- DL manuals

- Magiglo

- Indoor Fireplace

- DUO POWER SV Series

- User, Installation & Servicing Instructions

Magiglo DUO POWER SV Series User, Installation & Servicing Instructions

Users,

Installation & Servicing

Instructions

MUST BE LEFT WITH THE USER

DUO POWER SV

Please Note: These instructions do not cover Duo Power 2 models

Models:

SV – Side and Top Venting

Fuel Effect Options:

Coal Effect

Pebble Effect

Both available on NG & LPG

Control Options:

Manual Control

Installation Options:

Installation using Freedom Surround

For use on Natural Gas (G20) at a supply pressure of 20mbar

or Propane (G31) at a supply pressure of 37mbar in GB and IE

(Dependent upon model)

Summary of DUO POWER SV Series

Page 1

Users, installation & servicing instructions must be left with the user duo power sv please note: these instructions do not cover duo power 2 models models: sv – side and top venting fuel effect options: coal effect pebble effect both available on ng & lpg control options: manual control installatio...

Page 2

Manufacturer contact details: burley appliances ltd. Lands end way oakham, rutland, le15 6rb tel: +44 (0)1572 725570 fax: +44 (0)1572 724390 general e-mail: info@magiglo.Co.Uk web site: www.Magiglo.Co.Uk technical support: direct dial on (01572) 725570 or email: technical@magiglo.Co.Uk burley magigl...

Page 3: Contents

Page i contents 1. General information ........................................................................................................... 1 1.1. Important note about ods pilot ................................................................................ 3 1.2. Fire fret dimensions .........

Page 4

Page ii 3.9.2. Fitting the fire tray ............................................................................................ 35 3.9.3. Commissioning the installation .......................................................................... 36 3.9.4. Checking for spillage .........................

Page 5: 1. G

Page 1 1. G eneral i nformation introduction 1. This appliance is suitable for installation in gb and ie and should be installed in accordance with the rules in force. In gb, the installation must be carried out by a gas safe registered installer registered for working on this type of appliance. It ...

Page 6

Page 2 current edition of i.S.813 which makes clear the conditions that must be met to demonstrate that sufficient ventilation is available. 2. If provided, any purpose provided ventilation must be checked periodically to ensure it is free from obstructions. 3. When fitting the fire in northern irel...

Page 7

Page 3 1.1. Important note about ods pilot this fire is fitted with an ods pilot which causes the appliance to shut down in the event of a reduction of oxygen (e.G. Caused by poor ventilation) in the room. Should this happen, follow the lighting instructions to re-light the fire. In the event that t...

Page 8: 1.2. Fire Fret Dimensions

Page 4 1.2. Fire fret dimensions all models can be used with the burley magiglo range of frets or any other fire fret that falls within the dimensions shown below the fireplace opening must be suitable in size to accommodate the fire being installed. If the appliance is to be used with other firepla...

Page 9: 2. U

Page 5 2. U ser i nstructions 2.1. Lighting the pilot 1. Ensure that the fan switch (figure 3) is in the off position then switch on the mains electrical supply to the appliance. 2. Switch the fan on – you should hear the fan start and a few seconds later, the green neon will illuminate. This neon i...

Page 10: 2.3. Turning The Fan Off

Page 6 2.2. Lighting the main burner 1. Once the pilot is established, the main burner can be operated by turning the control knob anti-clockwise. The preset minimum is found with the arrow in the 9 o’clock position as shown in figure 6. 2. The preset maximum (as shown in figure 7 is found by turnin...

Page 11: 2.4. Fuel Effect Layout

Page 7 2.4. Fuel effect layout you fire has been supplied with either coal or pebble effect. Please refer to the relevant section for instructions on how to arrange the imitation fuels. Fuel effect tray type refer to coal effect natural gas & lpg section 2.4.1 pebble effect natural gas & lpg section...

Page 12

Page 8 2.4.1. Coal effect layout this fire is supplied with different sizes of ceramic coal as follows: qty small square coals 8 medium square coals 4 random coals 8 small random coals 9 aeration tubes 2 ½ aeration tubes 1 proceed with the coal layout as follows: - 1. Following the appropriate set o...

Page 13

Page 9 2.4.2. Pebble effect layout the fire is supplied with ceramic pebble sets as follows:- qty large pebbles (a, b & k) 9 medium pebbles (c & d) 6 small pebbles (g) 3 flat pebbles (h) 4 front pebbles (e & j) 6 aeration tubes 2 ½ aeration tubes 1 note: when placing pebbles on the tray ensure the l...

Page 14

Page 10 2.5. Fitting standard trim (if supplied) 1. Most trims are coated with a protective film. This must be removed by peeling off before fitting the trim. 2. The trim is held on by four magnets. These will either be attached to the trim or supplied loose in a separate envelope. Space them as sho...

Page 15: 2.7. Home Improvements

Page 11 2.7. Home improvements warning: if after installation of this fire any home improvements (e.G. Double glazing, secondary double glazing, draught proofing, fitting extractor fans, laminate flooring etc.) are carried out to the property it is essential to carry out a spillage test on the fire ...

Page 16

Page 12 2.8. Cleaning and care instructions caution: ensure that the appliance is off (including the pilot light) and has completely cooled (off for at least 2 hours) before carrying out any cleaning or maintenance. Rcf advice: this product may use components (coals, pebbles & ceramic backs) contain...

Page 17

Page 13 2.8.2. Cleaning the pilot the oxygen depletion sensing pilot fitted to your burley magiglo fire is a highly reliable safety device which causes the fire to shut down in the unlikely event of a reduction of oxygen in the room where the fire is fitted. After a period of time, it is possible fo...

Page 18

Page 14 2.8.5. Brass or chrome surfaces these surfaces should be cleaned with a proprietary non-abrasive metal cleaner. Remove the trim (if fitted), the fret and the ash-pan cover before cleaning. The trim is held in place by means of four magnets at the rear of the trim. The fret and the ash-pan co...

Page 19: 3. I

Page 15 3. I nstallation i nstructions before installation, ensure that the local distribution conditions (identification of the type of gas and pressure) and the adjustment of the appliance are compatible 3.1. General safety requirements before commencing installation, ensure that the intended inst...

Page 20: 675M

Page 16 3.2.2. Additional dimensions for duo power with freedom surround flue adapter 675m m 70 0mm 545 mm 570 mm 18 0m m figure 20

Page 21: 3.3. Appliance Location

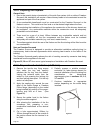

Page 17 3.3. Appliance location the fire must be fitted on a flat non-combustible base. In addition a non-combustible hearth or physical barrier with minimum dimensions shown in figures belowshould be provided in front of the fireplace opening where relevant. However, with hole in the wall fire inst...

Page 22

Page 18 3.3.1. Floor level and raised fireplace openings ow o h od hw hd 50mm figure 21 ow oh od hw hd 50mm ah figure 22 models without freedom surround oh 560mm ow 430mm od 180mm hw a minimum of 150mm either side of any incandescent material hd must project a minimum of 300mm in front of any naked ...

Page 23

Page 19 3.3.2. Physical barrier any physical barrier should meet the following requirements: 1. Provide at least the equivalent level of warning to the approach of an open fire, to that of a hearth. 2. Define a clear zone where occupants must exercise additional caution. 3. Should be constructed of ...

Page 24

Page 20 fire bed x x y x=150mm, less dimension y figure 26 fire bed x x x=150mm figure 27 figure 28, figure 29, figure 30 and figure 31show examples of how the requirements for the physical barrier may be met. D w figure 28 – example of physical barrier (dimensions as stated in table 5 – protected a...

Page 25

Page 21 3.3.3. Flue terminal location the minimum acceptable dimensions from the flue terminal to obstructions and ventilating openings are shown in table 6 and figure 32. Dimension terminal position value mm a directly below an opening, air brick, opening windows, etc. 300 b above an opening, air b...

Page 26: 3.4. Ventilation

Page 22 3.4. Ventilation for models with heat inputs not exceeding 6.9kw, normal adventitious ventilation is usually sufficient to satisfy the ventilation requirements of these appliances. In gb reference should be made to bs 5871 part 3, and in ie reference should be made to the current edition of ...

Page 27: 3.6. Contents Checklist

Page 23 3.6. Contents checklist before proceeding with installation of the fire check the contents as follows: carton 1 - basic kit quantity item 1 gas fire 1 imitation fuel – coal (ng/lpg) or pebble set (ng/lpg) 1 trim (optional) 1 fire fret (optional) 1 freedom surround (optional) supplied fitted ...

Page 28

Page 24 3.7. Installation procedure (examples) 3.7.1. Examples of installation (without freedom surround) figure 33 7 metres max 2.7 metres (standard kit) fan box outer wall firebox low level false chimney breast (could be full height) 200mmx100mm (8”x4”) hole 90 0 mm mi n. 150mm min 180mm min (stan...

Page 29

Page 25 3.7.2. Examples of installation with freedom surround floor level le n g th o f d u c t p r e p a r e d t o s u it h e ig h t o f a p p l ia n c e a b ov e f l oo r l e v e l he ig ht ab ove f l oor l e v e l all ducts must be insulated with 25mm rockwool or masterboard flue connector duct f...

Page 30

Page 26 . Base flue duct constructed chimney breast cable fixing floor level non-combustible wall figure 38 – sectional view of installation with freedom surround.

Page 31: 3.8. Installation Procedure

Page 27 3.8. Installation procedure before commencing installation, ensure that the intended installation will comply with details in general information on page 1 carefully unpack the contents of the carton and check them against the checklist given on page 23. Make sure that the fireplace opening ...

Page 32

Page 28 3.8.2. Examples of flueing options it is permissible to add 90 0 (or 45 0 ) bends and/or elbows to the flue system in the following manner. However, the final dimensions of the flue system must not exceed those shown in table 7 below. Configuration number of additional bends and/or elbows ma...

Page 33

Page 29 3.8.3. Spare parts the following spare parts are available in order to create the required flue selection for a particular installation. When extending beyond the standard side vent kit, additional cable lengths will be required. Item part no. Description 860m m 42mm 16 0 m m pf00346 860mm s...

Page 34

Page 30 3.8.4. Preparing the fireplace general note 1. Due to the special design characteristic of the side flue system (with or without freedom surround) the installation will require a false chimney breast to be constructed around the appliance and part of the flue system. 2. A non-combustible bas...

Page 35

Page 31 3.8.6. Installing the fire without freedom surround 1. Place the firebox at the desired position on the prepared hearth/base and mark, drill and plug the two rear holes on the base of the firebox onto the hearth. 2. Fit a suitable gas supply so that it terminates at appropriate position insi...

Page 36

Page 32 3.8.8. Preparing the flue ducts (for hearth mounting) note: this procedure describes the preparation of flue system shown in figure 39. For other examples of flue systems shown in figure 40 follow similar procedure. 1. Assemble the 3 elbows and the two short ducts (140mm and 490m long) as sh...

Page 37

Page 33 3.8.10. Installing the fan chamber 1. Remove the fan carrier from the fan chamber by first removing the fan carrier cover and then the three screws securing fan carrier to the fan chamber. 2. Referring to figure 46 assemble the flue connector duct (860mm) to the bottom of the fan chamber as ...

Page 38

Page 34 3.8.11. Installing the fan box 1. Facing the fan chamber (outside), offer the fan-carrier to the top of the fan chamber and screw it into place with the three screws previously removed. Make sure that the cable entry hole is to the right. 2. Feed the 5 core silicone rubber cable through the ...

Page 39

Page 35 3.9. Completing the installation 3.9.1. Electrical wiring connection can be made using one of the following methods: a) a fused spur providing 230v 50hz ac, protected with 3a fuse, located adjacent to the appliance. B) a bs1363/a approved (three pin) plug with a 3 amp rated fuse, can be fitt...

Page 40

Page 36 3.9.3. Commissioning the installation 1. Ensure that the power supply is off at the mains switch. 2. Turn on the service cock and purge the gas line up to the gas valve. Check all gas joints (up to solenoid valve) for gas soundness. 3. Remove the pressure test point screw (see figure 51 for ...

Page 41

Page 37 3.9.4. Checking for spillage 1. Close all doors and windows. 2. Turn the fire on to full rate and leave it burning for 5 minutes. 3. Test for spillage using a smoke match (in a ‘blume tube’) at the top of the appliance opening along the centre, with the smoke match being approximately 25mm b...

Page 42

Page 38 this page is left intentionally blank.

Page 43: 4. S

Page 39 4. S ervicing i nstructions note: for any spare parts that are required, please contact either your supplier or the manufacturer directly. You will need the model name i.E. Model number, the gas type, the type of control and serial number. Only approved parts should be used. 4.1. General req...

Page 44: 4.3. Replacing Parts

Page 40 8. Check the portholes against light to see if they are clear of debris. Blow through them to clear them of any debris or obstructions. Alternatively a low powered vacuum cleaner with a small nozzle can be used to clean the surface and the portholes. 9. Check the board for any substantial da...

Page 45

Page 41 refer to figure 53 for identification of parts for rest of the instructions. Control valve control knob control cover ods pilot assembly fire tray fixing screws silencer housing solenoid plug gas outlet nut pressure test point piezo/ht lead control fixing screw pilot assemby fixing screws in...

Page 46

Page 42 4.3.4. Injector replacement 1. Remove the control assembly from under the tray by following instructions 1 - 4 in the section bm control valve replacement . 2. Remove the old injector (detail o) and replace with new one. 3. Refit control assembly onto the tray in reverse order. 4.3.5. Bm con...

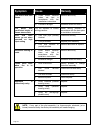

Page 47: Symptom

Page 43 4.4. Installation and operational troubleshooting the table below is intended for problems related to the fire and its gas controls. It is a guide only and does not take into account every eventuality. Servicing must be carried out in accordance with the current gas safety (installation and ...

Page 48: Symptom

Page 44 symptom cause remedy fire burns with blue flames a) coals and/or aeration tubes not laid in accordance with the installation instructions remove and re-lay b) excessive draught establish cause and rectify fire burns with insufficient height of flames above coals fire not adjusted to correct ...

Page 49

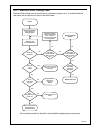

Page 45 4.4.1. Electrical fault finding chart electrical fault finding must be carried out by competent persons only. A suitable electrical test meter will be required for some of the tests listed. Switch on the mains power supply at isolating switch start at mains isolating switch check 3 amp fuse ...

Page 50

Page 46 4.5. Fan box assembly schematic f rl aps f - fan / motor rl - latching relay aps - air pressure switch figure 54 - fan box assembly schematic 4.6. Wiring in fan box schematic fan motor earth socket air press.Switch relay 0 1 4 2 6 8 comm n/c n/o figure 55- wiring in fan box schematic.

Page 51: 4.7. Circuit Diagram

Page 47 4.7. Circuit diagram figure 56 - circuit diagram 4.8. Wiring inside control box colour coding bk - black bl - blue br - brown r - red w - white g/y - green/yellow 1 2 3 4 5 6 7 8 power supply to fan box g/y g/y g/y w bk bk br br bl bl bl br bl bl neon bl bk bk r r fan switch br bk figure 57 ...

Page 52

Bbmf167.12 burley magiglo fires are protected by uk patents 2193802, 2240620 and 2256920 other patents pending magiglo is a registered trademark of burley appliances ltd burley appliances ltd, lands end way oakham, rutland, le15 6rb tel: 01572 725570 fax: 01572 724390 www.Magiglo.Co.Uk email: info@m...