- DL manuals

- Mackie

- Speakers

- SRM 450

- Service Manual

Mackie SRM 450 Service Manual

Summary of SRM 450

Page 1

Srm450 powered speaker service manual 1999, 2000 mackie designs, inc. 820-184-00 page 3 is interactive go to bulletins.

Page 2

2 service on this equipment is to be performed by experienced repair technicians only.

Page 3: Contents

3 contents introduction ..................................................................... 3 block diagram .................................................................. 4 specifications ................................................................... 5 overview ..............................

Page 4

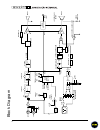

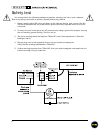

4 block diagram input thr u 1 j15 1 hi-p ass lo w cut cont our compressor threshold compressor sweeping fil ter lo-p ass dela y 176us hi-freq 40-120 hz lo-freq uency driver tweet lo-freq amp hi-freq amp sense resist or bass contr ol ser v o loop w oof peak light peak detection threshold lpf threshol...

Page 5

5 specifications low-frequency transducer diameter 300mm (12”) voice coil diameter 63.5mm (2.5”) sensitivity (1w@1m) 98 db nominal impedance 8 ohms power handling 300w frequency range 50hz – 3000hz high-freq driver and horn diaphragm diameter 44.5mm (1.75”) exit throat diameter 24.5mm (1”) diaphragm...

Page 6

6 overview the srm450 is an active two-way loudspeaker system capable of extremely high sound pressure levels. The transducers the srm450 active monitors feature a 12” high-power low-frequency woofer and a 1.75” titanium diaphragm high-output precision compression driver. This high frequency driver ...

Page 7

7 the crossover the built-in electronic crossover is a 24 db/octave linkwitz-riley design. Although more expensive than other crossover designs, the benefits provided by the linkwitz-riley design have been well documented. These benefits include: • absolutely flat frequency response throughout the b...

Page 8

8 you must perform the following leakage test before returning the unit to your customer. Take every safety precaution to protect yourself while doing this test. 1. Make a small loading rc circuit as shown in the diagram below, and connect the ac volt meter between the ac power source ground and any...

Page 9

9 bias adjustment 1. Place the srm450 on its side so that the heatsink fins are horizontal. 2. Connect the power cord and turn it on, with no input signal applied. Make sure that the timed turnoff switch is off. 3. Let it sit this way for an hour or more to allow the heatsink temperature to rise. Yo...

Page 10

10 lo w freq uency bias test point lo w freq uency bias adjustment po t high freq uency bias test point high freq uency bias adjustment po t +80v +15 vdc -15 vdc -80v +45v -45v.

Page 11

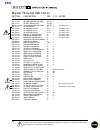

A-1 part# description pages 090-132-xx master parts a-2 080-136-00 cabinet subassembly a-3 055-227-00 main board a-4 srm-450 parts list parts numbering guide 040- cables 055- finished pcb assy 100- pots and resistors 200- capacitors 300- semiconductors 400- jacks/connectors 500- switches 510- fuses ...

Page 12: 247B

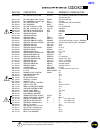

A-2 part no. Description rev qty notes 090-132-00 srm450 120v 9 a3 1 080-112-00 sa htsk/xfmr/bd 12in spkr b1 a2 1 080-112-01 sa amp srm450 230v a2 a2 1 055-227-00-02 pcb assy srm450 amplifier 2c a2 1 see page a-4 080-137-00 sa sw srm450 b 1 080-138-00 sa xfmr 600-034-00 b a1 1 for 120v units 080-138...

Page 13

A-3 part no. Description rev qty notes 055-280-00 pcb assy led 1 080-156-00 sa cable pcb led blk/wht 1 080-157-00 sa support driver throat 1 080-158-00 sa harness blu & blu/blk 1 080-159-00 wire yel woofer 1 490-025-00 comp driver 1 comp driver 490-042-00 woofer srm450 1 woofer 490-047-00 srm front ...

Page 14: 227C

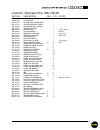

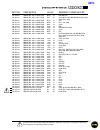

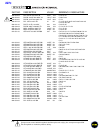

A-4 055-227-00 main pcb assembly 227c part no. Description value reference designators 040-311-00 dis 18ga 1010 gnyl 5 hklg p1 100-084-00 res cf .125w 5% 30k ohm 30k 5% r189 r215 105-464-00 res mf .125w 1% 60k4 ohm 60k4 1% r177 r203 110-025-00 res cf .25w 5% 100 ohm 100 5% r266 115-361-00 res mf .25...

Page 15: 227C

A-5 part no. Description value reference designators 227c 145-358-00 res mf sm .1w 1% 4k75 ohm 4k75 1% r42 r99-100 145-361-00 res mf sm .1w 1% 5k11 ohm 5k11 1% r3-4 r9 r11 r30 r66-69 r79-81 r102 r120 r124 r127 r142 145-369-00 res mf sm .1w 1% 6k19 ohm 6k19 1% r15 145-371-00 res mf sm .1w 1% 6k49 ohm...

Page 16: 227C

A-6 227c 200-004-02 ply .047uf 10% 100v tr 0.047 10% c130 c141 200-023-00 ply/bx .001uf 20% 250v y2 .001uf 20% c168 c169 200-024-00 ply/bx .01uf 20% 250v y2 .01uf 20% c172 200-027-02 ply .1uf 5% 100v tr 0.1 5% c118 c123 c128 c133 c136 c144-145 c152 c163-164 200-041-00 ply/fl .01uf 10% 250v 0.01 10% ...

Page 17: 227C

A-7 227c 300-003-00 dio sw dl4148 100v sm dl4148 d1-15 d19-21 d23-25 d27-31 d35 d37-41 d44 d47-48 d54 300-010-00 dio sig rls245 220v 200ma rls245 d26 d32 d34 d36 301-019-00 dio pwr brdg 25a 400v sip 25a d55-56 301-021-00 dio pwr dl4004 sm dl4004 d16 d22 d33 d42 d45 d52 d57 301-023-00 dio pwr sr505 s...

Page 18

Srm450 bias sse june 1999 1. Place the srm450 on its side so that the heatsink fins are horizontal. 2. Connect the power cord and turn it on, with no input signal applied. Make sure that the timed turnoff switch is off. 3. Let it sit this way for an hour or more to allow the heatsink temperature to ...

Page 19

The mackie fixer mackie designs service news srm450 bias sse june 1999 lo w freq uency bias test point lo w freq uency bias adjustment po t high freq uency bias test point high freq uency bias adjustment po t +80v +15 vdc -15 vdc -80v +45v -45v srm450 bias adjustment, sheet 2 of 2.

Page 20: Srm450 Pole Mount Insert

Description rev date initial release a srm450 pole mount insert rework instructions 851-033-00 rev a prepared by: ______________________________date: _____________ chad trani manufacturing engineer approved by: ______________________________date: _____________ ray vancour field service manager appro...

Page 21

Page 2 of 4 srm450 pole mount insert rework instructions note: these instructions are to be used along with mackie kit p/n 020-006-00 to repair srm450s which already have the pole mount insert stripped out. The pole mount bolt assembly (bolt, knurled brass insert and alignment bushing) must still be...

Page 22

Page 3 of 4 installation tool assembly insert installation 6) place the tool (insert first) into the pole mount hole. 7) using the small pipe, gently tap the bushing into place so it fits snug. The bushing only needs to be partially installed (as a guide) since it will be removed shortly. Remove the...

Page 23

Page 4 of 4 9) reverse the drill and back the tool out. A quick, sharp twist once you start to back the tool out will break the tool free from the insert. You do not need to remove the tool slowly as with the installation. The metal bushing will easily pull out along with the installation tool. 10) ...

Page 24: Srm450/c300 Stabilizing Feet

1 2 3 1 2 3 ©2000 mackie designs inc. All rights reserved the following are trademarks or registered trademarks of mackie designs inc.: “mackie” and the “running man” figure. Part no. 820-158-01 rev a 8/2000 srm450/c300 stabilizing feet ©2000 mackie designs inc. All rights reserved the following are...