- DL manuals

- Magicard

- Printer

- Prima 4

- User Manual

Magicard Prima 4 User Manual

Summary of Prima 4

Page 1

User manual prima500 doc no:1385 issue 1.03 ultra electronics card systems www.Magicard.Com double-sided inline laminator prima 4 driver manual 2012:layout 1 5/4/12 14:57 page 1.

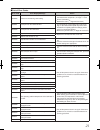

Page 2: Characteristics of This Unit

Before use characteristics of this unit this laminator attaches a protective layer to one or both sides of the card printed by the card printer. A hologram that helps to enhance the security level of the card can be formed on the protective layer. This laminator can be made to operate in conjunction...

Page 3

Read through the following carefully before operating to ensure proper use of this laminator. After reading, store this manual at a place that can be easily retrieved when necessary. Caution: changes or modifications not approved by party responsible for compliance could void user's authority to ope...

Page 4: Safety Precautions

Before use safety precautions.

Page 6: About This Manual

Before use about this manual symbols used in this manual cautions : states precautions to be taken during operation. Memo : states restrictions on the functions or use of this equipment. For reference purposes. A : indicates the page numbers or items to refer to. Contents of this manual the copyrigh...

Page 7: Capability of This Unit

Capability of this unit this laminator selects the side of the card to be laminated by the presence of the film cassette. Refer to the following table and load the film cassette to the side of the card to be laminated. Side to be laminated film cassette status top side film cassette bottom side film...

Page 8

Before use right a b c d card feed port feeds the printed card from the card printer that is connected to the laminator. Infrared window sends or receives data via infrared communication by connecting with the card printer. Filter cover remove when you want to exchange the filter. When moving the la...

Page 9: Internal Mechanism

Internal mechanism diagram o n m a c b d u t s r q p e f g h i j k l top take-up side laminate film top side laminate pressure motor top side laminate heater pressure mechanism top supply side laminate film top side laminate film supply motor top side laminate film position sensor card lamination po...

Page 10: Specifications

Before use 10 specifications main specifications item description recording system dc heat roller system transfer time approx. 22 sec. To 38 sec. (time varies according to the setting.) operating environment conditions temperature: 15 °c to 28 °c humidity: 35 % to 60 % (no condensation) storage envi...

Page 11

11 installation and connection installation location ventilation holes for the cooling fan are located at the rear of the laminator as well as the side and rear of the card printer. Allow a clearance of at least 20 cm between the sides of the laminator and the wall. Allow a clearance of at least 10 ...

Page 12: Setting Laminate Film

Setup 1 card stacker 1 hook the tab of the card stacker that is supplied with the card printer to the card stacker attachment slot a b d c card outlet card stacker attachment slot tab card stacker power cord connection 1 insert the power cord (supplied) to the ac inlet at the rear of the laminator 2...

Page 13

1 2 press and hold down the cassette button, and pull out the film cassette 3 attach the tip of the new laminate film to the bobbin place the new laminate film and the take-up bobbin side by side on a clean and flat platform. Attach the tip of the new laminate film to the take-up bob- bin using the ...

Page 14: Operation Panel

Operating the laminator 1 operation panel the status display of the laminator is displayed on the operation panel of the card printer as well as the status monitor of the computer that is connected to the card printer. The status is indicated on the laminator unit using a combination of solid and bl...

Page 15

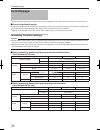

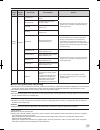

1 laminator status, led display and card printer’s operation panel display laminator status led display (red) led display (blue) card printer operation panel display description initializing off blinking (slow) initializing.. Initializing in progress preheating preheating.. Adjusts the heating rolle...

Page 16

Operating the laminator 1 checking the laminator settings settings can be viewed on the card printer’s operation panel. Settings can be changed on the status monitor of the computer that is connected to the card printer. ( a page 20 “ status monitor settings ”) 1 press i enter the setting mode. R e ...

Page 17: Initializing

1 factory settings item factory settings mode laminate film-t patch film-b patch film-t pos 0 film-b pos 0 hr-t temp 140 degc hr-b temp 140 degc speed 7.0 mm/s cooling time 0sec count 0 initializing performing the operations below will reset the laminator settings. Thereafter, when the heating rolle...

Page 18: Turning On The Power

Operating the laminator 1 turning on the power 1 check to ensure that the card printer and laminator are properly connected 2 turn on the power of the laminator 3 turn on the power of the card printer cautions: turn on the power for the laminator first. If the power for the card printer is turned on...

Page 19: Firmware Update

1 firmware update setting the laminator and card printer to download mode enables you to update the firmware for the laminator by using a pc through card printer connection. 1 press and hold down the operation button, and turn on the power at the same time both the led displays are lit. 2 turn on th...

Page 20: Status Monitor Settings

Settings 0 status monitor settings what is status monitor? Status monitor is a software that displays the status for the card printer and laminator, and enables you to adjust the settings for the card printer and laminator. Start the status monitor by using a computer that is connected to the card p...

Page 21

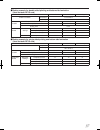

1 list of error codes error code error display message action 05000050 failure occurred during card loading. Check to ensure that the laminator is properly connected to the card printer. ( a page 11 “card printer connection”) remove the card. ( a page 32 “card jam”) ● ● 05000051 card jam near the ca...

Page 22: Printer Driver Settings

Settings [laminator] tab sheet for changing laminator settings. Basic laminate mode laminate laminates the card. Pass through passes through the card without laminating. Hr control this setting works simultaneously with the card printer setting. The default setting is [enable]. For setting whether t...

Page 23: Laminate Film

Laminate film this laminator selects the side of the card to be laminated by the presence of the film cassette. Load the film cassette to the side of the card to be laminated. Cautions: if the security lock of the card printer is on, deactivate it. After work is complete, activate the security lock ...

Page 24

Replacement 5 attach the tip of the new laminate film to the bobbin place the new laminate film and the take-up bobbin side by side on a clean and flat platform. Attach the tip of the new laminate film to the take-up bob- bin using the fixing tape. Use the fixing tape after peeling off the adhesive ...

Page 25: Card Feed Roller/heating

Film residue and dust may cause lamination defects if they are accumulated inside the laminator. Clean all parts regularly. Cautions: after cleaning is complete, check to ensure that all dismantled parts are restored to their original positions. Failure to restore the parts may result in malfunction...

Page 26

Maintenance 7 insert the cleaning card (sold separately) into the card cleaner the cleaning card is discharged from the card outlet of the laminator. 8 reverse the adhesive face of the cleaning card, and insert it into the card printer again the cleaning card is discharged from the card outlet of th...

Page 27

4 press the operation button for two seconds or longer the cleaning process starts. Cautions: the cleaning operation does not start if the heating roller is still hot. Turn off the power, and perform cleaning after the heating roller has cooled down completely. 5 peel off the backing paper from the ...

Page 28: Fan Filter

Maintenance fan filter cautions: start work after ensuring that the power has been turned off. Replace the fan filter with a new one after using it for about one year. For details on its replacement, please consult our authorized dealers. 1 remove the filter cover at the back of the laminator inlet ...

Page 29

2 remove any slack in the laminate film turn the knob on the film cassette in the direction indicated by the arrow. 3 press and hold down the cassette button, and pull out the film cassette ● 4 remove the laminate film from the film cassette 5 apply alcohol to a rag that does not produce lint easily...

Page 30: Interior of Laminator

Maintenance 0 interior of laminator dirt during card feed or burrs caused by friction between the bobbin holder and bobbin may adhere to the card or film, causing lamination defects as a result. Cautions: start work after ensuring that the power has been turned off. If the security lock of the card ...

Page 31

1 4 apply alcohol to a cotton swab (large), and use it to wipe the bobbin holder (x4) (cotton swab and alcohol: sold separately) 5 apply alcohol to a cotton swab (large), and use it to wipe the guide rail (x2) at the back cautions: do not touch the sensor and other parts inside the laminator. Doing ...

Page 32: Card Jam

Troubleshooting card jam use the jog dial to remove the card. Make use of the jog dials that are supplied with the card printer. Cautions: if the security lock of the card printer is on, deactivate it. After work is complete, activate the security lock again. For details on locking/unlocking the sec...

Page 33

6 attach the jog dial to the jog dial insertion slot 7 turn the jog dial in the anti-clockwise direction the card is discharged from the card outlet. 8 restore the jog dial to its original position 9 remove any slack in the laminate film if the film is entangled, refer to ( a page 34 “film is entang...

Page 34: Film Is Entangled

Troubleshooting film is entangled when the film cassette is taken out and the film is entangled due to the laminate film been peeled off from the film cassette or card jams, use the methods below to untangle and reattach the film. Cautions: if the security lock of the card printer is on, deactivate ...

Page 35: Misaligned Patch Position

3 attach the unused portion at the supply side to the other end at the take-up side using an adhesive tape, while making sure that the joint surface is even top side film cassette bottom side film cassette 4 turn the take-up side using your hand until the broken portion can no longer be seen top sid...

Page 36: Card Warpage

Troubleshooting card warpage during laminating, heating by the heating roller may cause warpage in cards with a low heat resistance, such as pvc ones. If card is significantly warped lowering the temperature or increasing the speed helps to reduce the heat load on the card, thus causing less warpage...

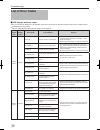

Page 37

Setting example for double-sided printing and bottom side lamination (heat-resistant pet-g card) film 1mil 0.6mil overlay ambient condition temperature 15 °c to 28 °c humidity 35 % to 60 % laminator cl-600d temperature (bottom side) 155 °c 155 °c 125 °c speed 5.0 mm/s 12.0 mm/s 5.0 mm/s cooling time...

Page 38: List of Error Codes

Troubleshooting list of error codes led displays and error codes the error codes are displayed on the operation panel of the card printer as well as the status monitor of the computer that is connected to the card printer. For error codes displayed on the status monitor, refer to page 21. Led displa...

Page 39

Led display (red) led display (blue) error code error content actions blinking (fast) light off thermistor-t 67 the top side heating roller thermistor is faulty. Turn off the power and turn it on again. If the same problem occurs, consult our authorized dealers or servicing personnel. ● thermistor-b...

Page 40

0

Page 41

Ultra electronics card systems hampshire road, weymouth, dorset dt4 9xd, united kingdom tel: +44 (0) 1305 767 100 fax: +44 (0) 1305 777 904 email: info@magicard.Com ultra electronics card systems inc. North american sales & support center 6711 - 176th avenue ne redmond, wa 98052 toll free: 877 236 0...