- DL manuals

- MacDon

- Lawn Mower Accessories

- FD75

- Operator's Manual

MacDon FD75 Operator's Manual

Summary of FD75

Page 1

Fd75 flexdraper ® ® combine header operator ’s manual 214323 revision a 2018 model year original instruction featuring macdon flex-float technology ™ the harvesting specialists..

Page 2

Fd75 flexdraper ® combine header 1000310 published: july 2017.

Page 3

Introduction this instructional manual contains information on the fd75 flexdraper ® header and the ca25 combine adapter. It must be used in conjunction with your combine operator's manual. The fd75 flexdraper ® is specially designed as a straight cut header and is equipped to work well in all strai...

Page 4

Conventions the following conventions are used in this document: • right and left are determined from the operator’s position. The front of the header is the side that faces the crop; the back of the header is the side that connects to the combine. • unless otherwise noted, use the standard torque v...

Page 5

List of revisions at macdon, we ’re continuously making improvements, and occasionally these improvements affect product documentation. The following list provides an account of major changes from the previous version of this document. Summary of change refer to added conventions used in this docume...

Page 6

Changed “lexion” to “claas” throughout. Moved recommended fluids and lubricants to inside back cover. 214323 iv revision a.

Page 7

Model and serial number record the model number, serial number, and model year of the header, combine adapter, and transport/stabilizer wheel option (if installed) in the spaces provided. Note: right and left designations are determined from the operator ’s position, facing forward. 1022661 a figure...

Page 8

1005072 a figure 4. Transport/stabilizer option slow speed transport/stabilizer wheel option serial number: year: the serial number plate (a) is located on the right axle assembly. 214323 vi revision a.

Page 9

214323 vii revision a introduction................................................................................................................................................I list of revisions .........................................................................................................

Page 10

214323 viii revision a 3.6.1 header attachments.................................................................................................................. 42 3.6.2 header settings ....................................................................................................................

Page 11

214323 ix revision a 3.8.2 case ih 2300/2500 and 5088/6088/7088 combines .................................................................. 107 engaging auto header height control (case ih 2300) .............................................................. 107 calibrating auto header height control...

Page 12

214323 x revision a checking voltage range from combine cab (john deere 60 series) ......................................... 165 calibrating auto header height control (john deere 60 series)................................................. 167 turning accumulator off (john deere 60 series) ............

Page 13

214323 xi revision a engaging auto header height control (new holland cr series) ................................................ 233 checking voltage range from combine cab (new holland cr series) ...................................... 235 calibrating auto header height control (new holland cr seri...

Page 14

214323 xii revision a 4.5.1 attaching header to claas combine....................................................................................... 293 4.5.2 detaching header from claas combine.................................................................................. 297 4.6 new holland com...

Page 15

214323 xiii revision a 5.7.4 removing auger drive chain ................................................................................................... 362 5.7.5 installing auger drive chain ..................................................................................................... 366...

Page 16

214323 xiv revision a 5.11.1 removing stripper bars ......................................................................................................... 416 5.11.2 installing stripper bars .............................................................................................................

Page 17

214323 xv revision a 5.14.5 replacing reel drive motor.................................................................................................... 469 removing reel drive motor..................................................................................................... 469 installing...

Page 18

214323 xvi revision a 7.2 cutting action and knife components ............................................................................................... 492 7.3 reel delivery ...........................................................................................................................

Page 19

214323 1 revision a 1 safety 1.1 safety alert symbols 1000915 figure 1.1: safety symbol this safety alert symbol indicates important safety messages in this manual and on safety signs on the machine. This symbol means: • attention! • become alert! • your safety is involved! Carefully read and follow...

Page 20

214323 2 revision a 1.2 signal words three signal words, danger, warning, and caution, are used to alert you to hazardous situations. The appropriate signal word for each situation has been selected using the following guidelines: danger indicates an imminently hazardous situation that, if not avoid...

Page 21

214323 3 revision a 1.3 general safety 1000004 figure 1.2: safety equipment caution the following are general farm safety precautions that should be part of your operating procedure for all types of machinery. Protect yourself. • when assembling, operating, and servicing machinery, wear all protecti...

Page 22

214323 4 revision a 1000007 figure 1.5: safety around equipment • wear close-fitting clothing and cover long hair. Never wear dangling items such as scarves or bracelets. • keep all shields in place. Never alter or remove safety equipment. Make sure driveline guards can rotate independently of shaft...

Page 23

214323 5 revision a 1.4 maintenance safety 1000009 figure 1.8: safety around equipment to ensure your safety while maintaining machine: • review operator’s manual and all safety items before operation and/or maintenance of machine. • place all controls in neutral, stop the engine, set the park brake...

Page 24

214323 6 revision a 1.5 hydraulic safety 1001205 figure 1.11: testing for hydraulic leaks • always place all hydraulic controls in neutral before dismounting. • make sure that all components in hydraulic system are kept clean and in good condition. • replace any worn, cut, abraded, flattened, or cri...

Page 25

214323 7 revision a 1.6 safety signs 1000694 figure 1.14: operator ’s manual decal • keep safety signs clean and legible at all times. • replace safety signs that are missing or become illegible. • if original parts on which a safety sign was installed are replaced, be sure repair part also bears cu...

Page 26

214323 8 revision a 1.7 safety decal locations figure 1.15: upper cross auger 1003348 a a a a - md #174682 figure 1.16: slow speed transport 1003341 a a a - md #220799 safety.

Page 27

214323 9 revision a figure 1.17: slow speed transport tow-bar 1003338 a b a b a - md #220797 b - md #220798 figure 1.18: vertical knife 1003382 a a a - md #174684 safety.

Page 28

214323 10 revision a figure 1.19: endsheets, reel arms, and backsheet 1022664 b a a c c e d e c a b e b c f d f g g g a - md #174632 b - md #131393 c - md #184422 d - md #131392 (double reel only) e - md #131391 f - md #166466 g - md #174436 safety.

Page 29

214323 11 revision a figure 1.20: backtube 1003403 a b c d e 1009678 a b c d c a e a - md #184372 b - md #166466 c - md #131391 d - md #131392 e - md #184372 (split frame) safety.

Page 30

214323 12 revision a 1.8 understanding safety signs 1003356 figure 1.21: md #131391 md #131391 crushing hazard danger • rest header on ground or engage safety props before going under unit. 1003404 figure 1.22: md #131392 md #131392 crushing hazard warning • to avoid injury from fall of raised reel;...

Page 31

214323 13 revision a 1000706 figure 1.24: md #166466 md #166466 high pressure oil hazard warning • do not go near leaks. • high pressure oil easily punctures skin causing serious injury, gangrene, or death. • if injured, seek emergency medical help. Immediate surgery is required to remove oil. • do ...

Page 32

214323 14 revision a 1000920 figure 1.27: md #174436 md #174436 high pressure oil hazard warning • do not go near leaks. • high pressure oil easily punctures skin causing serious injury, gangrene, or death. • if injured, seek emergency medical help. Immediate surgery is required to remove oil. • do ...

Page 33

214323 15 revision a 1003383 figure 1.30: md #174684 md #174684 sharp component hazard caution • wear heavy canvas or leather gloves when working with knife. • be sure no one is near the vertical knife when removing or rotating knife. 1001648 figure 1.31: md #184371 md #184371 open drive hazard warn...

Page 34

214323 16 revision a • disengage header drive, put transmission in neutral, and wait for all movement to stop before leaving operator ’s position. • stop the engine and remove the key from ignition before servicing, adjusting, lubricating, cleaning, or unplugging machine. • engage safety props to pr...

Page 35

214323 17 revision a 1001647 figure 1.35: md #193147 md #193147 transport/roading hazard warning • ensure tow-bar lock mechanism is locked. 1000925 figure 1.36: md #194521 md #194521 auger entanglement hazard caution • to avoid injury from entanglement with rotating auger, stand clear of header/mowe...

Page 36

214323 18 revision a 1003333 figure 1.37: md #220797 md #220797 tipping hazard in transport mode warning • read the operator’s manual for more information on potential tipping or roll-over of header while transporting. 1003337 figure 1.38: md #220798 md #220798 loss of control hazard in transport ca...

Page 37

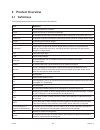

214323 19 revision a 2 product overview 2.1 definitions the following terms and acronyms may be used in this manual. Term definition api american petroleum institute astm american society of testing and materials bolt a headed and externally threaded fastener that is designed to be paired with a nut...

Page 38

214323 20 revision a term definition soft joint a joint made with use of a fastener where joining materials are compressible or experience relaxation over a period of time truck a four-wheel highway/road vehicle weighing no less than 3400 kg (7500 lb.) tension axial load placed on a bolt or screw, u...

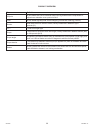

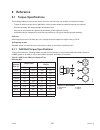

Page 40

214323 22 revision a table 2.1 header specifications (continued) conveyor (draper) and decks draper width 1057 mm (41.61 in.) s draper drive hydraulic s draper speed: ca25 combine adapter controlled 141 m/min. (0 –464 fpm) s delivery opening width 1870 mm (73.62 in.) s pr15 pick-up reel quantity of ...

Page 41

214323 23 revision a table 2.2 header attachments ca25 combine adapter s feed draper width 2000 mm (78.7 in.) s feed draper speed 107 –122 m/min (350 –400 fpm) s feed auger width 1660 mm (65.3 in.) s feed auger outside diameter 559 mm (22 in.) s feed auger tube diameter 356 mm (14 in.) s feed auger ...

Page 42

214323 24 revision a 2.3 component identification 2.3.1 fd75 flexdraper ® ® figure 2.2: fd75 flexdraper ® ® components 1004524 a b c d e g f h j k l m n a - wing float linkage b - center-link c - center reel arm prop handle d - transition pan e - reel fore-aft cylinder f - reel lift cylinder g - end...

Page 43

214323 25 revision a 2.3.2 ca25 combine adapter figure 2.3: header side of ca25 combine adapter 1004589 a c d e f f g b b a - feed auger b - header float springs c - center-link d - hydraulic reservoir e - gearbox f - header support arm g - feed draper figure 2.4: combine side of ca25 combine adapte...

Page 45

214323 27 revision a 3 operation 3.1 owner/operator responsibilities caution • it is your responsibility to read and understand this manual completely before operating the header. Contact your macdon dealer if an instruction is not clear to you. • follow all safety messages in the manual and on safe...

Page 46

214323 28 revision a 3.2 operational safety 1001602 figure 3.1: no riders caution adhere to the following safety precautions: • follow all safety and operational instructions provided in your operator ’s manuals. If you do not have a combine manual, get one from your dealer and read it thoroughly. •...

Page 47

214323 29 revision a 3.2.2 reel safety props the reel safety props, located on the reel support arms, prevent the reel from unexpectedly lowering. Warning to avoid bodily injury from fall of raised reel, always engage reel safety props before going under raised reel for any reason. Important: to pre...

Page 48

214323 30 revision a 1001695 a c b figure 3.4: reel safety prop – center arm 3. Use handle (a) to move lock rod to inboard position (b) which engages pin (c) under prop. 4. Lower reel until safety props contact the outer arm cylinder mounts and the center arm pins. Disengaging reel safety props 1004...

Page 49

214323 31 revision a 1001697 b a figure 3.6: reel safety prop – center arm 3. Use the handle (b) to move the lock rod (a) to the outboard position. 3.2.3 endshields a hinged, polyethylene endshield is fitted on each end of the header. Opening endshield 10013651001365 a b c figure 3.7: left endshield...

Page 50

214323 32 revision a 1001363 figure 3.9: left endshield open important: do not force endshield once it has reached its end of travel or damage to endshield structure may result. The endshield is designed to open sufficiently to allow access to drive system and manual case. Note: to access the knife ...

Page 51

214323 33 revision a 10013651001365 a b c figure 3.12: left endshield pin 5. Replace tool (b) and lynch pin (a) on top pin (c). Removing endshield 1001228 a b figure 3.13: left endshield 1. Open the endshield. Refer to opening endshield, page 31 . 2. Remove the acorn nut (a) securing the endshield t...

Page 52

214323 34 revision a installing endshield 1001675 b a figure 3.14: left endshield 1. Position the endshield onto support (a), and align the hole in the endshield with stud (b) on the support. 1001681 a figure 3.15: left endshield 2. Secure the endshield to the support with acorn nut (a). 3. Close th...

Page 53

214323 35 revision a adjusting endshield polyethylene endshields expand or contract when subjected to large temperature changes. The position of the top pin and lower catch can be adjusted to compensate for dimensional changes. 1001672 x figure 3.16: left endshield 1. Measure gap (x) between the fro...

Page 54

214323 36 revision a if adjustments are required, proceed as follows: 1001364 a b c figure 3.17: left endshield 2. Open the endshield. Refer to opening endshield, page 31 . 3. Loosen nut (a) on pin (b) from inside the endsheet using a 19 mm (3/4 in.) socket. 4. Close the endshield and adjust its pos...

Page 55

214323 37 revision a 1004528 a figure 3.19: linkage cover 2. Rotate cover (a) upward until inboard end can be lifted off. Installing linkage covers 1004530 a b figure 3.20: linkage cover 1. Position inboard end of cover (a) over linkage and behind indicator bar (b). 2. Lower cover until secure and a...

Page 56

214323 38 revision a 3.2.5 daily start-up check 1001351 figure 3.22: safety devices caution • clear the area of other persons, pets, etc. Keep children away from machinery. Walk around the machine to be sure no one is under, on, or close to it. • wear close-fitting clothing and protective shoes with...

Page 57

214323 39 revision a 3.3 break-in period caution before investigating an unusual sound or attempting to correct a problem, shut off engine and remove key. Note: until you become familiar with the sound and feel of your new header, be extra attentive. After attaching the header to the combine for the...

Page 58

214323 40 revision a 3.4 shutting down the machine danger to avoid bodily injury or death from unexpected start-up of machine, always stop engine and remove key from ignition before leaving operator ’s seat for any reason. To shut down, and before leaving the combine seat for any reason, follow thes...

Page 59

214323 41 revision a 3.5 cab controls caution be sure all bystanders are clear of machine before starting engine or engaging any header drives. Refer to your combine operator ’s manual for identification of the following in-cab controls: • header engage/disengage control • header height • header ang...

Page 60

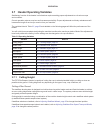

214323 42 revision a 3.6 header setup 3.6.1 header attachments several attachments to improve the performance of your fd75 flexdraper ® header are available as options that can be installed by your macdon dealer. Refer to 6 options and attachments, page 479 for descriptions of available items. 3.6.2...

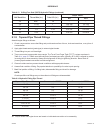

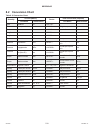

Page 61

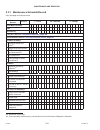

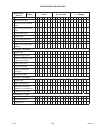

214323 43 revision a t able 3.2 fd75/ca25 combine header recommended settings crop t ype stubble height mm (in.) crop condition divider rods draper speed setting 6 header angle 78 reel cam reel speed % 9 reel position skid shoe position 8 stabilizer wheels 10 upper cross auger cereals ( light of f 8...

Page 62

214323 44 revision a t able 3.2 fd75/ca25 combine header recommended settings (continued) crop t ype stubble height mm (in.) crop condition divider rods draper speed setting 11 header angle 1213 reel cam reel speed % 14 reel position skid shoe position 13 stabilizer wheels 15 upper cross auger canol...

Page 63

214323 45 revision a t able 3.2 fd75/ca25 combine header recommended settings (continued) crop t ype stubble height mm (in.) crop condition divider rods draper speed setting 17 header angle 1819 reel cam reel speed % 20 reel position skid shoe position 19 stabilizer wheels 21 upper cross auger calif...

Page 64

214323 46 revision a t able 3.2 fd75/ca25 combine header recommended settings (continued) crop t ype stubble height mm (in.) crop condition divider rods draper speed setting 22 header angle 2324 reel cam reel speed % 25 reel position skid shoe position 24 stabilizer wheels 26 upper cross auger calif...

Page 65

214323 47 revision a t able 3.2 fd75/ca25 combine header recommended settings (continued) crop t ype stubble height mm (in.) crop condition divider rods draper speed setting 27 header angle 2829 reel cam reel speed % 30 reel position skid shoe position 29 stabilizer wheels 31 upper cross auger edibl...

Page 66

214323 48 revision a t able 3.2 fd75/ca25 combine header recommended settings (continued) crop t ype stubble height mm (in.) crop condition divider rods draper speed setting 32 header angle 3334 reel cam reel speed % 35 reel position skid shoe position 34 stabilizer wheels 36 upper cross auger lenti...

Page 67

214323 49 revision a 3.6.3 optimizing header for straight combining canola ripe canola can be straight combined, but most varieties are very susceptible to shelling and subsequent seed loss. This section provides recommended attachments and settings to optimize fd75 flexdraper ® headers for straight...

Page 68

214323 50 revision a 1. Raise header to full height. 2. Shut down the combine, and remove the key from the ignition. 3. Engage header lift cylinder safety props. 1009147 a b c figure 3.23: spring tensioner 4. Check the thread length protruding past the nut (b). Length should be 15 mm (0.60 in.). If ...

Page 69

214323 51 revision a 3.6.4 reel settings note: the reel settings chart is also applicable for reel tines. Table 3.4 fd75 recommended reel settings cam setting number (finger speed gain) reel position number reel finger pattern 1 (0) 6 or 7 1001819 2 (20%) 6 or 7 1001820 operation.

Page 70

214323 52 revision a table 3.4 fd75 recommended reel settings (continued) cam setting number (finger speed gain) reel position number reel finger pattern 3 (30%) 3 or 4 1001821 4 (35%) 2 or 3 1001822 note: • adjust the reel forward to position the fingers closer to the ground, while tilting the head...

Page 71

214323 53 revision a 3.7 header operating variables satisfactory function of the header in all situations requires making proper adjustments to suit various crops and conditions. Correct operation reduces crop loss and increases productivity. Proper adjustments and timely maintenance will increase t...

Page 72

214323 54 revision a adjusting stabilizer/slow speed transport wheels a properly adjusted header will achieve a balance between the amount of header weight carried by the float and the amount carried by the stabilizer/slow speed transport wheels. Refer to 3.6.2 header settings, page 42 for recommend...

Page 73

214323 55 revision a 1013795 a figure 3.26: load indicator 12. Lower the header to the desired cutting height using the combine controls and check the load indicator (a). 1001655 a figure 3.27: spring compression important: continuous operation with excessive spring compression (that is, load indica...

Page 74

214323 56 revision a 1001654 a b c figure 3.28: stabilizer wheel 2. Support the wheel weight by lifting slightly with one hand on handle (b), and pull up on handle (a) to release the lock. 3. Lift the wheel using handle (b), and engage the support channel into center slot (c) in the upper support. 4...

Page 75

214323 57 revision a the header float system floats the header over the surface to compensate for ridges, trenches, and other variations in ground contour to prevent the cutterbar from pushing into the ground or leaving uncut crop. Refer to the following for additional information: • adjusting inner...

Page 76

214323 58 revision a • adjusting stabilizer wheels, page 55 • adjusting stabilizer/slow speed transport wheels, page 54 1001658 a b c figure 3.32: outer skid shoe 3. Remove lynch pin (a) from each skid shoe (b). 4. Hold shoe (b) and remove adjustment pin (c) by disengaging from the frame and pulling...

Page 77

214323 59 revision a 1009194 a figure 3.34: cutting on the ground 1. Set the float for cutting on the ground as follows: a. Ensure the header float locks are disengaged. Refer to locking/unlocking header float, page 64 . B. Lower feeder house using the combine header controls until float indicator (...

Page 78

214323 60 revision a 1009646 a figure 3.36: center-link 3. Adjust center-link to between b and c on indicator (a). 4. Position cutterbar 200 –300 mm (8–12 in.) off the ground. 5. Stop engine and remove key from ignition. 1008761 a figure 3.37: wing lock in lock position 6. Place wing lock spring han...

Page 79

214323 61 revision a 1001702 b a figure 3.39: left wheel 8. Place stabilizer wheels and slow speed transport wheels (if equipped) in storage position as follows: a. Support wheel weight by lifting slightly with one hand, and pull up on handle (a) to release the lock. B. Lift wheels to desired height...

Page 80

214323 62 revision a 1001217 a b c figure 3.41: left side of adapter 1001218 a c b figure 3.42: right side of adapter 10. Place supplied torque wrench (a) onto float lock (b). Note position of wrench for checking left or right side. 11. Push down on wrench to rotate bell crank (c) forward. 1019192 a...

Page 81

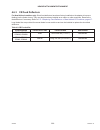

214323 63 revision a table 3.6 float settings header size torque settings cutting on ground cutting off ground 9.1 m (30 ft.) 1-1/2 to 2 2 to 2-1/2 10.6 m (35 ft.) 1-1/2 to 2 2 to 2-1/2 12.2 m (40 ft.) 2 to 2-1/2 2-1/2 to 3 13.7 m (45 ft.) 2 to 2-1/2 2-1/2 to 3 1001641 a b figure 3.44: float adjustm...

Page 82

214323 64 revision a 1001131 a figure 3.45: torque wrench 17. Return torque wrench (a) to its storage location at right side of adapter frame. Locking/unlocking header float two header float locks —one on each side of the adapter—lock and unlock the header float system. Important: the float locks mu...

Page 83

214323 65 revision a locking/unlocking header wings the fd75 flexdraper ® header is designed to operate with the cutterbar on the ground. The three header sections move independently to follow the ground contours. In this mode, each wing is unlocked and is free to move up and down. The fd75 flexdrap...

Page 84

214323 66 revision a 1003620 a b figure 3.49: torque wrench on wing nut 5. Place the torque wrench (a) on bolt (b) and use it to move the wing until the lock disengages. 6. Replace torque wrench (a) and reinstall the linkage cover. 7. The wings should now freely move up and down with equal hand forc...

Page 85

214323 67 revision a 1003620 a b figure 3.52: header wing 5. Place torque wrench (a) on bolt (b) and use it to move the wing until the lock engages. 6. Replace torque wrench (a) and reinstall the linkage cover. Note: the wings will not move relative to the header. 3.7.3 checking and adjusting header...

Page 86

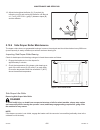

214323 68 revision a 1009084 a b figure 3.53: wing imbalance if a wing has a tendency to be in a smile (a) or frown (b) position, wing balance may require adjusting. Perform the following steps to verify if the wings are not balanced and the degree of imbalance: 1009646 a figure 3.54: center-link 1....

Page 87

214323 69 revision a 1004577 a figure 3.56: linkage cover note: refer to decal (a) inside each linkage cover. 1003618 a figure 3.57: torque wrench 6. Retrieve wrench (a) from right leg of adapter. 1003620 a b figure 3.58: balance linkage 7. Place torque wrench (a) on bolt (b). Operation.

Page 88

214323 70 revision a 1004580 a b c d figure 3.59: balance linkage 8. Check that pointer (d) is properly positioned as follows: a. Use wrench (a) to move bell crank (b) so that lower edge of bell crank is parallel to top-link (c). B. Check that pointer (d) is lined up with the top- link (c). Bend poi...

Page 89

214323 71 revision a 1003643 a b c figure 3.62: balance linkage 11. Move wing downward with torque wrench (a) until pointer upper alignment tab (c) lines up with the lower edge of top-link (b). Observe indicator reading (a) on the wrench and record it. • if the difference between the readings is 0.5...

Page 90

214323 72 revision a 1003618 a figure 3.65: torque wrench 12. Place wrench (a) back onto right leg of adapter. 1003596 a figure 3.66: wing lock in lock position 13. Lock the wings by moving spring handles (a) to upper lock position. 1003595 a b figure 3.67: linkage cover 14. Reinstall linkage cover ...

Page 91

214323 73 revision a adjusting wing balance warning to avoid bodily injury or death from unexpected startup of machine, always stop engine and remove key before adjusting machine. Before proceeding, check the wing balance to verify how to adjust the wing. Refer to checking wing balance, page 67 . No...

Page 92

214323 74 revision a 1004577 a figure 3.70: linkage cover note: refer to decal (a) inside each linkage cover. 1009645 a figure 3.71: wing lock in unlock position 6. Unlock the wings by moving handle (a) to lower (unlock) position. 1003618 a figure 3.72: torque wrench 7. Retrieve wrench (a) from adap...

Page 93

214323 75 revision a 1003620 a b figure 3.73: balance linkage 8. Place torque wrench (a) on bolt (b). 1009647 a b c figure 3.74: balance linkage 9. Loosen clevis bolt (a) for the wing requiring adjustment as determined by the wing balance check. Note: do not loosen any other hardware. 1008650 a b c ...

Page 94

214323 76 revision a 1003596 a figure 3.76: wing lock in lock position 14. Move handle (a) to the upper lock position. 15. If lock does not engage, move the wing up and down with torque wrench until it locks. When locked, there will be some movement in the linkage. 16. If the cutterbar is not straig...

Page 95

214323 77 revision a controlling header angle the header/guard angle is controlled from the combine cab with a switch on the operator ’s control console and an indicator on the center-link. To change the header/guard angle, adjust the length of the center-link between the combine adapter and the hea...

Page 96

214323 78 revision a 1022936 a figure 3.81: toggle switch location – john deere john deere: the reel fore-aft / header tilt switch (a) is located on the right side of armrest. 1013810 a d figure 3.82: center-link 1. Set the header angle according to the type and condition of crop and soil as follows...

Page 97

214323 79 revision a 3.7.5 reel speed reel speed is one of the factors that determines how crop is moved from the cutterbar onto the drapers. The reel performs best when it appears to be driven by the ground. It should move the cut crop evenly through the cutterbar and onto the drapers without bunch...

Page 98

214323 80 revision a 3.7.6 ground speed operating at the proper ground speed will result in cleanly cut crops and evenly distributed material into the combine. Reduce ground speed in difficult cutting conditions to reduce loads on cutting components and drives. Use lower ground speeds in very light ...

Page 99

214323 81 revision a adjusting side draper speed the side drapers carry the cut crop to the adapter feed draper which then feeds it into the combine. The speed is adjustable to suit crops and crop conditions. A 1006122 figure 3.85: side drapers the side drapers (a) are driven by hydraulic motors and...

Page 100

214323 82 revision a adjusting feed draper speed the feed draper moves the cut crop from the side drapers into the adapter feed auger. 1005890 a figure 3.87: ca25 combine adapter the adapter feed draper (a) is driven by a hydraulic motor and a pump that is powered by the combine feeder house drive t...

Page 101

214323 83 revision a table 3.10 fd75 header knife speed header size (m [ft.]) recommended knife drive speed range (rpm) single-knife drive double-knife drive 9.1 (30) 600 –700 — 10.6 (35) 550 –650 — 12.2 (40) 525 –600 550 –700 13.7 (45) — 550 –700 important: ensure the knife speed is within the rang...

Page 102

214323 84 revision a 6. Shut down the combine. 7. Compare pulley rpm measurement with the rpm values in the knife speed chart. Refer to 3.7.8 knife speed, page 82 . 8. Contact your macdon dealer if the pulley rpm measurement exceeds the specified rpm range for your header. 3.7.9 reel height the crop...

Page 103

214323 85 revision a 1009308 a b figure 3.90: fore-aft decal a decal (a) is attached to the right reel support arm for identifying reel position. The aft edge of the cam disc (b) is the reel fore-aft position marker. For straight standing crop, center the reel over the cutterbar (4 –5 on decal). For...

Page 104

214323 86 revision a reposition the center arm cylinder as follows: note: reel components not shown in illustration for improved clarity. Note: to move a split reel into canola position, the short brace kit for center reel arm (b5605) is required. 1001843 c a b figure 3.92: right arm – forward posit...

Page 105

214323 87 revision a reposition right arm cylinder as follows: note: reel components not shown in illustration for improved clarity. 1009310 a b c figure 3.94: forward position 1009312 a b c figure 3.95: rearward position 6. Remove four bolts (a) securing cylinder bracket (b) to the reel arm. 7. Pus...

Page 106

214323 88 revision a reposition the left reel arm cylinder as follows: note: reel components not shown in illustration for improved clarity. 1001761 c d b a d figure 3.96: forward position 9. Remove pin (a) securing cylinder (b) to bracket/light assembly (c). 10. Remove bolts (d) securing bracket/li...

Page 107

214323 89 revision a repositioning fore-aft cylinders with multi-crop rapid reel conversion option the reel can be moved approximately 227 mm (9 in.) farther aft by repositioning the fore-aft cylinders on the reel arms. Danger to avoid bodily injury or death from unexpected start-up of machine, alwa...

Page 108

214323 90 revision a reposition the center arm cylinder as follows: note: reel components not shown in illustration for improved clarity. 1010500 a b c d figure 3.100: forward position – center arm 1010499 a b c d figure 3.101: aft position – center arm 6. Remove cotter pin (a) and clevis pin (b). 7...

Page 109

214323 91 revision a reposition the right arm cylinder as follows: note: reel components not shown in illustration for improved clarity. 1010503 a b c d figure 3.102: forward position – right arm 1010504 a b c d figure 3.103: aft position – right arm 9. Remove cotter pin (a) and clevis pin (b). 10. ...

Page 110

214323 92 revision a 1001819 figure 3.104: finger profile – position 1 cam position 1, reel position 6 or 7 delivers the most even crop flow onto the drapers without fluffing up or disturbing the material. • this setting will release crop close to the cutterbar and works best if the cutterbar is on ...

Page 111

214323 93 revision a 1001822 figure 3.107: finger profile – position 4 cam position 4, reel position 2 or 3 is used with the reel fully forward to leave the maximum amount of stubble in lodged crops. • this position allows the reel to reach forward and lift the crop across the knife and onto the dra...

Page 112

214323 94 revision a adjusting reel cam danger to avoid bodily injury or death from unexpected start-up of machine, always stop engine and remove key from ignition before leaving operator ’s seat for any reason. 1001149 a b c figure 3.109: cam disc positions 1. Turn latch pin (a) counterclockwise us...

Page 113

214323 95 revision a 1005674 a b c figure 3.110: crop divider 3. Lift safety lever (a). 4. Hold onto crop divider (b), push lever (c) to open latch, and lower crop divider. 1001833 a b figure 3.111: stored crop divider 5. Lift crop divider off endsheet and store as follows: a. Insert pin (a) on crop...

Page 114

214323 96 revision a 1001841 a b figure 3.112: crop divider 3. Remove bolt (a), lock washer, and flat washer. 4. Lower crop divider (b) and then lift to remove from endsheet. 5. Close or install endshields. Refer to 3.2.3 endshields, page 31 . Operation.

Page 115

214323 97 revision a installing crop dividers with latch option onto header danger to avoid bodily injury or death from unexpected start-up or fall of raised machine, always stop engine, remove key, and engage safety props before going under header for any reason. 1. Lower reel, raise header, stop e...

Page 116

214323 98 revision a 1001839 a figure 3.115: crop divider 7. Pull at the tip of the crop divider and ensure there is no lateral movement. If necessary, adjust bolts (a) to tighten crop divider and eliminate lateral movement. 8. Close or install endshields. Refer to 3.2.3 endshields, page 31 . Instal...

Page 117

214323 99 revision a 1001216 a figure 3.117: crop divider 4. Position crop divider as shown by inserting lugs (a) into holes in endsheet. 1001834 a b c figure 3.118: crop divider 5. Lift forward end of crop divider and install bolt (a) and special stepped washer (b) (step towards divider). Tighten b...

Page 118

214323 100 revision a removing crop divider rods 1010234 a b figure 3.119: crop divider rod 1. Loosen bolt (a) and remove crop divider rod (b) from both sides of header. 1004684 a figure 3.120: right endsheet 2. Store both crop divider rods (a) inboard on the right endsheet. Installing crop divider ...

Page 119

214323 101 revision a 1010234 a b figure 3.122: divider rod on crop divider 2. Position crop divider rod (b) on tip of crop divider as shown and tighten bolt (a). 3. Repeat procedure at opposite end of header. Rice divider rods 1001582 figure 3.123: divider rod for rice optional rice divider rods pr...

Page 120

214323 102 revision a 3.8 auto header height control (ahhc) macdon ’s auto header height control (ahhc) feature works in conjunction with the ahhc option available on certain combine models. A sensor is installed in float indicator box (a) on the ca25 combine adapter. This sensor sends a signal to c...

Page 121

214323 103 revision a • 3.8.2 case ih 2300/2500 and 5088/6088/7088 combines, page 107 • 3.8.3 case ih 5130/6130/7130, 7010/8010, 7120/8120/9120, and 7230/8230/9230 combines, page 111 • 3.8.4 challenger 6 and 7 series combines, page 122 • 3.8.5 gleaner r62/r72 combines, page 129 • 3.8.6 gleaner r65/r...

Page 122

214323 104 revision a manually checking voltage range the output voltage range of auto header height control (ahhc) sensors in some combines can be checked from cab. For instructions, refer to your combine operator ’s manual or ahhc instructions later in this document. To manually check sensor ’s ou...

Page 123

214323 105 revision a 1003462 a figure 3.127: measuring voltage at float indicator box 4. Use a voltmeter (a) to measure voltage between ground (pin 2) and signal (pin 3) wires at ahhc sensor in float indicator box. Ensure it is at high voltage limit for combine. Refer to table 3.13, page 103 . Note...

Page 124

214323 106 revision a 1022917 a b figure 3.129: ahhc sensor assembly for use with claas combines 1. Complete the following steps to adjust high voltage limit: a. Extend guard angle fully; header angle indicator should be at d. B. Position header 152 –254 mm (6–10 in.) above ground; float indicator s...

Page 125

214323 107 revision a 3.8.2 case ih 2300/2500 and 5088/6088/7088 combines engaging auto header height control (case ih 2300) note: changes may have been made to combine controls or display since this document was published. Refer to combine operator ’s manual for updates. 1003788 a b figure 3.132: c...

Page 126

214323 108 revision a calibrating auto header height control (ahhc) (case ih 2300/2500 and 5088/6088/7088) note: changes may have been made to combine controls or display since this document was published. Refer to combine operator ’s manual for updates. To calibrate the ahhc system, follow these st...

Page 127

214323 109 revision a 1010069 a figure 3.137: joystick lever (case ih 5088/6088/7088) 1002565 a b figure 3.138: float indicator box note: the ideal ground pressure —in most cases—is one number (on float indicator box) above header suspended off ground. For example, if float indicator needle (b) is p...

Page 128

214323 110 revision a 1018824 a b c d figure 3.139: combine controls 1. Use header settings key (a) to display header sensitivity change page. 2. Use up (b) or down (c) keys to adjust highlighted item. The height sensitivity setting range is 0 (least sensitive) to 250 (most sensitive) in increments ...

Page 129

214323 111 revision a 3.8.3 case ih 5130/6130/7130, 7010/8010, 7120/8120/9120, and 7230/8230/9230 combines checking voltage range from combine cab (case 8010) note: changes may have been made to combine controls or display since this document was published. Refer to combine operator ’s manual for up...

Page 130

214323 112 revision a 1003676 a figure 3.143: case 8010 combine display 5. Select diag (a) on universal display main page. The diag page displays. 1003677 a figure 3.144: case 8010 combine display 6. Select sub system (a). The sub system page displays. 1003678 a figure 3.145: case 8010 combine displ...

Page 131

214323 113 revision a 1003679 a figure 3.146: case 8010 combine display 8. Select left sen (a). The exact voltage is displayed. Raise and lower header to see full range of voltage readings. 1003680 figure 3.147: case 8010 combine display 9. Adjust voltage limits (refer to adjusting voltage limits, p...

Page 132

214323 114 revision a 1020453 a b figure 3.149: case combine display 1. To be able to swap between reel fore/aft controls and header fore/aft tilt controls, go to the layout tab, select fore/aft control (a) from the legend, and place it on one of the operator configurable screens — harv1, harv2, har...

Page 133

214323 115 revision a 1003464 a b figure 3.151: float indicator box 3. Adjust cable take-up bracket (b) (if necessary) until pointer (a) on float indicator is on 0. 4. Ensure header float is unlocked. 1003672 a figure 3.152: case ih combine display 5. Select diagnostics (a) on main page. The diagnos...

Page 134

214323 116 revision a 1003674 a figure 3.154: case ih combine display 8. Select header height/tilt (a). The parameter page opens. 1003675 a b figure 3.155: case ih combine display 9. Select left header height sen (a), and then select graph button (b). The exact voltage is displayed at top of page. R...

Page 135

214323 117 revision a calibrating auto header height control (case ih 5130/6130/7130, 7010/8010; 7120/8120/9120; 7230/8230/9230) for best performance from the auto header height control (ahhc), perform these procedures with center-link set to d. When setup and calibration are complete, adjust center...

Page 136

214323 118 revision a 1003939 figure 3.159: case ih combine display 7. Install reel fore-back (if applicable). 8. Set height sensitivity to desired value. The recommended starting point is 180. 1003940 figure 3.160: case ih combine display 9. Install fore-aft control and hdr fore-aft tilt (if applic...

Page 137

214323 119 revision a calibrating auto header height control (case combines with version 28.00 or higher software) for best performance of the auto header height control (ahhc), perform these procedures with center-link set to d. When setup and calibration are complete, adjust center-link back to de...

Page 138

214323 120 revision a 1009755 a b figure 3.164: case ih combine display 8. Ensure auto height icon (a) appears on monitor and is displayed as shown at (b). When header is set for cutting on ground, this verifies that combine is correctly using potentiometer on header to sense ground pressure. Note: ...

Page 139

214323 121 revision a note: if float was set heavier to complete ground calibration procedure, adjust to recommended operating float after calibration is complete. 13. If unit does not function properly, conduct maximum stubble height calibration. Setting preset cutting height (case 7010/8010, 7120/...

Page 140

214323 122 revision a 1014883 a figure 3.169: float indicator box note: the ideal ground pressure —in most cases—is one number (on float indicator box) above header suspended off ground. For example, if float indicator needle (a) is positioned at 0 with header suspended off ground, then ideal ground...

Page 141

214323 123 revision a 1003464 a b figure 3.171: float indicator box 3. Adjust cable take-up bracket (b) (if necessary) until pointer (a) on float indicator is on 0. 1003681 a figure 3.172: challenger combine display 4. Go to field page on combine monitor, and then press diagnostics icon. The miscell...

Page 142

214323 124 revision a 1003683 figure 3.174: challenger combine display 7. Fully lower combine feeder house (adapter should be fully separated from header). Note: you may need to hold header down switch for a few seconds to ensure feeder house is fully lowered. 8. Read voltage. 9. Raise header so cut...

Page 143

214323 125 revision a calibrating auto header height control (challenger 6 series) note: for best performance of auto header height control (ahhc) system, perform these procedures with center-link set to d. When setup and calibration are complete, adjust center-link back to desired header angle. Ref...

Page 144

214323 126 revision a 1003668 figure 3.178: challenger combine display 4. Press header button. The header calibration page displays a warning. 1003669 figure 3.179: challenger combine display 5. Read warning message, and then press green check mark button. 1003670 figure 3.180: challenger combine di...

Page 145

214323 127 revision a adjusting header height (challenger 6 series) once auto header height control (ahhc) is activated, press and release header lower button on control handle. The ahhc will automatically lower header to selected height setting. Note: changes may have been made to combine controls ...

Page 146

214323 128 revision a 1003730 a figure 3.183: challenger combine display 2. Press header control (a). The header control page displays. 1003731 figure 3.184: challenger combine display 3. Go to table settings tab. 4. Press up arrow on max up pwm to increase percentage number and increase raise speed...

Page 147

214323 129 revision a 1003730 a figure 3.185: challenger combine display 2. Press header control button (a). The header control page appears. You can adjust sensitivity on this page using up and down arrows. 1003732 figure 3.186: challenger combine display 3. Adjust sensitivity to maximum setting. 4...

Page 148

214323 130 revision a calibrating auto header height control (gleaner r62/r72) for best performance of the auto header height control (ahhc), perform these procedures with center-link set to d. When setup and calibration are complete, adjust center-link back to desired header angle. Refer to 3.7.4 h...

Page 149

214323 131 revision a 1003611 b a figure 3.188: combine control console 1. Engage main threshing clutch (a) and header clutch (b). 1003612 a figure 3.189: throttle 2. Speed throttle (a) to over 2000 rpm. Operation.

Page 150

214323 132 revision a 1003615 a b figure 3.190: combine header control system 3. Push auto header height button (a). The led light (b) should flash continuously indicating that it is in standby mode and waiting for a response from operator. 1003616 a figure 3.191: header down button 4. Briefly press...

Page 151

214323 133 revision a 3.8.6 gleaner r65/r66/r75/r76 and s series combines (except s9 series) checking voltage range from combine cab (gleaner r65/r66/r75/r76 and s series) note: changes may have been made to combine controls or display since this document was published. Refer to combine operator ’s ...

Page 152

214323 134 revision a figure 3.195: combine heads-up display 1003563 a b c 4. Ensure header float is unlocked. 5. Press and hold button (a) on heads-up display for three seconds to enter diagnostic mode. 6. Scroll down using button (b) until left is displayed on lcd screen. 7. Press ok button (c). T...

Page 153

214323 135 revision a figure 3.196: combine auto header height controls 1003579 a b 1. Press auto mode (a) button until ahhc led light (b) begins flashing. If rtc light is flashing, press auto mode (a) button again until it switches to ahhc. 1003580 a figure 3.197: control handle 2. Briefly press bu...

Page 154

214323 136 revision a note: changes may have been made to combine controls or display since this document was published. Refer to combine operator ’s manual for updates. Figure 3.198: combine auto header height controls 1003586 a b c d e f g a - auto mode button b - ahhc light c - cal1 button d - ra...

Page 155

214323 137 revision a 8. Wait for header tilt left light (not shown) to start flashing, and then tilt header to maximum left position. 9. Press cal2 button (g) until header tilt left light (not shown) stops flashing, and release button when header tilt right light (not shown) begins flashing. 10. Ti...

Page 156

214323 138 revision a 1003733 a b figure 3.200: header raise and lower adjustable restrictors the auto header height control (ahhc) system ’s stability is affected by hydraulic flow rates. Ensure that header raise (a) and header lower (b) adjustable restrictors in hydraulic valve block are adjusted ...

Page 157

214323 139 revision a 1002565 a b figure 3.202: float indicator box note: the ideal ground pressure, in most cases, is one number of separation on ahhc from having header fully suspended off ground (b) to just resting on ground (a). Adjusting sensitivity of auto header height control (gleaner r65/r6...

Page 158

214323 140 revision a when sensitivity adjustment dial (a) is set to maximum (turned completely clockwise), only small changes in ground height are needed to cause feeder house to raise or lower. In this position, cutterbar moves up and down approximately 19 mm (3/4 in.) before control module signal...

Page 159

214323 141 revision a displayed on lcd (a) as xxx cm or xx in. Figure 3.205: combine heads-up display 1003626 a b c d e f operation.

Page 160

214323 142 revision a alarm conditions: if an error message is received from fuse panel, an audible alarm sounds. The lcd on electronic instrument panel (eip) indicates header system in error as hdr ctrl followed by hgt err for height, and hdr ctrl followed by tilt err for tilt. The header height le...

Page 161

214323 143 revision a 1018443 a b c d figure 3.206: gleaner s9 a - tyton terminal b - hydro handle/ground speed lever c - throttle lever d - header control cluster the agco tyton terminal is used to set up and manage a macdon draper header on an gleaner s9 combine. The terminal has a touch screen so...

Page 162

214323 144 revision a 1018403 a b e c d e figure 3.209: header configuration menu on header settings page 3. Touch header configuration field (a). A page showing predefined headers opens. • if your macdon header is already set up, it appears on header list. Touch macdon header title (b) to highlight...

Page 163

214323 145 revision a 1018413 10184131018413 a figure 3.210: header settings 4. To specify type of header installed on machine, touch header type field (a). 1018404 a b figure 3.211: header type 5. A list of predefined header types appears. • for macdon draper and flexdraper headers, touch power flo...

Page 164

214323 146 revision a 1018411 a b figure 3.213: header settings 7. Touch reel diameter field (a) and a numeric keypad displays. Enter 40 as macdon reel diameter. 8. Touch reel ppr (speed pulses per revolution) field (b) and enter 30 as ppr value for your macdon header. (ppr is number of teeth on ree...

Page 165

214323 147 revision a note: changes may have been made to combine controls or display since this document was published. Refer to combine operator ’s manual for updates. 1018428 a figure 3.216: reel settings on combine main menu 1. From combine main menu, touch reel settings (a) to open reel setting...

Page 166

214323 148 revision a 1018475 figure 3.219: calibration progress 6. A message appears in calibration wizard when reel calibration has started. The reel will begin turning slowly and increase to high speed. A progress bar is provided. If necessary, touch red x to cancel. Otherwise, wait for message t...

Page 167

214323 149 revision a 1018432 a figure 3.221: header speed control settings 3. Header speed: header tilt and raise/lower speed is adjusted in header control speed area (a) of header settings page. • tilt left and right is lateral tilt of combine faceplate. • header up and down (slow and fast speeds)...

Page 168

214323 150 revision a figure 3.223: header settings inputs for macdon headers calibrating header (gleaner s9 series) the auto header control functions are configured on header settings page. Caution clear the area of other persons, pets, etc. Keep children away from machinery. Walk around the machin...

Page 169

214323 151 revision a 1018420 1018420 a figure 3.225: calibration 2. Touch calibrate (a) at bottom right of page. The header calibration page displays. 1018426 a b c figure 3.226: header calibration page the right of page shows calibration information (a). Results are shown for a variety of sensors ...

Page 170

214323 152 revision a 1018422 a figure 3.228: header calibration 4. When sensor values are stable, touch calibrate icon (a). 1018438 figure 3.229: header calibration warning 5. The hazard message warning page for header calibration appears. Before proceeding with calibration by touching green check ...

Page 171

214323 153 revision a 1018436 a b c figure 3.231: completed calibration page 7. When calibration is complete, a message displays, and summary information (a) is shown. Green check marks confirm functions have been calibrated (b). Touch bottom green check mark (c) to save. 1018440 a figure 3.232: dir...

Page 172

214323 154 revision a 1018443 a b c d figure 3.233: gleaner s9 a - tyton terminal b - hydro handle/ground speed lever c - throttle lever d - header control cluster these are primary controls to be used to engage and use auto header height control (ahhc) function. 1018468 a b figure 3.234: header con...

Page 173

214323 155 revision a 1018469 a figure 3.236: header control cluster 4. Use header height setpoint control dial (a) as necessary to fine-tune setpoint position. Header in-field settings note: changes may have been made to combine controls or display since this document was published. Refer to combin...

Page 174

214323 156 revision a 1018476 a figure 3.238: scroll wheel for adjustments the scroll wheel (a) is on right of tyton terminal. 1018469 a figure 3.239: header control cluster header height setpoint control dial (a) is on header control cluster. 3.8.8 john deere 50 series combines output voltage range...

Page 175

214323 157 revision a 1003464 a b figure 3.240: float indicator box with auto header height sensor 1. Position header 150 mm (6 in.) above ground, and rest it on safety props. Unlock adapter float. Note: if header is not on down stops during next two steps, voltage may go out of range during operati...

Page 176

214323 158 revision a checking voltage range from combine cab before checking voltage range, follow these steps: 1. Position header 150 mm (6 in.) above ground, and unlock adapter float. 1001416 a b figure 3.243: float lock 2. Check that float lock linkage is on down stops (washer [a] and nut [b] ca...

Page 177

214323 159 revision a figure 3.245: john deere combine display 1003559 a b c d 4. Press diagnostic button (d) on monitor —dla appears on monitor. 5. Press up button (a) until eo1 appears on monitor —this is header adjustment. 6. Press enter button (c). 7. Press up (a) or down button (b) until 24 is ...

Page 178

214323 160 revision a adjusting voltage limits 1002553 a b c d figure 3.246: ahhc sensor assembly a - sensor support mounting bolts b - sensor support c - sensor mounting bolts d - potentiometer 1. To adjust high voltage limit: a. Extend guard angle fully. Header angle indicator should be at d. B. P...

Page 179

214323 161 revision a a 1018828 1018828 figure 3.247: combine display 4. Press diagnostic button (a) on monitor —dla appears on monitor. 1018829 a figure 3.248: combine display 5. Press cal button (a) —dia-cal appears on the monitor. Operation.

Page 180

214323 162 revision a 1003592 figure 3.249: combine display 6. Press up or down buttons until hdr appears on the monitor. 7. Press enter button —hdr h-dn appears on the monitor. 8. Fully lower feeder house to ground. Note: hold header down switch for 5 –8 seconds to ensure feeder house is fully lowe...

Page 181

214323 163 revision a 1003642 a b c d e figure 3.251: john deere combine display 1. Press diagnostic button (a) on monitor. Dia appears on the monitor. 2. Press up button (b) until eo1 appears on monitor, and press enter (d). This is header adjustment. 3. Press up (b) or down (c) button until 112 is...

Page 182

214323 164 revision a note: the numbers depicted on displays in these illustrations are for reference purposes only; they are not intended to represent specific settings for your equipment. Operating auto header height to operate your auto header height, follow these steps: 1015233 a figure 3.253: a...

Page 183

214323 165 revision a 1015143 a b c figure 3.255: hydrostatic lever 2. Once header height resume and auto header control are turned on, use buttons 2 (b) and 3 (c) on your hydrostatic lever for active header control. Note: button 1 (a) is reserved for auto height resume which will return header to a...

Page 184

214323 166 revision a combine low voltage limit high voltage limit minimum range john deere 60 series 0.7 v 4.3 v 3.0 v check sensor ’s output voltage range from combine cab according to instructions that follow. Note: changes may have been made to combine controls or display since this document was...

Page 185

214323 167 revision a figure 3.260: john deere combine display 1003559 a b c d 4. Press diagnostic button (d) on monitor —dia appears on monitor. 5. Press up button (a) until eo1 appears on monitor —this is header adjustment. 6. Press enter button (c). 7. Press up (a) or down button (b) until 24 is ...

Page 186

214323 168 revision a caution check to be sure all bystanders have cleared the area. 1. Ensure center-link is set to d. 2. Rest header on down stops, and unlock adapter float. 3. Put wings in locked position. 4. Start combine. 1003591 a b figure 3.261: john deere combine display 5. Press diagnostic ...

Page 187

214323 169 revision a 1003593 a b figure 3.263: john deere combine display 10. Press cal button (a) to save calibration of header. Hdr h-up appears on monitor. 11. Raise header three feet off ground and press cal (a) button. Eoc appears on monitor. 12. Press enter button (b) to save calibration of h...

Page 188

214323 170 revision a 1003642 a b c d e figure 3.265: john deere combine display 1. Press diagnostic button (a) on monitor. Dia appears on the monitor. 2. Press up button (b) until eo1 appears on monitor, and press enter (d). This is header adjustment. 3. Press up (b) or down (c) button until 128 is...

Page 189

214323 171 revision a 1003642 a b c d e figure 3.267: john deere combine display 1. Press diagnostic button (a) on monitor. Dia appears on the monitor. 2. Press up button (b) until eo1 appears on monitor, and press enter (d). This is header adjustment. 3. Press up (b) or down (c) button until 112 is...

Page 190

214323 172 revision a note: the numbers depicted on displays in these illustrations are for reference purposes only; they are not intended to represent specific settings for your equipment. 3.8.10 john deere 70 series combines checking voltage range from combine cab (john deere 70 series) the auto h...

Page 191

214323 173 revision a 1003464 a b figure 3.270: float indicator box 3. Adjust cable take-up bracket (b) (if necessary) until pointer (a) on float indicator is on 0. 1003568 a figure 3.271: john deere combine display 4. Press home page button (a) on main page of combine display. 1003569 a figure 3.27...

Page 192

214323 174 revision a 1003570 a b figure 3.273: john deere combine control console 6. Use scroll knob (a) to highlight middle icon (the green i) and press check mark button (b) to select it. This will display message center. 1003571 a b figure 3.274: john deere combine display 7. Use scroll knob to ...

Page 193

214323 175 revision a 1003573 b a c figure 3.276: john deere combine display 10. Use scroll knob to highlight down arrow (a) and press check mark button to scroll through list until 029 data (b) is displayed and voltage reading (c) appears on combine display. 11. Ensure header float is unlocked. 12....

Page 194

214323 176 revision a 1003597 a b figure 3.277: john deere combine display 5. Press button located fourth from left along top of monitor (a) to select icon that resembles an open book with a wrench on it (b). 6. Press top button (a) a second time to enter diagnostics and calibration mode. 1015017 a ...

Page 195

214323 177 revision a note: if an error code appears on page, sensor is not in correct working range. Refer to checking voltage range from combine cab (john deere 70 series), page 172 to check and adjust range. Setting sensitivity of auto header height control (john deere 70 series) note: changes ma...

Page 196

214323 178 revision a 1003636 a b c figure 3.282: john deere combine control console 1. Press button (a) and current raise/lower rate setting will appear on monitor (the lower reading, slower rate). 2. Use scroll knob (b) to adjust rate. The adjustment will be saved automatically. Note: if page rema...

Page 197

214323 179 revision a 1001416 a b figure 3.284: float lock 2. Check that float lock linkage is on down stops (washer [a] and nut [b] cannot be moved) at both locations. Note: if header is not on down stops during next two steps, voltage may go out of range during operation causing a malfunction of a...

Page 198

214323 180 revision a 1003767 a figure 3.287: john deere combine display 5. Press diagnostic readings icon (a) on calibration page. The diagnostic readings page appears. This page provides access to calibrations, header options, and diagnostic information. 1003768 a figure 3.288: john deere combine ...

Page 199

214323 181 revision a 1003770 a figure 3.290: john deere combine display 9. Press icon (a) until it reads page 5 near top of the page and following sensor readings appear: • left header height • center header height • right header height a reading is displayed for only center header height sensor. O...

Page 200

214323 182 revision a 1016113 a b figure 3.292: john deere combine display note: the feeder house fore/aft tilt controls can be changed to work with buttons e and f by pressing hydro handle icon (a) and then selecting feeder house fore/aft tilt from drop-down menu (b) on combine display. To calibrat...

Page 201

214323 183 revision a 1016119 a figure 3.294: john deere combine display 5. Select calibrations drop-down menu (a) to view list of calibration options. 1016123 a figure 3.295: john deere combine display 6. Press arrow (a) to cycle up though calibration options and select feeder house fore/aft tilt r...

Page 202

214323 184 revision a 1016137 figure 3.297: john deere combine display 8. Follow instructions that appear on combine display. As you proceed through calibration process, display will automatically update to show next step. Note: if an error code appears during calibration, sensor is out of voltage r...

Page 203

214323 185 revision a 1003776 a figure 3.299: john deere combine display 5. Select threshing clearance (a) and a list of calibration options appears. 1003777 a b figure 3.300: john deere combine display 6. Select feeder house speed (a) and calibrate. 7. Select header (b) and calibrate. 1003778 a fig...

Page 204

214323 186 revision a 1 003779 a figure 3.302: john deere combine display 9. Click button (a) and instructions will appear on screen to guide you through remaining calibration steps. Note: if an error code appears during calibration, sensor is out of voltage range and will require adjustment. Refer ...

Page 205

214323 187 revision a 1003758 a figure 3.304: john deere combine display 2. Press – or + icon (a) to adjust rates. Note: the numbers depicted on displays in these illustrations are for reference purposes only; they are not intended to represent specific settings for your equipment. Adjusting manual ...

Page 206

214323 188 revision a 1003759 a figure 3.306: john deere combine display 2. Press – or + icon (a) to adjust rates. Note: the numbers depicted on displays in these illustrations are for reference purposes only; they are not intended to represent specific settings for your equipment. 1014883 a figure ...

Page 207

214323 189 revision a 1003955 a figure 3.309: combine display 2. Select combine – header setup ahc icon (a). The combine – header setup ahc screen appears. 1018640 a b figure 3.310: combine display 3. Select top-left (a) and top-center (b) icons for auto height sensing and return to cut. 10039571003...

Page 208

214323 190 revision a 1014883 a figure 3.312: float indicator box note: the ideal ground pressure —in most cases—is one number (on float indicator box) above header suspended off ground. For example, if float indicator needle (a) is positioned at 0 with header suspended off ground, then ideal ground...

Page 209

214323 191 revision a 3.8.12 john deere s7 series combines this section applies to john deere s7 series combines only. Setting up header (john deere s7 series) note: changes may have been made to combine controls or display since this document was published. Refer to combine operator ’s manual for u...

Page 210

214323 192 revision a 1022768 a figure 3.317: john deere s7 display – header details window 3. Verify correct header width is displayed under width. 4. To change header width, select field (a). The width window opens. 1022769 figure 3.318: john deere s7 display – setting header width 5. Use the on-s...

Page 211

214323 193 revision a 1022770 a figure 3.320: john deere s7 display – header page 7. The raise/lower speed, tilt speed, height sensitivity, and tilt sensitivity can all be adjusted from this page. Select the option (a) you would like to adjust. This example shows the raise/lower speed adjustment. 10...

Page 212

214323 194 revision a 1022773 a figure 3.323: john deere s7 display – auto header controls 11. If the header has not been calibrated yet, an error icon will appear on the height sensing button (a). Select button (a) to view error message. 1022775 1022775 figure 3.324: john deere s7 display – height ...

Page 213

214323 195 revision a 1001416 a b figure 3.325: float lock 2. Check that float lock linkage is on down stops (washer [a] and nut [b] cannot be moved) at both locations. Note: if header is not on down stops during next two steps, voltage may go out of range during operation causing a malfunction of a...

Page 214

214323 196 revision a 1022779 a b figure 3.328: john deere s7 display – menu 5. On the menu page, select the system tab (a). The menu opens. 6. Select diagnostics center icon (b). The diagnostics center opens. 1022780 a figure 3.329: john deere s7 display – diagnostics center 7. Select ahc - sensing...

Page 215

214323 197 revision a calibrating feeder house (john deere s7 series) feeder house calibration must be done before header calibration. For best performance of auto header height control (ahhc), perform these procedures with center-link set to d. When setup and calibration are complete, adjust center...

Page 216

214323 198 revision a 1022789 a b figure 3.333: john deere s7 display – calibrations and procedures 7. Select header tab (a). 8. Select feeder house raise speed calibration (b). The fh raise speed calibration page displays. 1022793 a figure 3.334: john deere s7 display – feeder house calibration 9. ...

Page 217

214323 199 revision a 1022813 figure 3.336: john deere s7 display – feeder house calibration 11. Follow the instructions on the screen. As you proceed through the calibration process, the display will automatically update to show next step. Note: if an error code appears during calibration, the sens...

Page 218

214323 200 revision a 1022778 a figure 3.338: john deere s7 display – harvesting page 4. On the harvesting page, select the menu icon (a) in the bottom right corner of screen. The menu opens. 1022786 a b figure 3.339: john deere s7 display – machine settings 5. Select the machine settings tab (a), 6...

Page 219

214323 201 revision a 1022799 a figure 3.341: john deere s7 display – header calibration 9. Select calibrate (a) at bottom of page. The calibration overview window opens. 1022802 a figure 3.342: john deere s7 console 10. Press button (a) on console to set engine to high idle. 1022810 figure 3.343: j...

Page 220

214323 202 revision a 1022828 13. When calibration is complete, select save to confirm calibration. 3.8.13 claas 500 series combines auto header height sensor voltage requirements the auto header height sensor output must be within a specific voltage range for the feature to work properly. Combine l...

Page 221

214323 203 revision a 1003462 a figure 3.345: float indicator reading 1 v 3. Measure voltage between ground and signal wires at ahhc sensor in float indicator with a voltmeter (a). Note: the voltage reading should be below 4.3 v. 1003465 a figure 3.346: float indicator reading 4.3 v 4. Fully lower c...

Page 222

214323 204 revision a c. Loosen potentiometer mounting bolts (c). D. Rotate potentiometer (d) clockwise to increase low voltage limit, or counterclockwise to decrease it. E. Tighten potentiometer mounting bolts (c). 3. When readings are in proper range, auto header height control can be calibrated. ...

Page 223

214323 205 revision a 1003749 a b c figure 3.349: claas combine controls 3. Use – key (a) or + key (b) to turn on ahhc, and press ok (c). 4. Engage threshing mechanism and header. 1003782 figure 3.350: claas combine display 5. Use key to select cutt.Height limits, and press ok. 6. Follow procedure d...

Page 224

214323 206 revision a 1003784 a b figure 3.352: claas combine display 9. Use line (a) or value (b) to determine sensitivity setting. Note: the setting can be adjusted from 0 –100%. When sensitivity is adjusted to 0%, signals from sensing bands have no effect on automatic cutting height adjustment. W...

Page 225

214323 207 revision a 1010068 c d a b e figure 3.354: claas combine controls 6. Use key (d) to select cutting height page, and press ok key (e). 7. Use – key (a) or + key (b) to set desired cutting height. An arrow indicates selected cutting height on scale. 1003744 a b figure 3.355: joystick button...

Page 226

214323 208 revision a 1003746 a b c d figure 3.356: joystick buttons 1. Use button (a) to raise header, or button (b) to lower header to desired cutting height. 2. Press and hold button (c) for three seconds to store cutting height into claas electronic on-board information system (cebis). An alarm ...

Page 227

214323 209 revision a 1003784 a b figure 3.358: claas combine display 3. Use line (a) or value (b) to determine sensitivity setting. Operation.

Page 228

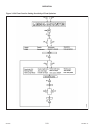

214323 210 revision a figure 3.359: flow chart for setting sensitivity of float optimizer 1018094 operation.

Page 229

214323 211 revision a adjusting auto reel speed (claas 500 series) the reel speed can be preset when automatic header functions are activated. Follow these steps to preset reel speed. Note: changes may have been made to the combine controls or display since this document was published. Refer to the ...

Page 230

214323 212 revision a 1003753 a figure 3.362: combine rotary switch 4. If desired, manually adjust reel speed by rotating rotary switch to reel position (a), and then use – or + key to set reel speed. Window e15 will display selected reel speed. 1003744 a b figure 3.363: joystick buttons 5. Press an...

Page 231

214323 213 revision a 1003750 figure 3.364: combine display 1003754 figure 3.365: combine display 6. Use key to select reel window. When reel window is selected, window e15 will display current advance or retard speed of reel in relation to ground speed. 1010068 c d a b e figure 3.366: combine contr...

Page 232

214323 214 revision a 1003751 a b c d figure 3.367: joystick buttons note: reel fore-aft position can also be set using joystick. 9. Press and hold button (c) or button (d) for 3 seconds to store setting into cebis (claas electronic on-board information system). An alarm will sound when the new sett...

Page 233

214323 215 revision a 1022918 a b figure 3.368: float indicator with auto header height sensor 2. The pointer (a) on float indicator should point at 0. If it does not, adjust cable bracket (b) until pointer (a) on float indicator points to 0. 1003462 a figure 3.369: float indicator reading 1 v 3. Me...

Page 234

214323 216 revision a adjusting voltage limits 1002553 a b c d figure 3.371: ahhc sensor assembly 1. To adjust high voltage limit: a. Extend guard angle fully. Header angle indicator should be at d. B. Position header 150 –254 mm (6–10 in.) above ground. Float indicator should be at 0. C. Loosen sen...

Page 235

214323 217 revision a 1003686 a b figure 3.372: claas combine display, console, and joystick 3. To calibrate auto contour, use control knob (a) to scroll left and right in top row until auto contour icon (b) is highlighted. Press control knob (a) to select it. 1003688 a b figure 3.373: claas combine...

Page 236

214323 218 revision a 1003689 a b figure 3.375: claas combine display, console, and joystick 6. After pressing control knob, letter a and screwdriver icon (b) appear on screen (as shown). 7. Use control knob (a) to highlight the screwdriver icon (b). 8. Exit cab to engage combine separator and feede...

Page 237

214323 219 revision a setting cutting height (claas 700 series) to set cutting height, follow these steps. Caution check to be sure all bystanders have cleared the area. Note: changes may have been made to the combine controls or display since this document was published. Refer to the combine operat...

Page 238

214323 220 revision a 1003736 a b figure 3.380: claas combine display, console, and joystick lever 1. Use control knob (a) to highlight header/reel icon (b), and press control knob (a) to select it. The header/reel dialog box opens. 2. Select header icon. 1003737 a b figure 3.381: claas combine disp...

Page 239

214323 221 revision a adjusting auto reel speed (claas 700 series) adjust auto reel speed as follows: note: changes may have been made to the combine controls or display since this document was published. Refer to combine operator ’s manual for updates. 1003736 a b figure 3.383: claas combine displa...

Page 240

214323 222 revision a 1003740 a figure 3.385: claas combine display, console, and joystick 3. Select actual value (a) from auto reel speed dialog menu (if you are using auto reel speed). The actual value indicates auto reel speed. 1003741 a figure 3.386: claas combine display, console, and joystick ...

Page 241

214323 223 revision a 3.8.15 new holland combines cx/cr series (cr series – model year 2014 and earlier) note: for new holland cr models 6.80, 6.90, 7.90, 8.90, 9.90, and 10.90, refer to 3.8.16 new holland combines (cr series – model year 2015 and later), page 233 . Checking voltage range from combi...

Page 242

214323 224 revision a 1003672 a figure 3.390: new holland combine display 5. Select diagnostics (a) on main page. The diagnostics page displays. 6. Select settings. The settings page displays. 1003673 a figure 3.391: new holland combine display 7. Select group drop-down arrow (a). The group dialog b...

Page 243

214323 225 revision a 1003675 a b figure 3.393: new holland combine display 9. Select left header height sen (a), and then select graph button (b). The exact voltage is displayed at top of page. 10. Raise and lower header to see full range of voltage readings. 11. Adjust voltage limits (refer to adj...

Page 244

214323 226 revision a 1003582 figure 3.395: new holland combine display 3. Select header autofloat, and press enter. 4. Use up and down navigation keys to move between options, and select installed. Calibrating auto header height control (new holland cr/cx series) for best performance of auto header...

Page 245

214323 227 revision a 1003605 a figure 3.396: new holland combine display 2. Select header (a), and press enter. The calibration dialog box opens. Note: you can use up and down navigation keys to move between options. 1003606 1003606 figure 3.397: new holland combine display 3. Follow calibration st...

Page 246

214323 228 revision a caution check to be sure all bystanders have cleared the area. 1003774 figure 3.398: new holland calibration dialog box 1. Select maximum stubble height calibration dialog box. As you proceed through calibration process, display will automatically update to show next step. 1003...

Page 247

214323 229 revision a 1003628 figure 3.400: new holland combine display 1. Select header raise rate on combine display. 2. Use + or – buttons to change setting. 3. Press enter to save new setting. Note: the raise rate can be changed from 32 to 236 in steps of 34. The factory setting is 100. Setting ...

Page 248

214323 230 revision a 1003627 figure 3.402: new holland combine display 1. Engage threshing and feeder house. 2. Select height sensitivity on combine display screen. 3. Use + or – buttons to change setting to 200. 4. Press enter to save new setting. Note: the sensitivity can be changed from 10 to 25...

Page 249

214323 231 revision a note: it is not necessary to press rocker switch (d) again after adjusting. 1014883 a figure 3.404: float indicator box note: the ideal ground pressure —in most cases—is one number (on float indicator box) above header suspended off ground. For example, if float indicator needl...

Page 250

214323 232 revision a 1015006 a figure 3.406: new holland combine display 2. On head 1 page, change cutting type from flex to platform as shown at (a). 1015007 a figure 3.407: new holland combine display 3. On head 2 page, change header sub type from default to 80/90 as shown at (a). 1015008 a b c f...

Page 251

214323 233 revision a 3.8.16 new holland combines (cr series – model year 2015 and later) this section applies only to 2015 and later cr models (6.80, 6.90, 7.90, 8.90, 9.90, and 10.90). For other new holland combine models, refer to 3.8.15 new holland combines cx/cr series (cr series – model year 2...

Page 252

214323 234 revision a 1016105 a b c figure 3.411: new holland combine display 4. Select head 1 (a). The header setup 1 page displays. 5. Select cutting type drop-down arrow (b) and change cutting type to platform (c). 1016059 a figure 3.412: new holland combine display 6. Select header sub type drop...

Page 253

214323 235 revision a 1016057 a figure 3.414: new holland combine display 8. Select head 2 (a). The header setup 2 page displays. 1016062 a b c d figure 3.415: new holland combine display 9. Select autofloat drop-down arrow and set autofloat to installed (a). 10. Select auto header lift drop-down ar...

Page 254

214323 236 revision a caution check to be sure all bystanders have cleared the area. 1. Position header 150 mm (6 in.) above ground, and unlock adapter float. 1001416 a b figure 3.417: float lock 2. Check that float lock linkage is on down stops (washer [a] and nut [b] cannot be moved) at both locat...