- DL manuals

- Magiglo

- Indoor Fireplace

- Duo Power 2

- User, Installation & Servicing Instructions

Magiglo Duo Power 2 User, Installation & Servicing Instructions

Users,

Installation & Servicing

Instructions

MUST BE LEFT WITH THE USER

DUO POWER 2

Models:

RV – Rear Venting

Fuel Effect Options:

Coal Effect

Pebble Effect

Both available on NG & LPG

Control Options:

Manual Control

Installation Options:

Installation using Freedom Surround

For use on Natural Gas (G20) at a supply pressure of 20mbar

or Propane (G31) at a supply pressure of 37mbar in GB and IE

(Dependent upon model)

Summary of Duo Power 2

Page 1

Users, installation & servicing instructions must be left with the user duo power 2 models: rv – rear venting fuel effect options: coal effect pebble effect both available on ng & lpg control options: manual control installation options: installation using freedom surround for use on natural gas (g2...

Page 2

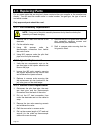

Manufacturer contact details: burley appliances ltd. Lands end way oakham, rutland, le15 6rb tel: +44 (0)1572 725570 fax: +44 (0)1572 724390 general e-mail: info@magiglo.Co.Uk web site: www.Magiglo.Co.Uk technical support: direct dial on (01572) 725570 or email: technical@magiglo.Co.Uk magiglo docum...

Page 3: Contents

Page i contents 1. General information ........................................................................................................... 1 1.1. Important note about ods pilot ................................................................................ 3 1.2. Fire fret dimensions .........

Page 4

Page ii 3.7.16. Fan unit installation ........................................................................................... 38 3.7.17. Commissioning the installation .......................................................................... 40 3.7.18. Checking for spillage .......................

Page 5: 1. G

Page 1 1. G eneral i nformation introduction 1. This appliance is suitable for installation in gb and ie and should be installed in accordance with the rules in force. In gb, the installation must be carried out by a gas safe registered installer registered for working on this type of appliance. It ...

Page 6

Page 2 reference should be made to bs 5871 part 2, and in ie reference should be made to the current edition of i.S.813 which makes clear the conditions that must be met to demonstrate that sufficient ventilation is available. 2. If provided, any purpose provided ventilation must be checked periodic...

Page 7

Page 3 1.1. Important note about ods pilot this fire is fitted with an ods pilot which causes the appliance to shut down in the event of a reduction of oxygen (e.G. Caused by poor ventilation) in the room. Should this happen, follow the lighting instructions to re-light the fire. In the event that t...

Page 8: 1.2. Fire Fret Dimensions

Page 4 1.2. Fire fret dimensions all models can be used with the burley magiglo range of frets or any other fire fret that falls within the dimensions shown below the fireplace opening must be suitable in size to accommodate the fire being installed. If the appliance is to be used with other firepla...

Page 9: 2. U

Page 5 2. U ser i nstructions 2.1. Lighting the pilot 1. Confirm that the fused spur serving this appliance is switched on, and power is available. 2. Depress and release the fan’s on button, as shown in figure 3 - you will hear the fan start at its maximum speed and the indicating neon will be illu...

Page 10: 2.3. Turning The Fan Off

Page 6 2.2. Lighting the main burner 1. Once the pilot is established, the main burner can be operated by turning the control knob anti-clockwise. The preset minimum is found with the arrow in the 9 o’clock position as shown in figure 6. 2. The preset maximum (as shown in figure 7 is found by turnin...

Page 11: 2.4. Fuel Effect Layout

Page 7 2.4. Fuel effect layout you fire has been supplied with either coal or pebble effect. Please refer to the relevant section for instructions on how to arrange the imitation fuels. Fuel effect tray type refer to coal effect natural gas & lpg section 2.4.1 pebble effect natural gas & lpg section...

Page 12

Page 8 2.4.1. Coal effect layout this fire is supplied with different sizes of ceramic coal as follows: qty small square coals 8 medium square coals 4 random coals 8 small random coals 9 aeration tubes 2 ½ aeration tubes 1 proceed with the coal layout as follows: - 1. Following the appropriate set o...

Page 13

Page 9 2.4.2. Pebble effect layout the fire is supplied with ceramic pebble sets as follows:- qty large pebbles (a, b & k) 9 medium pebbles (c & d) 6 small pebbles (g) 3 flat pebbles (h) 4 front pebbles (e & j) 6 aeration tubes 2 ½ aeration tubes 1 note: when placing pebbles on the tray ensure the l...

Page 14

Page 10 2.5. Fitting the trim (optional) 1. Most trims are coated with a protective film. This must be removed by peeling off before fitting the trim. 2. The trim is held on by four magnets. These will either be attached to the trim or supplied loose in a separate envelope. Space them as shown in fi...

Page 15: 2.7. Home Improvements

Page 11 2.7. Home improvements warning: if after installation of this fire any home improvements (e.G. Double glazing, secondary double glazing, draught proofing, fitting extractor fans, laminate flooring etc.) are carried out to the property it is essential to carry out a spillage test on the fire ...

Page 16

Page 12 2.8. Cleaning and care instructions caution: ensure that the appliance is off (including the pilot light) and has completely cooled (off for at least 2 hours) before carrying out any cleaning or maintenance. Rcf advice: this product may use components (coals, pebbles & ceramic backs) contain...

Page 17

Page 13 2.8.2. Cleaning the pilot the oxygen depletion sensing pilot fitted to your burley magiglo fire is a highly reliable safety device which causes the fire to shut down in the unlikely event of a reduction of oxygen in the room where the fire is fitted. After a period of time, it is possible fo...

Page 18

Page 14 2.8.5. Brass or chrome surfaces these surfaces should be cleaned with a proprietary non-abrasive metal cleaner. Remove the trim (if fitted), the fret and the ash-pan cover before cleaning. The trim is held in place by means of four magnets at the rear of the trim. The fret and the ash-pan co...

Page 19: 3. I

Page 15 3. I nstallation i nstructions before installation, ensure that the local distribution conditions (identification of the type of gas and pressure) and the adjustment of the appliance are compatible 3.1. General safety requirements before commencing installation, ensure that the intended inst...

Page 20

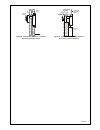

Page 16 3.2.2. Dimensions for duo power 2 with freedom surround 675m m 70 0mm 545 mm 570 mm 18 0m m figure 22 – duo power 2 with freedom surround.

Page 21: 3.3. Appliance Location

Page 17 3.3. Appliance location the fire must be fitted on a flat non-combustible base. In addition a non-combustible hearth or physical barrier with minimum dimensions shown in figures belowshould be provided in front of the fireplace opening where relevant. However, with hole in the wall fire inst...

Page 22

Page 18 3.3.1. Floor level and raised fireplace openings ow o h od hw hd 50mm figure 23 ow oh od hw hd 50mm ah figure 24 models without freedom surround oh 560mm ow 430mm od 180mm hw a minimum of 150mm either side of any incandescent material hd must project a minimum of 300mm in front of any naked ...

Page 23

Page 19 3.3.2. Flue terminal location the minimum acceptable dimensions from the flue terminal to obstructions and ventilating openings are shown in table 5 and figure 25 . Dimension terminal position value mm a directly below an opening, air brick, opening windows, etc. 300 b above an opening, air ...

Page 24

Page 20 3.3.3. Physical barrier any physical barrier should meet the following requirements: 1. Provide at least the equivalent level of warning to the approach of an open fire, to that of a hearth. 2. Define a clear zone where occupants must exercise additional caution. 3. Should be constructed of ...

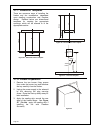

Page 25

Page 21 figure 31, figure 32, figure 33 and figure 34 show examples of how the requirements for the physical barrier may be met. D w figure 31 – example of physical barrier (dimensions as stated in table 6 – protected area) d w figure 32 – example of physical barrier (dimensions as stated in table 6...

Page 26: 3.4. Ventilation

Page 22 3.4. Ventilation for models with heat inputs not exceeding 6.9kw, normal adventitious ventilation is usually sufficient to satisfy the ventilation requirements of these appliances. In gb reference should be made to bs 5871 part 3, and in ie reference should be made to the current edition of ...

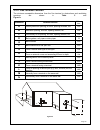

Page 27: 3.6. Contents Checklist

Page 23 3.6. Contents checklist before proceeding with installation of the fire check the contents as follows: carton 1 - basic kit quantity item 1 gas fire 1 imitation fuel – coal (ng/lpg) or pebble set (ng/lpg) 1 length of foam sealing strip 1 isolating valve carton 2 - fan unit kit quantity item ...

Page 28

Page 24 3.7. Installation procedure (examples) before commencing installation, ensure that the intended installation will comply with details in general information on page 1. The burley magiglo duo power 2 is designed to be inset into a 16” opening. Any surround that is to be installed with the bur...

Page 29

Page 25 flue duct terminal fan box / spacer frame figure 39 - installation of appliance in freedom surround with spacer frame flue duct terminal fan box / constructed false cimney breast prepared base figure 40 - installation of appliance in freedom surround in front of a solid wall.

Page 30

Page 26 3.7.2. Examples of protecting combustible materials (e.G. Timber framed dwelling installation) a minimum of 50mm thick rockwool or equivalent material between top of appliance & any combustible material non combustible fire surround 24mm thick ‘superlux’ or equivalent to top and rear of appl...

Page 31

Page 27 3.7.3. Preparing the installation general notes 1. Attempt to keep the recess and any hole sizes as close as possible to the minimum dimensions. This will keep the installation tidy without the need for excessive sealing afterwards. 2. Ensure any damp course, electrical wiring and any pipewo...

Page 32

Page 28 3.7.5. Freedom surround installation (if applicable) 1. Using figure 44, mark out and create the appropriate opening in the wall at the desired height above the floor to accommodate the freedom surround. Figure 44 also includes details of the cut out in the outer wall for the flue duct and t...

Page 33

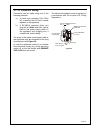

Page 29 vine eyes cable cable tensioners vine eyes figure 46 base plate fixing screws wing nut fixing ( on underside) base plate (trim switch models) figure 47 3.7.6. Installation using a spacer frame (if applicable) in order to reduce the installation depth required, the freedom surround may be ins...

Page 34

Page 30 3.7.7. Dimension templates there are numerous ways of installing the firebox and fan combination, dependant upon dwelling construction and fireplace design. Detailed below are dimensional templates for creating the appropriate openings, which will be referred to in the appropriate section. 5...

Page 35

Page 31 3.7.9. Recessed firebox preparation on the inside wall: 1. Measure the height of the hearth and mark a horizontal line on the wall at the same height. 2. Above the hearth level draw a rectangle to the dimensions of the recess as detailed in figure 49. Note that a lintel may be required above...

Page 36

Page 32 3.7.10. Surface mounted firebox preparation on the inside wall: 1. Measure the height of the hearth and mark a horizontal line on the wall at the same height. 2. Using the template shown in figure 51, mark the position of the flue above the hearth. Drill a pilot hole in the centre through to...

Page 37

Page 33 3.7.11. Installation into timber framed buildings note: installation must be in accordance with the current edition of gas engineers publication ige/up/7 (gas installations in timber framed housing). Note: prior to cutting any holes within the inner wall for the firebox or the flue duct (plu...

Page 38

Page 34 3.7.12. The gas supply 1. The gas supply can be fed into the firebox from rear or the right hand side (see figure 54).Care should be taken to sleeve the pipe when passing through masonry. 2. Make an appropriate slit in the rubber grommet and feed the gas supply pipe through it. Seal gas inle...

Page 39

Page 35 3.7.13. Fitting the firebox (without freedom surround) before fitting the firebox it is necessary to install any fire surround that may be required. 1. Place the firebox centrally within the opening and push it back until the sealing strip abuts the face of the fire surround. Mark the two bo...

Page 40

Page 36 3.7.14. Fitting the firebox (with freedom surround) 1. Select the required gas entry point (choice of two). After creating a slit in the grommet, route the gas supply through, leaving the remaining two intact. 2. Feed the 5-core silicone rubber cable through the 30mm diameter hole in the out...

Page 41

Page 37 3.7.15. Electrical wiring connection can be made using one of the following methods: a) a fused spur providing 230v 50hz ac, protected with 3a fuse, located adjacent to the appliance. B) a bs1363/a approved (three pin) plug with a 3 amp rated fuse, can be fitted to the power supply cable on ...

Page 42

Page 38 3.7.16. Fan unit installation if installing a surface mounted fan unit: 1. Use the supplied paper template to mark, drill and plug the surface mount frame fixing positions. 2. Fix the surface mount frame in position as shown in figure 57. Use mastic to seal the frame against the wall. 3. Con...

Page 43

Page 39 7. Replace the motor assembly over the four fixing studs and secure in place using the driver nuts, as shown in figure 60. 8. Connect the fan supply cable, using the 6-pin plug, and fit the cover as detailed in figure 61, taking particular note of the top locating detail. 9. Complete the ins...

Page 44

Page 40 3.7.17. Commissioning the installation 1. Turn on the service cock and purge the gas line up to the gas valve. Check all gas joints (up to solenoid valve) for gas soundness. 2. Remove the pressure test point screw (see figure 62, noting that the position of the lpg test point may vary) and c...

Page 45

Page 41 3.7.18. Checking for spillage 1. Close all doors and windows. 2. Turn the fire on at full rate and leave it burning for 5 minutes. 3. Test for spillage using a smoke match (in a ‘blume tube’) at the top of the appliance, fireplace opening or under the canopy at the centre, with the smoke mat...

Page 46

Page 42 this page is left intentionally blank.

Page 47: 4. S

Page 43 4. S ervicing i nstructions 4.1. General requirements all repairs and servicing must be carried out by a qualified registered gas installer (e.G. Member of gas safe in gb) in accordance with the current gas safety (installation and use) regulations and these instructions. Before any servicin...

Page 48: 4.3. Replacing Parts

Page 44 4.3. Replacing parts for any spare parts that are required, please contact either your supplier or the manufacturer directly. You will need the model name i.E. Model number, the gas type, the type of control and serial number. Only approved parts should be used. 4.3.1. Pilot assembly replace...

Page 49

Page 45 4.3.4. Control box replacement 1. With reference to figure 62, unscrew the control box retaining screw, until almost free. 2. By pulling the screw forward, this will release the control box from its mounting bracket. 3. The control box may now be drawn forward revealing a 12-pin plug, which ...

Page 50

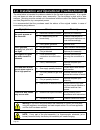

Page 46 4.4. Installation and operational troubleshooting the table below is intended for problems related to the fire and its gas controls. It is a guide only and does not take into account every eventuality. The fan system is dealt with in later sections. Servicing must be carried out in accordanc...

Page 51

Page 47 note: for any spare parts that are required, please contact either your supplier or the manufacturer directly. You will need the model name i.E. Model number, the gas type, the type of control and serial number. Only approved parts should be used..

Page 52

Page 48 4.4.1. Electrical fault finding chart electrical fault finding must be carried out by competent persons only. A suitable electrical test meter will be required for some of the tests listed. Switch on the mains power supply at isolating switch start at fused spur, check 3 amp fuse - replace i...

Page 53

Page 49 4.5. Wiring in fan box schematic figure 64 - wiring in fan box schematic 4.6. Wiring inside control box co m m o n lo w blue b lu e blu e brown hi g h fan gas valve co m no nc power supply control box terminal cable to fan box t o s o le n o id 1 2 4 3 5 6 brown brown brow n brown brown figu...

Page 54

Page 50 this page is left intentionally blank.

Page 55

Page 51 this page is left intentionally blank.

Page 56

Mf388.5 burley magiglo fires are protected by uk patents 2193802, 2240620 and 2256920 other patents pending magiglo is a registered trademark of burley appliances ltd burley appliances ltd, lands end way oakham, rutland, le15 6rb tel: 01572 725570 fax: 01572 724390 www.Magiglo.Co.Uk email: info@magi...