- DL manuals

- MacDon

- Tractor

- M105

- Operator's Manual

MacDon M105 Operator's Manual

Summary of M105

Page 1

M105 self-propelled windrower operator’s manual md #169552 rev. C $25.

Page 2

This manual contains instructions for “safety”, “operation”, and “maintenance/service” for your new macdon model m105 self-propelled windrower. California proposition 65 warning diesel engine exhaust and some of its constituents are known to the state of california to cause cancer, birth defects, an...

Page 3: 1 Introduction

169552 / 169554 / 169555 1 revision c 1 introduction this manual contains information on the model m105 self-propelled windrower that is designed to cut and lay in windrows, a wide variety of grain, hay, and specialty crops. Windrowing allows starting the harvest earlier, protects the crop from wind...

Page 4

169552 / 169554 / 169555 2 revision c 2 model and serial number record the model number, serial number, and model year of the windrower and engine on the lines below: windrower serial no._________________year______ serial number plate is located on the left side of the main frame near the walking be...

Page 5

Table of contents section/title page 169552 / 169554 / 169555 3 revision c 1 introduction .................................................................................................................................... 1 2 model and serial number ....................................................

Page 6

Table of contents section/title page 169552 / 169554 / 169555 4 revision c 5.18 cab display module (cdm) ................................................................................................. 38 5.18.1 engine and windrower functions ...........................................................

Page 7

Table of contents section/title page 169552 / 169554 / 169555 5 revision c 7.3 maintenance specifications ......................................................................................... 110 7.3.1 recommended torques .............................................................................

Page 8

Table of contents section/title page 169552 / 169554 / 169555 6 revision c 7.11.5 traction drive hydraulics ..................................................................................................................... 176 7.11.6 hoses and lines ..................................................

Page 9: 3 Safety

Safety 169552 / 169554 / 169555 7 revision c 3 safety 3.1 safety alert symbol this safety alert symbol indicates important safety messages in this manual and on safety signs on the machine. This symbol means: attention! Become alert! Your safety is involved! Carefully read and follow the safety mess...

Page 10

Safety 169552 / 169554 / 169555 8 revision c safety sign locations (cont’d) a – lh fan shroud md# 166450 – top part of fan shroud md# 166451 – middle part of fan shroud md# 166452 – bottom part of fan shroud b – lh platform md# 166425 – lh of step md# 166440 – rh of step c – lh frame md# 166466 d – ...

Page 11

Safety 169552 / 169554 / 169555 9 revision c safety sign locations (cont’d).

Page 12

Safety 169552 / 169554 / 169555 10 revision c safety sign locations (cont’d) a – rh fan shroud md# 166451 – top md# 166452 – bottom b – hydraulic oil reservoir md# 174436 – center of tank c – traction pump mount md# 166425 d – left hand interior cab post md# 166457 – above vent md# 166234 – below ve...

Page 13

Safety 169552 / 169554 / 169555 11 revision c safety sign locations (cont’d).

Page 14

Safety 169552 / 169554 / 169555 12 revision c 3.3.3 safety sign interpretations in the safety sign explanations below, (a) refers to the top or left position panel, (b) refers to the bottom or right position of the safety decal depending on decal orientation. Note if there are more than two panels i...

Page 15

Safety 169552 / 169554 / 169555 13 revision c 4. Md# 166439 a. Crushing hazard. B. Danger rest header on ground or engage mechanical locks before going under unit. 5. Md# 166440 a. Loss of control hazard. B. Caution to prevent machine damage and/or loss of control, it is essential that the machi...

Page 16

Safety 169552 / 169554 / 169555 14 revision c 9. Md# 166454 a. General hazard pertaining to machine operation and servicing. B. Caution to avoid injury or death from improper or unsafe machine operation: i. Read the operator’s manual, and follow all safety instructions. If you do not have a manual, ...

Page 17

Safety 169552 / 169554 / 169555 15 revision c 12. Md# 166457 a. General hazard pertaining to machine operation and servicing. B. Caution to avoid injury or death from improper or unsafe machine operation: i. Read the operator’s manual, and follow all safety instructions. If you do not have a manual,...

Page 18

Safety 169552 / 169554 / 169555 16 revision c 14. Md# 166462 a. Collision hazard in transport. B. Warning collision between windrower and other vehicles may result in injury or death. When driving windrower on public roadways: i. Obey all highway traffic regulations in your area. Use pilot vehicle...

Page 19

Safety 169552 / 169554 / 169555 17 revision c 17. Md# 184372 a. General hazard pertaining to machine operation and servicing. B. Caution to avoid injury or death from improper or unsafe machine operation: i. Read the operator’s manual, and follow all safety instructions. If you do not have a manual,...

Page 20

Safety 169552 / 169554 / 169555 18 revision c 3.4 general safety caution the following are general farm safety precautions that should be part of your operating procedure for all types of machinery. Protect yourself. when assembling, operating, and servicing machinery, wear all the protective clot...

Page 21

Safety 169552 / 169554 / 169555 19 revision c do not modify the machine. Unauthorized modifications may impair the function and/or safety and affect machine life. stop engine, and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling...

Page 22: 4 Description

Description 169552 / 169554 / 169555 20 revision c 4 description 4.1 definitions the following terms/abbreviations may be used in this manual: term definition api american petroleum institute apt articulating power tongue astm american society of testing and materials cab-forward windrower operation...

Page 23

Safety 169552 / 169554 / 169555 21 revision c 4.2 specifications engine type cummins qsb - 4.5l 4 cylinder turbo diesel. Bio-diesel b20 approved. Displacement 275 cu. In. (4.5 l) power rated 110 hp (81 kw) @ 2,500 rpm peak 115 hp (86 kw) @ 2,300 rpm bore 4-21/100 in (107 mm) stroke 4-22/25 in. (124 ...

Page 24

Description 169552 / 169554 / 169555 22 revision c pump (c): header lift / tilt type hydraulic double acting cylinders. Tilt - optional hydraulic positioning, optional hydraulic center-link gear pump displacement 1.02 cu. In. (16.7 cc) flow 11.5 gpm (44 l/min) system pressure (relief/max) 2,500 psi ...

Page 25

Safety 169552 / 169554 / 169555 23 revision c 4.3 windrower dimensions see illustration on next page. Wheel position tread inch/mm hubs inch/mm casters inch/mm tires inch/mm shipping inch/mm wheel base inch/mm forward reverse drive tires 18.4 x 26 bar and turf rims inset * inner/outer 123.1/3,127 13...

Page 26

Description 169552 / 169554 / 169555 24 revision c windrower dimensions (cont’d) reverse tread casters wheel base forward 45.7 in. (1,160 mm) tread hubs tires wheel base 133 in. (3,378 mm).

Page 27

Safety 169552 / 169554 / 169555 25 revision c 4.4 component identification header lift leg field / road lights operator’s station header float springs door windshield wiper mirror maintenance platform center-link turn signal/ hazard lights hand rails flood lights - rear swath lights drive wheel turn...

Page 28: 5 Operator’S Station

Operator’s station 169552 / 169554 / 169555 26 revision c 5 operator’s station the operator’s station is designed for operating the windrower in a cab-forward mode. 5.1 operator console the console contains controls to operate the windrower as well as amenities for the operator. 5.2 seat adjustments...

Page 29

Operator’s station 169552 / 169554 / 169555 27 revision c 5.3 training seat (optional) a wall mounted fold-up training seat complete with seat belt is provided for use as described below. to lower seat, lift latch (a), and lower seat (b). for storage, lift seat (b), and secure with latch (a). Wa...

Page 30

Operator’s station 169552 / 169554 / 169555 28 revision c 5.6 operator presence the operator presence system is a safety feature that is designed to deactivate or alarm selected systems when the operator is not seated at the operator’s station. These systems include: header drive. transmission. ...

Page 31

Operator’s station 169552 / 169554 / 169555 29 revision c 5.7 lights the field and transport light switches are located on a panel in the cab headliner. For location of lights, refer to illustrations below: 5.7.1 field lighting high / low lights controls high / low beam for road lights on cab roof l...

Page 32

Operator’s station 169552 / 169554 / 169555 30 revision c 5.7.2 road lighting the following lights are on/functional when the switch is in the road position. The hazard lights must be activated with the switch on the cab display module (cdm) when driving on the road. 5.7.3 beacon lighting: export (n...

Page 33

Operator’s station 169552 / 169554 / 169555 31 revision c 5.8 windshield wiper the windshield wiper control is located in the cab headliner. 5.9 rear view mirrors two adjustable outside mounted mirrors provide rear view vision. The mirror/light assembly is designed to fold backwards if accidentally ...

Page 34

Operator’s station 169552 / 169554 / 169555 32 revision c 5.10 cab temperature the cab environment is controlled by a climate-control system that provides clean air-conditioned or heated air for the operator. The heater/evaporator/blower assembly is located under the cab floorboard, and is accessibl...

Page 35

Operator’s station 169552 / 169554 / 169555 33 revision c 5.10.4 a/c compressor protection the compressor is protected from excessively low and high pressures by two switches that shut down the compressor to prevent damage to the system. the low pressure switch opens when the pressure falls to 2–8...

Page 36

Operator’s station 169552 / 169554 / 169555 34 revision c 5.13 radios 5.13.1 am/fm radio a radio (a) is available as optional equipment from your dealer, and a space is provided in the cab headliner to accommodate the installation. Two pre-wired speakers (b) have been factory-installed in the headli...

Page 37

Operator’s station 169552 / 169554 / 169555 35 revision c 5.15 engine controls 5.16 windrower controls reverse hazard warning lights activates signals on windrower and header. Push-on / push-off fast slow ground speed lever (gsl) controls speed and direction of movement. F - forward n - neutral n-de...

Page 38

Operator’s station 169552 / 169554 / 169555 36 revision c 5.17 header controls all header controls are conveniently located on the operator’s console, and on the ground speed lever (gsl) handle. Note some controls are optional equipment, and may not be present in your unit. Some controls may be inst...

Page 39

Operator’s station 169552 / 169554 / 169555 37 revision c 5.17.3.1 display selector switch selects and displays the settings in the cab display module (cdm) display top line read-out for each of the header controls. press the switch to scroll through settings. 5.17.3.2 reel position switches note ...

Page 40

Operator’s station 169552 / 169554 / 169555 38 revision c 5.18 cab display module (cdm) 5.18.1 engine and windrower functions 5.18.2 header functions turn signal switches activates turn signals on windrower and header. Push-on / push-off ignition switch positions accessory / stop / run / start hazar...

Page 41

Operator’s station 169552 / 169554 / 169555 39 revision c 5.18.3 operating screens the m105 windrower cab display module (cdm) and the windrower control module (wcm) provide information on several functions for the engine, header, and windrower. The information displayed in various operating modes i...

Page 42

Operator’s station 169552 / 169554 / 169555 40 revision c engine running / header disengaged (scroll through display with cab display module [cdm] switch or ground speed lever [gsl] switch) display (lower or upper line) description #####.# engine hrs total engine operating time. #####.# unit hrs tot...

Page 43

Operator’s station 169552 / 169554 / 169555 41 revision c engine running / header engaged auger header (scroll through display with cab display module [cdm] switch or ground speed lever [gsl] switch) display (lower or upper line) description #####.# engine hrs total engine operating time. #####.# un...

Page 44

Operator’s station 169552 / 169554 / 169555 42 revision c engine running / header engaged draper header / index switch off (scroll through display with cab display module [cdm] switch or ground speed lever [gsl] switch) display (lower or upper line) description #####.# engine hrs total engine operat...

Page 45

Operator’s station 169552 / 169554 / 169555 43 revision c engine running / header engaged draper header / index switch on (scroll through display with cab display module [cdm] switch or ground speed lever [gsl] switch) display (lower or upper line) description #####.# engine hrs total engine operati...

Page 46

Operator’s station 169552 / 169554 / 169555 44 revision c cab display module (cdm) warnings/alarms the cdm displays warnings and sounds alarms to notify the operator of abnormal windrower status at startup when the ignition is turned on, and at engine operating speeds above 500 rpm. 5.18.3.1 engine ...

Page 47

Operator’s station 169552 / 169554 / 169555 45 revision c 5.18.3.2 display warnings display warnings and alarms - engine/transmission display flashing alarm tone description engine oil pressure continuous loud tone until oil pressure is regained. Low engine oil pressure. Accompanied by warning light...

Page 48

Operator’s station 169552 / 169554 / 169555 46 revision c display warnings and alarms - windrower display flashing alarm tone description center steering beeps at 2 per second interlock switch not closed with key on / engine off. Gsl not in n-detent or steering wheel not centered. Disengage header n...

Page 49

Operator’s station 169552 / 169554 / 169555 47 revision c 5.18.4 cab display module (cdm) programming the monitoring system requires programming for each header, and the header must be attached to the windrower. Programming the system may be accomplished with or without the engine running. If the en...

Page 50

w i n d...

Page 51

e n a b l ...

Page 52

d i ...

Page 53

v i e w w i n d r w r c ...

Page 54

a c t i v a t e f u n c t i o n ...

Page 55

Operator’s station 169552 / 169554 / 169555 53 revision c 5.18.5 engine error codes the cab display module (cdm) displays error codes when there is a fault with one of the several sensors that monitor and control engine operation, to assist the operator or technician in locating a specific problem w...

Page 56: 6 Operation

Windrower operation 169552 / 169554 / 169555 54 revision c 6 operation 6.1 owner/operator responsibilities caution it is your responsibility to read and understand this manual completely before operating the windrower. Contact your dealer if an instruction is not clear to you. follow all safety ...

Page 57

Windrower operation 169552 / 169554 / 169555 55 revision c 6.2.2 windrower operating symbols turn signals windshield wiper hazard warning lights seat height up forward seat height down neutral seat fore and aft reverse seat fore aft isolator headlights low beam/road lights seat back fore and aft hea...

Page 58

Windrower operation 169552 / 169554 / 169555 56 revision c 6.3 windrower operation 6.3.1 operational safety follow these safety precautions: caution wear close fitting clothing and protective shoes with slip resistant soles. remove foreign objects from the machine and surrounding area. as well...

Page 59

Windrower operation 169552 / 169554 / 169555 57 revision c 6.3.3 daily check a. Check the machine for leaks or any parts that are missing, broken, or not working correctly. Note: use proper procedure when searching for pressurized fluid leaks. See section 7.11.6 hoses and lines. B. Clean the windows...

Page 60

Windrower operation 169552 / 169554 / 169555 58 revision c 6.3.4 engine operation 6.3.4.1 starting danger avoid possible injury or death from a runaway machine. this machine has safety devices which allow the engine to start only when the ground speed lever (gsl) is in n-detent, the steering whe...

Page 61

Windrower operation 169552 / 169554 / 169555 59 revision c caution be sure the area is clear of other persons, pets etc. Before proceeding. Single loud tone sounds, engine warning lights illuminate, and cab display module (cdm) displays “header disengaged” and “in park”. Turn ignition key to start u...

Page 62

Windrower operation 169552 / 169554 / 169555 60 revision c 6.3.4.2 engine intermediate speed control (isc) this is useful when operating loads are reduced such as in light crop conditions that do not require the maximum engine rpm. Reduced engine speed lowers fuel consumption, noise levels, and exha...

Page 63

Windrower operation 169552 / 169554 / 169555 61 revision c 6.3.4.5 engine temperature the normal engine operating temperature range is 180°–225°f (82°–107°c). If the temperature exceeds 230°f (110°c), an ongoing intermittent tone will be heard, and the cab display module (cdm) will flash “engine tem...

Page 64

Windrower operation 169552 / 169554 / 169555 62 revision c 6.3.5 driving the windrower warning before starting engine, securely fasten your seat belt, and ensure trainer’s seat belt is fastened (if occupied). The seat belt can help ensure your safety if it is used and maintained. Warning avoid dri...

Page 65

Windrower operation 169552 / 169554 / 169555 63 revision c avoid inclines, ditches and fences. do not rapidly accelerate or decelerate when turning. reduce speed before turning, crossing slopes, or travelling over rough ground. do not allow anyone to stand behind the machine while operating....

Page 66

Windrower operation 169552 / 169554 / 169555 64 revision c 6.3.5.2 operation a. Place ground speed lever (gsl) (a) in n-detent. B. Fasten seat belt. Start engine. See section 6.3.4.1 starting. Set ground speed range switch (b) to either: 2 for road speed: 0–16 mph (25.7 km/h) or 1 for field spee...

Page 67

Windrower operation 169552 / 169554 / 169555 65 revision c 6.3.5.3 spin turn hydrostatic steering gives the operator significantly more manoeuvrability than mechanical steering. Caution be sure area is clear before making turns. Although windrower pivots on the spot, the ends of header travel faster...

Page 68

Windrower operation 169552 / 169554 / 169555 66 revision c 6.3.6 adjustable caster tread width the rear casters can be adjusted to a narrow tread width to allow loading and shipping without having to remove them. A narrow tread width also suits smaller headers by allowing more space to the uncut cro...

Page 69

Windrower operation 169552 / 169554 / 169555 67 revision c d. Position bracket (a), and install bolts (b). The two shorter bolts are installed at the back inboard locations. E. Install bottom bolts (c). F. Tighten bolts as follows: 1. Snug bottom bolts (c). 2. Tighten and torque back bolts (b) to 33...

Page 70

Windrower operation 169552 / 169554 / 169555 68 revision c 6.3.7 transporting 6.3.7.1 driving on road warning collision between windrower and other vehicles may result in injury or death. Warning when driving windrower on public roadways: obey all highway traffic regulations in your area. Use pilo...

Page 71

Windrower operation 169552 / 169554 / 169555 69 revision c f. Press switch (a) on cab display module (cdm) to activate hazard lights (export optional). G. Set ground speed range switch (b) for road speed. Cdm will display road gear at (c). Note windrower can be moving, but speed must be less than 5 ...

Page 72

Windrower operation 169552 / 169554 / 169555 70 revision c 6.3.7.2 towing header with windrower the windrower can be used to tow a macdon harvest header with the slow speed transport option installed, provided the weight box option is installed on the windrower or an approved header transporter with...

Page 73

Windrower operation 169552 / 169554 / 169555 71 revision c 6.3.7.2.1 from field to transport mode a. Set header on the ground. Danger stop engine, and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. B. Disconnect hydraulic...

Page 74

Windrower operation 169552 / 169554 / 169555 72 revision c 2. Release safety lock on the header lift cylinders. 3. Lower header down onto the transport wheels. 4. Disengage top link from the header. If necessary, use the header tilt switch to release load on the cylinder. Mechanical link 1. Loosen n...

Page 75

Windrower operation 169552 / 169554 / 169555 73 revision c m. Attach tow-bar to windrower. The m105 transport drawbar provides approximately 12 in. (300 mm) of fore-aft movement to ease the attachment of a towed implement. 1. Back the windrower up to the tow-bar (a) so that drawbar hole (b) is withi...

Page 76

Windrower operation 169552 / 169554 / 169555 74 revision c n. Connect safety chain (g) through the slot (h) in drawbar support, and securely attach the hook (j) to the chain. Leave enough slack to allow the hitch to pivot. O. At the drawbar, connect the tow-bar harness plug (k) to the receptacle on ...

Page 77

Windrower operation 169552 / 169554 / 169555 75 revision c 6.3.7.2.2 from transport mode to field operation danger stop engine, and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. A. Shut down windrower, and remove key. B....

Page 78

Windrower operation 169552 / 169554 / 169555 76 revision c important to prevent damage to the lift system when lowering header lift linkages without a header or weight box attached to windrower, ensure that float engagement pin is installed in storage location (k), and not installed at hole location...

Page 79

Windrower operation 169552 / 169554 / 169555 77 revision c 6.3.8 towing the windrower in emergency situations (for example, towing out of a field or into a shop), windrower may be towed without a trailer, providing the following precautions are followed: warning a proper towing apparatus is critical...

Page 80

Windrower operation 169552 / 169554 / 169555 78 revision c 6.3.9 storage at the end of each operating season: a. Clean the windrower thoroughly. Warning never use gasoline, naphtha or any volatile material for cleaning purposes. These materials are toxic and/can be flammable. B. Store windrower in a...

Page 81

Header operation - general 169552 / 169554 / 169555 79 revision c 6.4 header operation the m105 windrower is designed to use the macdon a-series auger header, and 65 series rigid draper headers (up to 35 ft) with or without a hay conditioner. This section describes the attachment and detachment proc...

Page 82

Header operation - general 169552 / 169554 / 169555 80 revision c 6.4.2 header flotation float is intended for cutting crops that require the cutterbar to be in contact with the ground. Optimum float is for the cutterbar to maintain contact with the ground with minimum bouncing and scooping or pushi...

Page 83

Header operation - general 169552 / 169554 / 169555 81 revision c header force to lift cutterbar at ends with lift cylinder fully retracted auger 75–85 lbf (335–380 n) draper 75–85 lbf (335–380 n) with stabilizer/transport wheels raised (if equipped). B. If necessary, adjust the float with the drawb...

Page 84

Header operation - general 169552 / 169554 / 169555 82 revision c 6.4.3 levelling the windrower linkages are factory-set to provide the proper level for the header, and should not normally require adjustment. If the header is not level, perform the following checks prior to adjusting the leveling li...

Page 85

Header operation - general 169552 / 169554 / 169555 83 revision c f. If additional levelling is required, install the removed shim on the opposite linkage. G. Once header is level, return float pins to their engaged location (f). Note if required, additional shims are available from your macdon deal...

Page 86

Header operation - general 169552 / 169554 / 169555 84 revision c change header angle as follows: hydraulic center-link (optional) a. To decrease (flatten) header angle, operate header tilt up switch on ground speed lever) gsl handle so that cylinder (a) retracts. The cab display module (cdm) displa...

Page 87

Header operation - general 169552 / 169554 / 169555 85 revision c 4. Push up on actuator rod (c), and pin should lift with the handle. 6.4.6 cutting height the header is raised or lowered with the header up or header down switches on the ground speed lever (gsl). See illustration. The cdm indicates ...

Page 88

Header operation - general 169552 / 169554 / 169555 86 revision c b. Use the return to cut feature as follows: important ensure the header is engaged, and the return to cut switch is illuminated. Note the header can be raised or lowered at any time by depressing and holding the header up or header d...

Page 89

Header operation - d series 169552 / 169554 / 169555 87 revision c 6.5 d series header operation 6.5.1 configure hydraulics the m105 windrower must be fitted with a draper drive basic kit to operate the d-series draper headers. Windrowers equipped with d-series hydraulics have four header drive hose...

Page 90

Header operation - d series 169552 / 169554 / 169555 88 revision c b. Locate boot (d) on lift linkage (e), and re-install pin (c). Pin may be installed from either side of boot. C. Secure pin (c) with hairpin. D. Repeat for opposite side. 6.5.3 header attachment a. Remove hairpin on pins (f), and re...

Page 91

Header operation - d series 169552 / 169554 / 169555 89 revision c f. Connect center-link: hydraulic link activate header tilt cylinder switches on ground speed lever (gsl) to extend or retract center-link cylinder (g) so that the hook lines-up with the header attachment pin. Warning stop windrower ...

Page 92

Header operation - d series 169552 / 169554 / 169555 90 revision c danger to avoid bodily injury from fall of raised header, always engage header lift cylinder stops when working on or around raised header, and before going under header for any reason. H. Engage lift cylinder stops on both lift cyli...

Page 93

Header operation - d series 169552 / 169554 / 169555 91 revision c 6.5.4 header position see section 6.4 header operation for procedures for controlling header height, header tilt, and float. 6.5.5 reel fore-aft position press and hold the switch for the desired fore or aft movement of the reel. 6...

Page 94

Header operation - d series 169552 / 169554 / 169555 92 revision c 6.5.7 reel speed the speed of the reel is controlled with switches on the ground speed lever (gsl) in the cab. On d series draper headers, it can be set relative to the ground speed of the windrower using the header index feature, or...

Page 95

Header operation - d series 169552 / 169554 / 169555 93 revision c example : windrower is operating at 8 mph with header index on, and set at -1.0. Display shows: 7.0 -1.0 reel ind where 7.0 (8.0 - 1.0) is the reel speed in mph, and -1.0 is the header index setting. windrower speed drops to 7.5 ...

Page 96

Header operation - d series 169552 / 169554 / 169555 94 revision c 6.5.8 draper speed draper speed affects the orientation of stalks in the windrow. Faster draper speeds tend to form herringbone or dovetail configurations. Refer to your header operator’s manual for guidelines on what speed to use. T...

Page 97

Header operation - d series 169552 / 169554 / 169555 95 revision c example: windrower is operating at 8 mph with header index on, and set at 1.5. Display shows: 9.5 1.5 drap indx where 9.5 (8 + 1.5) is the draper speed in mph, and 1.5 is the header index setting. windrower speed drops to 7.5 mph...

Page 98

Header operation - d series 169552 / 169554 / 169555 96 revision c 6.5.9 knife speed the ideal cutting speed of the knife should be such that a clean cut is achieved. Crop types and conditions usually influence the knife and forward speeds. Refer to the header operator’s manual for more information ...

Page 99

Header operation - d series 169552 / 169554 / 169555 97 revision c note one turn of the adjuster screw (b) will change the knife speed by approximately 116 strokes per minute, or the sickle drive box pulley speed by 58 revolutions per minute. 4. Once adjustment has been made, re-torque jam nut (a) a...

Page 100

Header operation - d series 169552 / 169554 / 169555 98 revision c 6.5.11 header detachment a. Raise header fully with the header up switch on the ground speed lever (gsl). Stop engine, and remove key. Danger to avoid bodily injury from fall of raised header, always engage header lift cylinder stops...

Page 101

Header operation - d series 169552 / 169554 / 169555 99 revision c j. Disconnect header drive hydraulics (f) and electrical harness (g) from header. Refer to the draper header operator’s manual. K. Disconnect reel hydraulics (h), and store on bracket at windrower lh side. L. Disconnect center-link a...

Page 102

Header operation - a series 169552 / 169554 / 169555 100 revision c 6.6 a series header operation 6.6.1 header attachment a. Remove hairpin from pin (a), and remove pin from left and right header boots (b) on header. Important to prevent damage to the lift system when lowering header lift linkages w...

Page 103

Header operation - a series 169552 / 169554 / 169555 101 revision c d. Slowly drive windrower forward so that feet (h) on windrower enter boots (b) on the header. Continue to drive slowly forward until feet engage the boots, and header nudges forward. E. Connect center-link as follows: hydraulic lin...

Page 104

Header operation - a series 169552 / 169554 / 169555 102 revision c danger to avoid bodily injury from fall of raised header, always engage header lift cylinder stops when working on or around raised header, and before going under the header for any reason. H. Engage lift cylinder stops on both lift...

Page 105

Header operation - a series 169552 / 169554 / 169555 103 revision c 6.6.2 auger speed caution check to be sure all bystanders have cleared the area. 6.6.2.1 a40-d headers on a40-d double knife headers, the auger speed is interdependent on reel speed, and is controlled by a switch on the ground speed...

Page 106

Header operation - a series 169552 / 169554 / 169555 104 revision c 6.6.3 reel speed 6.6.3.1 a30-s and a30-d headers the reel speed is fixed to the auger speed and to the knife speed. Both can be changed by installing alternate drive sprockets. Refer to your auger header operator’s manual. 6.6.3.2 a...

Page 107

Header operation - a series 169552 / 169554 / 169555 105 revision c 6.6.4 knife speed the ideal cutting speed of the knife should be such that a clean cut is achieved. Crop types and conditions usually influence the knife and forward speeds. The knife speed is manually set by making adjustments to t...

Page 108

Header operation - a series 169552 / 169554 / 169555 106 revision c note one turn of the adjuster screw (b) will change the knife speed by approximately 116 strokes per minute, or the sickle drive box pulley speed by 58 revolutions per minute. 4. Once adjustment has been made, re-torque jam nut (a) ...

Page 109

Header operation - a series 169552 / 169554 / 169555 107 revision c 6.6.5 header detachment a. Raise the header fully with the header up switch on the ground speed lever (gsl). Stop engine, and remove key. Danger to avoid bodily injury from fall of raised header, always engage header lift cylinder s...

Page 110

Header operation - a series 169552 / 169554 / 169555 108 revision c h. Disconnect center-link: hydraulic link (optional) 1. Activate header tilt cylinder switches on ground speed lever (gsl) to release load on center-link cylinder (k). Warning stop windrower engine, and remove key before making adju...

Page 111: 7 Maintenance

Maintenance and servicing 169552 / 169554 / 169555 109 revision c 7 maintenance and servicing the following instructions are provided to assist the operator in the use of the m105 windrower. Detailed maintenance, service, and parts information are contained in the technical manual and parts catalog ...

Page 112

Maintenance and servicing 169552 / 169554 / 169555 110 revision c 7.3 maintenance specifications 7.3.1 recommended torques the tables shown below give correct torque values for various bolts and cap screws. tighten all bolts to the torques specified in chart (unless otherwise noted throughout this...

Page 113

Maintenance and servicing 169552 / 169554 / 169555 111 revision c 7.3.1.3 flare type hydraulic fittings a. Check flare and flare seat for defects that might cause leakage. B. Align tube with fitting before tightening. C. Lubricate connection, and hand-tighten swivel nut until snug. D. To prevent twi...

Page 114

Maintenance and servicing 169552 / 169554 / 169555 112 revision c 7.3.1.5 o-ring face seal (orfs) hydraulic fittings * torque values and angles shown are based on lubricated connection, as in re-assembly. ** always default to the torque value for evaluation of adequate torque. *** o-ring face seal t...

Page 115

Maintenance and servicing 169552 / 169554 / 169555 113 revision c 7.3.2 recommended fuel, fluids and lubricants 7.3.2.1 fuel use good quality diesel fuel in your vehicle from a reputable supplier. For most year-round service, no. 2 diesel fuel meeting astm specification d-975 grade s15 will provide ...

Page 116

Maintenance and servicing 169552 / 169554 / 169555 114 revision c 7.3.3 conversion chart quantity inch-pound units factor si units (metric) unit name abbr. Unit name abbr. Area acres acres x 0.4047 = hectares ha flow gallons per minute (us) gallons per minute (imp) gpm (us) gpm x 3.7854 = x 4.5460 =...

Page 117

Maintenance and servicing 169552 / 169554 / 169555 115 revision c 7.4 maintenance requirements periodic maintenance requirements are organized by service intervals. Regular maintenance is the best insurance against early wear and untimely breakdowns. Following this schedule will increase machine lif...

Page 118

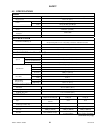

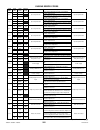

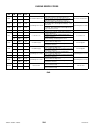

Maintenance and servicing 169552 / 169554 / 169555 116 revision c 7.4.1 maintenance schedule / record m105 windrower serial number: _______________________ combine this page with the record in the header operator’s manual. Copy this page to continue the record. Action: - check - lubricate - change...

Page 119

Maintenance and servicing 169552 / 169554 / 169555 117 revision c action: - check - lubricate - change - clean + - add ma in ten anc e reco r d hour meter reading date serviced by 250 hours or annually * engine air filter primary element ** 7.8.5 engine oil and filter 7.8.4 formed caster wheel hub...

Page 120

Maintenance and servicing 169552 / 169554 / 169555 118 revision c 7.4.2 break-in inspections item see section every 1/4 hour road or 1 hour field check drive wheel nut torque - 220 lb·ft (300 n·m). Repeat checks until torque stabilizes. 7.12.1.2 at 5 hours check a/c belt tension. 7.8.10.1 check cast...

Page 121

Maintenance and servicing 169552 / 169554 / 169555 119 revision c 7.4.3 pre-season/annual service a. Perform the following at the beginning of each operating season: caution review the operator’s manual to refresh your memory on safety and operating recommendations. review all safety signs and o...

Page 122

Maintenance and servicing 169552 / 169554 / 169555 120 revision c 7.4.4 end of season service perform the following at the end of each operating season: a. Clean the machine thoroughly. Caution never use gasoline, naphtha or any volatile material for cleaning purposes. These materials may be toxic a...

Page 123

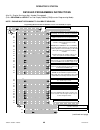

Maintenance and servicing 169552 / 169554 / 169555 121 revision c every 50 hours forked caster spindle bearings two places (both wheels) top link - two fittings (both sides) walking beam pivot caster pivot (both sides) high temperature extreme pressure (ep2) performance with 1% max molybdenum disulp...

Page 124

Maintenance and servicing 169552 / 169554 / 169555 122 revision c every 250 hours high temperature extreme pressure (ep2) performance with 1% max molybdenum disulphide (nlgi grade 2).Lithium base. Formed caster wheel bearing 1 place (both wheels).

Page 125

Maintenance and servicing 169552 / 169554 / 169555 123 revision c 7.5 engine compartment hood the engine hood has two open positions: the lowest is for general maintenance such as checking and adding fluid, servicing the cooling box, etc. the highest accommodates full access to the engine bay a....

Page 126

Maintenance and servicing 169552 / 169554 / 169555 124 revision c 7.6 maintenance platform a swing away platform/stair is provided for access to the operator’s station and engine bay maintenance. 7.6.1 opening/closing platform a. Push latch (a) inward, grasp handle (b), and pull platform (c) toward ...

Page 127

Maintenance and servicing 169552 / 169554 / 169555 125 revision c caution do not stand on the platform in the unlocked position. It is unstable and may result in a fall. E. Close platform as follows: 1. Swing link (d) all the way forward. 2. Move platform front end inboard while moving it away from ...

Page 128

Maintenance and servicing 169552 / 169554 / 169555 126 revision c 7.7 operator’s station 7.7.1 seat belts a. Keep sharp edges and items that can cause damage away from the belts. B. From time to time, check belts, buckles, retractors, tethers, slack take-up system, and mounting bolts for damage. C. ...

Page 129

Maintenance and servicing 169552 / 169554 / 169555 127 revision c 7.7.3 ground speed lever (gsl) adjustments 7.7.3.1 ground speed lever (gsl) lateral movement danger stop engine, and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling ...

Page 130

Maintenance and servicing 169552 / 169554 / 169555 128 revision c 7.7.3.3 ground speed lever (gsl) position the gsl should be centered fore-aft (a) in the n-detent slot when the steering wheel is centered and locked. If necessary, adjust as follows: important neutral interlock must be properly adjus...

Page 131

Maintenance and servicing 169552 / 169554 / 169555 129 revision c 7.7.4 steering adjustments 7.7.4.1 steering link pivots perform the following checks annually: danger stop engine, and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idlin...

Page 132

Maintenance and servicing 169552 / 169554 / 169555 130 revision c g. If steering link bolts (e) are loose: 1. Back off outer jam nut (g). 2. Tighten inside nut (h) to 5–10 lb-ft (7–13 n·m). 3. Hold inside nut (h), and tighten jam nut (g) to 60–70 lb-ft (81–95 n·m). H. If steering link ball joint (f)...

Page 133

Maintenance and servicing 169552 / 169554 / 169555 131 revision c 7.7.6 hvac system 7.7.6.1 fresh air intake filter the fresh air filter is located under the cab roof behind the rear window, and should be serviced daily. Service the filter as follows: danger stop engine, and remove key from ignition...

Page 134

Maintenance and servicing 169552 / 169554 / 169555 132 revision c 7.7.6.2 return air filter the return air filter is located behind the operator’s seat on the cab wall, and should be serviced every 100 hours as follows: danger stop engine, and remove key from ignition before leaving operator’s seat ...

Page 135

Maintenance and servicing 169552 / 169554 / 169555 133 revision c b. Remove the ten fasteners (h) that attach the cover (j), and remove the cover. Warning to avoid cuts from evaporator fins, do not use bare hands to brush away clogs. C. Use a vacuum or compressed air to remove dirt from inside the u...

Page 136

Maintenance and servicing 169552 / 169554 / 169555 134 revision c 7.8 engine caution never operate engine in a closed building. Proper ventilation is required to avoid exhaust gas hazards. keep the engine clean. Straw and chaff on a hot engine are a fire hazard. never use gasoline, naphtha, or...

Page 137

Maintenance and servicing 169552 / 169554 / 169555 135 revision c 7.8.3 oil level check engine oil level frequently, and watch for any signs of leakage. Note during the break-in period, a higher than usual oil consumption should be considered normal. Check the oil level as follows: a. Stop engine, a...

Page 138

Maintenance and servicing 169552 / 169554 / 169555 136 revision c 7.8.4 changing oil and oil filter note the engine should be warm prior to changing the oil. A. Stop engine, and remove key. B. Place a drain pan of about 6 u.S. Gallons (24 liters) under engine oil drain. C. Remove oil pan drain plug ...

Page 139

Maintenance and servicing 169552 / 169554 / 169555 137 revision c 7.8.5 air intake system important do not run engine with air cleaner disconnected or disassembled. Engine intake air (a) is drawn through a duct (b) from the cooling box that pre-cleans the air, and then through a dual element filter ...

Page 140

Maintenance and servicing 169552 / 169554 / 169555 138 revision c d. If service indicator was red, service filters. E. Slightly lift catch (g) at side of end cap (f), and rotate end cap counter clockwise until it stops, and arrow (h) lines-up with unlock symbol on end cap. F. Pull off the end cap (f...

Page 141

Maintenance and servicing 169552 / 169554 / 169555 139 revision c p. Inspect the air intake piping for damage, cracked hoses, loose clamps, etc. Repair or replace damaged parts, and tighten loose clamps. Q. If spring type clamps (m) require tightening, use a gauge as shown. R. Close engine compartme...

Page 142

Maintenance and servicing 169552 / 169554 / 169555 140 revision c 7.8.6 fuel system 7.8.6.1 fuel tank venting the fuel tank is vented by a hose that is connected to the filler tube. The hose is connected to a filter that should be changed annually. Change the filter as follows: danger stop engine, a...

Page 143

Maintenance and servicing 169552 / 169554 / 169555 141 revision c change both filters as follows every 500 hours of operation: a. Close fuel supply valve (e) under fuel tank. B. Change primary filter (c) as follows: 1. Clean around the filter head (f). 2. Disconnect water in fuel (wif) sensor (g) fr...

Page 144

Maintenance and servicing 169552 / 169554 / 169555 142 revision c 7.8.6.3 draining fuel tank draining the fuel tank is necessary to remove old or contaminated fuel. Danger stop engine, and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an i...

Page 145

Maintenance and servicing 169552 / 169554 / 169555 143 revision c 7.8.6.4 separator a fuel water separator is incorporated into the primary fuel filter (a). The separator is equipped with a sensor (b) that detects water in the fuel (wif) and alerts the operator on the cab display module (cdm), and a...

Page 146

Maintenance and servicing 169552 / 169554 / 169555 144 revision c 7.8.7 engine cooling system the engine cooling system is designed to maintain the engine operating temperature within the specified operating range. Note anti-freeze is essential in any climate. It broadens the operating temperature r...

Page 147

Maintenance and servicing 169552 / 169554 / 169555 145 revision c 7.8.7.2 radiator cap warning to avoid personal injury from hot coolant, do not turn radiator cap until engine has cooled. engine exhaust may be hot. A. Move maintenance platform to aft position. B. Remove the radiator cap, and che...

Page 148

Maintenance and servicing 169552 / 169554 / 169555 146 revision c f. Remove the radiator cap, and open radiator drain valve (b) on the engine side of the radiator lower tank. Use a deflector or a hose to prevent coolant running onto frame. G. Close the heater shut-off valve (c), and disconnect hose ...

Page 149

Maintenance and servicing 169552 / 169554 / 169555 147 revision c 7.8.8 exhaust system caution to avoid burns, do not touch muffler when engine is running, or before allowing sufficient cooling time after shut-down the exhaust system requires no regular maintenance, but it should be inspected period...

Page 150

Maintenance and servicing 169552 / 169554 / 169555 148 revision c 7.8.9 belts danger stop engine, and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. 7.8.9.1 tension a. The alternator, water pump, and fan belt are automati...

Page 151

Maintenance and servicing 169552 / 169554 / 169555 149 revision c c. Loosen compressor mounting hardware (b), and push compressor towards engine to release belt (a) tension. D. Remove belt (a). E. Insert the drive end of a 1/2 inch drive ratchet wrench into the belt tensioner (c). F. Rotate tensione...

Page 152

Maintenance and servicing 169552 / 169554 / 169555 150 revision c 7.9 cooling box 7.9.1 cooling box screen the cooling box screen is equipped with an automatic cleaning device that vacuums the screen by means of two rotors. They only operate when the engine is running. The rotors are electrically dr...

Page 153

Maintenance and servicing 169552 / 169554 / 169555 151 revision c 7.9.2 rotor to screen clearance a. Check clearance between trailing edge of rotor (a) and the screen. It should be 1/25–8/25 inches (1–8 mm) at all locations when rotating. Note rotor may touch screen as long as it continues to rotate...

Page 154

Maintenance and servicing 169552 / 169554 / 169555 152 revision c 7.9.3 cooling box maintenance the radiator and oil cooler should be cleaned daily with compressed air. More frequent cleaning may be necessary in severe conditions. The charge air cooler and air conditioning condenser may also be clea...

Page 155

Maintenance and servicing 169552 / 169554 / 169555 153 revision c f. Lift latch (k), and open access door (l) at left side of cooling box. G. Remove wing nut (m), and open access door (n) at top of cooling box. Important fins on coolers can be very easily bent which may interfere with its function. ...

Page 156

Maintenance and servicing 169552 / 169554 / 169555 154 revision c l. Close side access door (g), and lock with lever (f). M. Close top door (n), and secure with wing nut (m). N. Unhook support rod (c) in screen door, and store in screen door. O. Close screen door (b) until latch engages pin (a). P. ...

Page 157

Maintenance and servicing 169552 / 169554 / 169555 155 revision c 7.10 electrical system 7.10.1 batteries the m105 is equipped with two batteries that are located under the engine compartment hood at the left side of the engine compartment. A battery main disconnect switch is located on the battery ...

Page 158

Maintenance and servicing 169552 / 169554 / 169555 156 revision c 7.10.1.1 maintenance caution do not attempt to service battery unless you have the proper equipment and experience to perform the job. Have it done by a qualified dealer. A. Check battery charge once a year, and more often if operatin...

Page 159

Maintenance and servicing 169552 / 169554 / 169555 157 revision c 7.10.1.2 charging caution ventilate the area where batteries are being charged. do not charge a frozen battery. Warm to 60 f (16c) before charging. do not connect or disconnect live circuits. To prevent sparks, turn off charge...

Page 160

Maintenance and servicing 169552 / 169554 / 169555 158 revision c c. Attach one end of battery cable to positive terminal (a) of booster battery, and other end to positive terminal (b) of windrower batteries. D. Attach second cable to negative terminal (c) of booster battery, and then to a good grou...

Page 161

Maintenance and servicing 169552 / 169554 / 169555 159 revision c 7.10.1.5 replacing battery caution do not attempt to service battery unless you have the proper equipment and experience to perform the job. Have it done by a qualified dealer. Danger stop engine, and remove key from ignition before l...

Page 162

Maintenance and servicing 169552 / 169554 / 169555 160 revision c 7.10.1.6 preventing electrical system damage a. Carefully observe polarity when attaching booster battery. B. Do not short across battery or alternator terminals, or allow battery positive (+) cable or alternator wire to become ground...

Page 163

Maintenance and servicing 169552 / 169554 / 169555 161 revision c 7.10.2 headlights danger stop engine, and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. Note header should be attached and raised to maintain proper windr...

Page 164

Maintenance and servicing 169552 / 169554 / 169555 162 revision c e. Align lugs on new bulb (f) with slots (g) in body, and push into place. F. Secure bulb with wire retainer (e) g. Replace rubber insulator boot (d). H. Push connector onto bulb (f). I. Position headlight into light receptacle, ensur...

Page 165

Maintenance and servicing 169552 / 169554 / 169555 163 revision c 7.10.4 flood lights: forward the forward floodlights are not adjustable. Replace bulbs as follows: a. Shut down engine, and remove key. Turn lights off. B. Hold onto hand-holds (a) on cab front corners, and stand on header anti-slip s...

Page 166

Maintenance and servicing 169552 / 169554 / 169555 164 revision c 7.10.5 flood lights: rear danger stop engine, and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. 7.10.5.1 adjustment the rear floodlights are best adjusted...

Page 167

Maintenance and servicing 169552 / 169554 / 169555 165 revision c 7.10.6 swath lights danger stop engine, and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. The swath lights are not adjustable. Replace bulbs as follows: a...

Page 168

Maintenance and servicing 169552 / 169554 / 169555 166 revision c 7.10.7 amber lights a. Shut down engine, and remove key. Turn lights off. Note hold onto hand-holds (a) on cab front corners and stand on header anti-slip strips, or stand on maintenance platform when accessing the amber lights. B. Re...

Page 169

Maintenance and servicing 169552 / 169554 / 169555 167 revision c c. Pinch retainer, and remove it from lamp socket. D. Pull lamp out of socket. E. Disconnect harness from lamp. Important do not touch the glass of the halogen bulb as the oils or other chemicals from your skin will cause the bulb to ...

Page 170

Maintenance and servicing 169552 / 169554 / 169555 168 revision c 7.10.9 dome light a. Shut down engine. B. Remove two screws (a) from plastic lens, and remove lens. C. Replace bulb. D. Re-install plastic lens with screws (a). 7.10.10 ambient light a. Shut down engine. B. Push against tabs (b) with ...

Page 171

Maintenance and servicing 169552 / 169554 / 169555 169 revision c 7.10.12 circuit breakers and fuses danger stop engine, and remove key from ignition before leaving operator’s seat for any reason. A child or even a pet could engage an idling machine. The circuit breakers and fuses are located inside...

Page 172

Maintenance and servicing 169552 / 169554 / 169555 170 revision c 7.10.12.3 fuse box decal.

Page 173

Maintenance and servicing 169552 / 169554 / 169555 171 revision c 7.10.12.4 main fuses—125 amp the 125 amp main fuse holders are located inside the frame beside the battery, and are accessed from underneath the windrower. A. Stop engine, and remove key. B. To check condition of fuse, pull tab (a), a...

Page 174

Maintenance and servicing 169552 / 169554 / 169555 172 revision c 7.11 hydraulic system the m105 windrower hydraulic system provides oil for the windrower drive system, the header lift, and the drive systems. Warning avoid high pressure fluids. Escaping fluid can penetrate the skin causing serious...

Page 175

Maintenance and servicing 169552 / 169554 / 169555 173 revision c e. Maintain level between low and full marks. If necessary, add sae 15w40 compliant with sae specs for api class sj and ch-4 engine oil. Note low to full capacity is approximately 1 u.S. Gallon (4 liters). F. Re-install filler cap, an...

Page 176

Maintenance and servicing 169552 / 169554 / 169555 174 revision c 7.11.4 header and reel hydraulics 7.11.4.1 pressure compensator valve if lift and drive capacity problems develop, the pressure compensator valve may require adjusting. Contact your dealer, or refer to the technical manual for your wi...

Page 177

Maintenance and servicing 169552 / 169554 / 169555 175 revision c 7.11.4.4 header drop rate the header should lower gradually when the lower header switch is pressed. From full height to ground should take approximately 3.5 seconds. Adjust as follows: danger stop engine, and remove key from ignition...

Page 178

Maintenance and servicing 169552 / 169554 / 169555 176 revision c 7.11.5 traction drive hydraulics 7.11.5.1 transmission oil pressure the windrower transmission consists of two variable displacement axial piston hydraulic pumps—one for each drive wheel. The pumps are driven through a gearbox from th...

Page 179

Maintenance and servicing 169552 / 169554 / 169555 177 revision c 7.11.6 hoses and lines check hydraulic hoses and lines daily for signs of leaks. Warning avoid high-pressure fluids. Escaping fluid can penetrate the skin causing serious injury. Relieve pressure before disconnecting hydraulic lines...

Page 180

Maintenance and servicing 169552 / 169554 / 169555 178 revision c 7.12 wheels and tires 7.12.1 drive wheels 7.12.1.1 tire inflation a. Visually check daily that tires have not lost pressure. Under-inflation of drive tires can cause side wall cracks. Danger to avoid severe personal injury or death ca...

Page 181

Maintenance and servicing 169552 / 169554 / 169555 179 revision c 7.12.1.3 lubricant the drive wheel gearbox lubricant should be changed after the first 50 hours. Check the level every 200 hours or annually, and change every 1,000 hours. The windrower should be on level ground when checking lubrican...

Page 182

Maintenance and servicing 169552 / 169554 / 169555 180 revision c 7.12.1.4 drive wheel removal/installation danger to avoid severe personal injury or death caused by machine runaway, shut off engine, and remove key before performing any of the following checks and/or adjustments. A. Remove header. B...

Page 183

Maintenance and servicing 169552 / 169554 / 169555 181 revision c 7.12.2 caster wheels 7.12.2.1 tire inflation a. Visually check daily that tires have not lost pressure. Under-inflation of drive tires can cause side wall cracks. Danger to avoid severe personal injury or death caused by machine runaw...

Page 184

Maintenance and servicing 169552 / 169554 / 169555 182 revision c 7.12.2.2 ballast requirements fluid ballasting of rear caster tires is recommended to provide adequate machine stability when using large headers on the windrower. Also, the stability of machine varies with different attachments, wind...

Page 185

Maintenance and servicing 169552 / 169554 / 169555 183 revision c 7.12.2.3 wheel nut torque at first use, or when a wheel is removed, check caster wheel bolt torque as follows after 5 hours, and then at 200 hour intervals: note to avoid damage to wheel rims, do not over-tighten wheel nuts. Forked ca...

Page 186

Maintenance and servicing 169552 / 169554 / 169555 184 revision c 7.12.2.5 formed caster wheel removal and installation danger to avoid severe personal injury or death caused by machine runaway, shut off engine, and remove key before performing any of the following checks and/or adjustments. A. Remo...

Page 187: 8 Troubleshooting

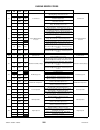

Troubleshooting * see your macdon dealer ** refer to windrower technical manual 169552 / 169554 / 169555 185 revision c 8 troubleshooting 8.1 engine symptom problem solution section engine hard to start or will not start. Controls not in neutral. Move gsl to neutral. 6.3.4.1 move steering wheel to l...

Page 188

Troubleshooting * see your macdon dealer ** refer to windrower technical manual 169552 / 169554 / 169555 186 revision c symptom problem solution section engine runs irregularly or stalls frequently. Unsteady fuel supply. Change filter on fuel tank vent line. Replace clogged fuel filter. 7.8.6.1 7.8....

Page 189

Troubleshooting * see your macdon dealer ** refer to windrower technical manual 169552 / 169554 / 169555 187 revision c symptom problem solution section high fuel consumption. Improper type of fuel. Use proper fuel. 7.3.2.1 clogged or dirty air cleaner. Service air filter/cleaner. 7.8.5.1 engine ove...

Page 190

Troubleshooting * see your macdon dealer ** refer to windrower technical manual 169552 / 169554 / 169555 188 revision c 8.2 electrical symptom problem solution section low voltage and/or battery will not charge. Defective battery. Have battery tested. 7.10.1.1 loose or corroded connections. Clean an...

Page 191

Troubleshooting * see your macdon dealer ** refer to windrower technical manual 169552 / 169554 / 169555 189 revision c 8.4 header drive symptom problem solution section header drive not engaging. Header drive switch in cab not engaged. Engage switch. 5.17.1 operator presence switch not closed or fa...

Page 192

Troubleshooting * see your macdon dealer ** refer to windrower technical manual 169552 / 169554 / 169555 190 revision c symptom problem solution section both wheels will not pull in forward or reverse. Pump arms have broken shaft or loose hardware. Repair or tighten. ** brakes binding or not releasi...

Page 193

Troubleshooting * see your macdon dealer ** refer to windrower technical manual 169552 / 169554 / 169555 191 revision c 8.6 steering and ground speed control symptom problem solution section machine will not steer straight. Linkage worn or loose. Replace worn parts. Adjust linkage. 7.7.4.1 machine m...

Page 194

Troubleshooting * see your macdon dealer ** refer to windrower technical manual 169552 / 169554 / 169555 192 revision c symptom problem solution section air conditioning not cooling. (cont’d) clutch coil burned out or disconnected. Contact your dealer. * broken or disconnected electrical wire. Check...

Page 195

Troubleshooting * see your macdon dealer ** refer to windrower technical manual 169552 / 169554 / 169555 193 revision c symptom problem solution section air conditioning system too noisy. Defective winding or improper connection in compressor clutch coil or relay. Contact your dealer. * excessive ch...

Page 196: 9 Options / Attachments

Options / attachments 169552 / 169554 / 169555 194 revision c 9 options / attachments 9.1 am-fm radio available for installation into pre-wired cab. Speakers are factory installed. Refer to m105 self-propelled windrower unloading and assembly instructions supplied with your windrower for installatio...

Page 197

Options / attachments 169552 / 169554 / 169555 195 revision c 9.16 warning beacons two roof mounted rotating warning beacons are available for installation into pre-wired cab. The beacons are standard equipment for export windrowers, and optional for north america. Installation instructions are incl...

Page 198

Cdm / wcm fault codes 169552 / 169554 / 169555 196 revision c e 1 e 2 r t c h n o t a l l o w e d return to cut height activated with the header off. E 3 e 4 e 5 e 6 t e m p g a u g e s h o r t wiring / connection problem. E 7 s p e e d s t i c k s h o r t wiring / connection problem. E 8 h e a d e ...

Page 199

Cdm / wcm fault codes 169552 / 169554 / 169555 197 revision c e n g i n e o i l p r e s s u r e engine oil pressure warning. E n g i n e t e m p e r a t u r e engine coolant temperature warning. C a n b u s s e r r o r j1939 can error k n i f e s p d o v e r l o a d low knife speed detected (less th...

Page 200

Engine error codes 169552 / 169554 / 169555 198 revision c example: cdm displays the error code 110s 16f 28c step 1. 110s - s is spn column, then locate code 110 in that column . Step 2. 16f - f is the fmi column, then locate code 16 in that column. Step 3. 28c - c is occurrences, 28 is the quantity...

Page 201

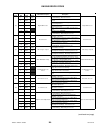

Engine error codes 169552 / 169554 / 169555 199 revision c (continued next page) j1939 spn j1939 fmi lamp color cummins code j1939 spn description description 1 red 415 oil pressure low - data valid but below normal operational range - most severe level 2 amber 435 oil pressure sensor circuit - data...

Page 202

Engine error codes 169552 / 169554 / 169555 200 revision c (continued next page) 1 red 235 coolant level low - data valid but below normal operating range - most severe level 2 amber 422 coolant level - data erratic, intermittant or incorrect 3 amber 195 coolant level sensor circuit - voltage above ...

Page 203

Engine error codes 169552 / 169554 / 169555 201 revision c (continued next page) j1939 spn j1939 fmi lamp color cummins code j1939 spn description description 16 amber transmission output shaft speed - data valid but above normal operating range - moderately severe level 18 amber transmission output...

Page 204

Engine error codes 169552 / 169554 / 169555 202 revision c (continued next page) j1939 spn j1939 fmi lamp color cummins code j1939 spn description description 5 amber 322 injector solenoid cylinder #1 circuit - current below normal, or open circuit 6 n/a injector current high 7 amber 1139 injector c...

Page 205

Engine error codes 169552 / 169554 / 169555 203 revision c (continued next page) j1939 spn j1939 fmi lamp color cummins code j1939 spn description description 1043 4 amber 284 internal sensor voltage supply engine speed/position sensor (crankshaft) supply voltage circuit - voltage below normal, or s...

Page 206

Engine error codes 169552 / 169554 / 169555 204 revision c end j1939 spn j1939 fmi lamp color cummins code j1939 spn description description 3 amber 1239 accelerator pedal or lever position sensor 2 circuit - voltage above normal, or shorted to high source 4 amber 1241 accelerator pedal or lever pos...

Page 207

Index 169552 / 169554 / 169555 205 revision c abbreviations .................................................................. 20 air cleaner .................................................................... 137 air conditioning compressor belt .......................................................

Page 208

Index 169552 / 169554 / 169555 206 revision c fan belt replacement ..............................................................148 tension ......................................................................148 fault codes ............................................................. 53, 197 fie...

Page 209

Index 169552 / 169554 / 169555 207 revision c relief valve ................................................................... 176 return to cut ................................................................... 85 rotors ........................................................................... 1...