- DL manuals

- MacDon

- Tractor

- M155

- Operator's Manual

MacDon M155 Operator's Manual

Summary of M155

Page 1

The harvesting specialists. M155 self-propelled windrower operator’s manual 147649 revision a 2016 model year original instruction.

Page 2

This manual contains instructions for safety, operation, and maintenance/service for the macdon m155 self-propelled windrower. Featuring the dual direction ® and ultra glide ® suspension on the m155. Published june, 2015 california proposition 65 warning diesel engine exhaust and some of its constit...

Page 3: Declaration Of Conformity

Declaration of conformity figure 1: declaration of conformity (page 1 of 2) 147649 i revision a.

Page 4

Figure 2: declaration of conformity (page 2 of 2) 147649 ii revision a.

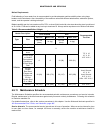

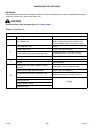

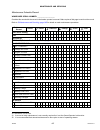

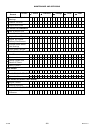

Page 5: Noise Levels

Whole body and hand-arm vibration levels the weighted root mean square acceleration, to which the whole body is subjected, ranges from 0.57 to 1.06 m/s 2 as measured on a representative machine during typical operations and analyzed in accordance with iso 5008. During the same operations, the weight...

Page 6: Introduction

Introduction this manual contains information on the macdon m155 self-propelled windrower which, when coupled with one of macdon’s auger, rotary, or draper headers, provides a package designed to cut and lay in windrows a variety of grain, hay, and specialty crops. The m155 windrower is dual directi...

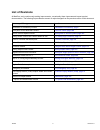

Page 7: List Of Revisions

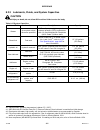

List of revisions at macdon, we’re continuously making improvements: occasionally these improvements impact product documentation. The following list provides an account of major changes from the previous version of this document. Summary of change location declaration of conformity revised. Declara...

Page 8: Serial Number

Serial number if you require macdon technical assistance, please have the serial number recorded and ready before you call. Record the model number, model year, and serial number of the windrower and engine on the lines below. The windrower serial number plate (a) is located on the left side of the ...

Page 9

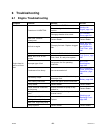

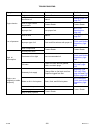

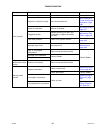

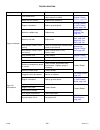

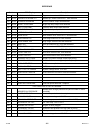

Table of contents declaration of conformity .................................................................................................................. I whole body and hand-arm vibration levels ..................................................................................... Iii noise le...

Page 10

Table of contents 3.10.1 heater shut-off...................................................................................................................... 56 3.10.2 air distribution .....................................................................................................................

Page 11

Table of contents activating the rotary header drive hydraulics on an m155 ..............................................102 setting the knife overload speed ...................................................................................103 setting the rotary disc overload speed....................

Page 12

Table of contents 4.3 operating the windrower...............................................................................................................157 4.3.1 operational safety ................................................................................................................157...

Page 13

Table of contents 4.4.11 swath roller operation..........................................................................................................212 4.5 attaching and detaching headers..................................................................................................213 4.5.1 ...

Page 14

Table of contents setting disc speed ........................................................................................................303 5 maintenance and servicing ................................................................................................................305 5.1 prepara...

Page 15

Table of contents replacing bulbs in red and amber lights .......................................................................388 replacing red tail lights (if installed) .............................................................................388 replacing the bulbs in beacon lights (if inst...

Page 16

Table of contents 7.1.21 warning beacons ..................................................................................................................450 7.1.22 weight box ..............................................................................................................................

Page 17: Safety

1 safety 1.1 safety alert symbols this safety alert symbol indicates important safety messages in this manual and on safety signs on the . This symbol means: • attention! • become alert! • your safety is involved! Carefully read and follow the safety message accompanying this symbol. Why is safety i...

Page 18: 1.2

Safety 1.2 signal words three signal words, danger, warning, and caution, are used to alert you to hazardous situations. The appropriate signal word for each situation has been selected using the following guidelines: danger indicates an imminently hazardous situation that, if not avoided, will resu...

Page 19: 1.3

Safety 1.3 general safety caution the following are general farm safety precautions that should be part of your operating procedure for all types of machinery. Protect yourself. • when assembling, operating, and servicing machinery, wear all the protective clothing and personal safety devices that c...

Page 20

Safety • wear close-fitting clothing and cover long hair. Never wear dangling items such as scarves or bracelets. • keep all shields in place. Never alter or remove safety equipment. Make sure driveline guards can rotate independently of the shaft and can telescope freely. • use only service and rep...

Page 21: 1.4

Safety 1.4 maintenance safety to ensure your safety while maintaining the machine: • review the operator’s manual and all safety items before operation and/or maintenance of the machine. • place all controls in neutral, stop the engine, set the park brake, remove the ignition key, and wait for all m...

Page 22: 1.5

Safety 1.5 hydraulic safety • always place all hydraulic controls in neutral before dismounting. • make sure that all components in the hydraulic system are kept clean and in good condition. • replace any worn, cut, abraded, flattened, or crimped hoses and steel lines. • do not attempt any makeshift...

Page 23: 1.6

Safety 1.6 tire safety • follow proper procedures when mounting a tire on a wheel or rim. Failure to do so can produce an explosion that may result in serious injury or death. Figure 1.14: overinflated tire • do not attempt to mount a tire unless you have the proper training and equipment. • have a ...

Page 24: 1.7

Safety 1.7 battery safety warning • keep all sparks and flames away from the batteries, as a gas given off by electrolyte is explosive. • ventilate when charging in enclosed space. Figure 1.16: safety around batteries warning • wear safety glasses when working near batteries. • do not tip batteries ...

Page 25: 1.8

Safety 1.8 welding precaution high currents and voltage spikes associated with welding can cause damage to electronic components. Before welding on any part of the windrower or an attached mower conditioner, disconnect all electronic module harness connections as well as the battery cables. Refer to...

Page 26: 1.9

Safety 1.9 engine safety warning do not use aerosol types of starting aids such as ether. Such use could result in an explosion and personal injury. Caution • in the initial start-up of a new, serviced, or repaired engine, always be ready to shut the engine off in order to stop an over-speed. This m...

Page 27

Safety 1.9.2 engine electronics warning tampering with the electronic system installation or the original equipment manufacturer (oem) wiring installation can be dangerous and could result in personal injury or death and/or engine damage. Warning electrical shock hazard. The electronic unit injector...

Page 28: 1.10

Safety 1.10 safety signs • keep safety signs clean and legible at all times. • replace safety signs that are missing or become illegible. • if original parts on which a safety sign was installed are replaced, be sure the repair part also bears the current safety sign. • safety signs are available fr...

Page 29: 1.11

Safety 1.11 safety sign locations figure 1.20: safety sign locations (left cab-forward side) a - hazard sign (md #135378) b - cab door and rim (md #166454) c - oil reservoir under hood (md #166466) d - exhaust cover (md #166450) e - close to radiator cap (md #166461) f - fan shroud (top) (md #166450...

Page 30

Safety figure 1.21: safety signs (left cab-forward side) 147649 14 revision a.

Page 31

Safety figure 1.22: safety sign locations (right cab-forward side) a - hazard sign on seat (md #115148) b - lift linkage (md #166439) c - frame (md #166455) d - frame (md #166456) e - cab frame (md #184372) f - platform (md #166425) g - shroud (md #166451) h - shroud (md #166452) j - hydraulic reser...

Page 32

Safety figure 1.23: safety signs (right cab-forward side) 147649 16 revision a.

Page 33: 1.12

Safety 1.12 understanding safety signs md #166233 run-over hazard danger • do not start engine by shorting across starter or starter relay terminals. Machine will start with drive engaged and move if starting circuitry is bypassed. • start engine only from operator’s seat. Do not try to start engine...

Page 34

Safety md #166439 roll-over hazard warning • stop the engine and remove the key from ignition before servicing, adjusting, lubricating, cleaning, or unplugging the machine. Figure 1.27: md #166439 md #166438 crushing hazard danger • rest header on ground or engage safety props before going under uni...

Page 35

Safety md #166439 crushing hazard danger • rest header on ground or engage safety props before going under unit. Figure 1.29: md #166439 md #166441 loss of control hazard caution • to prevent machine damage and/or loss of control, it is essential that the machine be equipped such that weights are wi...

Page 36

Safety md #166450 hot surface hazard warning • to avoid injury, keep a safe distance from hot surface. Figure 1.31: md #166450 md #166451 rotating fan hazard warning • to avoid injury, stop the engine and remove the key before opening engine hood. Figure 1.32: md #166451 147649 20 revision a.

Page 37

Safety md #166454 general hazard pertaining to machine operation and servicing. Caution • read the operator’s manual and follow all safety instructions. If you do not have a manual, obtain one from your dealer. • do not allow untrained persons to operate the machine. • review safety instructions wit...

Page 38

Safety md #166456 battery acid hazard warning • corrosive and poisonous battery acid. Acid can severely burn your body and clothing. Figure 1.35: md #166456 147649 22 revision a.

Page 39

Safety md #166457 general hazard pertaining to machine operation and servicing caution to avoid injury or death from improper or unsafe machine operation: • read the operator’s manual and follow all safety instructions. If you do not have a manual, obtain one from your dealer. • do not allow untrain...

Page 40

Safety md #166461 hot fluid under pressure hazard caution • coolant is under pressure and may be hot. Never remove radiator cap when engine is hot. Figure 1.37: md #166461 md #166463 collision hazard in transport warning • collision between windrower and other vehicles may result in injury or death....

Page 41

Safety md #166465 loss of control hazard warning to avoid serious injury or death from loss of control: • do not make abrupt changes in steering direction. • anticipate turns by slowing down well in advance. • do not rapidly accelerate or decelerate while turning. • limit speed to maximum 20 mph (32...

Page 42

Safety md #166833 run-over hazard warning • remove key from ignition. • read tractor and mower manufacturer’s manuals for inspection and maintenance instructions. • read the windrower and header manuals for inspection and maintenance instructions. Figure 1.41: md #166425 md #167502 pinch point hazar...

Page 43

Safety md #174436 high pressure oil hazard warning • do not go near leaks. • high pressure oil easily punctures skin causing serious injury, gangrene, or death. • if injured, seek emergency medical help. Immediate surgery is required to remove oil. • do not use finger or skin to check for leaks. • l...

Page 45: Product Overview

2 product overview 2.1 definitions the following terms and acronyms may be used in this manual. Term definition a-series header macdon auger header api american petroleum institute astm american society of testing and materials bolt a headed and externally threaded fastener that is designed to be pa...

Page 46

Product overview term definition npt national pipe thread: a style of fitting used for low pressure port openings threads on npt fittings are uniquely tapered for an interference fit orb o-ring boss: a style of fitting commonly used in port opening on manifolds, pumps, and motors orfs o-ring face se...

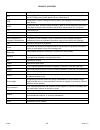

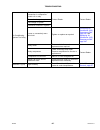

Page 47: 2.2

Product overview 2.2 specifications engine type cummins qsb-4.5l cm850 4 cylinder turbo diesel. B20 biodiesel approved. Displacement 275 cu. In. (4.5 l) rated 148 hp (110 kw) @ 2300 rpm power peak 156 hp (116 kw) @ 2000 rpm electrical system recommended battery (2) 12 volt, maximum dimension: 13.25 ...

Page 48

Product overview header lift/tilt type hydraulic double acting cylinders. Tilt - optional hydraulic positioning, optional hydraulic center-link function lift / tilt / float header float primary adjustment manual, external, drawbolt with springs (1 per side). One inner booster spring on left side. Fi...

Page 49

Product overview header compatibility auger headers a30-d, a40-d all sizes draper headers d50, d60, and d65 2 up to 35 ft. Draper headers d60 and d65 40 ft 2 40 ft. Rotary disc r80 and r85 13 ft. Only 3 note: specifications and design are subject to change without notice or obligation to revise prev...

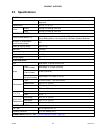

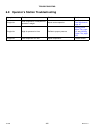

Page 50: 2.3

Product overview 2.3 windrower dimensions figure 2.1: windrower dimensions – cab-forward a - drive tire tread b - drive tire hubs c - drive tires f - 45-3/4 in. (1160 mm) g - 133 in. (3378 mm) h - 158-5/16 in. (4022 mm) j - 207-7/8 in. (5280 mm) table 2.2 drive tires tire size wheel position tread (...

Page 51

Product overview tire size wheel position tread (a) in. (mm) hubs (b) in. (mm) tires (c) in. (mm) inner/outer (shipping) 126-1/8 (3203) 140-9/16 (3571) 149-5/16 (3793) outer/outer 133-3/16 (3383) 147-11/16 (3751) 156-7/16 (3973) 23.1-26 turf tires inner/inner 119 (3023) 133-1/2 (3391) 142-1/4 (3613)...

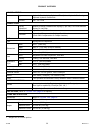

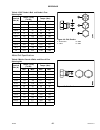

Page 52: 2.4

Product overview 2.4 component location figure 2.3: front cab-forward view a - header lift leg b - header float springs c - operator’s station d - windshield wiper e - turn signal / hazard lights f - tail light engine-forward g - field/road lights h - handholds j - tail light engine-forward k - mirr...

Page 53

Product overview figure 2.4: rear cab-forward view a - caster wheel b - walking beam c - tail lights - cab-forward (option) d - engine compartment hood e - windshield wiper f - field lights g - horn h - turn signal/hazard lights j - mirror k - door l - drive wheel m - maintenance platform 147649 37 ...

Page 55: Operator’S Station

3 operator’s station the operator’s station is designed for operating the windrower in a cab-forward mode (working mode) or in an engine-forward mode (transport mode). The operator’s station, which includes the seat, console, and steering column, pivots 180 degrees so that the operator maintains acc...

Page 56

Operator’s station 2. Adjusting only fore-aft: a. Loosen nuts (a) under console. B. Move console as required. C. Tighten nuts (a). Figure 3.3: seat fore-aft 147649 40 revision a.

Page 57: 3.2

Operator’s station 3.2 operator presence system the operator presence system is a safety feature designed to deactivate or alarm selected systems when the operator is not seated at the operator’s station. These systems include: • header drive • engine and transmission 3.2.1 header drive • requires t...

Page 58: 3.3

Operator’s station 3.3 operator’s seat adjustments the operator’s seat has several adjustments. Refer to the following for the location and description of each adjustment. 3.3.1 fore-aft adjusts fore-aft position. 1. Pull lever (a) up to release. 2. Move seat forward or rearward. 3. Release lever (a...

Page 59

Operator’s station 3.3.3 vertical dampener adjusts suspension dampening. Increase: turn knob (a) counterclockwise. Decrease: turn knob (a) clockwise. Figure 3.6: vertical dampener 3.3.4 armrest raise armrest (a) for easier access to seat. Lower armrest (a) after seat belt is buckled. Figure 3.7: arm...

Page 60

Operator’s station 3.3.5 fore-aft isolator lock locks seat fore-aft isolator. Lock: push lever (a) down. Unlock: pull lever (a) up. Figure 3.8: fore-aft isolator lock 3.3.6 seat tilt to adjust seat tilt: 1. Pull lever (a) up to release. 2. Position seat back as desired. 3. Release lever (a). Figure ...

Page 61

Operator’s station 3.3.7 armrest angle adjusts angle of armrest. Increase: rotate knob (a) clockwise. Decrease: rotate knob (a) counterclockwise. Figure 3.10: armrest angle 3.3.8 lumbar support adjusts stiffness of seat back. Increase: rotate knob (a) upward. Decrease: rotate knob (a) downward. Figu...

Page 62: 3.4

Operator’s station 3.4 training seat a wall-mounted fold-up training seat complete with seat belt is provided. Warning • the training seat is provided for an experienced operator of the machine when a new operator is being trained. • the training seat is not intended as a passenger seat or for use b...

Page 63: 3.5

Operator’s station 3.5 seat belts the windrower is equipped with a seat belt on the operator’s and trainer’s seats. Warning the seat belt can help ensure your safety if it is used and maintained. • before starting the engine, securely fasten your seat belt. Ensure that anyone occupying the trainee’s...

Page 64: 3.6

Operator’s station 3.6 steering column adjustment the steering column can be adjusted to suit each particular operator and for easier entry to and exit from the seat. To adjust the steering column: 1. Hold onto steering wheel, lift handle (a), and move steering wheel up or down to desired position. ...

Page 65: 3.7

Operator’s station 3.7 lighting the field and road light switches are located on a panel in the cab headliner. The position of the operator’s station (cab-forward mode or engine-forward mode) automatically determines the lighting. The hazard lights are activated automatically when certain conditions...

Page 66

Operator’s station the two field lights (a) at the rear of the cab are adjustable. Refer to adjusting rear flood lights, page 386 . The two swath lights (b) in the hood are adjustable but, because they are used as road lights in engine-forward mode and adjusted accordingly, they should not be adjust...

Page 67

Operator’s station • amber turn signals and hazard lights (a) on mirror supports front view • headlights (b) in hood with low/high the two headlights in the hood are adjustable. Refer to aligning headlights, page 376 . Figure 3.22: engine-forward: front view 3.7.3 cab-forward lighting: road (optiona...

Page 68

Operator’s station • red lights (c) in hood note: the hazard lights will be automatically activated when certain conditions are met. The windrower must be cab-forward, medium range, brake off, and header off. Important: optional red tail lighting and marking kit must be installed so that road travel...

Page 69

Operator’s station 3.7.5 hid auxiliary lighting (optional) two optional high intensity discharge (hid) lights (md #b5596) provide additional lighting during field operation. If installed, hid auxiliary lighting is located on the mirror supports (a) and operates in cab-forward mode only. Figure 3.28:...

Page 70: 3.8

Operator’s station 3.8 windshield wipers the windshield wiper controls are located in the cab headliner. The illustration shows the controls in cab-forward mode. Figure 3.30: wiper controls a - rear wiper b - front wiper 147649 54 revision a.

Page 71: 3.9

Operator’s station 3.9 rear view mirrors two outside mounted, adjustable mirrors (a) provide a rear view when the windrower is in cab-forward mode. A single interior mounted mirror (b) provides a rear view in the engine-forward mode. The mirror/light assembly (a) is designed to fold back if accident...

Page 72: 3.10

Operator’s station 3.10 cab temperature the cab environment is controlled by a climate control system that provides clean air-conditioned or heated air for the operator. The heater/evaporator/blower assembly is located under the cab floorboard and is accessible from beneath the windrower. 3.10.1 hea...

Page 73

Operator’s station 3.10.3 climate controls a – blower switch controls the blower speed. • off / low / medium / high b – air conditioning (a/c) switch controls a/c system. • off: a/c does not operate. • on: a/c operates with blower switch on. C – outside air witch controls the air source. • fresh air...

Page 74: 3.11

Operator’s station 3.11 interior lights two interior lights are installed in the cab headliner. A low intensity led light (a) is located directly overhead to provide ambient lighting if desired. It functions only when the key is in the run position. An on/off switch is located on the light. The othe...

Page 75: 3.12

Operator’s station 3.12 emergency exit the emergency exit is located behind the operator console. An emergency exit sign (a) is located above the window. Figure 3.36: emergency exit sign to open the emergency exit window, do the following: 1. Release the window latch (a). 2. Remove the latch pin (b)...

Page 76: 3.13

Operator’s station 3.13 operator amenities the operator’s station includes the following amenities: operator’s console a - auxiliary power outlet b - utility tray (under armrest) c - cigarette lighter d - ashtray / cup holder e - utility tray figure 3.38: console window shades (optional) retractable...

Page 77

Operator’s station manual storage a manual storage case (a) is located under the training seat. Figure 3.41: operator’s manual storage coat hook a coat hook (a) is located above the training seat, left of the operator. Figure 3.42: coat hook 147649 61 revision a.

Page 78: 3.14

Operator’s station 3.14 radio a radio is available as optional equipment from your dealer. 3.14.1 am/fm radio a space (b) is provided in the cab headliner to accommodate the installation of an am/fm radio that is available as optional equipment from your dealer. Two pre-wired speakers (a) have been ...

Page 79

Operator’s station the knockout (a) is located on the exterior right cab-forward rear corner post of the cab, under the roof, between the horn and the light. Figure 3.45: knockout location in cab to make your own mount, refer to dimensions template. Use 11 ga. Or 3.0 mm steel sheet. Figure 3.46: tem...

Page 80: 3.15

Operator’s station 3.15 horn the horn is activated by pushing button (a) located on the panel in the headliner. Sound the horn three times prior to starting the engine. Figure 3.47: horn button location the horn (a) is located outside the cab on the rear right cab-forward corner of the cab, under th...

Page 81: 3.16

Operator’s station 3.16 engine controls and gauges the following engine controls and gauges are conveniently located on the operator’s console. A – ignition switch • acc: fully counterclockwise • off: all electrical systems off • run: clockwise • start: fully clockwise to crank engine: release and s...

Page 82: 3.17

Operator’s station 3.17 windrower controls console controls: a – turn signals activate turn signals on windrower and header • push-on / push-off b – ground speed lever (gsl) controls speed and direction of movement • f: forward • n: neutral • n-detent: engages neutral interlock, and applies park bra...

Page 83

Operator’s station the autosteer engagement switch harness end (a) is beneath the cab between the fuel tank and evaporator box. Figure 3.52: autosteer harness 147649 67 revision a.

Page 84: 3.18

Operator’s station 3.18 header controls all header controls are conveniently located on the operator’s console and on the ground speed lever (gsl) handle. Note: some controls are optional equipment and may not be present in your unit. Some controls may be installed but nonfunctional for certain head...

Page 85

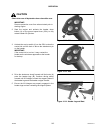

Operator’s station 3.18.3 ground speed lever (gsl) header switches the switches on the gsl (a) control the most common header functions. Note: a decal (b) identifying switch functions is located on the cab post above the operator’s console. Figure 3.55: gsl figure 3.56: gsl function groups a - reel ...

Page 86

Operator’s station display selector switch pressing the display selector switch (a) selects and displays the settings on the cab display module (cdm) top line read-out for each of the header controls. Press switch (a) to scroll through settings. Figure 3.57: gsl reel position switches the functions ...

Page 87

Operator’s station header position switches use the header position switches on the ground speed lever (gsl) to adjust the position of the header, relative to the ground. • to lower the header down, press switch (a) • to raise the header up, press switch (c) • to tilt the header down, press switch (...

Page 88

Operator’s station 3.18.4 console header switches the operator’s console contains switches for the following header functions: deck shift/float preset switch draper header with deck shift option • controls deck shifting and float settings for double windrowing options with a draper header figure 3.6...

Page 89

Operator’s station double windrow attachment (dwa) / swath roller switch (if installed) with double windrow attachment • if switch (a) is installed in the console, the dwa deck is raised with switch in position (c) or lowered in position (b). The cab display module (cdm) must be programmed for this ...

Page 90: 3.19

Operator’s station 3.19 cab display module (cdm) 3.19.1 engine and windrower functions figure 3.64: cab display module (cdm) engine and windrower functions a – engine rpm b – ground speed: mph or km/h c – display: engine/windrower functions d – hazard warning lights switch: activates hazard warning ...

Page 91

Operator’s station 3.19.2 header functions figure 3.65: cab display module (cdm) • (a) display: header functions • (b) select switch: allows operator to select display item on lower line. Push to select. • (c) float switch – header right side: changes header float. The system remembers setting with ...

Page 92

Operator’s station 3.19.3 operating screens the cab display module (cdm) and the windrower control module (wcm) provide information on several functions for the engine, header, and windrower. The information displayed in various operating modes is described in the following sections. Figure 3.66: cd...

Page 93

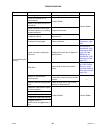

Operator’s station engine-forward, engine running display description road gear (upper line) ground speed range switch in high range. #####.# engine hrs (upper or lower line) total engine operating time. #####.# header hrs (upper or lower line) total header operating time. ###### total acres (upper ...

Page 94

Operator’s station display (lower or upper line) description ##.# acres/hour ##.# hectares/hour (if metric) actual cutting rate in acres (hectares)/hour. ###.# sub acres ###.# sub hectares (if metric) area cut since last reset. To reset, display sub acres on lower line, and hold down program switch ...

Page 95

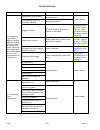

Operator’s station cab-forward, engine running, header engaged, auger header index switch on scroll through display with cab display module (cdm) switch or ground speed lever (gsl) switch. Display (lower or upper line) description #####.# engine hrs total engine operating time. #####.# header hrs to...

Page 97

Operator’s station cab-forward, engine running, header engaged, draper header, index switch off scroll through display with cab display module (cdm) switch or ground speed lever (gsl) switch. Display (lower or upper line) description #####.# engine hrs total engine operating time. #####.# header hrs...

Page 98

Operator’s station cab-forward, engine running, header engaged, draper header, index switch on scroll through display with cab display module (cdm) switch or ground speed lever (gsl) switch. Display (lower or upper line) description #####.# engine hrs total engine operating time. #####.# header hrs ...

Page 99

Operator’s station cab-forward, engine running, header engaged, rotary header installed scroll through display with cab display module (cdm) switch or ground speed lever (gsl) switch. Display (lower or upper line) description #####.# engine hrs total engine operating time. #####.# header hrs total h...

Page 100

Operator’s station display (upper line) description in park gsl in n-detent position. Indicates left turn when left arrow is pressed on cdm. Engine-forward mode only 11 . ■ right turn > indicates right turn when right arrow is pressed on cdm. Engine forward mode only 12 ■ hazard ■ indicates hazard w...

Page 101

Operator’s station 3.19.4 cab display module (cdm) warning/alarms the cdm displays warnings and sounds alarms to notify of abnormal windrower status at startup when the ignition is turned on, and at engine operating speeds above 500 rpm. Engine warning lights figure 3.67: cdm engine warning lights a...

Page 102

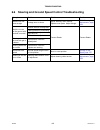

Operator’s station display warnings and alarms informs operator of abnormal windrower conditions. Figure 3.68: cdm display warnings and alarms display (a) flashing alarm tone description brake off x short beep with each flash engine running, brake solenoid not activated brake on x short beep with ea...

Page 103

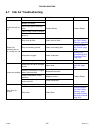

Operator’s station display (a) flashing alarm tone description engine temperature x ongoing intermittent moderate tone until temperature is below 215°f (102°c) engine temperature over 230°f (110°c) header disengaged none normal disengage header x none header switch is in the on position when ignitio...

Page 104

Operator’s station display (a) flashing alarm tone description no operator continuous tone operator not detected in seat with header engaged or out of n-detent: engine shutdown after 5 seconds no operator engine shut down continuous tone engine shutdown when operator not detected in seat with machin...

Page 105

Operator’s station 3.19.5 cab display module (cdm) programming figure 3.69: cdm a - side display b - main display c - select switch d - menu item scroll forward e - menu item scroll backward f - program switch side display : displays software revision status. • upper line – c### (cdm) • lower line –...

Page 106

Operator’s station note: contact your macdon dealer for information regarding software updates to the electronic modules. Your dealer will have the necessary interface tools and access to the latest software upgrades. Note: the following menus are available when ignition key is set to run: • windrow...

Page 107

Operator’s station 3. Press select (b) until cab display setup? Is displayed on the upper line. • no/yes is displayed on the lower line. Figure 3.71: m155 cab display setup 4. Press right (c) arrow select yes. Press select (d). • display language? Is displayed on the upper line. • default language i...

Page 108

Operator’s station 3. Press select (b) until cab display setup? Is displayed on the upper line. • no/yes is displayed on the lower line. 4. Press right (a) arrow to select yes. Press select (b). • display language? Is displayed on the upper line. Figure 3.74: m155 cab display setup 5. Press select (...

Page 109

Operator’s station 3. Press select (b) until cab display setup? Is displayed on the upper line. • no/yes is displayed on the lower line. 4. Press right (a) arrow to select yes. Press select (b). • display language? Is displayed on the upper line. Figure 3.77: m155 cab display setup 5. Press select (...

Page 110

Operator’s station 3. Press select (b) until cab display setup? Is displayed on the upper line. • no/yes is displayed on the lower line. 4. Press right (a) arrow to select yes. Press select (b). • display language? Is displayed on the upper line. Figure 3.80: m155 cab display setup 5. Press select (...

Page 111

Operator’s station 3. Press select (b) until cab display setup? Is displayed on the upper line. • no/yes is displayed on the lower line. 4. Press right (a) arrow to select yes. Press select (b). • display language? Is displayed on the upper line. Figure 3.83: m155 cab display setup 5. Press select (...

Page 112

Operator’s station 1. Turn ignition key to run, or start the engine. 2. Press program (a) and select (c) on cab display module (cdm) to enter programming mode. • windrower setup? Is displayed on the upper line. 3. Press select (c) until calibrate sensors? Is displayed on the upper line. • no/yes is ...

Page 113

Operator’s station caution check to be sure all bystanders have cleared the area. 6. Press and hold the header up (c) button on the ground speed lever (gsl). • calibrating height is displayed on the upper line. • raise header hold is displayed on the lower line. Note: the word hold will flash during...

Page 114

Operator’s station calibrating the header tilt sensor note: • the header must be attached to the windrower to perform this procedure. The cab display module (cdm) automatically adjusts its programming for each header. Refer to 4.5 attaching and detaching headers, page 213 . • this procedure requires...

Page 115

Operator’s station caution check to be sure all bystanders have cleared the area. 6. Press and hold the header tilt extend (b) button on the ground speed lever (gsl). • calibrating tilt is displayed on the upper line. • extend tilt hold is displayed on the lower line. Note: the word hold will flash ...

Page 116

Operator’s station calibrating the header float sensors note: • the header must be attached to the windrower to perform this procedure. The cab display module (cdm) automatically adjusts its programming for each header. For more information, refer to 4.5 attaching and detaching headers, page 213 . •...

Page 117

Operator’s station 6. Press and hold float + button (a) on the cdm. • calibrating float is displayed on the upper line. • float ( + ) hold is displayed on the lower line. Note: the word hold will flash during calibration. Float (+) done will display on the lower line once calibration is complete. 7....

Page 118

Operator’s station 1. Turn ignition key to run, or start the engine. 2. Press program (a) and select (c) on cab display module (cdm) to enter programming mode. • windrower setup? Is displayed on the upper line. • no/yes is displayed on the lower line. 3. Press right (b) arrow to select yes. Press se...

Page 119

Operator’s station 4. Press select (d) until disc blk installed? Is displayed on the upper line. • no/yes is displayed on the lower line. 5. Press right (c) arrow to select yes. Press select (d). 6. Press program (a) to exit programming mode or press select (d) to proceed to next windrower setup act...

Page 120

Operator’s station 4. Press select (d) until knife overload spd? Is displayed on the upper line. • current overload speed is displayed on the lower line. Note: default setting is -300 spm. Range is -500 to -100 spm. 5. Press left (b) or right (c) arrows to set knife overload speed. Press select (d)....

Page 121

Operator’s station 4. Press select (d) until disk overload spd? Is displayed on the upper line. • the current overload speed is displayed on the lower line. Note: default setting is -300 spm. Range is -500 to -100 rpm. 5. Press left (b) or right (c) arrows to set disc overload speed. Press select (d...

Page 122

Operator’s station 4. Press left (b) or right (c) arrows to select knife speed. Press select (d). 5. Press program (a) to exit programming mode or press select (d) to proceed to next windrower setup action. Figure 3.106: m155 knife speed setting the hydraulic overload pressure note: • this procedure...

Page 123

Operator’s station 4. Press select (d) until overload pressure? Is displayed on the upper line. • the current overload pressure is displayed on lower line. Note: pressure range is 2500–5000 psi (17,237–34,474 kpa). 5. Press left (b) or right (c) arrows to set hydraulic overload pressure. Press selec...

Page 124

Operator’s station 4. Press select (d) until header index mode? Is displayed on the upper line. • reel & conveyor or reel only is displayed on the lower line. 5. Press left (b) or right (c) arrows to set header index mode. Press select (d). 6. Press program (a) to exit programming mode or press sele...

Page 125

Operator’s station 4. Press select (d) until return to cut mode? Is displayed on the upper line. • height & tilt or height only will be displayed on the lower line. 5. Press left (b) or right (c) arrows to select return to cut mode. Press select (d). 6. Press program (a) to exit programming mode or ...

Page 126

Operator’s station 4. Press select (d) until hdr cut width? #### is displayed on the upper line. • previous cutting width is displayed on the lower line. 5. Press left (b) or right (c) arrows to change the headers cut width. Press select (d). 6. Press program (a) to exit programming mode or press se...

Page 127

Operator’s station 4. Press select (b) until dwa installed? Is displayed on the upper line. • no/yes is displayed on the lower line. 5. Press right (a) arrow to select yes. Press select (b). Figure 3.116: m155 dwa controls 6. Swap dwa controls? Is displayed on the upper line. • no/yes is displayed o...

Page 128

Operator’s station setting the auto raise height for more information on the auto raise height feature, refer to 4.4.8 auto raise height, page 209 . Note: the header must be attached to the windrower to perform this procedure. The cab display module (cdm) automatically adjusts its programming for ea...

Page 129

Operator’s station 1. Turn ignition key to run, or start the engine. 2. Press program (a) and select (c) on cab display module (cdm) to enter programming mode. • windrower setup? Is displayed on the upper line. • no/yes is displayed on the lower line. 3. Press right (b) arrow to select yes. Press se...

Page 130

Operator’s station 1. Turn ignition key to run, or start the engine. 2. Press program (a) and select (c) on cdm to enter programming mode. • windrower setup? Is displayed on the upper line. • no/yes is displayed on the lower line. 3. Press right (b) arrow to select yes. Press select (c). • set knife...

Page 131

Operator’s station 4. Press select (d) until set tire size? Is displayed on the upper line. • currently installed tire size is displayed on the lower line. Note: the following tire sizes are available: • 18.4 x 26 turf • 18.4 x 26 bar • 23.1 x 26 turf • 600 – 65 r28 5. Press left (b) or right (c) ar...

Page 132

Operator’s station 4. Press select (c) until set engine isc rpm? Is displayed on the upper line. • no/yes is displayed on the lower line. 5. Press right (b) arrow to select yes. Press select (c). • press hazard to set is displayed on the upper line. • isc rpm #### is displayed on the lower line. Not...

Page 133

Operator’s station 3.19.9 activating cab display lock outs you can lock some of the header functions controlled by the cab display module (cdm) to prevent accidental changes to header settings. You can use this feature to keep header settings constant when several different operators use the windrow...

Page 134

Operator’s station 6. Press select (d) until knife speed is displayed on the upper line. • enabled/locked is displayed on the lower line. 7. Press left arrow (b) to enable knife speed control switch, or press right arrow (c) to lock knife speed control switch. 8. Press program (a) to exit programmin...

Page 135

Operator’s station 4. Press select (b) until set control locks? Is displayed on the upper line. • no/yes is displayed on the lower line. 5. Press right (a) arrow to select yes. Press select (b). Figure 3.135: m155 control locks 6. Press select (d) until disk speed is displayed on the upper line. • e...

Page 136

Operator’s station 1. Turn ignition key to run, or start the engine. 2. Press program (a) and select (c) on cab display module (cdm) to enter programming mode. • windrower setup? Is displayed on the upper line. • no/yes is displayed on the lower line. 3. Press right (b) arrow to select yes. Press se...

Page 137

Operator’s station activating the draper speed control lock out note: • this procedure is for draper headers only. • the header must be attached to the windrower to perform this procedure. The cab display module (cdm) automatically adjusts its programming for each header. For more information, refer...

Page 138

Operator’s station 6. Press select (d) until draper speed is displayed on the upper line. • enabled/locked is displayed on the lower line. 7. Press left arrow (b) to enable draper speed control switch, or press right arrow (c) to lock draper speed control switch. 8. Press program (a) to exit program...

Page 139

Operator’s station 4. Press select (b) until set control locks? Is displayed on the upper line. • no/yes is displayed on the lower line. 5. Press right (a) arrow to select yes. Press select (b). Figure 3.144: m155 control locks 6. Press select (d) until auger speed is displayed on the upper line. • ...

Page 140

Operator’s station 1. Turn ignition key to run, or start the engine. 2. Press program (a) and select (c) on cab display module (cdm) to enter programming mode. • windrower setup? Is displayed on the upper line. • no/yes is displayed on the lower line. 3. Press right (b) arrow to select yes. Press se...

Page 141

Operator’s station activating the reel fore-aft control lock out note: • this procedure is for draper headers only. • the header must be attached to the windrower to perform this procedure. The cab display module (cdm) automatically adjusts its programming for each header. For more information, refe...

Page 142

Operator’s station 6. Press select (d) until reel fore/aft is displayed on the upper line. • enabled/locked is displayed on the lower line. 7. Press left (b) arrow to enable reel fore/aft control switch. Press right (c) arrow to lock reel fore/aft control switch. 8. Press program (a) to exit program...

Page 143

Operator’s station 4. Press select (b) until set control locks? Is displayed on the upper line. • no/yes is displayed on the lower line. 5. Press right (a) arrow to select yes. Press select (b). Figure 3.153: m155 control locks 6. Press select (d) until header tilt is displayed on the upper line. • ...

Page 144

Operator’s station 1. Turn ignition key to run, or start the engine. 2. Press program (a) and select (c) on cab display module (cdm) to enter programming mode. • windrower setup? Is displayed on the upper line. • no/yes is displayed on the lower line. 3. Press right (b) arrow to select yes. Press se...

Page 145

Operator’s station 6. Press left (b) or right (c) arrow to cycle between control switch lock outs. The displayed control switches are as follows: • header tilt • header float • reel fore/aft • draper speed • auger speed • knife speed • disk speed • reel speed note: not all control locks apply to eve...

Page 146

Operator’s station 1. Turn ignition key to run, or start the engine. 2. Press program (a) and select (c) on cab display module (cdm) to enter programming mode. Press select (c). • windrower setup? Is displayed on the upper line. 3. Press select (c) until diagnostic mode? Is displayed in upper line. ...

Page 147

Operator’s station 10. Press right (c) arrow to select yes. Press select (d). 11. Press and left (b) or right (c) arrow to cycle through the last 10 recorded engine error codes until exit engine codes is displayed. • refer to 8.4 engine error codes, page 469 . 12. Press right (c) arrow to select yes...

Page 148

Operator’s station 5. Press select (b) until enter sensor setup? Is displayed on the upper line. • no/yes is displayed on the lower line. 6. Press right (a) arrow to select yes. Press select (b). • knife speed sensor is displayed on the lower line. • enable/disable is displayed on the lower line. Fi...

Page 149

Operator’s station 1. Turn ignition key to run, or start the engine. 2. Press program (a) and select (c) on cab display module (cdm) to enter programming mode. • windrower setup? Is displayed on the upper line. • no/yes is displayed on the lower line. Figure 3.165: m155 cdm programming buttons 3. Pr...

Page 150

Operator’s station forcing a header id the header must be attached to the windrower to troubleshoot certain issues. If damage has occurred to the header wiring or no header is available, you can force the windrower control module (wcm) to read a header id. The wcm reverts to reading no header each t...

Page 151

Operator’s station 5. Press select (b) until force header type? Is displayed on the upper line. • no/yes is displayed on the lower line. 6. Press right (a) arrow to select yes. Press select (b). • select header type is displayed on the upper line. • disk header is displayed on the lower line. Figure...

Page 152

Operator’s station 1. Turn ignition key to run, or start the engine. 2. Press program (a) and select (c) on cab display module (cdm) to enter programming mode. Press select (c). • windrower setup? Is displayed on the upper line. Figure 3.172: m155 cdm programming buttons 3. Press select (b) until di...

Page 153

Operator’s station caution check to be sure all bystanders have cleared the area. 7. Press select (d) until activate header ht is displayed on the upper line. • down/up is displayed on the lower line. 8. Press and hold left (b) arrow to lower header or, press and hold right (c) arrow to raise header...

Page 154

Operator’s station 3. Press select (b) until diagnostic mode? Is displayed in upper line. • no/yes is displayed on the lower line. 4. Press right (a) arrow to select yes. Press select (b). Figure 3.177: m155 diagnostic functions 5. Press select (d) until activate functions? Is displayed on the upper...

Page 155

Operator’s station testing the header tilt activate function using the cab display module (cdm) note: • the header must be attached to the windrower to perform this procedure. The cab display module (cdm) automatically adjusts its programming for each header. For more information, refer to 4.5 attac...

Page 156

Operator’s station 5. Press select (d) until activate functions? Is displayed on the upper line. • no/yes is displayed on the lower line. 6. Press right (c) arrow to select yes. Press select (d). Figure 3.182: m155 functions caution check to be sure all bystanders have cleared the area. 7. Press sel...

Page 157

Operator’s station 1. Turn ignition key to run, or start the engine. 2. Press program (a) and select (c) on cab display module (cdm) to enter programming mode. • windrower setup? Is displayed on the upper line. Figure 3.184: m155 cdm programming buttons 3. Press select (b) until diagnostic mode? Is ...

Page 158

Operator’s station 7. Press select (d) until activate reel f/a is displayed on the upper line. • fore/aft is displayed on the lower line. 8. Press and hold left (b) arrow to move reel forward. Press and hold right (c) arrow to move reel backward. Verify reel fore-aft is functioning properly. 9. Pres...

Page 159

Operator’s station 3. Press select (b) until diagnostic mode? Is displayed in upper line. • no/yes is displayed on the lower line. 4. Press right (a) arrow to select yes. Press select (b). Figure 3.189: m155 diagnostic functions 5. Press select (b) until activate functions? Is displayed on the upper...

Page 160

Operator’s station note: holding the right arrow activates a timed purge cycle. The cdm will jump to the exit menu if the arrow is released before the end of the timed cycle. 9. Press and hold right (a) arrow to activate purge cycle. • purge cycle started will display on the upper line. 10. When pur...

Page 161

Operator’s station 3. Press select (b) until diagnostic mode? Is displayed in upper line. • no/yes is displayed on the lower line. 4. Press right (a) arrow to select yes. Press select (b). Figure 3.194: m155 diagnostic functions 5. Press select (b) until activate functions? Is displayed on the upper...

Page 162

Operator’s station testing the draper drive circuit activate function using the cab display module (cdm) important: do not over-speed a drive for a significant length of time. Doing so can lead to vibration, belt failures. Or other over-speeding related problems. Note: • a draper header must be atta...

Page 163

Operator’s station 5. Press select (b) until activate functions? Is displayed on the upper line. • no/yes is displayed on the lower line. 6. Press right (a) arrow to select yes. Press select (b). • activate header ht is displayed on the upper line. Figure 3.199: m155 functions caution check to be su...

Page 164

Operator’s station 1. Turn ignition key to run, or start the engine. 2. Press program (a) and select (c) on cab display module (cdm) to enter programming mode. • windrower setup? Is displayed on the upper line. Figure 3.201: m155 cdm programming buttons 3. Press select (b) until diagnostic mode? Is ...

Page 165

Operator’s station caution check to be sure all bystanders have cleared the area. 7. Press select (e) until reel drv spd xxxx is displayed on the upper line. Important: do not over speed the reel. 8. Press and hold hazard (c) button. • press left (b) arrow to decrease reel speed. • press right (d) a...

Page 166

Operator’s station 3. Press select (b) until diagnostic mode? Is displayed in upper line. • no/yes is displayed on the lower line. 4. Press right (a) arrow to select yes. Press select (b). Figure 3.206: m155 diagnostic functions 5. Press select (b) until activate functions? Is displayed on the upper...

Page 167

Operator’s station testing the double windrower attachment (dwa) drive activate function using the cab display module (cdm) important: do not over-speed a drive for a significant length of time. Doing so can lead to vibration, belt failures, or other over-speeding related problems. Note: • dwa must ...

Page 168

Operator’s station 5. Press select (b) until activate functions? Is displayed on the upper line. • no/yes is displayed on the lower line. 6. Press right (a) arrow to select yes. Press select (b). • activate header ht is displayed on the upper line. Figure 3.211: m155 functions 7. Press select (e) un...

Page 169: Operation

4 operation 4.1 owner/operator responsibilities caution • it is your responsibility to read and understand this manual completely before operating the windrower. Contact your dealer if an instruction is not clear to you. • follow all safety messages in the manual and on safety signs on the machine. ...

Page 170: 4.2

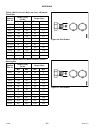

Operation 4.2 symbol definitions the following symbols are used to depict functions or reactions at the various instruments and controls. Learn the meaning of these symbols before operating the windrower. 4.2.1 engine functions these are the symbols that are used on the console. Figure 4.1: engine f...

Page 171

Operation 4.2.2 windrower operating symbols these are the symbols used on the console for windrower operation. Figure 4.2: windrower operating symbols a - turn signals b - hazard warning lights c - forward d - neutral e - reverse f - headlights low beam g - headlights high beam h - work light j - li...

Page 172

Operation 4.2.3 header functions figure 4.3: header function symbols a - program b - header index c - return to cut d - conveyor/auger speed e - float left f - float right g - reel speed h - disc speed j - reel down k - reel forward l - reel up m - reel rearward n - display select o - dwa down p - d...

Page 173: 4.3

Operation 4.3 operating the windrower 4.3.1 operational safety caution follow these safety precautions: • wear close fitting clothing and protective shoes with slip resistant soles. • remove foreign objects from the machine and surrounding area. • carry with you any protective clothing and personal ...

Page 174

Operation 4.3.2 break-in period the windrower is ready for normal operation. However there are several items to check and watch out for during the first 150 hours. In addition to the following, perform the items specified in break-in inspections, page 426 . Danger before investigating an unusual sou...

Page 175

Operation d. Adjust tension on air conditioning (a/c) compressor belt. Refer to tensioning air conditioner (a/c) compressor belt, page 367 . E. Distribute a/c refrigerant by cycling a/c switch. Refer to air conditioning compressor coolant cycling, page 159 . F. Check the entire a/c system for leakag...

Page 176

Operation 4.3.5 engine operation starting the engine danger • avoid possible injury or death from a runaway machine. • this machine has safety devices which allow the engine to start only when the ground speed lever is in n-detent, the steering wheel is locked in the neutral position, and the header...

Page 177

Operation 2. Ensure lock (a) at the base of the steering column is engaged at cab-forward or engine-forward position. 3. Move ground speed lever (gsl) (b) into n-detent. 4. Turn steering wheel until it locks. It may be possible to move the steering wheel slightly in the locked position. Important: d...

Page 178

Operation important: • do not operate starter for longer than 15 seconds at a time. • if engine does not start, wait at least two minutes before trying again. • after the third 15 second crank attempt, allow solenoid to cool for 10 minutes before further cranking attempts. If engine still does not s...

Page 179

Operation engine intermediate speed control (isc) the engine operating speed can be programmed to enable the windrower to operate at reduced engine rpm (that is, 1800, 2000, or 2200 rpm) without significantly affecting the ground or header speeds. The default setting is 2200 rpm or the last selected...

Page 180

Operation warning • to avoid personal injury or death from explosion or fire, do not smoke or allow flame or sparks near fuel tank when refueling. • never refuel the windrower when the engine is hot or running. Caution do not allow tank to empty. Running out of fuel can cause air locks and/or contam...

Page 181

Operation engine oil pressure the nominal engine oil pressure is 10 psi (69 kpa) at low idle and 55.1 psi (380 kpa) at maximum rated speed. If the oil pressure drops below the preset level of 7.5 psi (52 kpa), the cab display module (cdm) flashes an error code and error message. If the stop engine l...

Page 182

Operation warning • avoid driving the machine with header removed. Removing header decreases the weight on drive wheels, reducing steering control. • if necessary to drive machine with header removed, use transmission field speed range, do not exceed 1500 rpm engine speed, and avoid loose gravel and...

Page 183

Operation entering and exiting the windrower caution to provide more secure hand and foot mobility, preventing slipping and possible injury, always face the windrower and use the hand rail when dismounting (or mounting). Never attempt to get on or off a moving windrower. Before leaving the operator'...

Page 184

Operation driving forward in cab-forward mode caution operate both steering wheel and ground speed lever slowly for familiarization. Avoid the common tendency of new operators to oversteer. Warning do not drive windrower on road in cab-forward configuration, unless it is equipped with the proper lig...

Page 185

Operation important: the windrower can be equipped with an automatic steering system for use in the field. An automated steering system is available as an option and can be installed by a macdon dealer. The gsl has been pre-wired at the factory with a switch. Refer to 7.1.2 automated steering system...

Page 186

Operation driving forward in engine-forward mode in the engine-forward mode, the operator’s station is facing toward the engine. If necessary, swivel operator’s station to engine-forward position as follows: figure 4.20: engine-forward – seat faces engine 1. Place ground speed lever (gsl) (a) in n-d...

Page 187

Operation caution operate both steering wheel and ground speed lever slowly while becoming familiar with the machine. Remember that steering is more sensitive when speed-range control is in road speed position. Avoid the common tendency of new operators to oversteer. 8. If more tractive (lugging) po...

Page 188

Operation caution check to be sure all bystanders have cleared the area. 3. Move the ground speed lever (gsl) (c) rearward to desired speed. 4. Steer as shown. Figure 4.25: steering the windrower spin turning hydrostatic steering provides significantly more manoeuvrability than mechanical steering. ...

Page 189

Operation 1. Slowly return the ground speed lever (gsl) (a) to neutral and into n-detent. 2. Turn steering wheel until it locks. 3. Move throttle lever (b) to low idle position. Note: avoid unnecessary idling. Stop engine if it will be idling for longer than five minutes. Note: brakes are automatica...

Page 190

Operation adjust the caster tread width as follows: 1. Raise rear of windrower slightly so that most of the weight is off the casters, using a jack or other lifting device under the frame at (a). Note: lifting device should have a lifting capacity of at least 5000 lb (2270 kg). 2. Remove six bolts (...

Page 191

Operation 4. Line up holes then install shorter bottom bolts (b). 5. Position bracket (a) and install back bolts (c). 6. Tighten bolts as follows: a. Snug bottom bolts (b), then snug back bolts (c). B. Tighten and torque back bolts (c) to 330 ft lbf (447 n·m). C. Tighten and torque bottom bolts (b) ...

Page 192

Operation caution check local laws for width regulations and lighting and marking requirements before transporting on roads. Before driving windrower on a roadway: 1. Ensure header drive switch (a) is pushed to off position (down). 2. Clean flashing amber lamps, red tail and head lamps, and check th...

Page 193

Operation 8. Set ground speed range switch (a) for road speed. Cdm will display road gear at (f) if windrower is in engine-forward mode. Note: windrower can be moving, but speed must be less than 5 mph (8 km/h) for road gear to engage. 9. Slowly push throttle (b) to full forward (operating speed). C...

Page 194

Operation towing header with windrower the windrower can be used to tow a macdon draper header that has the slow speed transport option installed. Ensure the optional weight box or an approved header transporter is installed on the windrower to transfer weight to the lift arms. Warning • a windrower...

Page 195

Operation danger to avoid bodily injury from fall of raised header, always engage safety props when working on or around raised header, and before going under header for any reason. 1. Set header on the ground (field position). 2. Disconnect the following hydraulic and electrical connections: a. Lef...

Page 196

Operation 7. Remove float pin from engaged position (a) and insert in storage location (b). Secure with lynch pin. Figure 4.40: lift arms 8. Remove pins (a) from lower end of lift linkages. Note: pins (a) are also used to secure weight box to windrower linkage. 9. Release the safety props on the hea...

Page 197

Operation disconnect the center-link as follows: 13. To unlock the center-link, pull up on latch (a) and position latch into notch (b) on top of hook. 14. Lift center-link off header pin. Note: if center-link self-alignment kit is installed, start engine and raise center-link with the reel up switch...

Page 198

Operation 3. Disconnect wiring connector (a) at front wheel. Figure 4.46: header transport wheel 4. Remove clevis pin (d). 5. Push latch (c) and lift tow-bar (a) from hook. Release latch and replace clevis pin. 6. Unhook tow-bar from weight box. Figure 4.47: header transport wheel caution check to b...

Page 199

Operation 12. Move float pins from working hole location (a) to disengage the float and store pins at storage hole location (b). Important: to prevent damage to the lift system when lowering header lift linkages without a header or weight box attached to windrower, ensure that float engagement pin i...

Page 200

Operation attaching header transport hitch to header attach header transport hitch to header as follows: 1. Position end (a) of the aft section onto front wheel hook (b). 2. Push down until latch (c) captures the end (a). 3. Secure latch (c) with clevis pin (d). Figure 4.52: transport hitch 4. Remov...

Page 201

Operation 6. Fully insert l-pin (a) in upper hole and turn pin to lock it. Secure with ring pin (b). 7. Make electrical connection at the joint (c). Figure 4.55: transport hitch 8. Make the electrical connection at the header wheel (a). Figure 4.56: header transport wheel important: to prevent damag...

Page 202

Operation 9. Drive windrower so that windrower lift arms are positioned into the weight box pockets. 10. Raise lift arms slightly, install locking pins (a) into pockets, and through windrower header lift linkages. Secure with hairpin. Note: pins (a) were previously removed from the header lift linka...

Page 203

Operation 14. Start engine and press header down switch (a) on ground speed lever (gsl) to lower lift arms until the lift arm lifts away from the linkage at the rear of the lift arm. Figure 4.61: gsl 15. Attach slow speed transport hitch to the weight box tongue with drawbar pin. Secure using lynch ...

Page 204

Operation danger to avoid bodily injury from fall of raised header, always engage safety props when working on or around raised header, and before going under header for any reason. 1. Set header on the ground (field position). 2. Disconnect the following hydraulic and electrical connections: a. Lef...

Page 205

Operation 7. Remove float pin from engaged position (a) and insert in storage location (b). Secure with lynch pin. Figure 4.66: lift arms 8. Remove pins (a) from lower end of lift linkages. Note: pins (a) are also used to secure weight box to windrower linkage. 9. Release the safety props on the hea...

Page 206

Operation disconnect the center-link as follows: 13. To unlock the center-link, pull up on latch (a) and position latch into notch (b) on top of hook. 14. Lift center-link off header pin. Note: if center-link self-alignment kit is installed, start engine and raise center-link with the reel up switch...

Page 207

Operation warning with final drives disengaged, the windrower may roll on a sloped surface. Before disengaging final drives, attach windrower to towing vehicle. After towing, engage drives and ensure ground speed lever (gsl) is in n-detent before detaching from towing vehicle. Figure 4.72: correct t...

Page 208

Operation caution never operate engine in a closed building. Proper ventilation is required to avoid exhaust gas hazards. Caution remember when working around storage batteries that all of the exposed metal parts are live. Never lay a metal object across the terminals because a spark and short circu...

Page 209: 4.4

Operation 4.4 operating with a header the m155 self-propelled windrower is designed to operate with a macdon a-series auger header, r-series rotary header, or d-series rigid draper header with or without a hay conditioner. This section describes the attachment and detachment procedures and operating...

Page 210

Operation 3. Pull lever (a) and rotate toward header to lower safety prop (b) onto cylinder. Repeat for opposite cylinder. Figure 4.75: safety prop 4. Disengage safety props by turning lever (a) away from header to raise safety prop until lever locks into vertical position. Repeat for opposite cylin...

Page 211

Operation 4.4.2 header float the header float feature allows the header to closely follow ground contours and respond quickly to sudden changes or obstacles. The float setting is ideal when the cutterbar is on the ground with minimal bouncing, scooping, or pushing soil. Important: • set header float...

Page 212

Operation figure 4.77: cab display module (cdm) float adjustment a - cdm display b - left float adjustment c - right float adjustment d - header tilt down e - header lower f - header tilt up check header float as follows: danger to avoid bodily injury or death from unexpected startup of the machine,...

Page 213

Operation header force required to lift header at the ends with lift cylinder fully retracted auger 75–85 lbf (335–380 n) rotary 95–105 lbf (426–471 n) draper 75–85 lbf (335–380 n) with stabilizer/transport wheels raised (if equipped) adjusting float using drawbolts coarse float adjustment is done u...

Page 214

Operation float options for draper headers without the deck shift option, auger headers, and rotary headers, the float can be preprogrammed for three types of windrowing conditions. Example: • position 1: border • position 2: normal • position 3: rocky set float presets as follows: 1. Engage header....

Page 215

Operation 6. Select a second preset with the float preset 2 switch (c). 7. Repeat steps 1., page 198 and 2., page 198 to set the float. 8. Select a third preset with the float preset 3 switch (d). 9. Repeat steps 1., page 198 and 2., page 198 to set the float. 10. Operate windrower. Note: for draper...

Page 216

Operation 2. Park windrower on level ground. 3. Raise header fully and hold momentarily to allow lift cylinders to rephase. Figure 4.84: ground speed lever (gsl) 4. Set header approximately 6 in. (150 mm) off ground and check that member (a) is against link (b). Stop engine and remove key from ignit...

Page 217

Operation 8. Start engine and lower header onto ground until member (a) lifts off link (b) on both sides. 9. Stop engine and remove key. Figure 4.87: lift linkage 10. On high side, remove nut, washer, and bolt (a) that attaches shims (b) to link. 11. Remove one or both shims (b) and reinstall the ha...

Page 218

Operation 4.4.4 header drive all header controls are conveniently located on the operator’s console and on the ground speed lever (gsl) handle. Note: some controls are optional equipment and may not be present in your unit. Some controls may be installed, but will be nonfunctional for certain header...

Page 219

Operation reversing the header note: the optional hydraulic reversing kit must be installed. Important: hose plumbing to the reverser block is specific to the header type. To prevent damage to the reel on d-series headers, refer to the reverser kit installation instruction md# 169213 when switching ...

Page 220

Operation figure 4.92: operator console a - program button b - display c - header tilt down d - header tilt up e - display selector hydraulic link (optional) adjust the header angle as follows: • to decrease (flatten) header angle, operate header tilt up switch (d) on ground speed lever (gsl) handle...

Page 221

Operation mechanical link adjust header angle as follows: 1. Lower header to ground, shut down windrower and remove key from ignition. 2. Loosen nut (a) on center-link. • to increase (steepen) angle, rotate barrel (b) to lengthen center-link. • to decrease (flatten) angle, rotate barrel (b) to short...

Page 222

Operation 4. Push up on actuator rod and lock pin should lift with the handle. Figure 4.96: center-link hook 4.4.6 cutting height figure 4.97: operator console cutting height is adjusted by raising or lowering the header with the header up (b) or header down (c) switches on the ground speed lever (g...

Page 223

Operation 4.4.7 return to cut the m-series monitoring system will assist you in maintaining the desired cutting height with the return to cut feature. This feature can be turned off or on with a switch on the cab display module (cdm). The return to cut (rtc) feature provides preset cutting height an...

Page 224

Operation 4. Adjust the header angle with the header tilt up (e) or header tilt down (f) switches on the gsl. The cdm displays between 00.0 and 10.0. This step is not required when height only has been preselected. 5. Press the return to cut switch (a) on the cdm. The indicator light will illuminate...

Page 225

Operation note: if the header cannot return to the preset height or angle within 30 seconds, the return to cut feature will deactivate to prevent the hydraulic oil from overheating. Push the return to cut switch (a) to reactivate. 4.4.8 auto raise height the header can be automatically raised if pro...

Page 226

Operation 4. Press right arrow (d), then select. Set knife speed? Is displayed. 5. Press select (c) until auto raise height is displayed. 6. Press left arrow (e) or right arrow (d) to change value on lower line. Working range is 4.0 to 9.5. At 10.0, the feature is disabled and “off” is displayed. 7....

Page 227

Operation 4.4.10 double windrowing the double windrow attachment (dwa) deposits two windrows of conditioned material close together to be picked up by a forage chopper. The system is for use with the a-series auger header, r-series rotary disc header, and d65 draper header with hc10 hay conditioner....

Page 228

Operation double windrow attachment (dwa) draper speed the draper speed is controlled with the rotary switch (a) next to the rocker switch on the operator’s console. Figure 4.105: operator’s console 4.4.11 swath roller operation the swath roller is raised and lowered with the dwa up (a) and dwa down...

Page 229: 4.5

Operation 4.5 attaching and detaching headers 4.5.1 attaching a d-series header d50, d60, and d65 headers can be attached to an m155 or m205 self-propelled windrower. For attachment procedure, refer to the section for your specific windrower model. Refer to the following instructions based on the ty...

Page 230

Operation 2. Position boot (b) onto lift linkage (a) and reinstall pin (c). Pin may be installed from either side of boot. 3. Secure pin (c) with hairpin (d). 4. Repeat for opposite side. Figure 4.110: header boot attaching a d-series header: hydraulic center-link with optional self-alignment note: ...

Page 231

Operation caution check to be sure all bystanders have cleared the area. Important: remove protective cover from exhaust stack prior to starting engine. 2. Start the engine and activate the header down button (a) on the ground speed lever (gsl) to fully retract header lift cylinders. Figure 4.112: g...

Page 232

Operation 6. Use the following gsl functions to position the center-link hook above the header attachment pin: • reel up (a) to raise the center-link • reel down (b) to lower the center-link • header tilt up (c) to retract the center-link • header tilt down (d) to extend the center-link figure 4.115...

Page 233

Operation 11. Engage safety props on both lift cylinders as follows: a. Stop engine and remove key from ignition. B. Pull lever (a) and rotate towards the header to release and lower safety prop (b) onto the lift cylinder. C. Repeat for opposite lift cylinder. Figure 4.118: safety prop 12. Install p...

Page 234

Operation 14. Remove clevis pin from storage position (b) in linkage and insert into hole (a) to engage float springs. Secure with hairpin. Figure 4.120: header float linkage 15. Disengage safety prop by turning lever (a) downwards to release and lower stop until lever locks into vertical position. ...

Page 235

Operation 19. Connect header drive hoses (a) and electrical harness (b) to header. Refer to the draper header operator’s manual. Figure 4.123: header drive hoses and harness 20. Connect reel hydraulics (a) at right cab-forward side of windrower. Refer to the draper header operator’s manual. Figure 4...

Page 236

Operation 1. Remove hairpin (a) from pins (b), and remove pins from both header legs. Figure 4.125: header leg caution check to be sure all bystanders have cleared the area. Important: remove protective cover from exhaust stack prior to starting engine. 2. Start the engine and activate the header do...

Page 237

Operation 4. Drive the windrower slowly forward until the boots (a) enter the header legs (b). Continue driving slowly forward until lift linkages contact the support plates in the header legs and the header nudges forward. 5. Ensure the lift linkages are properly engaged in the header legs and are ...

Page 238

Operation caution check to be sure all bystanders have cleared the area. 10. Start the engine. 11. Press the header up switch (a) to raise header to maximum height. Note: if one end of the header does not fully raise, rephase the lift cylinders as follows: a. Press and hold the header up switch unti...

Page 239

Operation 13. Install pin (b) through the header leg (engaging u-bracket in lift linkage) on both sides and secure with hairpin (a). 14. Raise header stand (d) to storage position by pulling spring pin (c) and lifting stand into uppermost position. Release spring pin. Figure 4.133: header leg 15. Re...

Page 240

Operation caution check to be sure all bystanders have cleared the area. 18. Start the engine and activate the header down switch (a) on the gsl to fully lower the header. 19. Stop engine and remove key from ignition. Figure 4.136: gsl 20. Connect header drive hoses (a) and electrical harness (b) to...

Page 241

Operation attaching a d-series header: mechanical center-link note: draper header boots must be installed onto the windrower lift linkage before starting this procedure. Refer to attaching header boots, page 213 . Danger to avoid bodily injury or death from unexpected startup of the machine, always ...

Page 242

Operation 3. Drive the windrower slowly forward until the boots (a) enter the header legs (b). Continue driving slowly forward until lift linkages contact the support plates in the header legs and the header nudges forward. 4. Ensure the lift linkages are properly engaged in the header legs and are ...

Page 243

Operation 11. Engage safety props on both lift cylinders as follows: a. Stop engine and remove key from ignition. B. Pull lever (a) and rotate towards the header to release and lower safety prop (b) onto the lift cylinder. C. Repeat for opposite lift cylinder. Figure 4.144: safety prop 12. Install p...

Page 244

Operation 14. Remove clevis pin from storage position (b) in linkage and insert into hole (a) to engage float springs. Secure with hairpin. Figure 4.146: header float linkage 15. Disengage safety prop by turning lever (a) downwards to release and lower stop until lever locks into vertical position. ...

Page 245

Operation 19. Connect header drive hoses (a) and electrical harness (b) to header. Refer to the draper header operator’s manual. Figure 4.149: header drive hoses and harness 20. Connect reel hydraulics (a) at right cab-forward side of windrower. Refer to the draper header operator’s manual. Figure 4...

Page 246

Operation detaching a d-series header: hydraulic center-link danger to avoid bodily injury or death from unexpected startup of the machine, always stop the engine and remove the key from the ignition before leaving the operator’s seat for any reason. 1. Start engine and press header up (a) switch to...

Page 247

Operation 5. Remove the pin (b) by removing the hairpin (a) from header leg on both sides. 6. Lower header stand (d) by pulling spring loaded pin (c). Release spring pin to lock stand. Figure 4.153: header stand 7. Remove clevis pin from location (a) to disengage float springs and insert in storage ...

Page 248

Operation 10. Disconnect header drive hydraulics (a) and electrical harness (b) from header and store in support on windrower left cab-forward side. Refer to the draper header operator’s manual for further information. Figure 4.156: header drive hydraulics 11. Disconnect reel hydraulics (a) from hea...

Page 249

Operation 13. Disconnect center-link by lifting release (b) and lift hook (a) off header. Note: if optional center-link self-alignment kit is installed, lift release (b) and then operate the link lift cylinder with reel up switch on gsl to disengage the center-link from the header. Note: if hay cond...

Page 250

Operation 4. To engage the safety props, pull lever (a) and rotate toward header to lower safety prop (b) onto cylinder. Repeat for the opposite cylinder. Figure 4.162: safety prop 5. Remove the clevis pin (b) by removing hairpin (a) from header leg on both sides. 6. Lower header stand (d) by pullin...

Page 251

Operation 7. Remove the clevis pin from location (a) to disengage float springs and insert in storage hole (b). Secure with lynchpin. Caution to prevent damage to the lift system when lowering header lift linkages without a header or weight box attached to the windrower, ensure the float engagement ...

Page 252

Operation 11. Disconnect reel hydraulics (a) from header and store on bracket at windrower left cab-forward side. Refer to the draper header operator’s manual for further information. Figure 4.167: reel hydraulics 12. Loosen nut (a) and rotate barrel (b) to relieve load on link. 13. Remove cotter pi...

Page 253

Operation 4.5.3 attaching an a-series header a30-d, a30-s, and a40-d headers can be attached to an m155 or m205 self-propelled windrower. For attachment procedure, refer to the section for your specific windrower model. Refer to the following instructions based on the type of center-link installed o...

Page 254