements and clean ...

Page 114

Form # 46584 issue 11/06 web rev_01 112 maintenance/service cab air system compressor protection the compressor is protected from excessively low suction and high discharge pressures by two switches: • low suction pressure switch is located at the outlet of the evaporator (under seat in cab). It wil...

Page 115

Form # 46584 issue 11/06 web rev_01 113 maintenance/service maintenance schedule the following maintenance schedule is a listing of periodic maintenance procedures, organized by service intervals. For detailed instruction, see the specific heading in maintenance/service section. Use "fuels, fluids a...

Page 116

Form # 46584 issue 11/06 web rev_01 114 maintenance/service maintenance schedule 100 hours or annually * 1. Adjust park brake. 2. Clean cab return air filters. 200 hours or annually* 1. Change engine oil and filter. (200 hours or annually, for 2004 & older units) 2. Clean out muffler accumulation (n...

Page 117

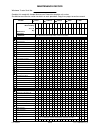

Form # 46584 issue 11/06 web rev_01 115 maintenance record windrower tractor serial no. Combine this record with header maintenance record for complete unit service. See maintenance/service section for details on each procedure. Copy these pages to continue record. Action: - check - lubricate s - ch...

Page 118

Form # 46584 issue 11/06 web rev_01 116 maintenance record (continued) action: - check - lubricate s - change - clean + - add engine hour meter reading: serviced by: maintenance procedure 300 hours s hydraulic oil filters 500 hours s engine oil & filter (2005 units) s fuel filters 1000 hours or 3 ye...

Page 119

Form # 46584 issue 11/06 web rev_01 117 trouble shooting symptom problem solution ref. Cab air system see page 112 for possible causes of abnormal high side / low side pressure. Blower fan will not run. Burned out motor. Replace motor. * burned out switch. Replace switch. * motor shaft tight or bear...

Page 120

Form # 46584 issue 11/06 web rev_01 118 trouble shooting symptom problem solution ref. Air conditioning not cooling. (continued) loose or broken drive belt. Replace drive belt and/ or tighten to specs. 66 compressor partially or completely seized. Remove compressor for service or replacement. * dirt...

Page 121

Form # 46584 issue 11/06 web rev_01 119 trouble shooting symptom problem solution ref. Air conditioning not producing sufficient cooling (continued). Clogged expansion valve. Recover system refrigerant and replace valve. Then, evacuate and charge system. * clogged receiver-drier. Recover system refr...

Page 122

Form # 46584 issue 11/06 web rev_01 120 trouble shooting symptom problem solution ref. Air conditioning system too noisy. (continued) excessive moisture in system. Replace receiver-drier, evacuate & charge system. * air conditioning cools intermittently. Compressor clutch slipping. Slippage over a p...

Page 123

Form # 46584 issue 11/06 web rev_01 121 trouble shooting symptom problem solution ref. Engine hard to start or will not start. (cont'd) water, dirt or air in fuel system. Drain, flush, fill and bleed system. 74 improper type of fuel. Use proper fuel for operating conditions. 59 n.A. Engine: hand lev...

Page 124

Form # 46584 issue 11/06 web rev_01 122 trouble shooting symptom problem solution ref. Engine runs irregularly or stalls frequently. Unsteady fuel supply. Change filter on fuel tank vent line. Replace clogged fuel filters. 71 water, dirt or air in fuel system. Drain, flush, fill and bleed system. 74...

Page 125

Form # 46584 issue 11/06 web rev_01 123 trouble shooting symptom problem solution ref. Warning alarm sounds. Engine overheated. Check coolant level and thermostat. 77 park brake engaged. Release brake. 22 low engine oil pressure. Check oil level. 65 low transmission oil pressure. Check oil level. 89...

Page 126

Form # 46584 issue 11/06 web rev_01 124 trouble shooting symptom problem solution ref. High fuel consumption (continued). Engine out of time. Time injection pump. * low engine temperature. Check thermostat. * injection nozzles dirty. Clean or replace injectors. * engine emits black or grey exhaust. ...

Page 127

Form # 46584 issue 11/06 web rev_01 125 trouble shooting symptom problem solution ref. Starter cranks slowly or will not operate (cont'd) relay not functioning. Check relay and wire connections. * loose or corroded battery connections. Clean and tighten loose connections. 81 key switch worn or termi...

Page 128

Form # 46584 issue 11/06 web rev_01 126 trouble shooting symptom problem solution ref. Lights do not light. Defective light switch. Replace switch. * broken wiring; open or defective circuit breaker. Check wiring for broken wire or shorts, check circuit breaker. 88 defective relay. Replace relay. * ...

Page 129

Form # 46584 issue 11/06 web rev_01 127 trouble shooting symptom problem solution ref. Both wheels will not pull in forward or reverse. Low oil level. Check oil reservoir level. 89 power wheels disengaged. Engage power wheels. 105 damaged hydraulic lines preventing proper oil flow. Replace damaged l...

Page 130

Form # 46584 issue 11/06 web rev_01 128 trouble shooting symptom problem solution ref. One wheel does not pull in forward or reverse (continued). Speed-range control not working. Check for faulty servo or blockage in hose. * high pressure relief valve stuck open, dam- aged seat. Check valve and clea...

Page 131

Form # 46584 issue 11/06 web rev_01 129 trouble shooting symptom problem solution ref. Header hydraulics header or reel not lifting. Contaminant in relief valve. Clean relief valve at cylinder control valve. 91 appropriate solenoids not being energized by activating switch. Check electrical connecti...

Page 132

Form # 46584 issue 11/06 web rev_01 130 trouble shooting symptom problem solution ref header drive sickle drive not engaging (continued) appropriate solenoid not being energized by activating switch. Check electrical connections; repair or replace solenoid. * header drive belt tension too low. Check...

Page 133

Form # 46584 issue 11/06 web rev_01 131 trouble shooting symptom problem solution ref header drive (continued) belt band frayed and separated from v-belt at one side. Belt has jumped one groove at front pulley: belt shield too far from pulley. Belt guides and shields not properly adjusted. Adjust pu...

Page 134

Form # 46584 issue 11/06 web rev_01 132 options and attachments consult your windrower dealer for details on the following options & attachments. Note: if not factory ordered, installation of these kits is to be done by windrower dealer. Air intake screen cleaner wholegoods order number: b2972 this ...

Page 135

Form # 46584 issue 11/06 web rev_01 133 unloading warning: to avoid personal injury or death do not attempt to drive the windrower off the carrier. It must be lifted or towed. When starting the windrower, slight movement of the steering wheel could cause fast and hard-to-correct movement on a small ...

Page 136

Form # 46584 issue 11/06 web rev_01 134 unloading with one forklift unloading one forklift method forklift requirement: one forklift with a 5,000 lb. (2270 kg) capacity. Chain requirements: overhead lifting quality chain with a minimum 5000 lb. (2270 kg) working load limit. 1. Back rear of truck bed...

Page 137

Form # 46584 issue 11/06 web rev_01 135 rear caster installation 16.5 tires on xx50/xx40 tractors assembly note: the purpose of shipping preparations such as having no battery is to better adapt the unit for an extended non-active period. If the machine is to remain non-active for a long period of t...

Page 138

Form # 46584 issue 11/06 web rev_01 136 rear caster installation: 9.5 tires on xx50/xx40 tractors assembly install tires 9.5 rear tires on xx50/xx40 model tractors: (forked or formed casters) 1. Lift rear end of windrower with forklift and remove yellow shipping support from walking beam (see b on p...

Page 139

Form # 46584 issue 11/06 web rev_01 137 assembly install tires drive tires install tires on a hard, level surface as follows: 1. Lift front end of windrower using a forklift and place 14” (35 cm) blocks under yellow skid shoes (s) on front frame legs. 2. Install drive tires onto power wheels ensurin...

Page 140

Form # 46584 issue 11/06 web rev_01 138 assembly battery the windrower is shipped without battery. Battery recommendations battery should meet the following specs: • 640 amps cold cranking at 0 ° f (-18 ° c) • reserve capacity: 180 minutes • size: approximately 13 x 6.8 x 9.4 inches (331 x 173 x 238...

Page 141

Form # 46584 issue 11/06 web rev_01 139 assembly battery install battery note: for easier installation, position a low platform on which to stand when placing battery. 1. Lower battery from above onto battery tray located at left rear corner of frame. Position + post towards rear of machine. 2. Inst...

Page 142

Form # 46584 issue 11/06 web rev_01 140 assembly preparing the tractor for 962/963 & 972/973 headers 1. Remove plastic blocks (a) on tractor lift legs and reinstall as shown with 1/2 x 5 inch bolts provided. Note: for 12’ 972 header only , install extensions (d) with 1/2 x 1 inch hex head bolts and ...

Page 143

Form # 46584 issue 11/06 web rev_01 141 assembly preparing 962/963 harvest header for windrower tractor 1. Attach lift linkage supports to lower header legs with 5/8 locknut at (a). Note: for 963 header, remove existing linkage supports first. 2. Attach connector shaft assembly to header frame tube ...

Page 144

Form # 46584 issue 11/06 web rev_01 142 assembly preparing 962/963 harvest header for windrower tractor (continued) 5. Attach reel lift hose and coupler (supplied in adapter kit) as follows: 30': attach to hydraulic line (f) at header left leg. 36': attach to hose (g) at header left leg. Attach reel...

Page 145

Form # 46584 issue 11/06 web rev_01 143 assembly preparing 972 harvest header (21' to 36') for windrower tractor 1. Attach lift linkage supports (a) inside lower header legs with 5/8 x 6-1/2 carriage bolt, lockwasher and nut. Use the top hole in the leg as shown. 2. For 21’ & 25’ headers, attach cen...

Page 146

Form # 46584 issue 11/06 web rev_01 144 assembly radio installation provision has been made for easy installation of a radio: • remove six screws around outer edge of panel (a). Panel hangs on wiper motor with a plastic tie. If it is desired to work at a bench, unplug turn signal lights and slip tie...

Page 147

Form # 46584 issue 11/06 web rev_01 145 assembly two-way radio installation at the rear of the side console (d), you will find two auxiliary power points provided for accessories such as a two-way radio. To mount antenna to cab roof: • remove console lower panel (to right of operator's seat) and rou...

Page 148

Form # 46584 issue 11/06 web rev_01 146 assembly swath roller a hitch for a pull-behind swath roller can be attached at two bottom bolts (a) on walking beam pivot plate. A direct mounted swath roller can be installed at holes provided in frame at (b). A attach swath roller hitch here b frame-mounted...

Page 149

Form # 46584 issue 11/06 web rev_01 147 index a page air cleaner – engine ....................................... 69 air conditioning system maintenance .......... 110 air intake screen cleaner (attachment)........ 132 air removal - fuel system.............................. 74 alarms - system malfun...

Page 150

Form # 46584 issue 11/06 web rev_01 148 index i page ignition switch ................................................. 20 j jacking procedure......................................... 107 l ladder – r/h side ........................................... 58 leaving the windrower............................

Page 151

Form # 46584 issue 11/06 web rev_01 149 index t cont'd. Page trouble shooting ........................................... 117 trouble shooting: a/c diagnostics ............... 112 two-way radio installation........................... 145 u unloading preparations................................. 133 ...

Page 153

Form # 46584 issue 11/06 self-propelled windrower pre-delivery checklist perform these checks and make adjustments as required prior to delivery to your customer. See the operator's manual for adjustment details. Caution: carefully follow the instructions given. Be alert for safety related messages ...

Page 155

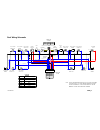

M 503 505 506 702 418 430 431 interior light rear right amber rear right worklight right rear headlight right front worklight right front amber right front headlight right ind light right speaker left speaker left ind light wiper motor left front headlight left front amber left rear headlight left r...

Page 156

S g l i s g l i s g l i s b r i a bat aux 6 a bat aux 6 a bat aux 25 a bat aux 10 a 5 4 2 3 6 1 b t h i r 30 87a 87 86 85 m l h b c 20 a 30 87a 87 86 85 30 87a 87 86 85 30 87a 87 86 85 connector to mac monitor 5 4 3 2 1 8 7 6 5 4 3 2 1 connector to mac monitor 30 87a 87 86 85 10 ohm 5 watt blower re...

Page 157

M m batt - + i g egr sol bat bal bat aux 50 a bat aux 50 a c l u t c h 2 s p e e d s3 s5 s1 s2 s4 l r m engine reel height switch header height switch cylinder control valve (for operation see view a below) deck shift connector for draper header header lights connector header control valve trans neu...

Page 158

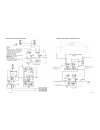

Form 46584 issue 11/06 header & reel lift: hydraulic schematic hydraulic options: reel fore-aft & header tilt 1. Pump 2. Reservoir 3. Filter 4. Cylinder control valve – relief pressure: model xx50/xx40 tractors – 2250 to 2500 psi model xx52 tractors – 2400 to 2650psi measured as described on pg. 91)...

Page 159

Form 46584 issue 11/06 header drive: hydraulic schematic.

Page 160

Form 46584 issue 11/06 traction drive: hydraulic schematic – turbo units 1 - pump 2 - left wheel motor 3 - right wheel motor 4 - reservoir 5 - oil cooler 6 - filter (500 psi) 7 - charge pump relief valve (cracking pressures: 190 psi except australian 250 psi australian units) 8 - oil pressure switch...