- DL manuals

- Mach

- Kitchen Appliances

- 403.002

- Installation, Use And Maintenance Manual

Mach 403.002 Installation, Use And Maintenance Manual

Summary of 403.002

Page 1

1 403002-04-05-07-08-09-10_en_ma_201 1 gravity slicers 403.008 403.002 403.010 403.004 403.007 403.009 403.005 installation use and maintenance manual.

Page 2: Contents

2 403002-04-05-07-08-09-10_en_ma_201 1 contents foreword ................................................................................................................3 scope of this manual .......................................................................................3 general information...

Page 3: Foreword

3 403002-04-05-07-08-09-10_en_ma_201 1 foreword scope of this manual this manual contains all the necessary information to install, use and service the gravity slicers for food (please see models in paragraph "technical description"). The scope of this document, hereinafter the "manual", is to permi...

Page 4: Plates – Conformity Marks

4 403002-04-05-07-08-09-10_en_ma_201 1 manufacturer's warranty and liability the manufacturer's warranty covering the good functioning of the machines and their compliance to the service for which they have been designed depends on the correct application of the instructions contained in this manual...

Page 5: Packing

5 403002-04-05-07-08-09-10_en_ma_201 1 packing opening the box on reception check packaging integrity, otherwise inform the forwarding agent or the area agent immediately. To unpack the machine, proceed as follows: open the box and remove your copy of the manual of use and maintenance, then procee...

Page 6: Technical Description And

6 403002-04-05-07-08-09-10_en_ma_201 1 technical description and proposed conditions of use general description the machine is essentially made of a base supporting a circular blade mounted in tilted position. This blade is driven by an electrical motor to slice foodstuffs. The machine is equipped w...

Page 7: Main Technical Data

7 403002-04-05-07-08-09-10_en_ma_201 1 dimensions main technical data gravity slicers intermittent service (5 min. Pause every 15-20 min. Of work) only for 403008. All the other machines have a ventilated motor. Version 403008 403007 403009 403002 403010 403004 403005 motor hp 0,20 0,25 0,30 0,35 0,...

Page 8

8 403002-04-05-07-08-09-10_en_ma_201 1 supplied literature and accessories if not otherwise defined at the moment of order, the machines are supplied together with the following: eu conformity declaration instructions manual for installation, use and maintenance. Products that can be sliced al...

Page 9: Main Components I

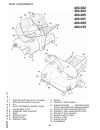

9 403002-04-05-07-08-09-10_en_ma_201 1 main components i 403.008 1. Startup button (green) 2. Stop button (red) 3. N.A. 4. Slice thickness control knob 5. Adjustable foot 6. Carriage tray support 7. Base 8. Product tray 9. Blade plate 10. Product grip 11. Blade 12. Product grip handle 13. Manufactur...

Page 10: 403.007

10 403002-04-05-07-08-09-10_en_ma_201 1 main components 403.007 403.002 403.009 403.004 403.005 1. Startup button (white or green) 2. Stop button (red or black) 3. N.A. 4. Slice thickness control knob 5. Adjustable foot 6. Carriage tray support 7. Base 8. Product tray 9. Blade plate 10. Product grip...

Page 11: Installing The Machine

11 403002-04-05-07-08-09-10_en_ma_201 1 machine commissioning and function tests installing the machine position the machine on a well leveled, smooth and dry top suitably dimensioned to withstand the machine weight. Electrical connection install the machine near a eu compliant outlet derived from a...

Page 12: Commands

12 403002-04-05-07-08-09-10_en_ma_201 1 commands start and stop buttons press the white or green button (1) to start running the blade. the light turns on to indicate that the machine works correctly. press the red or black button to stop the blade. Slice thickness can be adjusted by turning t...

Page 13: Using The Machine

13 403002-04-05-07-08-09-10_en_ma_201 1 using the machine loading the product on the tray and slicing ascertain that the thickness control knob is correctly positioned to '0'. draw back the carriage completely (towards the operator) to loading position. lift the product grip by pulling it away...

Page 14: Cleaning The Slicer

14 403002-04-05-07-08-09-10_en_ma_201 1 cleaning the slicer general the machine must always be accurately cleaned at least once a day, and more often if necessary. Always use protective gloves. Disassembling the machine for cleaning disconnect the plug from the mains; turn the gauge plate know t...

Page 15: Reassembling The Machine

15 403002-04-05-07-08-09-10_en_ma_201 1 reassembling the machine proceed as indicated for the previous operations but in reverse order. Maintenance general the operator is allowed to perform the following maintenance operations: blade sharpening: regularly (intervals and duration obviously depend ...

Page 16: Sharpening

16 403002-04-05-07-08-09-10_en_ma_201 1 sharpening models with separate sharpener 1. Clean the blade accurately using denaturized alcohol to degrease it. 2. Turn the graduated knob (1) towards the left to open completely. 3. Remove the sharpener from its box, unscrew the knurled knob and insert the ...

Page 17: Sharpening

17 403002-04-05-07-08-09-10_en_ma_201 1 sharpening versions with built-in sharpener to sharpen the blade periodically as soon as the cutting capacity decreases. Please proceed as per the following instructions: 1. After disconnecting form the mains, clean the blade accurately using denaturized alcoh...

Page 18: Lubrication

18 403002-04-05-07-08-09-10_en_ma_201 1 lubrication carriage sliding guides product grip (once a week) use only the oil provided, otherwise use white vaseline oil. Do not use vegetal oils. spread a small quantity of oil on the bar and move the assembly 3 or 4 times. clean as required to remove e...

Page 19

19 403002-04-05-07-08-09-10_en_ma_201 1 adjusting the motor belt tension after a given period of service an unusual noise may occur because of the belt bedding. In this case, tighten the belt-stretcher on the side of the motor under the machine base..

Page 20

20 403002-04-05-07-08-09-10_en_ma_201 1 troubleshooting and remedies the table below indicates the most common problems that may arise during slicing and the necessary remedies. Problem possible cause remedy the machine does not start when the green button is pressed no power supply the blade guard ...

Page 21: Dismantling The Slicer

21 403002-04-05-07-08-09-10_en_ma_201 1 dismantling the slicer these machines are made of the following elements: aluminium frame; stainless steel fittings and others; electrical parts and cords; electrical motor; plastic materials, etc. Whether dismantling is entrusted to third parties or...

Page 22: (Versions 403.002-7-8-9)

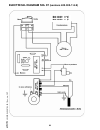

22 403002-04-05-07-08-09-10_en_ma_201 1 electrical diagram sig. 97 (versions 403.002-7-8-9) mod. 403.008 6,3 µf mod. 403.007 8 µf mod. 403.009 8 µf.